SEMI S23 Application Guide and Total Equivalent Energy

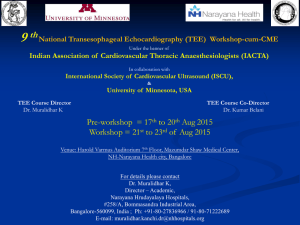

advertisement