Formulas in Solid Mechanics - Division of Solid Mechanics

advertisement

Formulas in Solid Mechanics

Tore Dahlberg

Solid Mechanics/IKP, Linköping University

Linköping, Sweden

This collection of formulas is intended for use by foreign students in the course TMHL61,

Damage Mechanics and Life Analysis, as a complement to the textbook Dahlberg and

Ekberg: Failure, Fracture, Fatigue - An Introduction, Studentlitteratur, Lund, Sweden, 2002.

It may be use at examinations in this course.

Contents

1. Definitions and notations

2. Stress, Strain, and Material Relations

3. Geometric Properties of Cross-Sectional Area

4. One-Dimensional Bodies (bars, axles, beams)

5. Bending of Beam Elementary Cases

6. Material Fatigue

7. Multi-Axial Stress States

8. Energy Methods the Castigliano Theorem

9. Stress Concentration

10. Material data

Version 03-09-18

Page

1

2

3

5

11

14

17

20

21

25

1. Definitions and notations

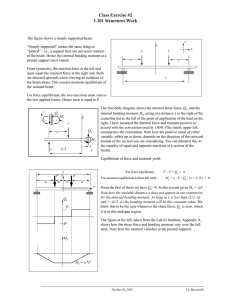

Definition of coordinate system and loadings on beam

Mz

Tz

Mx N

My

q ( x)

N Mx

x

Ty

Ty

y

z

A

L

My

Tz

Mz

Loaded beam, length L, cross section A, and load q(x), with coordinate system (origin at the

geometric centre of cross section) and positive section forces and moments: normal force N,

shear forces Ty and Tz, torque Mx, and bending moments My, Mz

Notations

Quantity

Symbol

SI Unit

Coordinate directions, with origin at geometric centre of

x, y, z

m

cross-sectional area A

Normal stress in direction i (= x, y, z)

σi

N/m2

Shear stress in direction j on surface with normal direction i τij

N/m2

Normal strain in direction i

εi

Shear strain (corresponding to shear stress τij)

γij

rad

Moment with respect to axis i

M, Mi

Nm

Normal force

N, P

N (= kg m/s 2)

Shear force in direction i (= y, z)

T, Ti

N

Load

q(x)

N/m

Cross-sectional area

A

m2

Length

L, L0

m

Change of length

δ

m

Displacement in direction x

u, u(x), u(x,y) m

Displacement in direction y

v, v(x), v(x,y) m

Beam deflection

w(x)

m

Second moment of area (i = y, z)

I, Ii

m4

Modulus of elasticity (Young’s modulus)

E

N/m2

Poisson’s ratio

ν

Shear modulus

G

N/m2

Bulk modulus

K

N/m2

Temperature coefficient

α

K− 1

1

2. Stress, Strain, and Material Relations

Normal stress σx

σx =

N

A

∆N = fraction of normal force N

∆A = cross-sectional area element

∆N

or σx = lim

∆A → 0 ∆A

Shear stress τxy (mean value over area A in the y direction)

τxy =

Ty

(= τmean)

A

Normal strain εx

Linear, at small deformations (δ << L0)

δ

du(x)

εx =

or εx =

L0

dx

δ = change of length

L0 = original length

u(x) = displacement

Non-linear, at large deformations

L

εx = ln

L0

L = actual length (L = L0 + δ)

Shear strain γxy

γxy =

∂u (x, y) ∂v(x, y)

+

∂y

∂x

Linear elastic material (Hooke’s law)

Tension/compression

σx

εx = + α ∆T

E

∆T = change of temperatur

Lateral strain

εy = − ν εx

Shear strain

τxy

γxy =

G

Relationships between G, K, E and ν

G=

E

2(1+ν)

K=

E

3 ( 1 − 2ν )

2

3. Geometric Properties of Cross-Sectional Area

e

The origin of the coordinate system Oyz is

at the geometric centre of the cross section

O

y

f

dA

z

Cross-sectional area A

A = ⌠ dA

⌡A

Geometric centre (centroid)

dA = area element

e = ζgc = distance from η axis to geometric

centre

f = ηgc distance from ζ axis to geometric

centre

e ⋅ A = ⌠ ζ dA

⌡A

f ⋅ A = ⌠ η dA

⌡A

First moment of area

S y = ⌠ zdA and Sz = ⌠ ydA

⌡A’

⌡A’

Second moment of area

A’ = the “sheared” area (part of area A)

Iy = ⌠ z 2dA

⌡A

Iy = second moment of area with respect to

the y axis

Iz = second moment of area with respect to

the z axis

Iz = ⌠ y 2dA

⌡A

Iyz = ⌠ yzdA

⌡A

Parallel-axis theorems

First moment of area

and

Sη = ⌠ (z + e) dA = eA

⌡A

Second moment of area

Iη = ⌠ (z + e)2 dA = Iy + e 2A ,

⌡A

Iyz = second moment of area with respect to

the y and z axes

Sζ = ⌠ (y + f) dA = fA

⌡A

Iζ = ⌠ (y + f)2 dA = Iz + f 2A ,

⌡A

Iηζ = ⌠ (z + e) (y + f) dA = Iyz + efA

⌡A

3

Rotation of axes

y

Coordinate system Ωηζ has been rotated

the angle α with respect to the coordinate

system Oyz

z

y

dA

z

Iη = ⌠ ζ2 dA = Iy cos2 α + Iz sin2 α − 2Iyz sin α cos α

⌡A

Iζ = ⌠ η2 dA = Iy sin2 α + Iz cos2 α + 2Iyz sin α cos α

⌡A

Iηζ = ⌠ ζη dA = (Iy − Iz ) sin α cos α + Iyz (cos2 α − sin2 α ) =

⌡A

Iy − Iz

sin 2α + Iyz cos 2α

2

Principal moments of area

I1, 2 =

Iy + Iz

±R

2

√

Iy − Iz 2 2

+ Iyz

2

where R =

I1 + I2 = Iy + Iz

Principal axes

sin 2α =

− Iyz

R

or cos 2α =

Iy − Iz

2R

A line of symmetry is always a principal

axis

Second moment of area with respect to axes through geometric centre for some

symmetric areas (beam cross sections)

B

y

Rectangular area, base B, height H

BH 3

HB 3

and Iz =

Iy =

12

12

H

z

y

Solid circular area, diameter D

πD 4

Iy = Iz =

64

D

z

y

Thick-walled circular tube, diameters D

and d

π

Iy = Iz = ( D 4 − d 4 )

64

d D

z

4

Thin-walled circular tube, radius R and

wall thickness t (t << R)

t

R

y

Iy = Iz = πR 3t

z

Triangular area, base B and height H

BH 3

HB 3

Iy =

and Iz =

36

48

H

y

B/ 2 B/ 2

z

a

a

y

a

Hexagonal area, side length a

5√

3 a 4

Iy = Iz =

16

a

a

z

2a

y

Elliptical area, major axis 2a and minor

axis 2b

πab 3

πba 3

Iy =

and Iz =

4

4

2b

z

Half circle, radius a (geometric centre at e)

π 8

4a

Iy = − a 4 ≅ 0, 110 a 4 and e =

3π

8 9π

a

y

e

z

4. One-Dimensional Bodies (bars, axles, beams)

Tension/compression of bar

Change of length

NL

δ=

or

EA

N, E, and A are constant along bar

L = length of bar

L

L

N(x)

δ = ⌠ ε(x)dx = ⌠

dx

⌡0 E(x)A(x)

⌡0

Torsion of axle

Maximum shear stress

Mv

τmax =

Wv

N(x), E(x), and A(x) may vary along bar

Mv = torque = Mx

Wv = section modulus in torsion (given

below)

Torsion (deformation) angle

Mv L

Θ=

GKv

Mv = torque = Mx

Kv = section factor of torsional stiffness

(given below)

5

Section modulus Wv and section factor Kv for some cross sections (at torsion)

Torsion of thin-walled circular tube, radius

R, thickness t, where t << R,

t

R

y

Wv = 2πR 2t

z

Thin-walled tube of arbitrary cross section

A = area enclosed by the tube

t(s) = wall thickness

s = coordinate around the tube

4A 2

Wv = 2Atmin

Kv =

⌠ [t(s)] − 1 ds

⌡s

(s)

s

t(s)

Area A

y

Thick-walled circular tube, diameters D

and d,

π D4 − d4

π

Kv = (D 4 − d 4)

Wv =

16 D

32

d D

z

y

Solid axle with circular cross section,

diameter D,

πD 3

πD 4

Kv =

Wv =

16

32

D

z

Solid axle with triangular cross section,

side length a

a3

a4 √

3

Kv =

Wv =

20

80

a

y

a/ 2 a/ 2

z

2a

y

Solid axle with elliptical cross section,

major axle 2a and minor axle 2b

π

πa 3b 3

Wv = a b 2

Kv = 2

2

a + b2

2b

z

Solid axle with rectangular cross section b

by a, where b ≥ a

Wv = kWv a 2b

Kv = kKv a 3b

b

y

Kv = 2πR 3t

a

z

for kWv and kKv, see table below

6

Factors kWv and kKv for some values of ratio b / a (solid rectangular cross section)

b/a

kWv

kKv

1.0

1.2

1.5

2.0

2.5

3.0

4.0

5.0

10.0

∞

0.208

0.219

0.231

0.246

0.258

0.267

0.282

0.291

0.312

0.333

0.1406

0.1661

0.1958

0.229

0.249

0.263

0.281

0.291

0.312

0.333

Bending of beam

Relationships between bending moment My = M(x), shear force Tz = T(x), and load q(x) on

beam

dT(x)

dM(x)

d2M(x)

= − q(x) ,

= T(x) , and

= − q(x)

dx

dx

dx 2

Normal stress

N Mz

σ= +

A

I

Maximum bending stress

| M|

I

| σ | max =

where Wb =

Wb

| z | max

I (here Iy) = second moment of area (see

Section 12.2)

Wb = section modulus (in bending)

Shear stress

TSA’

τ=

Ib

SA’ = first moment of area A’ (see Section

12.2)

b = length of line limiting area A’

T

τgc = shear stress at geometric centre

τgc = µ

µ

= the Jouravski factor

A

The Jouravski factor µ for some cross sections

rectangular

triangular

circular

thin-walled circular

elliptical

ideal I profile

1.5

1.33

1.33

2.0

1.33

A / Aweb

7

Skew bending

Axes y and z are not principal axes:

N My (zIz − yIyz ) − Mz (yIy − zIyz )

σ= +

A

Iy Iz − Iyz2

Iy, Iz, Iyz = second moment of area

Axes y’ and z’ are principal axes:

N M1 z’ M2 y’

σ= +

−

A

I1

I2

I1, I2 = principal second moment of area

Beam deflection w(x)

Differential equations

d2

d2

EI(x)

= q(x)

w(x)

dx 2

dx 2

EI

when EI(x) is function of x

d4

w(x) = q(x)

dx 4

when EI is constant

Homogeneous boundary conditions

Clamped beam end

d

w(*) = 0 and

w(*) = 0

dx

where * is the coordinate of beam end

(to be entered after differentiation)

Simply supported beam end

d2

w(*) = 0 and − EI 2 w(*) = 0

dx

x

x=L

x

x=L

Sliding beam end

d

d3

w(*) = 0 and − EI 3 w(*) = 0

dx

dx

x

Free beam end

d2

− EI 2 w(*) = 0

dx

x

d3

and − EI 3 w(*) = 0

dx

8

x=L

x=L

Non-homogeneous boundary conditions

(a) Displacement δ prescribed

w(*) = δ

x

x=L

(a)

(b) Slope Θ prescribed

d

w(*) = Θ

dx

O

(b)

z

M0

(c) Moment M0 prescribed

d2

− EI 2 w(*) = M0

dx

O

x=L M0

x

(c)

P

(d) Force P prescribed

d3

− EI 3 w(*) = P

dx

x=L

x

P

(d)

Beam on elastic bed

Differential equation

d4

EI 4 w(x) + kw(x) = q(x)

dx

EI = constant bending stiffness

k = bed modulus (N/m2)

Solution

w(x) = wpart(x) + whom(x) where

whom(x) = {C1 cos (λx) + C2 sin (λx)} eλx + {C3 cos (λx) + C2 sin (λx)} e − λx ; λ4 =

k

4EI

Boundary conditions as given above

Beam vibration

Differential equation

∂2

∂4

EI 4 w(x, t) + m 2 w(x, t) = q(x, t)

∂x

∂t

EI = constant bending stiffness

m = beam mass per metre (kg/m)

t = time

Assume solution w(x,t) = X(x)⋅T(t). Then the standing wave solution is

T(t) = e iωt and X(x) = C1 cosh (µx) + C2 cos (µx) + C3 sinh (µx) + C4 sin (µx)

where µ4 = ω2m /EI

Boundary conditions (as given above) give an eigenvalue problem that provides the

eigenfrequencies and eigenmodes (eigenforms) of the vibrating beam

9

Axially loaded beam, stability, the Euler cases

Beam axially loaded in tension

Differential equation

d4

d2

EI 4 w(x) − N 2 w(x) = q(x)

N = normal force in tension (N > 0)

dx

dx

Solution

w(x) = wpart(x) + whom(x) where

√

√

√

N

N

N

x + C3 sinh

x + C4 cosh

x

EI

EI

EI

New boundary condition on shear force (other boundary conditions as given above)

d3

d

T(*) = − EI 3 w(*) + N w(*)

dx

dx

whom(x) = C1 + C2

Beam axially loaded in compression

Differential equation

d2

d4

EI 4 w(x) + P 2 w(x) = q(x)

dx

dx

P = normal force in compression (P > 0)

Solution

w(x) = wpart(x) + whom(x) where

√

√

√

P

P

P

x + C3 sin

x + C4 cos

x

EI

EI

EI

New boundary condition on shear force (other boundary conditions as given above)

d3

d

T(*) = − EI 3 w(*) − P w(*)

dx

dx

whom(x) = C1 + C2

Elementary cases: the Euler cases (Pc is critical load)

Case 1

P

P

L, EI

Pc =

Case 2a

Pc =

Case 3

P

P

L, EI

π2EI

4L 2

Case 2b

L, EI

L, EI

π2EI

L2

Pc =

10

π2EI

L2

Pc =

2.05 π2EI

L2

Case 4

P

L, EI

Pc =

4π2EI

L2

5. Bending of Beam

Elementary Cases

Cantilever beam

P

w(x) =

L, EI

x

w(x)

z

PL 3

w(L) =

3EI

M

L, EI

q = Q/L

L, EI

z

ML 2 x 2

2EI L 2

w(L) =

ML 2

2EI

w(x) =

qL 4 x 4

x3

x2

4 − 4 3 + 6 2

24EI L

L

L

w(L) =

qL 4

8EI

x

w(x)

q0

L, EI

z

q0 L 4

w(x) =

120EI

x

w(x)

d

ML

w(L) =

dx

EI

d

qL 3

w(L) =

dx

6EI

x5

x3

x2

5 − 10 3 + 20 2

L

L

L

11 q0 L 4

w(L) =

120EI

q0 L 3

d

w(L) =

dx

8EI

q0 L 4 x 5

x4

x3

x2

w(x) =

− + 5 4 − 10 3 + 10 2

120EI L 5

L

L

L

q0

L, EI

z

d

PL 2

w(L) =

dx

2EI

w(x) =

x

w(x)

z

PL 3 x 2 x 3

3 −

6EI L 2 L 3

x

w(x)

q0 L 4

w(L) =

30EI

11

q0 L 3

d

w(L) =

dx

24EI

Simply supported beam

Load applied at x = αL (α < 1), β = 1 − α

L

P

L

w(x) =

+ =1

w(x)

for

x

≤α

L

PL 3 2 2

α β . When α > β one obtains

3EI

1+β

1+β

1 − β2

wmax = w L

= w(αL)

3β

3α

3

x

z

PL 3

x x3

β (1 − β2) − 3

6EI

L L

w(αL) =

L, EI

√

√

PL 2

d

PL 2

d

w(0) =

α β (1 + β)

w(L) = −

α β (1 + α)

dx

6EI

dx

6EI

MA

MB

w(x) =

MA L MB L

d

w(0) =

+

dx

3 EI 6 EI

x

w(x)

z

L

M

L, EI

w(x) =

L

z

L, EI

x

w(x)

w(L/2) =

L, EI

w(x) =

Q

w(x)

L, EI

w(x) =

Q

z

w(x)

5 QL 3

384 EI

L, EI

12

x

≤α

L

ML

d

w(L) =

(1 − 3α2)

dx

6EI

d

d

QL 2

w(0) = − w(L) =

dx

dx

24EI

QL 3 x 5

x3

x

3 5 − 10 3 + 7

180EI L

L

L

d

8 QL 2

w(L) = −

dx

180EI

QL 3 x 5

x4

x3

x

− 3 5 + 15 4 − 20 3 + 8

180EI L

L

L

L

d

8 QL 2

w(0) =

dx

180EI

x

for

x4

x3 x

4−2 3+

L

L L

d

7 QL 2

w(0) =

dx

180EI

x

z

ML 2

x x3

(1 − 3β2) − 3

6EI

L L

QL 3

w(x) =

24EI

Q

z

MA L MB L

d

w(L) = −

−

dx

6 EI 3 EI

ML

d

w(0) =

(1 − 3β2)

dx

6EI

x

w(x)

x x3

x2 x3

L2 x

MA 2 − 3

+

M

−

+

B

6EI L

L L 3

L 2 L 3

d

7 QL 2

w(L) = −

dx

180EI

Clamped simply supported beam and clamped clamped beam

Load applied at x = αL (α < 1), β = 1 − α

Only redundant reactions are given. For deflections, use superposition of solutions

for simply supported beams.

PL

P

+ =1

MA

MA =

β (1 − β2 )

L

L

2

x

z

L, EI

MA

MB

MA =

MB

2

MA =

M

(1 − 3β2 )

2

MA =

QL

8

MA =

2 QL

15

x

z

MA

L, EI

M

L

L

+ =1

x

z

L, EI

Q

MA

x

L, EI

z

Q

MA

MA

P

L

z

MA

L

L, EI

MB

MA = PL α β2

x

L, EI

L

MB

MA = − M β (1 − 3α )

x

+ =1

Q

MA = MB =

MB

MA

z

z

L, EI

QL

12

x

L, EI

Q

MA

MB = PL α2 β

+ =1

M

L

z

x

L, EI

z

MA =

MB

x

13

QL

10

MB =

QL

15

MB = M α (1 − 3β )

6. Material Fatigue

Fatigue limits (notations)

Load

Alternating

Pulsating

Tension/compression

± σu

σup ± σup

Bending

± σub

σubp ± σubp

Torsion

± τuv

τuvp ± τuvp

The Haigh diagram

a

σa = stress amplitude

σm = mean stress

σY = yield limit

σU = ultimate strenght

σu, σup = fatigue limits

λ, δ, κ = factors reducing fatigue limits

(similar diagrams for σub, σubp and τuv, τuvp)

Y

u

up

u

m

up

up

Y

U

Factors reducing fatigue limits

Surface finish κ

1.0

0.8

0.6

0.4

0.2

Factor κ reducing the fatigue limit due to

surface irregularities

(a)

(b)

(a) polished surface ( κ = 1)

(b) ground

(c) machined

(d) standard notch

(e) rolling skin

(f) corrosion in sweet water

(g) corrosion in salt water

(c)

(d)

(e)

(f)

(g)

300 600 900 1200 MPa

U

14

Volume factor λ (due to process)

Factor λ reducing the fatigue limit due to

size of raw material

1.0

(a) diameter at circular cross section

(b) thickness at rectangular cross section

0.8

(a) 20

(b) 10

40

20

60

30

80 100mm

40 50mm

Volume factor δ (due to geometry)

1.0

Factor δ reducing the fatigue limits σub and

τuv due to loaded volume.

Steel with ultimate strength σU =

(a) 1500 MPa

(b) 1000 MPa

(c) 600 MPa

(d) 400 MPa

(e) aluminium

Factor δ = 1 when fatigue notch factor Kf >

1 is used.

(a)

(b)

0.9

(c)

(d)

(e)

0.8

0

40 80 120

Diameter or thickness in mm

Fatigue notch factor Kf (at stress concentration)

Kt = stress concentration factor (see Section

Kf = 1 + q (Kt − 1)

12.8)

q = fatigue notch sensitivity factor

Fatigue notch sensitivity factor q

q

1.0

Fatigue notch sensitivity factor q for steel

(a)

with ultimate strength σU =

(a) 1600 MPa

0.8 (b)

(b) 1300 MPa

0.6 (c)

(c) 1000 MPa

(d)

(d) 700 MPa

0.4 (e)

(e) 400 MPa

0.2

0.1

0.5 1 2 5 10

Fillet radius r in mm

15

Wöhler diagram

a

σai = stress amplitude

Ni = fatigue life (in cycles) at stress

amplitude σai

ai

0 1 2 3 4 5 6 7

log N

Damage accumulation D

D=

ni = number of loading cycles at stress

amplitude σai

Ni = fatigue life at stress amplitude σai

ni

Ni

Palmgren-Miner’s rule

Failure when

I n

i

∑ =1

i = 1 Ni

ni = number of loading cycles at stress

amplitude σai

Ni = fatigue life at stress amplitude σai

I = number of loading stress levels

Fatigue data (cyclic, constant-amplitude loading)

The following fatigue limits may be used only when solving exercises. For a real

design, data should be taken from latest official standard and not from this table.1

Material

Carbon steel

141312-00

141450-1

141510-00

141550-01

141650-01

141650

Tension

alternating pulsating

MPa

MPa

± 110

± 140

± 230

± 180

± 200

Bending

alternating pulsating

MPa

MPa

Torsion

alternating pulsating

MPa

MPa

110 ± 110

130 ± 130

± 170

± 190

150 ± 150

170 ± 170

± 100

± 120

100 ± 100

120 ± 120

160 ± 160

180 ± 180

± 240

± 270

± 460

210 ± 210

240 ± 240

± 140

± 150

140 ± 140

150 ± 150

Stainless steel 2337-02, σu = ± 270 MPa

Aluminium SS 4120-02, σub = ± 110 MPa; SS 4425-06, σu = ± 120 MPa

1

Data in this table has been collected from B Sundström (editor): Handbok och Formelsamling i

Hållfasthetslära, Institutionen för hållfasthetslära, KTH, Stockholm, 1998.

16

7. Multi-Axial Stress States

Stresses in thin-walled circular pressure vessel

σt = circumferential stress

R

R

σt = p

and σx = p

(σz ≈ 0) σ = longitudinal stress

x

t

2t

p = internal pressure

R = radius of pressure vessel

t = wall thickness (t << R)

Rotational symmetry in structure and load (plane stress, i.e. σz = 0)

Differential equation for rotating circular plate

u = u(r) = radial displacement

d2 u 1 d u u

1 − ν2 2

−

ρω

+

=

−

r

ρ = density

E

d r2 r d r r2

ω = angular rotation (rad/s)

Solution

B0 1 − ν2

u (r) = uhom + upart = A0 r + −

ρ ω2 r 3

r

8E

Stresses

σr (r) = A −

where

B 3+ν

−

ρ ω2 r 2

2

8

r

A=

E A0

1−ν

and

σφ(r) = A +

and

B=

B 1 + 3ν

−

ρ ω2 r 2

2

8

r

E B0

1+ν

Boundary conditions

σr or u must be known on inner and outer boundary of the circular plate

Shrink fit

δ = difference of radii

p = contact pressure

u = radial displacement as function of p

δ = uouter(p) − uinner(p)

Plane stress and plane strain (plane state)

Plane stress (in xy-plane) when σz = 0, τxz = 0, and τyz = 0

Plane strain (in xy-plane) when τxz = 0, τyz = 0, and εz = 0 or constant

Stresses in direction α (plane state)

σ(α) = σx cos2(α) + σ y sin2(α) + 2τxy cos(α)sin(α)

y

τ(α) = − (σx − σ y ) sin(α)cos(α) + τxy (cos (α) − sin (α))

2

( )

2

σ(α) = normal stress in direction α

τ(α) = shear stress on surface with normal in direction α

17

( )

x

Principal stresses σ1, 2 and principal directions at plane stress state

σ1, 2 = σc ± R =

sin(2ψ1) =

τxy

R

σx + σ y

±

2

√

σx − σ y 2 2

+ τxy

2

or cos(2ψ1) =

ψ1 = angle from x axis (in xy plane) to

direction of principal stress σ1

σx − σ y

2R

Strain in direction α (plane state)

ε(α) = εx cos2(α) + εy sin2(α) + γxy sin(α)cos(α)

γ(α) = (εy − εx ) sin(2α) + γxy cos(2α)

ε(α) = normal strain in direction α

γ(α) = shear strain of element with normal in direction α

y

x

Principal strains and principal directions (plane state)

ε1, 2 = εc ± R =

sin(2ψ1) =

εx + εy

±

2

γxy

2R

√

εx − εy 2 γxy 2

+

2 2

or cos(2ψ1) =

ψ1 = angle from x axis (in xy plane) to

direction of principal strain ε1

εx − εy

2R

Principal stresses and principal directions at three-dimensional stress state

The determinant

σx τxy τxz

| S−σI| =0

Stress matrix S = τyx σ y τyz

gives three roots (the principal stresses)

τzx τzy σz

(contains the nine stress components σij)

1 0 0

Unit matrix I = 0 1 0

0 0 1

Direction of principal stress σi (i = 1, 2, 3) is given by

nix, niy and niz are the elements of the unit

(S − σi I) ⋅ ni = 0

and

vector ni in the direction of σi

T

( T means transpose)

ni ⋅ ni = 1

18

Principal strains and principal directions at three-dimensional stress state

Use shear strain εij = γij / 2 for i ≠ j

The determinant

| E−εI| =0

gives three roots (the principal strains)

εx

Strain matrix E = εyx

εzx

εxy

εy

εzy

εxz

εyz

εz

I = unit matrix

Direction of principal strain εi (i = 1, 2, 3) is given by

nix, niy and niz are the elements of the unit

(E − εi I) ⋅ ni = 0

and

vector ni in the direction of εi

T

T

(

means transpose)

ni ⋅ ni = 1

Hooke’s law, including temperature term (three-dimensional stress state)

εx =

1

[σ − ν(σy + σz )] + α ∆T

E x

εy =

1

[σ − ν(σz + σx )] + α ∆T

E y

εz =

1

[σ − ν(σx + σ y )] + α ∆T

E z

γxy =

τxy

G

γyz =

τyz

G

γzx =

α = temperature coefficient

∆T = change of temperature (relative to

temperature giving no stress)

τzx

G

Effective stress

The Huber-von Mises effective stress (the deviatoric stress hypothesis)

σvM

=√

σ2x + σ2y + σ2z − σx σ y − σ y σz − σz σx + 3τ2xy + 3τ2yz + 3τ2zx

e

=

√

1

{(σ1 − σ2)2 + (σ2 − σ3)2 + (σ3 − σ1)2 }

2

The Tresca effective stress (the shear stress hypothesis)

σTe = max [ | σ1 − σ2 | , | σ2 − σ3 | , | σ3 − σ1 | ] = σprmax − σprmin

19

(pr = principal stress)

8. Energy Methods

the Castigliano Theorem

Strain energy u per unit of volume

Linear elastic material and uni-axial stress

σε

u=

2

Total strain energy U in beam loaded in tension/compression, torsion, bending, and

shear

L

Mt(x)2 Mbend(x)2

N(x)2

T(x)2

dx

Utot = ⌠

+

+

+β

⌡0 2EA(x) 2GKv(x) 2EI(x)

2GA(x)

Mt = torque = Mx

Mbend = bending moment = My

Cross section

β

Kv = section factor of torsional stiffness

β = shear factor, see below

µ

Shear factor β

6/5

3/2

2

A ⌠ SA’

β = 2 dA

I ⌡A b

10/9

4/3

2

2

A/A web

β is given for some cross sections in the

table (µ is the Jouravski factor, see Section

12.3 One-Dimensional Bodies)

A/A web

Elementary case: pure bending

M1

Only bending momentet Mbend is present.

The moment varies linearly along the beam

with moments M1 and M2 at the beam ends.

One has

Mbend(x) = M1 + (M2 − M1)x /L, which gives

L

{M12 + M1 M2 + M22 }

Utot =

6EI

The second term is negative if M1 and M2

have different signs

M2

L, EI

x

M1

M

M2

The Castigliano theorem

δ=

∂U

∂P

and Θ =

δ = displacement in the direction of force P

of the point where force P is applied

Θ = rotation (change of angle) at moment

M

∂U

∂M

20

9. Stress Concentration

Tension/compression

Maximum normal stress at a stress concentration is σmax = Kt σnom, where Kt and σnom

are given in the diagrams

Kt

3.0

r

P

P

B

thickness h

P

=

nom

bh

B/b

2.0

1.5

1.2

1.1

1.05

1.01

2.0

1.5

0.1

0.2

r/b

Tension of flat bar with shoulder fillet

P

P

P

b

2.5

thickness h

=

nom

2.0

P

bh

B/b

2.0

1.2

1.1

1.05

1.01

1.5

1.0

0

0.1

0.2

0.3

0.4 0.5 0.6 r/b

r

Kt

3.0

P

P

d

D

P

B

Tension of flat bar with notch

r

Kt

3.0

r

b

2.5

1.0

0

Kt

3.0

D

d

2.5

2.5

nom

2.0

=

4P

d2

nom

D/d

2.0

1.5

1.2

1.1

1.05

1.01

1.5

1.0

0

0.1

0.2

2.0

D/d

1.5

1.2

1.1

1.05

1.01

1.0

0.3 r/d

Tension of circular bar with shoulder

fillet

= 4 P2

d

0

0.1

0.2

0.3 0.4

0.5 0.6 r/d

Tension of circular bar with U-shaped

groove

21

a

2r

0

0

B

Kt

B/a= 5

3.2

3.0

3

2.8

2.6

2.5

2.4

2.25

B

2.2

nom = B - 2 r

2

0

2.0

0

0.1

0.2

0.3

0.4

r/a

Tension of flat bar with hole

Bending

Maximum normal stress at a stress concentration is σmax = Kt σnom, where Kt and σnom

are given in the diagrams

d

d

Kt

Kt

Mb

Mb

Mb

Mb

3.0

3.0

D

B

2.5

thickness h

d/h = 0

0.25

0.5

2.0

1.0

2.0

1.5

nom

=

2.5

=

nom

2.0

Mb

D 3 d D2

32

6

1.5

6 Mb

(B-d)h

2

1.0

1.0

0

0.2

0.4

Bending of flat bar with hole

0.6 d/B

0

0.1

0.2

Bending of circular bar with hole

22

0.3 d/D

r

Kt

3.0

Mb

Mb

B

2.0

=

1.0

0.1

hb 2

0.2

r

Mb

3.0

2.5

thickness h

Mb

hb 2

1.0

0

0.1

0.2

0.3

0.4

0.5

0.6 r/b

Bending of flat bar with notch

Kt

r

Mb

Mb

3.0

D

2.5

B/b

1.2

1.1

1.05

1.01 1.02

1.5

d

D

6 Mb

=

nom

2.0

r/b

Bending of flat bar with shoulder fillet

Kt

b

6 Mb

B/b

6.0

2.0

1.2

1.05

1.01 1.02

1.5

Mb

B

thickness h

nom

r

Mb

b

2.5

0

Kt

3.0

d

2.5

=

nom

2.0

32 M b

d3

2.0

D/d

6.0

2.0

1.2

1.05

1.01 1.02

1.5

1.0

0

0.1

0.2

=

nom

d3

D/d

1.5

1.2

1.05

1.01 1.02

1.0

0.3 r/d

Bending of circular bar with shoulder

fillet

32M b

0

0.1

0.2 0.3 0.4

0.5 0.6 r/d

Bending of circular bar with U-shaped

groove

23

Torsion

Maximium shear stress at stress concentration is τmax = Kt τnom, where Kt and τnom are

given in the diagrams

r

Kt

3.0

r

Kt

Mv

Mv

3.0

Mv

Mv

d

D

D

d

2.5

2.5

nom

=

16 M v

d3

nom

2.0

=

2.0

D/d

2.0

1.3

1.2

1.1

1.5

1.0

0

0.1

0.2

1.5

1.2

1.05

1.01

1.0

0

0.1

0.2

0.3

0.4 0.5 0.6 r/d

Torsion of circular bar with notch

r

Kt

4.0

D/d

0.3 r/d

Torsion of circular bar with shoulder

fillet

16 M v

d3

d

Kt

2.0

Mv

Mv

D

d /4

3.5

7d

8

nom

=

1.5

3.0

Mv

D 3 d D2

16

6

d

2.5

nom =

16 M v

d3

2.0

1.0

0

0.05

0.10

r/d

Torsion of bar with longitudinal keyway

0

0.1

0.2

Torsion of circular bar with hole

24

0.3 d/D

10. Material data

The following material properties may be used only when solving exercises. For a real

design, data should be taken from latest official standard and not from this table (two values

for the same material means different qualities).1

Material

Young’s

modulus

E

GPa

ν

Carbon steel

141312-00

206

0.3

141450-1

205

0.3

141510-00

205

0.3

141550-01

205

0.3

141650-01

206

0.3

141650

206

0.3

α106

Ultimate

strength

K-1

MPa

12

360

460

430

510

510

640

490

590

590

690

860

11

Yield limit

tension/

compression

MPa

bending

torsion

MPa

MPa

>240

260

140

>250

290

160

>270

360

190

>310

390

220

>550

610

>320

Offset yield strength Rp0.2 (σ0,2)

Stainless steel

2337-02

Aluminium

SS 4120-02

196

0.29 16.8

70

23

SS 4120-24

70

23

SS 4425-06

70

23

>490

>200

170

215

220

270

>340

>65

1

>170

>270

Data in this table has been collected from B Sundström (editor): Handbok och Formelsamling i

Hållfasthetslära, Institutionen för hållfasthetslära, KTH, Stockholm, 1998.

25