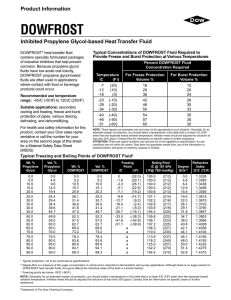

Engineering and Operating Guide

advertisement