MODELING OF SEPIC FED PMBLDC MOTOR FOR TORQUE

advertisement

International Journal of Research and Engineering

Volume 2, Issue 1

MODELING OF SEPIC FED PMBLDC MOTOR FOR TORQUE RIPPLE

MINIMIZATION

N.Lakshmipriya

S.Manivel

N.Sadeesh

M.E.,Assistant Professor

Department of EEE

Jay Shriram Group of Institution,

Tirupur, India

lakshmipriyame09@gmail.com

M.E.,Assistant Professor

Department of EEE

Jay Shriram Group of Institution

Tirupur, India

manivelee0719@gmail.com

M.E., Assistant Professor

Department of EEE

Jay Shriram Group of Institution

Tirupur, India

nsadeesh@gmail.com

Abstract— BLDC Motor suffers from commutation

torque ripple, which mainly depends on stator winding

impedance, speed and transient line current in the

conduction interval. This paper describes a novel circuit

topology and a dc input link voltage control strategy to

keep incoming and outgoing phase currents changing at

the same rate during commutation interval. A SEPIC

(single-ended primary inductor converter) and a switch

selection circuit are employed in the front of the inverter.

The desired commutation voltage is obtained by the

SEPIC converter. The input dc link voltage control

strategy is carried out by the switch selection circuit to

separate two procedures, adjusting the SEPIC converter

and regulating speed. The commutation torque ripple is

analyzed, and introduced the way to obtain the desired

dc link voltage in detail. Finally, simulation and

experimental results show that, compared with

conventional and the proposed method can obtain the

desired voltage is obtained and minimize commutation

torque ripple more efficiently.

Keywords- Brushless DC Motor, Torque ripple,

SEPIC Converter

I. Introduction

BLDC Motor is a type of Synchronous Motor. This

means magnetic field generated by the stator and magnetic

field generated by the rotor rotates at the same frequency.

DC motor also known as electronically commutated is

synchronous electric motors powered by direct current

electricity and having electronic commutation systems,

rather than mechanical commutators and brushes. The

current-to-torque and voltage to speed relationships of

BLDC motors are linear. THE brushless dc motor

(BLDCM) has been widely used in industrial fields that

require high reliability and precise control due to its simple

structure, high power density, and extended speeding range

[1]–[3]. The performance of such motors has been

significantly improved due to the great development of

power electronics, microelectronics, magnetic performance

of magnets, and motion control technology in recent years

[4]–[9]. BLDC motors may be described as stepper motors

with fixed permanent magnets and possibly more poles on

10

ISSN 2348-7852 (Print) | ISSN 2348-7860 (Online)

the stator than the rotor. The latter may be without

permanent magnets, just poles that are induced on the A

SEPIC is similar to a traditional buck-boost converter, but

has advantages of having non-inverted output (the output

has the same voltage polarity as the input), using a series

capacitor to couple energy from the input to the output (and

thus can respond more gracefully to a short-circuit output),

and being capable of true shutdown. When the switch is

turned off, its output drops to 0 V, following a fairly hefty

transient dump of charge when such large horsepower drives

are needed [10]-[11]. SEPIC converter and a switch in series

with each phase are proposed for driving a permanent

magnet brushless dc motor. The SEPIC converter is

designed to operate in the discontinuous conduction mode

for operation with an ac supply. In this operation mode, the

line current follows the line voltage waveform to a certain

extent. The dc link voltage control strategy is carried out by

the switch selection circuit to separate two procedures,

adjusting the SEPIC converter and regulating speed

The paper is organized as follows DC link voltage

control strategy to keep incoming and outgoing phase

currents changing at the same rate during commutation to

control of torque ripple. The desired commutation voltage is

accomplished by the SEPIC (Single-Ended Primary Inductor

Converter). SEPIC converter and a switch in series with

each phase are proposed for driving a permanent magnet

brushless dc motor. The SEPIC converter is designed to

operate in the discontinuous conduction mode for operation

with an ac supply. In this operation mode, the line current

follows the line voltage waveform to a certain extent. The dc

link voltage control strategy is carried out by the switch

selection circuit to separate two procedures, adjusting the

SEPIC converter and regulating speed.

II. BRUSHLESS DC MOTOR

The extraction of torque and ripple requires the

mathematical model. In three phases stators winding the

phase variable are given.

[v] [ R][i ] p[ L][i] [e]

(1)

Where vectors,

http://www.ijre.org

International Journal of Research and Engineering

[v]T

[va vb vc ],

[i]T

[ia ib ic ]

[e]T

[ea eb ec ]

Number of Pole

[ R]

La

0 R 0 , [ L]

0 0 R

Lba Lb Lcb

Lca Lcb Lc

:

6poles

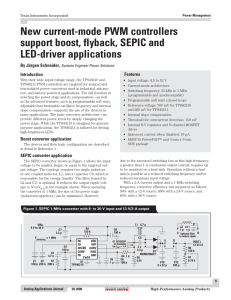

III. DESIGN OF SEPIC CONVERTER FEED WITH

BLDC MOTOR

The proposed converter with four controlled

switches and diode the frontend consists of a SEPIC dc/dc

converter comprised of inductors L1 and L2, switch S1,

intermediate capacitor C1, diode DA and output capacitor C2.

.

Here the resistance and inductances are given by

R 0 0

Volume 2, Issue 1

Lba Lca

Assuming a symmetrical structure of the inductance

La

Lb

Lca

Lcb

Lc

L

M

[v] [ R][i ] P[ L][i ] [e]

where

L

M

M

[ L' ]

M

L

M

Figure 1.show that Circuit Diagram of SEPIC Converter

M

M

L

In three phase system without a neutral

Ia+Ib+Ic=0,hence the motor current equation may be written

The set of differential equations mentioned defines the

developed model in terms of the variables and times as an

independent variable. The torque ripple is generated due to

the current ripple. This current ripple is depends on the

stator winding impedance and back electromagnetic force.

P[ L 1 ] [ L'' ] 1{[V ] [ R][i] [e]}

where,

1

[ L'' ]

1

(L M )

0

0

1

0

0

0

(l M )

0

1

(L M )

The electromagnetic torque (Te), is

Te

ea * i a

eb*ib

ec*ic Wm

(2)

The motion equation of the BLDC motor,

dwt d t

Te

T1

B

t

J

(3)

1. SPECIFICATION OF BLDC MOTOR

The diodes DA, DB and Dc serve to free wheel the

winding currents when the switches are turned off during

current regulation and phase commutation. The output of the

converter is used to energize the three phases of the motor,

and the for proper demagnetization of the phase after each

conduction interval and to prevent conduction during

periods of negative back-EMF, the instantaneous value of

VC1 should be greater than the peak value of the back-EMF,

voltage of capacitor C1 is used to demagnetize the phases

during turn-off and for current control.

VC1>E

By applying Kirchhoff’s voltage law to the SEPIC

front-end, we obtain

VIN=VL1+VC1+V12

Since the average voltages in the two inductors are

zero, we get

VIN=VC1

Emax=Vin assuming that the ripple in the

intermediate capacitor voltage is negligible. The maximum

operating speed is then given by Ω max=Vin/Ke, where Ke is

the phase back-EMF constant of the motor. The front-end

SEPIC converter can be designed for operation either in the

continuous conduction mode

in the discontinuous

conduction mode. In CCM, its voltage conversion ratio is

given by

Where, D is the duty cycle of the switch S1 in

DCM, its voltage conversion ratio is given by

The machine details of BLDC motor are given below.

11

Rated Power

: 60W

Rated Voltage

: 48V DC

Rated Speed

:

4500rpm

ISSN 2348-7852 (Print) | ISSN 2348-7860 (Online)

Where, K=2L1L2/RT(L1+L2) ,R being the

equivalent load resistance and T the time period of switch S 1

.The boundary value of K between continuous and

http://www.ijre.org

International Journal of Research and Engineering

Volume 2, Issue 1

discontinuous conduction modes, Kcrit can be calculated

(m=md) as

Kcrit = (1-D) 2

The converter operates in CCM when K > Kcrit and

in DCM when K < Kcrit. In both modes of operation, Vdc can

be regulated at a value higher (Boost operation) or lower

(Buck operation) than the input voltage Vin. From the

controls viewpoint, it is advantageous to have the converter

operating in the same mode under all load conditions.

IV. SIMULATION RESULTS

In this chapter describes mathematical model of

BLDC motor, and simulation model of SEPIC converter,

this mathematical model can be converter in to electrical

model by using Laplace transform. With the use of this

proposed method to get sinusoidal waveform and torque

ripple can be reduced.

Figure 2.show that modeling of BLDC with SEPIC

converter

In brushless dc motor, the armature current is

commutated; the current ripple is generated due to the stator

winding inductance and deviation of back electromagnetic

force. The torque ripple is generated due to the current

ripple. This current ripple is depends on the stator winding

impedance and back electromagnetic force

Figure 3.show that Back EMF of BLDC Motor

12

ISSN 2348-7852 (Print) | ISSN 2348-7860 (Online)

http://www.ijre.org

International Journal of Research and Engineering

Volume 2, Issue 1

Figure 4.show that Voltage Waveform of BLDC Motor

Fig.6 show that Output Voltage for Three Phase Inverter

The current ripple can be reduced by supplying the

appropriate magnitude of input voltage for free-wheeling

period. This consists of lot of distortion. The torque ripple is

generated due to the current ripple. This current ripple is

depends on the stator winding impedance and back

electromagnetic force.

The three phase current of Input voltage varying

method for brush less dc motor has been simulated. At

starting time the distortion is high. When 0.02 sec, the

distortion will be reducing. The current ripple can be

reduced by maintaining current constant in freewheeling

region. If the current of phase b is constant when the

commutation is occurred from phase C to phase A, the

current ripple is not produced.

V. HARDWARE SETUP

FPGA based sensor control of brushless DC motor

in minimizing the harmonics caused by torque ripple in the

system. Here the SEPIC Converter is introduced between

inverter and rectifier. For the proper commutation and

control of the BLDC motor an FPGA controller is used in it.

Figure 5.show that Torque and Speed waveform of BLDC

Motor

This pulsating torque will be reduced by input

voltage varying method. The figure 5 shows that rotor speed

torque characteristics of BLDC motor. The wave form is not

uniformly in nature.

Figure 6. Block Diagram of Hardware Setup

The single phase 230 volt AC supply is fed to the

rectifier. It is converted into dc using the rectifier and fed as

13

ISSN 2348-7852 (Print) | ISSN 2348-7860 (Online)

http://www.ijre.org

International Journal of Research and Engineering

Volume 2, Issue 1

input to the SEPIC converter. SEPIC converter fed to the

MOSFET inverter, Inverter switches are controlled by using

the FPGA controller and driver through Optoisolator, which

fed to BLDC motor. FPGA consists of gates circuit, which

fed to driver circuit. Separate supply is fed to the processor

and embedded C program is fed to generating PWM pulses.

Power Supply is the device that transfers electric power

from a source to a load using electronic circuits

Figure 8.shows that Output Voltage Waveform of Inverter

The three phase output voltage waveform of

voltage source inverter is taken from digital analyzer, In

inverter operation, if the switching angels calculated for the

equal-dc-source case is applied to the considered unequal

case. Obviously, by effectively solving the harmonics

elimination problem with large number of switching angles,

the SHE-PWM method can generate high-quality voltage

waveforms as well as less switching frequency as compared

to other modulation technique.

Figure 7.shows that Experimental Setup of Hardware

VI. HARDWARE RESULTS

The proposed SEPIC converter based scheme for

BLDC Motor drive is experimentally implemented using

FPGA controller board IR2110 for a laboratory 60W BLDC

Motor. The hardware result from the prototype such as input

and output voltage waveforms, current waveform and

Harmonics waveform are shown below. Hardware prototype

mainly consists of inverter series with SEPIC converter fed

BLDC motor. In this chapter held on different conventional

waveforms and proposed waveforms, these waveforms are

obtained by Digital Analyzer. Torque ripple can be

calculated by compare conventional method to proposed

method.

14

ISSN 2348-7852 (Print) | ISSN 2348-7860 (Online)

Figure 9.shows that Output Combined Voltage Waveform of

Inverter

http://www.ijre.org

International Journal of Research and Engineering

Volume 2, Issue 1

Figure 12.Show that Phase Current of BLDC Motor without

SEPIC Converter

Figure 10.Shows that Output Combined Current Waveform

The dc link voltage control strategy is carried out by

the switch selection circuit to separate two procedures,

adjusting the SEPIC converter and regulating speed. In this

project SEPIC converter series with inverter fed BLDC

motor Compared with the existing method, the proposed

method can obtain the desired voltage much faster and

minimize commutation torque ripple more efficiently at both

high and low speeds.

of Inverter

The phase voltage consists of distortion due to turn

on and turn off of switching process (certain change in

current). The voltage ripple can be reduced by SEPIC

converter.

Figure 13.Show that Phase Voltage of BLDC Motor with

Figure 11.Show that Phase Voltage of BLDC Motor without

SEPIC Converter

SEPIC Converter

The required torque can be produced by the initial current

constant. When armature current is commutated, the current

ripple is generated due to the stator winding inductance and

deviation of back EMF. The current ripple leads to

generation of torque ripple. BLDC motor does not make

constant speed.

Figure 14.Show that Phase Current of BLDC Motor with

SEPIC Converter

15

ISSN 2348-7852 (Print) | ISSN 2348-7860 (Online)

http://www.ijre.org

International Journal of Research and Engineering

By compare from without SEPIC converter, the

phase current consists of lower distortion. Phase Current of

BLDC Motor can be obtained from Digital storage

oscilloscope. DC link voltage control strategy to keep

incoming and outgoing phase currents changing at the same

rate during commutation to control of torque ripple. The

desired commutation voltage is accomplished by the SEPIC

(single-ended primary inductor converter) converter.

VII. CONCLUTION

Compared to conventional Torque ripple control

method, SEPIC converter based method will lead to lower

torque ripple. As a result, using the SEPIC converter based

input voltage varying method of brushless dc motor will

lead to increased efficiency. A new circuit topology and

control strategy has been proposed to suppress commutation

torque ripple of BLDCM. In this paper a SEPIC converter is

placed at the input of the inverter, and the desired dc link

voltage can be achieved by appropriate voltage switch

control. The switch control separates the two procedures,

adjustment of SEPIC converter, and regulation of speed so

that torque can respond immediately during transient.

REFERENCES

[1] Y.-C. Son, K.-Y. Jang, and B.-S. Suh, “Integrated

MOSFET inverter module of low-power drive system,”

IEEE Trans. Ind. Appl., vol. 44, no. 3, pp. 878–886,

May/Jun. 2008.

[2] A. Sathyan, N. Milivojevic, Y.-J. Lee, M.

Krishnamurthy, and A. Emadi, “An FPGA-based novel

digital PWM control scheme for BLDC motor drives,”

IEEE Trans. Ind. Electron., vol. 56, no. 8, pp. 3040–

3049,Aug. 2009.

[3] Anandsathyan, (2009)“A Alaincassat, (2009) “New

Torque Control Method for Torque Ripple

Minimization of BLDC Motors with Un-Ideal Back

EMF,’’ IEEE Transaction Industrial Electronics., vol.

37, no.4, pp. 8/1–8/4.

[4] New

Approach

for

Minimum-Torque-Ripple

Maximum-Efficiency Control of BLDC Motor,” IEEE

Transaction Industrial Electron., vol. 48, no. 6, pp.

1065–1073,

[5] Cheng Tsung Lin, (2005) “Presented Direct Torque and

Indirect Flux Control of Brushless DC Motor’’, vol. 18,

no. 6, pp. 1365–1375, Nov. 2005.

[6] Damodhan, (2010) “A Current Control Scheme with an

Adaptive Internal Model for Torque Ripple

Minimization and Robust Current Regulation,” IEEE

Power Application, vol. 152, no. 2, pp. 277–291.

[7] Doo-Hec Jung,(2012) “Torque Ripple Minimization in

PM Synchronous Motors Using Iterative Learning

Control,” IEEE Transaction Power Electronics., vol. 22,

no. 2, pp. 644–653

[8] Haifeng Lu, (2004) “BLDC Motor Stator and Rotor

Iron Losses and Thermal Behavior Based on Lumped

16

ISSN 2348-7852 (Print) | ISSN 2348-7860 (Online)

Volume 2, Issue 1

Schemes and 3-D FEM Analysis,” IEEE Transaction.

Power Electronics, vol. 15, no. 4, pp. 744–752.

[9] Hung-Chichen, (2010) “FPGA-Based Novel Digital

PWM Control Scheme for BLDC Motor Drives,” IEEE

Transaction Industrial Electronics, vol. 53, no. 2, pp.

352–362.

[10] Jian wen show, (2010) “Commutation-Torque-Ripple

Minimization

in

Direct-Torque-Controlled

PM

Brushless DC Drives,” IEEE Transaction Industrial.

Application, vol. IA-21, no. 4, pp. 595–601.

[11] Karthikeyan, (2010) “Operating Torque Estimation of

High-Speed slot less Brushless DC Machine

Considering Power Loss,” IEEE Transaction Power

Electronics., vol. 19, no. 6, pp. 1635–1645.

Biography

Mrs.N.Lakshmipiya completed her bachelor’s Degree in

Electrical and Electronics Engineering in Sri Ramakrishna

Engineering College, Coimbatore and Post Graduate in

Applied Electronics from Maharaja Engineering College.

She is currently working as an Assistant Professor in the

Department of Electrical and Electronics Engineering in Jay

Shriram Group of Institution, Tirupur

Mr.S.Manivel completed his bachelor’s degree in Electrical

and Electronics Engineering in Arunai College of

Engineering, Tiruvannamali and Post graduate in power

Electronics and Drives from KSR College of Technology,

Tiruchengode with GOLD medal. He is currently working

as an Assistant Professor in the Department of Electrical and

Electronics Engineering in Jay Shriram Group of Institution,

Tirupur.

Mr.N.Sadeesh received the Bachelor of Engineering in

Electrical and Electronics Engineering from Velalar College

of Engineering and Technology, Thindal, Erode in 2009.,

and the Master of Engineering degree in Control and

Instrumentation Engineering from Kongu Engineering

College, Perundurai, Erode in 2013. He is currently working

as an Assistant professor in the Department of Electrical and

Electronics Engineering in Jay Shriram Group of

Institutions,

Tirupur.

http://www.ijre.org