Overview of Chemical Hazards in the

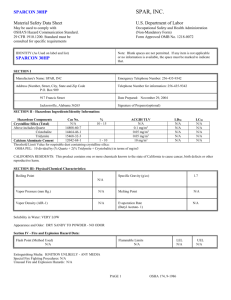

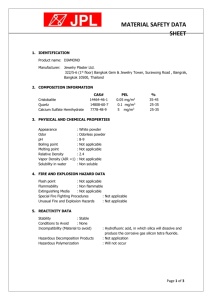

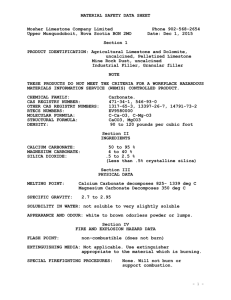

advertisement

OVERVIEW OF CHEMICAL HAZARDS IN THE WORKPLACE PREVENTION WORKSHOP SERIES Housekeeping Items Cell phones Washrooms / breaks Fire exits Evaluation Introductions Name Company Position / role in OH&S Ice breaker The Workplace Health, Safety and Compensation Commission Getting to Know Us! Our Vision “The vision of the Commission is of safe and healthy workplaces within a viable and sustainable system which reduces the impact of workplace injuries by providing the highest level of service to workers and employers” Prevention Services Field Services Health and Safety Advisors Consulting Mentoring OH&S program development and implementation support Auditing *Liaise with Department of Government Services (OH&S Division) Prevention Services Prevention Programs Injury trend analysis Training standards & certification OH&S committee / WH&S representative / designate Young workers Resource development New OH&S Certification Training Standards Traffic Control Person (TCP) – January 1, 2011 Fall Protection – January 1, 2012 Confined Space Entry – January 1, 2013 Workshop Objectives Common Places for Exposure to Chemicals Forms of Chemicals Routes of Exposure Threshold Limit Value Legislation – Chemicals (Hazardous Substances) Chemicals in Occupational Settings Risk Assessment Safe Work Practices/Procedures Common Places for Exposure to Chemicals When measuring or sampling Transferring hazardous materials Packaging & unpacking of hazardous materials Process operations involving hazardous materials, such as welding, machining, plating, spray coating, using cleaning solvents, etc. Maintenance activities involving hazardous materials Spills Forms of Chemicals Solids Liquids Particles Dust (formed by grinding/breaking); large particles Smoke (formed by burning); large particles Fumes (formed by heating); small particles Droplets (agitating a liquid) Gases Gas Vapour (gaseous phase of a chemical substance that is liquid or solid at normal temperature and pressure) Routes of Exposure Inhalation- breathing in contaminated air (dust, fumes, mist, smoke) Absorption – Involves skin contact. Chemical can pass through the skin into the blood stream Ingestion – Digestive system (eating). Swallowed accidentally if food, cigarettes or hands are contaminated Injection – A sharp object (e.g. needle) punctures the skin and injects chemical into blood stream Toxic Effect of Chemicals Effects may be local or systemic Local injuries involve area of the body in contact with the chemical and are typically caused by reactive or corrosive chemicals (e.g. strong acids) Systemic injuries involve tissues/organs unrelated to or removed from the contact site when toxins have been transported through the bloodstream Certain chemicals may affect a target organ E.g. The substance lead primarily affects the central nervous system (CNS), kidney, and red blood cells Toxic Effect of Chemicals Acute toxicity results from a single, short exposure Effects usually appear quickly and are often reversible Chronic toxicity results from repeated exposure over a long period of time Effects are usually delayed and gradual, and may be irreversible Signs of Exposure Dust, mist, smoke in the air Accumulation of dust or oils Unusual smells Unusual tastes Burning in the eyes Nose, throat irritation Feel better when away from workplace Factors that Influence Susceptibility to Effects of Chemical Exposure A small percentage of workers may experience discomfort from some substances at concentrations at or below the threshold limit A smaller percentage of workers may be affected more seriously if worker has a pre-existing condition, or by development of an occupational illness Factors that Influence Susceptibility to Effects of Chemical Exposure nutritional habits physical condition obesity medical conditions drinking and smoking pregnancy Threshold Limit Values (TLV) TLVs (for chemicals) refer to airborne concentrations of substances, and represents conditions under which it is believed that nearly all workers may be repeatedly exposed without adverse effects TLVs are developed as guidelines to assist in the control of health hazards Legislation WHMIS Workplace Hazardous Materials Information System Legislation – WHMIS Regulations Under OHS Act Section 3 (1) “These regulations apply to employers and workers in respect of controlled products used, stored and handled at a workplace.” Section 4 (1) “An employer shall ensure that a controlled product is not used, stored or handled in a workplace unless all of the applicable requirements of these regulations in respect of labels, identifiers, material safety data sheets and worker education are complied with.” Employers’ Responsibilities The WHMIS regulations outline employers’ responsibilities with regards to: labeling transportation placards production of a controlled product confidential business information notice of exemptions confidentiality of information, disclosures, etc. * Source: WHMIS Handbook Danatec Educational Services Employers’ Responsibilities Ensure All controlled products have correct WHMIS labels MSDS (material safety data sheets) for controlled products are up to date and easily accessible Procedure for the safe use, storage, handling, disposal and emergency plan for controlled product Workers receive required WHMIS training, and verify they understand it Program is reviewed at least annually, or more frequently if required by a change in work conditions or available hazard information, and in consultation with OHS committee Source: WHMIS Handbook Danatec Educational Services Suppliers, Importers & Distributors Responsibilities Classify products they sell or distribute Place supplier labels on controlled products Develop and provided MSDS for controlled products * Source: WHMIS Handbook Danatec Educational Services Workers’ Responsibilities Workers must: Use WHMIS information to protect themselves from any hazards Participate in WHMIS training WHMIS training will help workers understand the information found on WHMIS labels and MSDS and work safely with the controlled product Procedures for safe use, handling, storage, and disposal Procedures for emergencies involving controlled products 6 Classes of Controlled Products Class A - Compressed Gas Class B - Flammable and Combustible Material Class C - Oxidizing Materials Class D - Poisonous and Infectious Material Class E - Corrosive Material Class F - Dangerously Reactive Material Controlled Products Compressed Gas (Class A) Explodes if heated or struck, can become a “missile” if punctured Contact with the liquid form causes frostbite Example: compressed air, propane Controlled Products Flammable and Combustible Material (Class B) Catches fire if exposed to a source of ignition or if sufficiently heated Direct sunlight can generate enough heat to ignite some materials Examples: gasoline, toluene, metallic sodium Controlled Products Oxidizing Materials (Class C) Intensifies a fire Makes non-flammable materials flammable Examples: oxygen, calcium nitrate, chlorine Note: Keep these materials separated from flammables and combustibles Controlled Products Poisonous and Infectious Material (Class D) Materials Causing Immediate and Serious Toxic Effects (Division 1) Fast acting poisons with very serious effects Examples: carbon monoxide, hydrogen sulphide Poisonous and Infectious Material (Class D) Materials Causing Other Toxic Effects (Division 2) Effects on body organs after long exposure (asbestos, lead, silica) Cancer (benzene) Reproductive toxicity (many anaesthetic gases) Teratogenicity and embryotoxicity (ethyl alcohol) Poisonous and Infectious Material (Class D) Materials Causing Other Toxic Effects (Division 2) Mutagenicity (the medical drug diethylstibestrol) Sensitization of the skin or respiratory tract (formaldehyde (skin)) Skin or eye irritation (methanol) Note: the hazards in this division are not described by the symbol Poisonous and Infectious Material (Class D) Biohazardous Infectious Material (Division 3) Containers of microorganisms and certain products extracted from them Examples: AIDS virus, legionella, rubella virus Corrosive Material (Class E) Causes irreparable damage to skin or eyes on contact Examples: caustic soda, hydrochloric acid, slaked lime Dangerously Reactive Material (Class F) Becomes unstable or reacts with other materials to cause fires or explosions Reacts with water to give off toxic gases Examples: Acetylene, Potassium Cyanide Legislation All WHMIS labels have to be: Clear Easy to read Prominently displayed on the product In English and French WHMIS Labels Supplier labels – slash marked border Product name Supplier name Symbols for each class the product belongs to Main hazards of the product Precautions that you should take First aid measures Reference to the MSDS for more information WHMIS Labels Workplace labels are labels applied at the workplace Name of the product Information on how to use the product Reference to the MSDS for further information Material Safety Data Sheets (MSDS) Every controlled product received from a supplier must have a completed MSDS (not more than 3 years old) 9 Categories of Information Found on All MSDS Product name Hazardous ingredients Physical information Fire or explosion hazard Reactivity information Health hazard information Preventative measures First aid measures Preparation information Personal Protective Equipment (PPE) The type of PPE a worker requires in order to work with a particular chemical is outlined in the MSDS The following are some common PPE: There are 4 main ways to control a hazard (as per the “Hazard Hierarchy of Control”) PPE should be consider the last level of protection Hazard Hierarchy of Control Elimination – remove the hazard from the workplace Removing the hazard is always the preferred method of control Engineering – designs, modifications Administrative – alter the way work is done, policies, work practices, operating procedures PPE- equipment worn to reduce exposure to or contact with chemicals Provincial Occupational Health and Safety Regulations (2009) Part VI Occupational Health Requirements Section 42 - Hazardous Substances Where hazardous substances exist, employers must use engineering & administrative controls to ensure their safe use Hazardous substances are very detailed in the Regulations with reference to ACGIH Section 43 - Health Surveillance Employer must: (1) Assess the need for and extent of health surveillance of his or her workers [referring back to s. 42(2)] (2) Based on the results, establish and implement an occupational health surveillance program using two guidelines (3) Communicate the program to employees (4) Keep records and make available to employee, upon request Section 45 - Ventilation Employer must provide: Clean and wholesome air circulation Adequate ventilation Section 45 - Ventilation Local exhaust ventilation to be installed, where practicable, to prevent impurities from entering the workplace air and the breathing zone of workers Exhaust must be clear of the workplace and prevented from re-entering Requires internal combustion engines (ICEs) that are operated indoors to be vented to the outdoors (where possible) Engine serviced/maintained to minimize the concentration of contaminants in the exhaust to ACGIH standards Section 45 - Ventilation Levels of emissions in work area must be assessed If overexposure to exhaust gases can occur, must install engineering controls (e.g. scrubbers, catalytic converters) Section 46 - Silica Regulation Applies to silica processes * Compliance must meet regulations Section 47 - Silica Medical Surveillance Role of employer Re-evaluate assessment of exposures and implement controls, if required Inform workers of purpose and procedures for health surveillance and make arrangements for participation Keep a log of every worker referred for medical examination Section 47 - Silica Medical Surveillance Role of physician Give results and explanation to employee Give general outcome to employer and advice action Notify minister of adverse health effects remedial Section 48 - Asbestos Applies only to asbestos in work or manufacturing processes (not asbestos abatement) ACGIH guidelines referenced Separate Regulations “Asbestos Abatement Regulations” Hazmat Officers Written notification required Employer must be registered with the OHS Division in order to carry out asbestos abatement Section 49 - Lead Exposure Control Plan Outlines when a plan is required and what to include When: If possible exposure > TLV for more than 30 days per year If exposure could result in an elevated body burden Part VII Personal Protective Equipment (PPE) Sections 70 to 86 - PPE There are many different CSA standards that outline requirements of PPE Must be properly maintained Workers must be instructed in proper use, limitations & maintenance Must properly address identified hazards Sections 70 to 86 - PPE If using any respiratory protection, a written program must be established in accordance with applicable CSA Standards Respiratory protection is to be maintained & inspected regularly Part VII Personal Protective Equipment Section 70 - Definitions Section 71 – Selection, use and maintenance Section 72 - Instruction Section 73 – Personal clothing and accessories Section 74 – General requirements of safety headgear Section 75 – Eye and face protection Section 76 – Prescription safety eyewear Section 77 – Contact lenses Part VII Personal Protective Equipment Section 78 – General requirements of limb and body protection Section 79 – Leg protection Section 80 – Foot protection Section 81 – High visibility apparel Section 82 – Flame resistant clothing Section 83 – Respiratory protection program Section 84 – Respiratory protection Section 85 – Respiratory protection equipment Section 86 – Inspection and maintenance of respiratory protection equipment Occupational Health & Safety Regulations (2009) Other Relevant Sections Part VI Occupational Health Requirements Section 57 - Permitted quantities Section 58 - Incompatible substances Section 59 - Storage of hazardous substances Section 60 - Dispensing Section 63 - Emergency washing facilities Section 64 - Work clothing and accommodations Section 65 - Eating areas Section 69 - Painting, coating and working with plastics/resins Part V General Health and Safety Requirements Section 38 - Emergency plan risk assessment Part XIII Transportation of Workers Section 283 - Hazardous materials Part XVI Construction, Excavation and Demolition Section 398 - Hazardous materials Part XVIII Excavation, Underground Work and Rock Crushing Section 413 - Air quality Part XXI Welding, Burning and Cutting Operations Section 454 - Ventilation Section 455 - Coatings on metals Section 457 - Respiratory protection Part XXVII Confined Space Entry Section 512 - Corrective precautions Federal Canada Labour Code Part II and Canada Occupational Health & Safety Regulations Part X Canada Labour Code Part II Section 122.(1) - Definitions “hazardous substance” Section 125.1 – Duties of employer Ensure concentrations of hazardous substances in the work place are controlled Exposure assessment Records Section 139. (1) - Medical Surveillance Canada Occupational Health and Safety Regulations (Regulations under the Canada Labour Code Part II) Part X – Hazardous Substances Records of hazardous substances Hazard investigation Routes of exposure, concentration, control measures, etc. Medical examinations Storage, handling and use Warning of hazardous substances Employee education Substitution of substances Ventilation Control of hazards Chemical Hazards in Occupational Settings Silica Asbestos Lead Isocyanates Styrene Carbon Monoxide Silica Silica Many workplace activities that create dust can expose workers to airborne silica Industries include: Mining, quarrying, tunneling, stone cutting, polishing, cleaning & monument masonry, sand blasting, glass manufacturing, fillers, foundry work, ceramics, border scaling, manufacturing of cultured quartz crystals Health Effects of Silica Route of exposure is inhalation of airborne dust Coughing and mild, temporary irritation following a short-term exposure to high concentrations of dust Silicosis, a disease of the lungs (prolonged or repeated exposure to fine airborne crystalline silica dust may cause severe scarring of the lungs) Also linked to other diseases including bronchitis, tuberculosis, and lung cancer Silica Workers also exposed to silica dust during cleanup activities They may expose their families to silica dust if contaminated clothing is improperly handled Asbestos Asbestos Industries with possible exposure: Contracting, construction, demolition work, firefighting, power plants, automotive work, mining, shipyards, oil refineries, etc. Health Effects of Asbestos Route of exposure is through inhalation of airborne fibers Lung cancer Mesothelioma…a rare cancer usually caused by exposure to asbestos Non-malignant lung and pleural (lining of chest cavity) disorders Asbestosis - restricted use of the lungs due to retained asbestos fibers Health Effects of Asbestos Health effects from asbestos exposure may continue to progress even after exposure is stopped Smoking or cigarette smoke, together with exposure to asbestos, greatly increases the likelihood of lung cancer Lead Exposure Home renovation is a frequent source of lead exposure due to scraping, remodeling, or otherwise disturbing lead-based paint Renovation involving lead-based paint should only be undertaken after proper training, or with the use of certified personnel Industries with Possible Lead Exposure auto repair battery manufacturing bridge reconstruction construction firing range instruction gas station (past exposures) glass manufacturing lead manufacturing/mining/refining/smelting Industries with Possible Lead Exposure plastic manufacturing plumbing pipe fitting law enforcement (police officers) printing rubber product manufacturing shipbuilding steel welding or cutting Health Effects of Lead Route of exposure is through inhalation or ingestion of fumes or lead dust Workers may inhale lead dust and lead oxide fumes, as well as eat, drink & smoke in or near contaminated areas, thereby increasing their probability of lead ingestion Health Effects of Lead Lead accumulates in the body inorganic lead compounds are well known to cause significant health effects following long-term (chronic) exposure Symptoms may include headache, fatigue, nausea, abdominal cramps, joint pain, metallic taste in the mouth, vomiting and constipation or bloody diarrhea Case example moderate exposure to inorganic lead occurred while sandblasting lead-based paint for twelve hours Health Effects of Lead Lead can cause harmful effects on the nervous system, kidney, blood system Possible cancer hazard Based on animal studies Reproductive hazard May cause harmful effects to an unborn child and may have serious effects on the male and female reproductive systems Lead is also a mutagen May cause genetic damage Lead Workers can bring lead dust home on their skin, shoes, and clothing, thus exposing family members Need for showers and procedures to change/clean work clothes at worksite Industries with Possible Exposure to Isocyanates Automotive repair, construction & manufacturing industries Used in the production of paints and coatings to create weatherresistant surfaces (Spray painting and foam blowing) Industries with Possible Exposure to Isocyanates Used to make building materials (e.g., Styrofoam, flexible foams, adhesives, elastomers, & binders) Used in production of manufactured goods (e.g., bedding, furniture, clothing, appliances, electronics, tires, & packaging) Health Effects of Isocyanates Exposure mainly through inhalation of airborne particles Lungs Asthma (coughing, shortness of breath, wheezing, and chest tightness) Symptoms can occur soon after exposure or several hours later Hypersensitivity pneumonitis (inflammation of the lung) “Sensitizer” – Initial exposure triggers immune response and subsequent exposures cause more intense response (Asthma attack) Health Effects of Isocyanates Skin Severe skin rashes, both where the material contacts your skin and on other parts of your body Rash can also be caused by inhaling Eyes, nose and throat Chemical irritant Video: Hazard vs Risk Considerations for Risk Assessment Hazardous properties Health effects (MSDS) Level, type and duration of exposure Circumstances of the work Activities with potential for high exposure ACGIH exposure limits Prevention and control measures Exercise Risk Assessment for Silica Risk Identification, Assessment, & Control Identify the work activities that would put workers at risk of exposure (key step in developing a silica exposure control plan) Work activities that may generate airborne silica dust Route of exposure is through the inhalation of airborne dust Employer should have a qualified person review the planned work activities to identify those that may generate airborne silica www.worksafebc.com Risk Identification, Assessment, & Control Identify workers at risk of exposure e.g. workers who finish concrete would be at greater risk of exposure than plumbers or electrical workers Risk Identification, Assessment, & Control Amount of exposure Some work activities generate more dust than others Amount of exposure should be estimated Published resources are available that provide air sampling data and compare silica dust levels from various construction activities Duration of exposure Workers who grind concrete for a full shift would be at greater risk than workers jack hammering for an hour Risk Identification, Assessment, & Control Worker exposure measurements OHS Regulations (NL) state that dust levels must not exceed the TLV established by the ACGIH Concentration to which nearly all workers could be exposed for 8 hrs/day, 5 days/week, without adverse health effects As a suspected carcinogen, crystalline silica is also an ALARA substance, and exposures must be reduced to levels as low as reasonably achievable below guidelines *Source: WorkSafe BC Risk Identification, Assessment, and Control Construction work involving drilling, chipping, grinding, cutting, and sawing of concrete and concrete products conducted without using effective dust controls, potentially expose workers to airborne silica concentrations at levels far above the TLV guideline Employer may need to conduct air sampling in order to ensure that dust control methods are adequate, if worker exposure data is not available Risk Identification, Assessment, and Control The following hierarchy of control measures must be followed: Elimination/substitution (e.g., use products with less silica or use work methods that would eliminate the need for surface grinding) Engineering controls (e.g., water, local exhaust ventilation, enclosure of work area) Administrative controls (e.g., coordination of tasks with subcontractors, signage) PPE (e.g., coveralls, respiratory protection) Risk Control – Elimination/Substitution Example: Concrete Form Work Efforts taken to identify all practical approaches to eliminate or reduce the need for surface grinding Risk Control – Elimination/Substitution Example: Concrete Form Work Reduce surface grinding: Select better grades of concrete less susceptible to imperfection Use better design/grades of formwork Use system to identify problem formwork and ensure action taken to correct Plan work - complete concrete grinding when wet to reduce dust released Engineering Control for Dust Dust control systems use 3 well-established techniques: Local exhaust ventilation (LEV) Wet dust suppression (WDS) Restricting/isolating work activity with barriers or full enclosures (this may be the only option where LEV or WDS is not practical or effective) Engineering Control for Dust Appropriate control measures depend on the specifics of the operation Local exhaust ventilation (LEV) is more effective at controlling exposure (e.g., during grinding operations) than wetting methods In a different application, wetting may be more effective (e.g., during cutting operations) than LEV LEV may reduce the amount of final cleaning required (silica dust is captured) Risk Control - Administrative Controls Involve activities that are not directly related to the actual physical work Strategies to support the exposure control plan and ensure that all workers are protected from exposure to silica dust Examples of Administrative Controls Post warning signs Reschedule grinding at different times than other work performed Relocate unprotected workers away from dusty work Safe work practices/procedures Safe Work Practices/Procedures for Silica Employers must develop written, site-specific work procedures for controlling risk of exposure to silica Procedures should be made available to workers Silica accumulates on hands, clothing, and hair (dust disturbed, re-suspended in air, and inhaled) Workers should be able to wash and shower at end of shift No smoking, eating, drinking in contaminated areas Lunches stored in an uncontaminated area Safe Work Practices/Procedures for Silica SWPP must include task specific instructions such as: safe operation of all equipment, including dust control attachments and related equipment setting up enclosures vacuum maintenance cleanup procedures worker decontamination procedures (hygiene facilities to permit proper hand-washing are a basic expectation under all ECPs) Safe Work Practices/Procedures for Silica When water spray systems are used, follow these swps: Use pneumatic grinders instead of electric-powered grinders if water is the method of control Pressure and flow rate of water will be controlled in accordance with tool manufacturers’ specifications (for cutting saws, a minimum of 0.5 litres of water per minute should be used) Safe Work Practices/Procedures for Silica When water spray systems are used, follow these swps: When sawing concrete or masonry, use only saws that provide water to the blade Wet slurry will be cleaned from work surfaces when the work is completed, using a wet vacuum or wet sweeping Safe Work Practices/Procedures for Silica When LEV is used, employ the following systems and safe work practices: Vacuum attachment systems to capture and control the dust at its source whenever possible Dust control systems (used regularly and well maintained) Grinding wheels operated at the manufacturers’ recommended rpm (operating in excess of this can generate significantly higher airborne dust levels) Safe Work Practices/Procedures for Silica When LEV is used, employ the following systems and safe work practices: Work planning, so that concrete grinding can be completed when wet (dust release can be significantly reduced) Good housekeeping work practices. For example, use vacuums with high-efficiency particulate air (HEPA) filters, or use wet sweeping Train workers and supervisors on how to properly use and maintain the equipment Safe Work Practices/Procedures for Silica When barriers or enclosures are used, follow these swps: Site foreman will determine the type/design of barrier/enclosure (based on the work activity and the work area) Barriers may be simple hazard-flagging ribbon or more restrictive enclosure Use negative air units when constructing a full enclosure (maintain negative pressure conditions within enclosure to contain airborne dust) Safe Work Practices/Procedures for Silica Establish procedures for housekeeping, restricting work areas, personal hygiene, worker training, and supervision Assess when silica dust may be generated and plan ahead to eliminate or control the dust at the source (awareness and planning are key factors in the prevention of silicosis) Post warning signs to warn workers about the hazards of silica and to specify any protective equipment required (for example, respirators) Safe Work Practices/Procedures for Silica Work schedules will be posted at the boundaries of work areas contaminated with silica dust Work that generates silica dust will be conducted after hours, when access to other unprotected workers cannot be restricted Risk Control – PPE Respirators: Respirators should not be relied on as a primary means of preventing or minimizing exposure to silica dust Select respiratory protective equipment (RPE) carefully Different types can give widely varying levels of protection Employers may be able to rely on available exposure data to select the appropriate respiratory protection Improper selection can result in serious worker exposure Risk Control – PPE Respirators: Guidance on the selection and use of RPE can be obtained from respirator manufacturers and Occupational hygienists can provide information on approval and suitability OHS Regulations require the development of a respiratory protection program that sets out in detail how respiratory protective equipment will be selected, supervised, and maintained Risk Control – PPE Protective clothing Workers will wear protective clothing as specified in task-specific safe work procedures (coveralls, gloves, etc.) Prevent contamination of street clothing Rod Stickman Get connected through the web Available services: Employer Report of Injury (Form 7) Clearance letters Assessments account information Details health care cost reports OH&S Committee Minutes New for 2011 – Annual Employer Statements Employer Payroll Statement Occupational Health and Safety Statement Contractor Statement Please visit WHSCC website at www.whscc.nl.ca Our website contains information on: Prevention Services PRIME Ergonomics CEO Leadership Charter CONNECT You can also access from our website: Publications Forms Posters Training Providers See the resource tab in your booklet for an overview of additional information provided on our website