DATASHEET – DME 660-94º/10m

Distance measurement camera engine

General Description

Features

The DME 660 is a standalone 3D-TOF Distance Measurement

Camera with a resolution of 320x240 pixel (QVGA). It is a highly

integrated camera system with a wide field of view (FOV). The

operating range is up to 10m on white objects. The camera system

is a combination of a epc660 sensor board including a lens system,

an LED illumination board and a BeagleBone Black host controller

board. Even for mobile devices, only a few additional components

are needed to integrate this 3D camera, e.g. a housing.

The host controller operates the epc660 in all available operation

modes and reads the distance values over the TCMI communication. The controller reads the imager data, applies calibration and

compensation algorithms and delivers the results to an external

computer via its integrated API. It is also possible to operate the

DME 660 as a standalone sensor system. In this case, application

software can be downloaded and run on the BeagleBone Black

board also by using the full software framework like the operating

system and the 3D-TOF API.

■ 320 x 240 pixel (QVGA)

■ Wide field of view H94° x V69º

■ Up to 10m distance measurement range on white targets

■ Low power consumption

■ Robust and stable

■ High speed USB or ETHERNET interface

■ Linux server with 3D-TOF API

65 full frame TOF images are delivered by the epc660 camera chip

in maximal configuration. By using the advanced operation modes,

this can be boosted up to more than 1'000 TOF images per

second! The high degree of integration lays base for straight-forward system integration with minimal part count. The extremely

high sensitivity of the optical front end allows to operate with a low

power illumination subsystem which reduces the power consumption of the overall system significantly.

The camera comes with a fully documented SDK based on opensource SW and HW.

Applications

■ People detection and counting

■ Parcel size measurement

■ Machine safety

■ Object recognition

■ Automatic door safety

■ Humanoid robotics

■ Helicopter near terrain flight assistance

■ Man-Machine interface

■ Gesture control

■ Body size measurement

■ General volumetric mapping

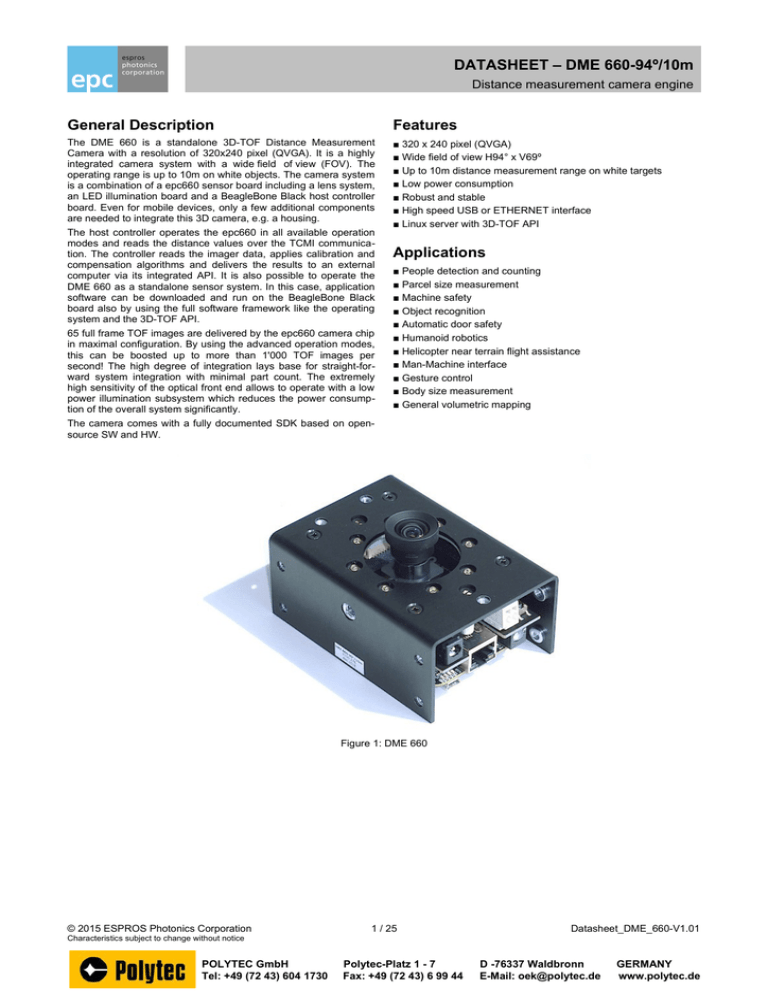

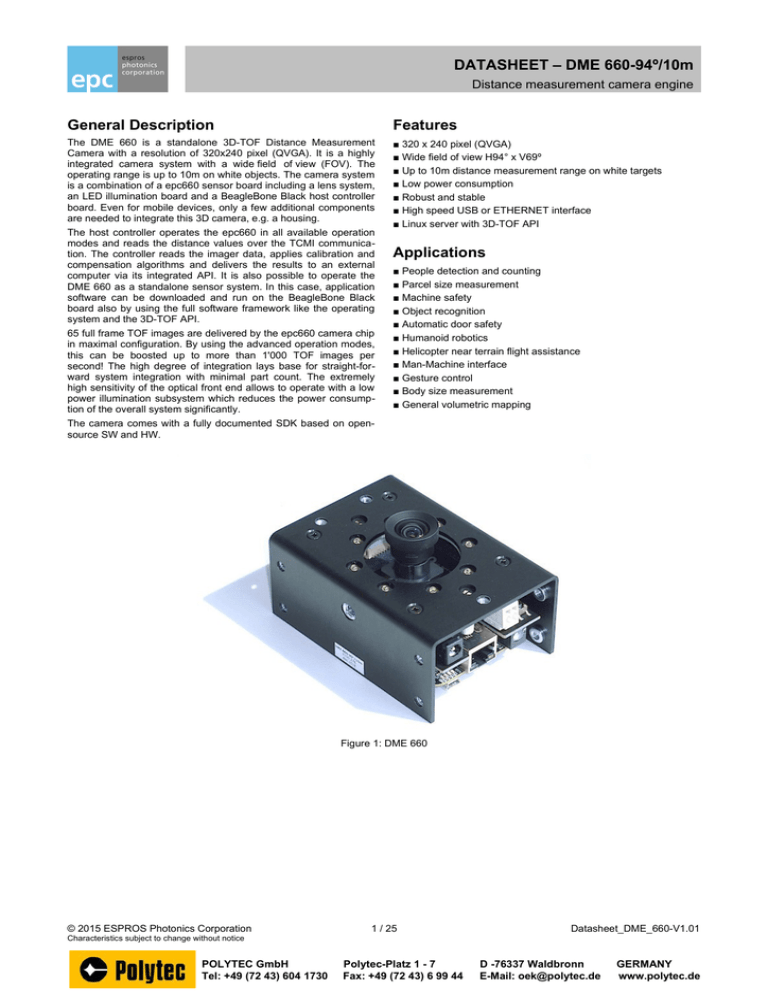

Figure 1: DME 660

© 2015 ESPROS Photonics Corporation

1 / 25

Datasheet_DME_660-V1.01

Characteristics subject to change without notice

32/<7(&*PE+ 3RO\WHF3ODW] ':DOGEURQQ *(50$1<

7HO)D[ (0DLORHN#SRO\WHFGH ZZZSRO\WHFGH Precaution and Safety

Eye safety: Do not look directly into the camera under operation. Depending on the mode of operation, the camera device

emits highly concentrated non-visible infrared light. It can be hazardous to the human eye. The use of these devices has

to follow the safety precautions given in IEC 60825-1 and IEC62471.

The DME 660 is a bare electronic device without a housing around. Therefore, handle it with the necessary ESD precaution.

Over-voltage: Use only power supplies which corresponds to the datasheet DME 660 to avoid damage of the DME 660 or cause

danger for humans.

Cable-tripping: Place the DME 660 with a tripod on a flat solid ground or fix it correctly on a solid support. Place cables carefully.

Falling devices can be damaged or harm persons.

This camera comes with its own calibrated firmware. For proper operation of the camera, upload the correct firmware with the

evaluation kit to the camera according the instructions given in the quick guide. Do this when you are changing the camera

module.

This camera comes with high quality lens. Do not touch, twist or turn it. Otherwise loss of performance occurs.

EMC compatibility: The DME 660 is designed on module level. It is not an EMC certified device. It is users responsibility to operate

it in compliance with the EMC regulations.

The DME 660 is designed on module level. It is NOT a CE, UL, CSA certified device. It is the users responsibility to operate it in

compliance with the relevant regulations.

The DME 660 and its software may only be be used in accordance of the datasheet DME 660

This devices may not be used in safety applications, explosive atmospheres or in radioactive environment.

Limited warranty - Loss of warranty

The DME 660 should only be installed and used by authorized people. All instructions in this datasheet and in the related docu ments shall be followed and fully complied with. In addition, the installer and user is required to comply with all local laws and regulations. Should any of these instructions not be carefully followed, seriously injury may occur. The installer and user is fully respon sible for the safe use and operation of the system. It is the sole responsibility of the installer and the user to ensure that this

product is used according to all applicable codes and standards in order to ensure safe operation of the whole application. Any

alteration to the devices by the buyer, installer or user may result in unsafe operating conditions. ESPROS Photonics AG is not

responsible for any liability or warranty claim which results from such manipulation or disregarding of given operating instructions.

ESPROS Photonics is constantly striving to provide comprehensive and correct product information. Therefore,

please check our website regularly for updated versions of datasheets and documentations: www.espros.com

Download the actual Datasheet epc660: www.espros.com → Downloads → Datasheets → Chips.

Download the actual Datasheet DME 660: www.espros.com → Downloads → Datasheets → Camera_and_Modules.

UPDATE DOWNLOAD: Click in the GUI of the epc660 Evaluation Kit onto the Chip ID. The GUI establishes a secure Internet

connection to the appropriate epc sftp server. The GUI displays a menu with the available functions for the connected DME 660

device e.g. camera specific calibration, SDK tool, emulation tools, …

Update the DME 660 (BeagleBone board) by going to the corresponding subfolder of the epc660_Evaluation_Kit_Install_vX.X.X /

server. Start the file “setup.xxx”. For default installation, press ENTER.

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

2 / 25

Datasheet_DME_660-V1.01

Table of Contents

General Description ......................................................................................................................................................................................... 1

Features ........................................................................................................................................................................................................... 1

Applications ...................................................................................................................................................................................................... 1

Precaution and Safety ...................................................................................................................................................................................... 2

The DME 660 Distance Measurement Engine ................................................................................................................................................ 4

1. System overview ..................................................................................................................................................................................... 4

1.1. Scope of Delivery ................................................................................................................................................................................. 5

1.1.1. Bill of Material ................................................................................................................................................................................... 5

1.1.2. Documentation .................................................................................................................................................................................. 5

2. Ordering Information ............................................................................................................................................................................... 6

3. Technical Data ........................................................................................................................................................................................ 7

3.1. Recommended operating conditions ................................................................................................................................................... 7

3.2. Optical Power Data .............................................................................................................................................................................. 7

3.3. Distance Measurement Timing ............................................................................................................................................................ 8

3.4. Absolute Maximum Ratings ................................................................................................................................................................. 9

4. Interfaces ................................................................................................................................................................................................ 9

4.1. Connectors ........................................................................................................................................................................................... 9

4.2. Indicators and reset button ................................................................................................................................................................ 10

4.2.1. Status LEDs .................................................................................................................................................................................... 10

4.2.2. Monitoring LEDs ............................................................................................................................................................................. 10

4.2.3. Reset button on BeagleBone .......................................................................................................................................................... 10

4.2.4. Reset button on TOF cape ............................................................................................................................................................. 10

5. Mechanical Properties .......................................................................................................................................................................... 11

5.1. Part list ............................................................................................................................................................................................... 11

5.2. Mechanical / Optical Properties ......................................................................................................................................................... 11

6. Electrical Circuits .................................................................................................................................................................................. 12

6.1. epc660 on Carrier .............................................................................................................................................................................. 12

6.1.1. Schematics ..................................................................................................................................................................................... 12

6.2. PCB Layout ........................................................................................................................................................................................ 13

6.3. Pin Table ............................................................................................................................................................................................ 14

7. TOF Cape ............................................................................................................................................................................................. 15

7.1. Schematics ........................................................................................................................................................................................ 15

7.2. PCB Assembly ................................................................................................................................................................................... 16

7.3. Pin Table J8 & J9 ............................................................................................................................................................................... 17

8. LED Cape ............................................................................................................................................................................................. 18

8.1. Schematics ........................................................................................................................................................................................ 18

8.2. PCB Assembly ................................................................................................................................................................................... 19

9. BeagleBone Black Board ...................................................................................................................................................................... 20

9.1. System Overview ............................................................................................................................................................................... 20

9.2. Documentation ................................................................................................................................................................................... 20

10. Installation and Setup ......................................................................................................................................................................... 21

10.1. Mechanical fixation .......................................................................................................................................................................... 21

10.2. Setup of the DME 660 ..................................................................................................................................................................... 21

10.3. Software Tools ................................................................................................................................................................................. 21

10.4. Exchange of epc660 on Card Edge Connector Carrier ................................................................................................................... 21

11. epc660 Evaluation Kit ......................................................................................................................................................................... 22

11.1. Scope of Delivery ............................................................................................................................................................................. 22

11.2. Ordering Information ........................................................................................................................................................................ 22

12. Maintenance and disposal .................................................................................................................................................................. 24

12.1. Maintenance .................................................................................................................................................................................... 24

12.2. Disposal ........................................................................................................................................................................................... 24

13. Addendum ........................................................................................................................................................................................... 24

13.1. Related documents .......................................................................................................................................................................... 24

13.2. Links ................................................................................................................................................................................................. 24

13.3. Licenses ........................................................................................................................................................................................... 24

IMPORTANT NOTICE ................................................................................................................................................................................... 25

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

3 / 25

Datasheet_DME_660-V1.01

The DME 660 Distance Measurement Engine

1. System overview

85...240 VAC

epc660 chip

Lens

Illumination

Mounting frame

PC with MS-Windows

Mac with OSX

LED cape

epc660 Carrier

Power supply 24 VDC

TOF cape

USB

ETHERNET

API

Ethernet

API

USB

API

HW I/O

Internet

3D TOF

kernel

User

software

DEBIAN

operating

system

www.espros.com

download center

Application

software

Point Cloud

Computing

Customer

Application

Open Source

Tools

BeagleBone Black

Figure 2: System overview

The DME 660 is a general purpose camera module based on the epc660 chip:

■ The camera is based on a BeagleBone Black (BBB) Linux computer board.

■ The TOF cape board communicates with the BBB and carries the epc660 Card Edge Connector Carrier board with the epc660 camera

chip and the lens with the lens holder. It carries also the single wire power supply for the hole camera system.

■ The camera's active illumination is done by 8 power LEDs on the LED cape which is driven by the TOF cape. The LED cape's metal

frame offers two camera mount 1/4” - 20UNC.

■ The application software runs on the DEBIAN GNU/Linux operating system. The 3D-TOF kernel manages the camera including correction algorithms. Data for further processing e.g. cloud computing is available on APIs (application programming interface) for USB,

Ethernet interfaces or hardware I/O. It opens the world for point cloud computing, using open source tools or creating own customer

applications.

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

4 / 25

Datasheet_DME_660-V1.01

1.1. Scope of Delivery

Attach and remove lens

cover carefully not to

damage the epc660 chip

Lens and sensor

Various locations with M4 nuts

for easy and robust mounting

➀ Metal frame with

illumination board (LED cape)

LED 8x

➁ Sensor board (TOF cape)

with epc660

Tripod mount

1/4“ - 20UNC

➂ BeagleBone Board

Figure 3: DME 660 overview

1.1.1. Bill of Material

No. Designation

➀

➁

➂

Remarks

Metal frame with camera/tripod mount 1/4” - 20UNC

Use only the 1/4” - 20UNC or the M4 tread inserts for mounting

the camera

LED cape: Illumination board

on Metal frame

TOF cape: Sensor board

on LED cape

epc660-CSP68 chip (ESPROS part no.P100 183) assembled

on card edge connector carrier (ESPROS part no. P100 244)

on TOF cape

Optical bandpass filter e.g. infrared filter 860nm

optional

Lens holder, M12-Mount (P/N P100 217)

on epc660 card edge connector carrier board

Lens for DME 660 (ESPROS part no. P100 295):

- FOV: H94°, V69°

- Lens with non-linear distortion

- optimized for NIR

- EFL 4.1mm (center)

- F2.0

- 1/2"

- M12 mount

on lens holder, including lens cover

BeagleBone Black board

Host controller

other lens types upon request

1.1.2. Documentation

Designation

Remarks

Datasheet DME 660

available at www.espros.com / Downloads

Datasheet epc660

available at www.espros.com / Downloads

Application and configuration software

Use the epc660 Evaluation Kit for accessing licensed corresponding tools and software development kit (SDK).

Table 1: Bill of material of the delivery

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

5 / 25

Datasheet_DME_660-V1.01

2. Ordering Information

Part Number

Part Name

Remark

RoHS compliance

P100 278

DME 660-94º/10m

completely assembled, tested and calibrated

Part Number

Part Name

Remark

P100 244

epc660-000 Card Edge Connector epc660 on chip carrier without optical filter

Carrier

P100 295

Lens FOV 122°, 1/2", M12

P100 217

Lens Holder, M12-Mount

Yes

Accessories:

Optical bandpass filters

RoHS compliance

Yes

Lens for DME 660:

- FOV: H94°, V69°

- Lens with non-linear distortion

- optimized for NIR

- EFL 4.1mm (center)

- F2.0

- 1/2"

- M12 mount

Please contact your sales office or info@espros.com

Table 2: Ordering Information

Support and technical contact: info@espros.com

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

6 / 25

Datasheet_DME_660-V1.01

3. Technical Data

3.1. Recommended operating conditions

(TA = 25°C, VSUPPLY = 24V, object reflectivity 90%, unless otherwise stated)

Parameter

Description

Min.

Typ.

Max.

Units

VSUPPLY

Supply voltage

21.6

24

26.4

VDC

VPP

Ripple on the supply voltage VSUPPLY

0.25

VPP

ISUPPLY

Supply current

Comments

Peak value must not below

min. and not above max.

supply voltage

Idle

0.10

A

after power up

Grayscale imaging

0.10

100 fps

3D-TOF imaging

0.25

25 fps, tINT = 1 ms

Image resolution

320 x 240

FOV

Field of view

H94 x V69

°

λ

Operating wavelength

850

nm

fLED_INT

Internal modulation frequency

0.675, 1.25, 2.5, 5, 10, 20

MHz

fLED_EXT

External modulation input

d

Operating range

Out

Distance output word

12

Res

Resolution

0.5

Measurement output

Pixel

with lens P/N P100 295

1

30

MHz

0.00

10.0

m

0

Software controllable

Measured with an object that

has a size at least the size of

the pixel (dPIXEL). It is depending on the integration time

tINT and the object reflectivity.

Bit

cm/LSB at 10 MHz modulation frequency

2'000

1.2

LSB

dCAL

Calibration distance

VAPM

Amplitude

0

2'000

LSB

useful amplitude range

ΦL

Ambient light suppression

0

130'000

Lux

indirect, depending on integration time and object distance, ABS on

Data interface

TA

Ambient temperature range (operation)

m

at 10 MHz modulation frequency, refers to 0.0 ...

10.0 m, measurement results depending on object reflectivity

Output @ 3.5m = 700 LSB

USB 2.0 full speed

or Ethernet

0

60

°C

Max.

Units

Comments

372

W/m

2

in 200mm distance to the

front surface of the DME 660

W/m2

in 200mm distance to the

front surface of the DME 660

Table 3: Operating conditions

3.2. Optical Power Data

Parameter

Description

Ee PEAK

Peak illumination irradiance

Ee AVG

Average illumination irradiance

Min.

Typ.

108

Table 4: Optical power data

The analysis of the photo-biological hazards show that the DME 660 emits radiation levels below the safety limits described in EN 62471.

The calculated exposure level is below the limit for any exposure time at a distance of 200 mm or more. Therefore, the DME 660 can be

assumed to be safe to the eye and skin in terms of the standard and would belong to the open group (RG0).

Refer also to the report 'DME_660_Photobiological_Safety_Analysis.pdf' which can be downloaded from the ESPROS website.

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

7 / 25

Datasheet_DME_660-V1.01

3.3. Distance Measurement Timing

Figure 4 shows the general timing diagram. For a full range measurement cycle, four differential correlation samples (DCSn in Figure 4)

have to the acquired. After each DCS acquisition, the image containing the DCS per pixel, has to be read out from the epc660 imager

(Data readout in Figure 4). Once four DCS are acquired, the distance is calculated on the BeagleBone Black board and an image

containing a point cloud is ready to through the API.

DCS0 DCS1 DCS2 DCS3

DCS0 DCS1 DCS2 DCS3

Acquisition

Data readout

Readout time tREAD

Integration time tINT

Distance calculation,

transmission over USB

Tx to GUI

Processing time tPROC

Figure 4: DME 660 measurement timing: 3D TOF with 4 DCS frames (standard API)

Parameter

Description

Min.

Typ.

tINT

Integration time selectable

tREAD

Full frame image readout time (1 DCS)

3.8

ms

with 40MHz TCMI data rate

tCYCLE

Total distance measurement cycle time

136.9

ms

tINT = 1.0ms, refer to Figure 4

TPWR_UP

Power up time

20

s

0.1

Max.

Units

4,000

µs

Comments

Refer to chapter 4.2

Table 5: Typical distance measurement timing parameters

There are various options to increase the frame rate:

Parameter

Description

Acquisition time reduction

Comments

No π-delay matching

DCS0 and DCS1 acquisition only

reduces the frame cycle by 2 * tINT

plus 2 * tREAD

In-pixel non-linearities and asymmetries reduce the distance measurement quality

Dual MGX

Acquires the odd DCS' in the odd rows reduces the frame cycle by 2 * tINT

and simultaneously the even DCS' in

plus 2 * tREAD

the even row

Pixel tolerances in the even and

odd rows reduce the distance measurement quality

No π-delay matching

and Dual MGX

Acquires DCS0 in the even rows and

simultaneously DCS1 in the odd row

reduces the frame cycle by 4 * tINT

plus 4 * tREAD

see above

ROI

A reduced ROI reduces tREAD and the

distance calculation time because less

data need to be processed

depending on ROI settings

reduced FOV

Row reduction

It is possible to skip rows at readout

depending on Row Reduction settings:

- Full = full frame

- Half = every second row is skipped

- Quarter: 3 out of for rows are skipped

- One-Eight: 7 out of 8 rows are skipped

Table 6: Frame rate tuning options

Additional options are to modify the calculation software in the API and utilizing the 3D graphics accelerator and the NEON floating-point

accelerator of the BeagleBone Black processor.

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

8 / 25

Datasheet_DME_660-V1.01

3.4. Absolute Maximum Ratings

Parameter

Conditions

ESD rating

Not classified. Handle it with the necessary ESD precaution.

Storage temperature range (TS)

-40°C to +85°C

Relative humidity

15 ... 95%, non-condensing

Table 7: Absolute maximum ratings

4. Interfaces

4.1. Connectors

View B

View A

View B

View A

Illumination LEDs

Control LEDs

➃ Ethernet

Status LEDs

➂ USB mini

➁ Industrial connector

(alternative to the 3.5mm Jack connector)

not used

➄ micro SD card

Power supply of the BeagleBone Black board.

It is intentionally covered. DO NOT USE!

➀ Supply 24VDC

Figure 5: Connectors, status and control LEDs

No. Connector

Plug

Remarks

Supply 24VDC / 2.5A

Power jack 5.0/2.1mm

for supply from power adapter 24VDC / 2.5A

Industrial supply

Power jack WAGO 3.5mm

for supply by industrial connection 24VDC / 2.5A

➂

USB micro

Micro USB-B

➃

ETHERNET

RJ45

➄

Micro SD card

➀

➁

NEVER CONNECT THE USB CABLE

AS LONG POWER IS NOT TURNED ON

COMPUTER AND/OR THE CAMERA

CAN BE DAMAGED!

Table 8: Connector list

Figure 6: View to the connector side

(USB and ETHERNET not connected)

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

9 / 25

Datasheet_DME_660-V1.01

4.2. Indicators and reset button

Supply 24VDC

RESET button

BeagleBone

ETERNET

connector

LED 0

BeagleBone

USB

connector

LED 3

BeagleBone

Figure 7: Status LEDs and RESET button

4.2.1. Status LEDs

Status

LED 0

LED 1

LED 2

LED 3

After power up or RESET.

Startup procedure of the board operating system.

For details refer to the BeagleBone manual

Trying to boot the epc660 chip

Wait until LED 0 only (most left) is flashing only.

LEDs 1 to 3 shall be off.

READY for handling requests

Server successfully started on DME 660.

Start communicating with the BeagleBone Black

server by using either Ethernet or USB.

BUSY:

Handles request of single command or video

READY again

Start-up DME 660 or BeagleBone:

The blue status LEDs start flashing

Remarks

After around 20s: Boot epc660 chip

Regular operation:

Error message:

Caught signal (Error), application closed

Error detected by API. Reset the BeagleBone.

Table 9: Blue status LEDs on BeagleBone, refer to Figure 7

Notes:

LED off

LED flashing

LED on

4.2.2. Monitoring LEDs

Red control LEDs on LED Cape, visible from the frontside; refer to Figure 5:

■ D12: On if the LED cape is powered e.g. 3D TOF modes. Safety advise: Be careful, IR LEDs are active during exposure.

Off during modes having not an active illumination e.g. greyscale mode without active illumination.

■ D13: On during integration period (exposure) independent of selected mode.

4.2.3. Reset button on BeagleBone

Resets the DME660. Instead of the this button, the terminal command, as described in the "Readme" of the GUI source, can be used.

4.2.4. Reset button on TOF cape

Do not use. Reset the epc660 chip only. Lost of the synchronization with the BeagleBone board.

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

10 / 25

Datasheet_DME_660-V1.01

5. Mechanical Properties

5.1. Part list

No.

Part name

Qty.

1

2

BeagleBone Black Rev. C

Illumination board: LED cape

1

1

3

4

Distance sleeve M3/18mm, hole/hole, PA

Distance sleeve M3/12mm, bolt/hole, PA

4

4

5

6

Lens head screw

Metal frame

4

1

7

8

Nut self-clinching

Sunk screw, M3x8

2

4

9

10

Lens FOV 122°, 1/2", M12 (P/N P100 295)

Connection Cable

1

1

11

12

Lens Holder, M12-Mount

Sensor board: TOF Cape

1

1

13

14

Self-locking screw, M1.6

Mounting pillar

2

2

15

16

Screw - cross recessed, M2x5

Female header Dip, 2.54, 180°

2

1

17

18

Screw - cross recessed, M1.6 x 3

epc660 Card Edge Connector Carrier

1

1

19

20

5.0/2.1mm DC Power Jack 24VDC / 2.5A

Industrial supply connector

1

1

21

22

Industrial supply

Micro SDHC card 16GB

1

1

23

IR filter: epc-bp860-8.0x8.0

8

6

7

19

2

20

9

21

3

18

10

13

11

14

12

17

23

15

4

1

16

22

5

optional

Figure 8: Part list and exploded view

5.2. Mechanical / Optical Properties

FOV 69°

FOV 94°

Contact surface of

epc660 chip

1/4"--20

1/4"--20

4 x M4

14.3

17.3

62.7

8

8

25

25

47.3

14.3

4 x M4

42.5

7.5

42.5

85

7.5

70 ±1

7.5

85

7.5

le

s

40

22.5

(8

19.13

ho

46.2

19.13

op 7 il

en lum

ing in

s ati

(1 on

0x

)

46.2

ar 5

ra 0

n

to ged hole

th in c

e

i

ce eq rcle

nt ua

re l p

) it

c

h

100

25

Values unless otherwise stated in mm

22.5

12.5

3 x M4

33

66

42.5

7.5

85

7.5

Figure 9: Reference dimensions of the optical axis and illumination

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

11 / 25

Datasheet_DME_660-V1.01

C19

10nF

C23

10nF

C18

1uF

C22

1uF

VSSIO

VDDIO

VDD

VSS

C15

10nF

C14

1uF

XSYNC_SAT 1

DATA0_FS 2

DATA1

3

VSSIO1

4

VDDIO1

5

DATA2

6

DATA3

7

VSS1

8

VDD1

9

DATA4

10

DATA5

11

VSSIO2

12

13

VDDIO2

DATA6

14

15

DATA7

DATA8

16

DATA9

17

XSYNC_SAT_CFG

DATA0_FS

DATA1

VSSIO1

VDDIO1

DATA2

DATA3

VSS1

VDD1

DATA4

DATA5

VSSIO2

VDDIO2

DATA6

DATA7

DATA8

DATA9

1uF

C7

10nF

1uF

C6

100nF

1uF

C5

10nF

C3

C2

TESTAIO2

TESTAIO1

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

epc660

C34

10nF

C36

1uF

C33

10nF

C35

1uF

LED

VSSLED

LEDFB

VDDPXM2

VDDPXH2

VSSPX2

VSSA2

VDDA2

VIR

VDDA1

VSSA1

VSSPX1

VDDPXH1

VDDPXM1

VBS

TESTAI_VFSDG

VFSAB

XTALOUT

XTALIN

MODCLK

VSSIO4

VDDIO4

DCLK

HSYNC_A1

VSYNC_PSDIAG_A0

VDDPLL

VSSPLL

XTALOUT

XTALIN_CLKIN

VDD3

VSS3

SHUTTER

RESET

NC

TESTAIO2

TESTAIO1

VDDIO3

VSSIO3

DATA10

DATA11

TDO

TDI

TCK

TMS

SCL

SDA

VDD2

VSS2

VSEAL

TESTAIHA

TESTAIHB

TESTAOHA

TESTAOHB

12 / 25

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Characteristics subject to change without notice

VDDIO3

VSSIO3

DATA10

DATA11

TDO

TDI

TCK

TMS

SCL

SDA

VDD2

VSS2

VSEAL

TESTAIHA

TESTAIHB

TESTAOHA

TESTAOHB

© 2015 ESPROS Photonics Corporation

MODCLK

VSSIO4

VDDIO4

DCLK

HSYNC

VSYNC

VDDPLL

VSS

XTA LOUT

XTA LIN

VDD3

VSS3

SHUTTER

RESET

C1

L1

100n

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

LED

VSSLED

LEDFB

VDDPXM2

VDDPXH2

VSSPX2

VSSA2

VDDA2

VIR

VDDA1

VSSA1

VSSPX1

VDDPXH1

VDDPXM1

VBS

TESTAI_VFSDG

VFSAB

U1

epc660

VSS

X1

C30

10uF

C29

100nF

C32

1uF

C27

4.7uF

C25

10uF

C24

100nF

C26

100nF

C21

1uF

C31

100nF

C13

4.7uF

C28

4.7uF

100n L3

C17

10uF

C12

4.7uF

C10

10uF

C20

100nF

C16

100nF

C11

100nF

C9

100nF

100n L2

VBS

VSSIO

VDDIO

VDDPXH

VDDA

VSSA

VSS

VDD

VSSLED

VSSA

XTALOUT

XTALIN

SHUTTER

RESET

VDDIO

VSSIO

VDD

VBS

VDDPXH

VSS

TESTAI_VFSDG

VFSAB

TESTAOHB

TESTAOHA

TESTAIHB

TESTAIHA

VSEAL

SCL

SDA

60

58

56

54

52

50

48

46

44

42

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

J1

59

57

55

53

51

49

47

45

43

41

39

37

35

33

31

29

27

25

23

21

19

17

15

13

11

9

7

5

3

1

LED

LEDFB

VDDA

TMS

TCK

TDI

TDO

DATA11

DATA10

DATA9

DATA8

DATA7

DATA6

DATA5

DATA4

DATA3

DATA2

DATA1

DATA0_FS

XSYNC_SAT

MODCLK

DCLK

HSYNC

VSYNC

TESTAIO2

TESTAIO1

6. Electrical Circuits

6.1. epc660 on Carrier

6.1.1. Schematics

Figure 10: Schematic

Datasheet_DME_660-V1.01

VSS

VDD

VDDIO

VSSIO

6.2. PCB Layout

Figure 11: PCB layout top

Figure 12: PCB layout top-middle

Figure 13: PCB layout bottom-middle

Figure 14: PCB layout bottom

Figure 15: PCB assembly top

Figure 16: PCB assembly bottom

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

13 / 25

Datasheet_DME_660-V1.01

36.00

18.000

7.50

7.50

3.00

3.10

Center of

Pixel-field

(not chip)

Pin 1

37.25

2.10

15.875

∅ 1.80

3.00

3.00

Pin 1 (top)

Top view

Figure 17: Mechanical dimensions PCB

6.3. Pin Table

VSS

TESTAI_VFSDG

VFSAB

TESTAOHB

TESTAOHA

TESTAIHB

TESTAIHA

VSEAL

SCL

SDA

VBS

VDDPXH

VSSIO

VDD

VDDIO

XTALOUT

XTALIN

SHUTTER

RESET

VSSA

VSSLED

60

58

56

54

52

50

48

46

44

42

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

59

57

55

53

51

49

47

45

43

41

39

37

35

33

31

29

27

25

23

21

19

17

15

13

11

9

7

5

3

1

TMS

TCK

TDI

TDO

DATA11

DATA10

DATA9

DATA8

DATA7

DATA6

DATA5

DATA4

DATA3

DATA2

DATA1

DATA0_FS

XSYNC_SAT

MODCLK

DCLK

HSYNC

VSYNC

TESTAIO2

TESTAIO1

VDDA

LED

LEDFB

J1

Figure 18: Pin table

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

14 / 25

Datasheet_DME_660-V1.01

1

3

2

DGND

6

5

4

3

2

1

Header 6

P3

2

R44

10k

1

BBB_+3.3V_ENABLE

13

epc660_ENABLE

+24V

C25

100nF

C23

10uF

+1.8V_VDD

DGND

R32

10k

C26

10uF

DGND

C27

10uF

10

9

8

7

6

5

4

3

2

1

Header 10

P2

DGND

TESTAIO1

TESTAIO2

VSEAL

TESTAOHB_BUFF

TESTAOHA_BUFF

TESTAIHA

TESTAIHB

TESTAI_VFSDG

VFSAB

R43

10k

C5

10uF

EN

NR/SS

IN

2

1

DGND

IC5

TPS7A4901

FB

OUT

L7

220uH

R83

1k

2

S1

Value

R46

1k

DGND

4

2

R19

100k

+3.3V_VDDIO

C24

10nF

R35

10k

R18

330k

C20

4.7uF

R82

12k

R76

0R

DGND

X1 4.000 MHz

DGND

R74

0R

DGND

1

1

R57

0R

R56

0R

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

VSSA

R13

0R

DGND

R36

1k

BBB_GNDA

BBB_AIN5

BBB_AIN3

BBB_AIN1

BBB_V_LED_ENABLE

BBB_DCLK

BBB_SPI1_CS0

BBB_SPI1_D1

BBB_epc660_SDA

EEPROM_SDA

DGND

R8

10k

R65

0R

R23

BBB_VSYNC 0R

DGND

10

9

8

7

6

5

4

3

2

1

R2 1

R54

100R

VSYNC

DCLK

DATA0_FS

DATA2

DATA4

DATA6

DATA9

DATA8

R66

0R

R62

0R

R60

0R

R53

0R

R51

0R

R49

0R

R47

XSYNC_SAT 0R

epc660_TDI

R77

0R

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

J8

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

DGND

epc660_TMS

epc660_TDI

BBB_DATA7

BBB_DATA5

BBB_DATA3

BBB_DATA1

BBB_DATA10

BBB_DATA11

BBB_HSYNC

TESTAOHA

TESTAOHB

1

2

CB1

CB2_SMD

R68

0R

R69

0R

CB2

CB2_SMD

1

2

R22

100R

T2

BC856B

R80

100R

R67

0R

R64

0R

R61

0R

R59

0R

R52

0R

R50

0R

R48

0R

DGND

J3

DATA1

DATA3

DATA5

DATA7

DATA11

DATA10

HSYNC

R81

100R

1

R24

100R

T3

BC856B

BBB_VDD_3V3B

A

5

6

B

IC2B

THS4012

7

R7 100R

IC2A

THS4012

1

R1 100R

C4

22pF

3

2

C1

22pF

TESTAOHB_BUFF

TESTAOHA_BUFF

R26

100R

DGND

VDDPXH

DGND

R29

10k

1

2

CB3

CB2_SMD

R72 0R

R73 0R

1

2

CB7

CB2_SMD

1

2

CB4

CB2_SMD

R71 0R

R70 0R

CB8

CB2_SMD

1

2

R28

10k

TCMI Bus

R27

10k

VDDIO

STRAP Pins

VSEAL

VFSAB

TESTAIHA

TESTAIHB

R30

10k

Buffer for the Test Pins

T4

BC856B

Needed to allow BBB to Boot

epc660_MODCLK

epc660_RESET

+5V_VDDA

Connector BeagleBoneBlack 2x23

epc660_TCK

epc660_TDO

BBB_DATA6

BBB_DATA4

BBB_DATA2

BBB_DATA0_FS

BBB_DATA8

BBB_DATA9

BBB_BOOT_DISABLE

BBB_XSYNC_SAT

DGND

C29

10uF

L3

600 R @ 100 MHz

R38

0R

epc660_TDO

epc660_TCK

R34

0R

R31

0R

epc660_TMS

R20

0R

R17

0R

R25

1k

Imax = 250mA

DGND

ILLB_epc660_LED

VDDA

DGND

R55

4k7

DGND

R21

10k

TMS

TCK

TDI

TDO

DATA11

DATA10

DATA9

DATA8

DATA7

DATA6

DATA5

DATA4

DATA3

DATA2

DATA1

DATA0_FS

XSYNC_SAT

MODCLK

DCLK

HSYNC

VSYNC

TESTAIO2

TESTAIO1

+24V

+24V

BBB_AIN4

BBB_AIN2

BBB_V_LED_ENABLE

ILLB_epc660_LEDFB

BBB_CALIB_LED_ENABLE

ILLB_epc660_LED

VSSLED

DGND

J1

59

57

55

53

51

49

47

45

43

41

39

37

35

33

31

29

27

25

23

21

19

17

15

13

11

9

7

5

3

1

BBB_BOOT_DISABLE

C3

100nF

R75

10k

5V Load Switch

TPS27081A

5 ON/OFF

VOUT 3

VOUT 2

ZH Connector top entry 10POL RM 1.5MM

10

9

8

7

6

5

4

3

2

1

J2

VIN

IC7

6 R1/C1

4

RDS_ON = max. 55mOhm

Pdiss = 4mW

60

58

VSS

TESTAI_VFSDG 56

VDDIO

54

VFSAB

52

TESTAOHB

50

TESTAOHA

48

R37

TESTAIHB

46

1k

TESTAIHA

44

VSEAL

BBB_epc660_SCL 42

BBB_epc660_SDA 40

38

36

VBS

34

VDDPXH

32

30

VSSIO

28

VDD

26

24

VDDIO

22

20

XTALOUT

18

XTALIN

BBB_epc660_SHUTTER 16

epc660_RESET 14

12

10

8

6

VSSA

4

2

VSSLED

DGND

BBB_VDD_3V3B

BBB_VDD_5V

BBB_SYS_5V

BBB_SYS_RESET

BBB_+3.3V_ENABLE

BBB_-5V_ENABLE

CB10

CB2_SMD

CB9

CB2_SMD

DGND

C32

10uF

VSSIO

C31

4.7uF

VSS

R11

0R

R3

10k

BBB_VDD_5V

+5V_VDDA_+10_VDDPXH_ENABLE

L1

600 R @ 100 MHz

Imax = 700mA ( 200mA needed for 3.3V)

R12

0R

Connector BeagleBoneBlack 2x23

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

J9

2

2

TESTAI_VFSDG

DGND

C30

10uF

L4

600 R @ 100 MHz

L6

600 R @ 100 MHz

BBB_SPI1_D0

BBB_SPI1_SCLK

BBB_AIN4

BBB_AIN6

BBB_AIN2

BBB_AIN0

BBB_CALIB_LED_ENABLE

BBB_VSYNC

C8

10uF

L5

600 R @ 100 MHz

Imax = 20mA

R84

1k

C6

10uF

4MHZ Clock

C9

18p

C7

18p

CB6

CB2_SMD

1

2

R85

1k

DGND

R10

10k

R4

10k

R2

10k

DGND

BBB_VDD_3V3B

BBB_VDD_5V

BBB_SYS_5V

BBB_PWR_BUT

BBB_+5V_+10V_ENABLE

BBB_epc660_ENABLE

BBB_epc660_SHUTTER

BBB_epc660_SCL

EEPROM_SCL

BBB_epc660_ENABLE

DGND

R79

0R

R78

0R

R63

0R

-10V_VBS

C35

4.7uF

R9

10k

L2

15uH 2.3A

+5V

D1

BAV99 70V/0.1A Imax possible = 1.5A

Imax needed = 950mA

D3

B340 40V 3A

Imax = 160mA

Imax = 30mA

C21

4.7uF

+10V_VDDPXH Imax = 20mA

Push Button to Reset the epc660

DGND

3

D5

B340 40V 3A

1

C33

1uF/50V

RDS_ON = max. 77mOhm

Pdiss = 3mW

C18

10nF

R2 1

IC8

TPS27081A

1

R6

22k

IC9

LMR14203

FB 3

6

SW

3.3V Load Switch

epc660_ENABLE

R42

10k

SHDN

VIN

VOUT 3

VOUT 2

5 ON/OFF

6 R1/C1

4 VIN

R39

0R

LDO 24V => 10V

C28

10nF

5

6

8

4

5

C14

470pF

DGND

C13

12pF

R5

22k

FB 7

SW 1

C2

100nF

24V => 5V Buck Converter

C11

2.2nF

5 SS/EN

2 Vin

IC1 IC SC4524A

Pdiss (90% eff) = 500mW

-10V Inverting Buck Regulator

C34

1uF/50V

C12

1uF/50V

Pdiss = 280mW

R87

10k

+3.3V_VDDIO_ENABLE

C19

10uF

R14

10k

T5

BC856B

R40

10k

T1

BC846B

R15

10k

DGND

BBB_VDD_3V3B

Debugging Connectors

DGND

VDD

VDDPXH

VBS

VDDA

VDDIO

R88

10k

IC4D

74HC08 TSSOP14

11 epc660_RESET

3

RESET of the epc660

DGND

R45

10k

12

GND

DGND

Vcc

BBB_SYS_RESET

R41

10k

BBB_SYS_RESET

IC4A

74HC08 TSSOP14

VOUT

Pdiss = 45mW

IC6

AP2120 1V8 SOT23

VIN

R86

10k

Imax = 220mA

6 +5V_VDDA_+10_VDDPXH_ENABLE

8

-5V_VBS_ENABLE

IC4B

74HC08 TSSOP14

DGND

LDO 3.3V => 1.8V

C22

1uF/50V

VDDIO

5

R33

10k

4

BBB_SYS_RESET

BBB_+5V_+10V_ENABLE

+24V

R16

10k

BBB_-5V_ENABLE 10

9

IC4C

IC 74HC08 TSSOP14

D4

B340 40V 3A

V_IN_24V_2

D2

B340 40V 3A

V_IN_24V_1

BBB_SYS_RESET

PowerJack 2.1mm

P1

2

1

J12

Pout = 4.75W

1

CB

J 2-POL 3.5mm WAGO

14

7

15 / 25

GND

GND

4

COMP

6

8

BST

GND

4

ROSC

3

GND

Characteristics subject to change without notice

2

© 2015 ESPROS Photonics Corporation

2

Pin (90% eff) = 5.25W

IC2C

THS4012

V- 4

V+ 8

DGND

C10

100nF

+24V

7. TOF Cape

7.1. Schematics

Figure 19: Schematic

Datasheet_DME_660-V1.01

7.2. PCB Assembly

Figure 20: PCB assembly top

Figure 21: PCB assembly bottom

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

16 / 25

Datasheet_DME_660-V1.01

7.3. Pin Table J8 & J9

DGND

1

2

BBB_VDD_3V3B

BBB_VDD_5V

BBB_SYS_5V

BBB_PWR_BUT

DGND

DGND

BBB_epc660_ENABLE

BBB_epc660_SHUTTER

BBB_epc660_SCL

2

DGND

BBB_VDD_3V3B

---

---

BBB_VDD_5V

---

---

BBB_SYS_5V

---

---

---

9 10 ---

BBB_+3.3V_ENABLE

---

---

BBB_-5V_ENABLE

---

epc660_RESETn

---

---

---

BBB_epc660_SDA

---

---

9 10 BBB_SYS_RESET

BBB_+5V_+10V_ENABLE

1

BBB_BOOT_DISABLE 19 20 BBB_HSYNC

EEPROM_SCL 19 20 EEPROM SDA

---

---

BBB_XSYNC_SAT

---

---

---

---

---

BBB_DCLK

---

---

BBB_VSYNC

---

BBB_DATA8

BBB_SPI1_CS0

BBB_SPI1_D0 29 30 BBB_SPI1_D1

BBB_SPI1_SCLK

BBB_DATA10

BBB_DATA9 29 30 BBB_DATA11

---

---

---

---

---

BBB_AIN4

BBB_GNDA

BBB_AIN6

BBB_AIN5

epc660_TCK

epc660_TMS

BBB_AIN2

BBB_AIN3

epc660_TDO

epc660_TDI

BBB_DATA6 39 40 BBB_DATA7

BBB_AIN0 39 40 BBB_AIN1

BBB_CALIB_LED_EN

BBB_V_LED_ENABLE

BBB_DATA4

BBB_DATA5

DGND

DGND

BBB_DATA2

BBB_DATA3

DGND

DGND

BBB_DATA0_FS

BBB_DATA1

Figure 22: Pin table J8 & J9

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

17 / 25

Datasheet_DME_660-V1.01

DGND

T8

BC846B

BBB_AIN4

R39

10k

C20

100uF

D12

LED ROT

I avg = 1mA

V_LED

V_LED = 15V

0R

R36

1

R28

27k

C19

220pF

C6

2.2nF

10uH

SGND

R29

27k

R26

330k

2

L1

Temperature Sensor Lower Side

D15

BAV99

R24

1k

I avg = 6mA

VDD_7V

C9

100nF

R37

220k

C8

4.7uF

C18

4.7uF

T5

BSD316SN

RDSon = 0.28OHM

P avg = 70mW

L5

100n

R23

3R3

C4

2.2nF

R9

3R9

R8

3R9

G

R4

3R9

G

T10

PMV45EN

T9

PMV45EN

G

C22

1nF

V_IN

C17

100nF

IC1F

74ACT04

Designed for:

I_Emitter_max = 2A

Frame Time = 40ms (25 fps)

Integ Time_max = 5ms

Duty Cycle = (4*5ms) / (2*40ms) = 0.25

VSSLED

13

12

1

11

HG

VCC

IC2

13

LG

12

BST

C21

470nF 10

SW

8

ILIM

R30 1k8

C16

2.2uF

FB

SS

EN

RON

VIN

LM3150

4

C23

33nF

330k

15k

3

6

R25

R27

7

2

Buck Regulator 24V => 15V 5A

DGND

Pdiss (90% eff) = 1.5W

Pout = 15W

Pin (90% eff) = 16.5W

ILLB_epc660_LEDFB

74ACT04

IC1B

C15

10nF

ILLB_epc660_LEDFB

R1

10k

V_LED_ENABLE

C26

10uF

D11

B340 40V 3A

D10

B340 40V 3A

8

C25

10nF

5

6

EN

NR/SS

IN

2

1

DGND

TPS7A4901

FB

OUT

Pdiss = 1W

IC5

R43

10k

R41

100k

1k

R20

C7

100nF

T1

BC856B

R21

1k

R18

4k7

R19

C24

10uF

1k

74ACT04

IC1E

D13

LED ROT

C27

10uF

DGND

Protect cirquit for the Illumination

T3

BC846B

1k

R17

R16

10k

BBB_V_LED_ENABLE

100k

I avg = 62mA

VDD_7V

Linear Regulator 24V => 7V

DGND

+24V

11

9

74ACT04

IC1D

R40

4k7

10

8

R22

10k

R6

3R9

L6

100n

R31

3R3

R7

3R9

R3

3R9

V = 2V @ 2A

P avg = 250mW

C5

2.2nF

T4

BSD316SN

RDSon = 0.28OHM

P avg = 70mW

D8

SFH4715s

D7

SFH4715s

D6

SFH4715s

D5

SFH4715s

R15

5R6

C3

4.7uF

C1

100nF

C11

10uF

10

9

8

7

6

5

4

3

2

1

+24V

+24V

BBB_AIN4

BBB_AIN2

BBB_V_LED_ENABLE

ILLB_epc660_LEDFB

BBB_CALIB_LED_ENABLE

ILLB_epc660_LED

VSSLED

DGND

Connector to the TOF_Cape

J ZH Connector top entry 10POL RM 1.5MM

10

9

8

7

6

5

4

3

2

1

J2

R11

10k

B

T11

BC817-40

D9

SFH4544

C13

2.2nF

C2

100nF

DGND

L2

600 R @ 100 MHz

V_IN

T2

BC846B DGND

R2

1k

D14

BAV99

I avg = 6mA

VDD_7V

Temperature Sensor Upper Side

BBB_AIN2

I avg = 500mA (@ 25Fps)

Ipeak = 2A

L4

600 R @ 100 MHz

V_LED

Additional Emitter for Calibration

BBB_CALIB_LED_ENABLE

4 Emitters Upper Side

R5

3R9

G

D17

B340 40V 3A

10R

3

5

DGND

0R

R38

C12

100nF

GND

IC1A

74ACT04

Vcc

2

VF @ 2A = 3.2V

P avg = 1.6W

R13

4

6

R12

47R

1

D17, R31, L6 and C5 are not

assembled. These parts

are placeholders to tune the

rise and fall time of the LED

according to the application

note paper from OSRAM.

R14

74ACT04

IC1C

D16

B340 40V 3A

Ipeak = 100mA

I avg = 25mA (@ 25Fps)

ILLB_epc660_LED

D16, R23, L5 and C4 are not

assembled. These parts

are placeholders to tune the

rise and fall time of the LED

according to the application

note paper from OSRAM.

VDD_7V

10R

D4

SFH4715s

D3

SFH4715s

D2

SFH4715s

D1

SFH4715s

4 Emitters Lower Side

R10

3R9

C14 V = 2V @ 2A

2.2nF P avg = 250mW

C10

100nF

VF @ 2A = 3.2V

P avg = 1.6W

D

S

14

7

I avg = 500mA (@ 25Fps)

Ipeak = 2A

D

S

L3

600 R @ 100 MHz

D

S

D

S

C

V_LED

14

PGND

9

SGND

5

SGND

EP

SGND

18 / 25

GND

Characteristics subject to change without notice

4

© 2015 ESPROS Photonics Corporation

E

I avg = 1A (@ 25Fps)

8. LED Cape

8.1. Schematics

Figure 23: Schematics

Datasheet_DME_660-V1.01

8.2. PCB Assembly

Figure 24: PCB assembly top

D1..D8:

Illumination LEDs

D12, D13:

Monitoring LEDs (red), refer to chapter 4.2.2, Monitoring LEDs

Figure 25: PCB assembly bottom

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

19 / 25

Datasheet_DME_660-V1.01

9. BeagleBone Black Board

9.1. System Overview

■ Processor: AM335x 1GHz ARM® Cortex-A8

■ 512MB DDR3 RAM, 4GB 8-bit eMMC on-board flash storage

■ 3D graphics accelerator, NEON floating-point accelerator,

2x PRU 32-bit micro controllers

■ USB client for power & communications, USB host, Ethernet

■ Software Compatibility: Debian, Android, Ubuntu, much more

■ Open-source tools:

Point Cloud Library (PCL); www.pointcloud.org

OpenCV; www.opencv.org

Figure 26: The BeagleBone Black board

9.2. Documentation

Technical description of the BeagleBone Black board can be downloaded from www.beagleboard.org.

■ BeagleBone Hardware Specs and Material, BeagleBone Black wiki

■ BeagleBone Black System Reference Manual, BeagleBoard.org, 2014

■ BeagleBone Black, Document No. 450-5500-001 (Schematics), BeagleBoard.org, 2014

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

20 / 25

Datasheet_DME_660-V1.01

10. Installation and Setup

10.1. Mechanical fixation

The DME 660 has various mounting options provided by the metal frame:

■ On each long side

□ one tripod mount 1/4” - 20UNC, refer to Figure 3

□ four nut M4

■ On top side: three nut M4

Use the options only to attach the DME 660 to a housing, a tripod or something else. Never use the threaded pillars or attache something

directly to one of the PCB. You may damage the PCB.

10.2. Setup of the DME 660

The DME 660 can be operated by using the GUI software provided with the epc660 Evaluation kit. The setup described by the QUICK

START GUIDE.

10.3. Software Tools

ESPROS Photonics supports the user's development and application by having available various support tools e.g. software development

kit (SDK), updates and emulation program downloads for the epc660 chip, application interfaces (API), etc. They are available by

contacting ESPROS by email at info@espros.com. The same way, the user can update the DME 660 (BeagleBone board) by using this

service.

10.4. Exchange of epc660 on Card Edge Connector Carrier

Make sure, all assembly procedures are executed on an ESD-compatible workstation.

■ Power off the DME 660 and remove cables

■ Remove the BeagleBone board

■ Remove the TOF cape

■ Remove the locking screws from the epc660 Card Edge Connector Carrier

Softly remove the epc660 Card Edge Connector Carrier. The epc660 chip can be destroyed when excessive force is applied.

■

■ Remove lens holder

■ Attach the lens holder to the new epc660 Card Edge Connector Carrier

■

Softly insert the new epc660 Card Edge Connector Carrier

■ Insert the locking screws for the epc660 Card Edge Connector Carrier

■ Install the TOF cape

■ Install the BeagleBone board

■

First power on the DME 660

■ Connect the USB cable

■ Start the epc660 Evaluation Kit GUI and run a black & white video (start)

■ Adjust lens focus

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

21 / 25

Datasheet_DME_660-V1.01

11. epc660 Evaluation Kit

There is an evaluation kit available which supports the development of own applications on the DME 660 in terms of the evaluation of the

optical performance parameters.

11.1. Scope of Delivery

➀ Toolbox

➈ Quick Guide

➄ USB cable

➆ Camera Tripod

➃ Power Cord

➂ Power Supply

➇ Toolbox belt

➁ DME 660

➅ Industrial connector

Figure 27: epc660 Evaluation Kit overview

No

Pieces

Designation

Remarks

➀

1

Toolbox

➁

1

DME 660-94º/10m

➂

1

Power Supply 24V/2.5A

➃

1

EU version: Power cord 2 pole EU version

US version: Power cord 2 pole US version

Power plug EU Europlug (CEE7/16, 2 pole)

Power plug US Type A (NEMA 1-15, 2 pole)

➄

1

Cable - USB 2.0, A plug - mini-B plug

Length 2m

➅

1

Plastic bag with Industrial Supply Connector and the

toolbox key

The connector can also be inserted in the DME

660

➆

1

Camera Tripod

➇

1

Toolbox belt

➈

1

epc660 Evalkit Quick Start Guide

also available at www.espros.com/Downloads

Datasheet DME 660

available at www.espros.com/Downloads

Datasheet epc660

available at www.espros.com/Downloads

Application and configuration software, SDK

Use the epc660 Evaluation Kit for accessing licensed corresponding tools and software development kit (SDK).

P/N P100 278; with quick release fastener of

the tripod

Table 10: Bill of material of the delivery

11.2. Ordering Information

Part Number

Part Name

Remarks

P100 280

epc660 Evaluation Kit EU

Power plug EU Europlug (CEE7/16, 2 pole)

P100 307

epc660 Evaluation Kit US

Power plug US Type A (NEMA 1-15, 2 pole)

Table 11: Ordering Information epc660 Evaluation Kit

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

22 / 25

Datasheet_DME_660-V1.01

Figure 28: DME 660 on tripod

Figure 29: epc660 Evaluation Kit

Figure 30: DME 660 tripod mounting

Figure 31: DME 660 with quick release fastener of the tripod

Figure 32: GUI - b&w picture

Figure 33: GUI - 3D TOF picture

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

23 / 25

Datasheet_DME_660-V1.01

12. Maintenance and disposal

12.1. Maintenance

The components of the device do not need regular maintenance. A functional check is recommended each time the device is taken into

operation:

■ Check the mounting position and the detection area of the sensor with respect to the operational conditions. Also check that there is no

hazardous situation.

■ From time to time, clean the lens with a soft towel and with a little soapy water to remove dust or dirt.

12.2. Disposal

Disposal should be done using the most up-to-date recycling technologies for electronic components according to the local regulations and

laws. The design and manufacture of the kit's components are done in compliance with the RoHS legal regulations. Traces of dangerous

materials may be found in the electronic components, but not in harmful quantities.

13. Addendum

13.1. Related documents

■ Datasheet epc660, ESPROS Photonics Corp.

■ BeagleBone Hardware Specs and Material, BeagleBone Black wiki

■ BeagleBone Black System Reference Manual, BeagleBoard.org

■ BeagleBone Black, Document No. 450-5500-001 (Schematics), BeagleBoard.org

13.2. Links

www.espros.com

www.beagleboard.org

www.pointcloud.org - Point Cloud Library (PCL)

www.pdal.io - Point Data Abstraction Library (PDAL)

www.opencv.org - OpenCV (OpenSource Computer Vision)

13.3. Licenses

We appreciate the use of the following open source or free software in our tools and respect the large amount of work the owners have

done:

■ Putty: http://www.chiark.greenend.org.uk/~sgtatham/putty/licence.html

Copyright (C) 1997-2015 Simon Tatham

■ Qt-4.8: http://www.gnu.org/licenses/old-licenses/lgpl-2.1.html

Copyright (C) 2012 Nokia Corporation

■ Qwt-6.1: http://qwt.sourceforge.net/qwtlicense.html

Copyright (C) 1997 Josef Wilgen & Copyright (C) 2002 Uwe Rathmann under Qwt License, Version 1.0

■ QwtPlot3D: http://qwtplot3d.sourceforge.net/web/navigation/license.txt

Copyright (C) 2003-2005 Michael Bieber

All rights reserved by the owners.

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS "AS IS" AND ANY EXPRESS OR IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT HOLDER OR CONTRIBUTORS BE LIABLE FOR

ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED

TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUP TION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

(INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF

THE POSSIBILITY OF SUCH DAMAGE.

© 2015 ESPROS Photonics Corporation

Characteristics subject to change without notice

24 / 25

Datasheet_DME_660-V1.01

IMPORTANT NOTICE

ESPROS Photonics AG and its subsidiaries (epc) reserve the right to make corrections, modifications, enhancements, improvements, and

other changes to its products and services at any time and to discontinue any product or service without notice. Customers should obtain

the latest relevant information before placing orders and should verify that such information is current and complete. All products are sold

subject to epc’s terms and conditions of sale supplied at the time of order acknowledgment.

epc warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with epc’s standard

warranty. Testing and other quality control techniques are used to the extent epc deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

epc assumes no liability for applications assistance or customer product design. Customers are responsible for their products and applica tions using epc components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

epc does not warrant or represent that any license, either express or implied, is granted under any epc patent right, copyright, mask work

right, or other epc intellectual property right relating to any combination, machine, or process in which epc products or services are used.

Information published by epc regarding third-party products or services does not constitute a license from epc to use such products or

services or a warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other

intellectual property of the third party, or a license from epc under the patents or other intellectual property of epc.

Resale of epc products or services with statements different from or beyond the parameters stated by epc for that product or service voids

all express and any implied warranties for the associated epc product or service. epc is not responsible or liable for any such statements.

epc products are not authorized for use in safety-critical applications (such as life support) where a failure of the epc product would reasonably be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically

governing such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications,

and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any use of epc products in such safety-critical applications, notwithstanding any applications-related information or support that

may be provided by epc. Further, Buyers must fully indemnify epc and its representatives against any damages arising out of the use of

epc products in such safety-critical applications.

epc products are neither designed nor intended for use in military/aerospace applications or environments unless the epc products are

specifically designated by epc as military-grade. Only products designated by epc as military-grade meet military specifications. Buyers

acknowledge and agree that any such use of epc products which epc has not designated as military-grade is solely at the Buyer's risk, and

that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

epc products are neither designed nor intended for use in automotive applications or environments unless the specific epc products are

designated by epc as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, epc will not be responsible for any failure to meet such requirements.

© 2015 ESPROS Photonics Corporation

25 / 25

Datasheet_DME_660-V1.01

Characteristics subject to change without notice

32/<7(&*PE+ 3RO\WHF3ODW] ':DOGEURQQ *(50$1<

7HO)D[ (0DLORHN#SRO\WHFGH ZZZSRO\WHFGH