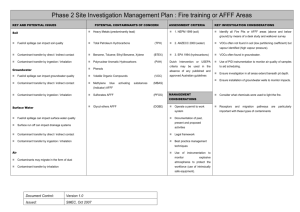

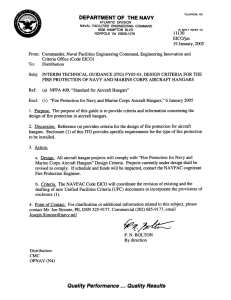

environmental issues associated with defence use of aqueous film

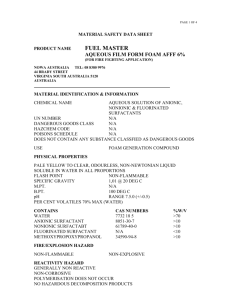

advertisement