Embedded atom potential for Fe–Cu interactions and

advertisement

Modelling Simul. Mater. Sci. Eng. 6 (1998) 19–28. Printed in the UK

PII: S0965-0393(98)88313-7

Embedded atom potential for Fe–Cu interactions and

simulations of precipitate–matrix interfaces

Matthias Ludwig†, Diana Farkas‡, Dora Pedraza§ and Siegfried Schmauder†

† Staatliche Materialprüfungsanstalt (MPA), University of Stuttgart, Pfaffenwaldring 32,

D-70569 Stuttgart, Germany

‡ Department of Materials Science and Engineering, Virginia Polytechnic Institute and

State University, Blacksburg, VA 24061, USA

§ Center for Materials Simulation, Institute of Materials Science, University of Connecticut,

Storrs, CT 06269-3136, USA

Received 17 June 1997, accepted for publication 29 September 1997

Abstract. A new empirical interatomic potential of the embedded atom type is developed for

the Fe–Cu system. The potential for the alloy system was constructed to reproduce known

physical parameters of the alloy, such as the heat of solution of Cu in Fe and the binding energy

of a vacancy and a Cu atom in the α-Fe matrix. The potential also reproduces first-principle

calculations of the properties of metastable phases in the system. This atomic interaction model

was used in simulation studies of the interface of small coherent Cu precipitates in α-Fe and

of dislocation core structure. The phase stability of the body-centred cubic Cu precipitates was

also analysed.

1. Introduction

Atomistic studies of the structures of dislocation cores, grain boundaries, point defects, and

cracks in Cu-containing ferritic steels are of great relevance to the understanding of the

irradiation embrittlement of pressure vessels and the alloying behaviour in these materials.

A large increase in hardness results both from thermal ageing and from irradiation of

steels with very low Cu content, and experimental evidence strongly relates this property

change to the occurrence of initially small body-centred cubic (bcc) Cu precipitates (∼1 to

2 nm in diameter). Upon further ageing, the precipitates grow with a spherical shape to a

mean diameter of about 6 nm, when they become unstable and transform apparently in a

martensitic mode to a complex presumably 9R [1] structure. Additional growth leads to the

stable face-centred cubic (fcc) phase. Although the mechanisms of precipitation are not well

understood, it is likely that vacancies—produced profusely by irradiation—are substantially

involved [2].

Atomistic simulations require the development of interatomic potentials for the alloy

system. Osetsky and Serra developed a pair potential for the Fe–Cu interactions [2] in terms

of the generalized pseudopotential theory, but pair potentials are not suitable to correctly

calculate surface energies or fracture properties. Ackland and co-workers recently developed

a potential that includes many-body terms and they have calculated point defect properties

for dilute solutions of Cu in Fe [3]. The recent work of Osetsky and Serra [2] using pair

potentials and molecular dynamics underlines the great importance of the precipitate–matrix

interface in the phase stability of small Cu precipitates in Fe.

c 1998 IOP Publishing Ltd

0965-0393/98/010019+10$19.50 19

20

M Ludwig et al

The objective of the present work is to develop a new interatomic potential that will

allow one to perform atomistic simulations of coherent Cu-precipitates in α-iron using

the embedded atom method (EAM) technique, and to gain insight into the nature and the

energies of the precipitate–matrix interface.

A detailed description of the embedded-atom method can be found in [4]. The total

energy Etot of a system of atoms is expressed as

X

X

1 X

V ij (rij ) +

F i (ρ̄i )

ρ̄i =

ρ j (rij )

(1)

Etot =

2 i,j (i6=j )

i

j (6=i)

where the superscripts i and j indicate atom types, and the subscripts indicate the atoms

themselves. The F i are the embedding functions, ρ̄i is the total host electron density of

atom i which consists of contributions ρ j (rij ) from atoms j that are at the interatomic

distances rij from atom i, and V ij are the pair potentials between atoms i and j .

Minimization of the total energy Etot using for example a conjugate gradient scheme

for a given initial atomic configuration, which may be one or several Cu atoms or even a

Cu precipitate in α-iron, leads to a relaxed stable configuration of the atom ensemble.

In the derivation of the potentials we have used a scheme similar to that used in previous

work on other alloy systems [5].

2. Interatomic potentials for the pure components

For α-Fe we used the interatomic pair potential given by Simonelli et al [6] and for Cu

we used the interatomic potential given by Voter [7]. Both potentials fit Roses’ equation

of state [8] and other element properties including lattice constant, cohesive energy, elastic

constants and vacancy formation energy. In the present computation, the first derivative of

the embedding function (F 0Fe or F 0Cu ) was set equal to zero for the electron density of the

perfect lattice (ρ̄0 ). In such a case, the potentials are said to be in their effective scheme

[9]. The interatomic potentials for the pure metals were not originally in the effective pair

scheme. Thus, we first transformed them into this scheme. The transformation used to

convert to the effective pair scheme is as follows [5]

Feff (ρ) = F (ρ) − ρF 0 (ρ̄0 )

Veff (r) = V (r) + 2ρ(r)F 0 (ρ̄0 )

where F is the embedding function (F Fe and F Cu , respectively), V the pair potential function

(V FeFe and V CuCu , respectively), ρ the electron density function, ρ̄0 the electron density in

the perfect lattice (bcc and fcc structure, respectively) of the pure crystal and r is the

interatomic distance. The values for the electron density of the perfect lattice of bcc Fe and

fcc Cu were normalized to the same value of 0.34.

2.1. Properties of bcc Cu

The Voter Cu potential has been developed based on the fcc phase and in this section we

summarize the behaviour of the bcc phase that it predicts. The lattice parameter of the bcc

Cu phase is calculated as 0.2880 nm. This parameter is the same as calculated by Osetsky

and Serra [10] (0.2885 nm), and in excellent agreement with first-principle calculations [11]

that give a parameter of 0.2873 nm, but it is significantly lower than that value of 0.296 nm

predicted by the potential used by Ackland et al [12]. These values can be compared with

the lattice parameter of bcc Fe, 0.2867 nm. As a result, in our simulations the Cu precipitates

are subject to much lower stresses than predicted by Ackland et al [3]. The strain of the

Embedded atom potential for Fe–Cu interactions

21

precipitates in the present work is 0.45%, whereas with the potentials of Ackland et al it is

3.2%. In our calculations, the energy of the strained lattice is 1 meV/atom higher than that

of equilibrium.

The difference in energy between the fcc and bcc phases given by the present potential

is 46 meV/atom.

3. Results for the Fe–Cu interaction

The data used in the development of the potentials are as follows.

b

= 0.14 eV. This

(1) The vacancy–Cu atom binding energy in the α-Fe matrix, EV−Cu

energy was obtained using muon spin rotation experiments on dilute Fe alloys [12].

(2) The energy of solution of one Cu atom in the α-Fe matrix ECu = 1.23 eV.

This energy was obtained using the partial molar energy for liquid alloys as 1823 K,

1ECu = 0.49 eV/atom, as given in [13]. The energy of one Cu atom in the α-Fe matrix

ECu can be calculated with the partial molar energy 1ECu as

ECu = EFe (bcc) − ECu (fcc) + 1ECu .

(2)

The cohesive energies EFe (bcc) and ECu (fcc) are 4.28 eV [6] and 3.54 eV [7], respectively.

(3) The kinetic binding energy between two Cu atoms in the α-Fe matrix defined by

Osetsky and Serra [2] as

b

b

− EV−Cu

Ekb (2) = E2Cu

(3)

b

E2Cu

is

should not exceed 0.05 eV to allow small Cu clusters in Fe to dissociate thermally.

b

has been defined earlier. This condition is

the binding energy of two Cu atoms and EV−Cu

consistent with a mechanism of precipitate growth and dissolution mediated by vacancies.

The mixed-pair interaction potential was obtained by empirically fitting these

experimental data to the calculated values obtained by a combination of the effective-pair

interactions of Fe and Cu. The general form for the combination used is as follows:

FeCu

Fe

Cu

(a + bx) = A[Veff

(c + dx) + Veff

(e + f x)]

Veff

(4)

where x takes values from zero to unity. The parameters a, b, c, d, e, f and A were

FeCu

must be

adjusted to give good overall fit to the properties considered. The potential Veff

calculated in an interatomic distance interval a, a + bx that must include the interval used

in the numerical simulations, and this is the only limitation to the values of a and b. As

Fe

Cu

and Veff

used in equation (3), this procedure entails keeping only the functional form of Veff

similar to the interaction potential that applies between atoms of the same species. Thus,

changing c and d (and e and f ) from the values that apply to the pair interaction only

implies a homogeneous expansion (or contraction) in the interatomic distances. Here, the

values of c, d, e and f were chosen to yield no change in the intervals c, c + d and e, e + d

used for the pair potentials. The other three parameters of equation (4) were systematically

varied and their effects on the properties of interest were studied to determine the most

suitable set of values to fit the entire system properties mentioned above. Varying A affects

mainly the cohesive energy of the lattice, while a and b have a stronger effect upon the

lattice parameter of mixed ordered phases.

Best fit values obtained for the parameters are given in table 1. With these parameters

we obtained the fitting result given in table 2. The calculated values match well with the

experimental data.

As a check for the mixed pair potential, the cohesive energies and lattice parameters

of two L12 structures in the system were calculated and compared with available LMTO

calculations [3]. These results are given in table 3, showing excellent agreement.

22

M Ludwig et al

Table 1. Parameters obtained for the mixed interaction potential. Distances are in 10−1 nm.

a

b

c

d

e

f

A

1.000

4.700

0.992

4.095

1.000

4.961

0.5

Table 2. Comparison of adjusted properties with experimental results. Energies are in eV.

Experimental value

Calculated, present work

Calculated, Ackland et al [3]

a

b

EV−Cu

ECu

Ekb (2)

b

E2Cu

0.14

0.18

0.09

1.23

1.23

0.05a

0.01

0.01

0.20

0.19

0.1

Assumed value (see [2]).

Table 3. Results for L12 structures.

Fe3 Cu,

Fe3 Cu,

Cu3 Fe,

Cu3 Fe,

LMTO

EAM

LMTO

EAM

Lattice

parameter (nm)

Cohesive

energy (eV)

Formation

energy (eV)

0.3546

0.3729

0.3555

0.371 44

3.9917

3.9125

3.6168

3.541 75

0.125

0.183

0.102

0.178

4. Calculation of interface energies

We used the potentials described above to calculate bcc Cu/α-Fe matrix interface energies.

In all the cases, the energy used for the Cu atoms in the lattice referred to as perfect

corresponded to the energy of the strained bcc Cu lattice. In this way, the interface

energy obtained does not include the effects of the strain on the precipitate. First, we

considered a spherical precipitate, 4 nm in diameter, in a simulation involving the relaxation

of 16 000 atoms (the block comprised an outer shell of 24 000 fixed atoms). The interface

energy in this morphology was obtained by calculating the difference in energy of the block

containing the precipitate and a block of the same number of atoms in a perfect lattice

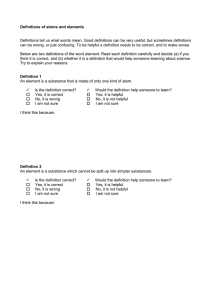

condition. The energy obtained for the spherical case is 207 mJ m−2 . Figure 1 shows a cut

of this precipitate through the maximum circle of the sphere in the (100) plane.

We also calculated the surface energy corresponding to a cylindrical interface with its

axis along the [001] direction. In this instance, the ‘infinite’ cylindrical precipitate had a

diameter of 4 nm. This surface energy was higher, at 245 mJ m−2 . As seen in figure 1, this

interface is composed mostly of small patches of {100} and {110} interfaces. We, therefore,

calculated the values for these two interfaces and found 318 mJ m−2 and 121 mJ m−2 ,

respectively. For these calculations, prismatic precipitates having a square cross section

with a 4 nm side were considered. All these values are listed in table 4.

These results suggest that the preferred interface plane is the most compact plane in the

bcc structure. They also show that the interface in the cube plane has a significantly higher

energy.

Embedded atom potential for Fe–Cu interactions

23

Figure 1. Cross section of a spherical bcc-Cu/α-Fe interface showing patches of {110} and {100}

interface. Relaxed atomic positions display insignificant deviations from perfect bcc structure.

Table 4. Results for interface energies.

Morphology

Energy (mJ m−2 )

Spherical precipitate

Cylindrical precipitate along [001]

{100} type planes

{110} type planes

207

245

318

121

5. Dislocation cores in Fe–Cu alloys

We studied the dislocation cores in Fe–Cu alloys in two cases. The first case was a 1/2h111i

screw dislocation in an Fe matrix containing a random distribution of Cu atoms. In pure

Fe, this dislocation is known to have a non-planar structure with a core spreading in three

different {110} planes [14], according to a core structure simulation study that used the

same Fe potential as we use in the present work. In order to study the possible effects of

the Cu atoms on the core structure of the dislocation, a relatively large concentration of

Cu atoms was included (16%). Figure 2 shows the dislocation core using the differential

displacement map technique where the length of the arrows indicates the extent of the

24

M Ludwig et al

deviation of the interatomic distances from the perfect lattice positions. Similar studies

were conducted previously for the effect of substitutional Cr atoms on the same dislocation

[15]. The results show that the effects of Cu and Cr are similar. The dislocation core

maintains the basic three-plane structure but there are deviations that can be observed at a

few interatomic distances from the dislocation centre. The core appears to have a strong

attractive interaction with the Cu atoms. This preference suggests that Cu atoms would tend

to segregate to the dislocation core.

Figure 2. Projection on plane {111} of a (111) screw dislocation core structure in an alloy

containing a random distribution of Cu substitutional atoms. Differential displacement map

with arrows showing extent of atomic displacements. Circles represent iron atoms and triangles

represent Cu atoms.

The second simulation involved a dislocation running through a spherical precipitate

4 nm in diameter. The calculation block included 16 000 free atoms. In this case, the

dislocation is of mixed type, with a Burgers vector 1/2h111i and the dislocation line

along a cube direction. The results of the simulation are shown in figure 3. Since this

dislocation has a large edge component, it is shown in a direct plot of atomic coordinates.

The figure shows the projection of the atomic coordinates of all atoms of the block on a plane

perpendicular to the dislocation line. The simulation was performed using periodic boundary

conditions along the dislocation line, with a periodicity of about 30 lattice parameters so

that the dislocation was free to bow out of the precipitate if this resulted in a lower energy

configuration. However, as can be seen in figure 3, no bowing occurred and the dislocation

inside the precipitate does not display a structure significantly different from the structure

seen in the Fe matrix outside the precipitate.

Embedded atom potential for Fe–Cu interactions

25

Figure 3. A mixed-type dislocation running across a bcc Cu precipitate and α-Fe matrix.

Dislocation line normal to view on the {001} plane.

6. Instability of the bcc precipitates

Initiation of the transformation to an fcc structure (or to another more complex phase) is

expected to occur as the size of the precipitate increases. Although the 4 nm diameter

spherical precipitate simulated above developed compressive strains, the Cu atoms did not

exhibit any deviations from perfect bcc lattice positions. We then changed the size of the

precipitate in order to study its stability against a phase transformation. As seen in figure 1,

in the projection of relaxed atomic coordinates on a cube plane for a spherical precipitate

4 nm in diameter, the atomic coordinates for the precipitate show that the relaxed atomic

positions do not deviate significantly from the perfect bcc lattice positions. This result is

another proof that the bcc structure in the Cu precipitate is fully stabilized by the presence

of the interface. A simulation performed with a similar precipitate containing a vacancy

concentration of 3% did not show any change either. For a precipitate that is 6 nm in

diameter substantial distortions from the bcc structure start appearing in the centre of the

precipitate. These deviations are particularly important in one out of every six compact

planes. This suggests that the incipient transformation might be accompanied by a shear

and produces a daughter phase bearing a definite orientation relationship with the parent bcc

phase. The precipitate size at which this instability is observed agrees very well with the

precipitate size where transformation of the bcc Cu phase is observed experimentally [1].

in this simulation, no vacancies were incorporated, therefore implying that the transition is

26

M Ludwig et al

not vacancy-assisted but is a result of phase instability alone. Further changes occur for a

7.5 nm precipitate, as illustrated in figure 4, where a slab of the sphere can be viewed in

the (001) plane.

Figure 4. Projection on plane {001} of the relaxed positions of a 7.5 nm diameter spherical

precipitate.

7. Summary and discussion

A many-body potential for the Fe–Cu system was developed in this paper in the framework

of the embedded atom approach using a very simple model. The potential was based upon

the same-atom interaction potentials developed by Voter [7] for pure Cu and by Simonelli

et al [6] for α-Fe. The procedure that was followed for the mixed-pair interaction potential

used three properties of Cu in Fe, viz, the vacancy-solute binding energy, the heat of solution

into liquid Fe and the binding energy of a Cu dimer in the ferritic matrix. Although the latter

does not come from experimental measurement, it is a very reasonable assumption based

on a very likely vacancy mediated precipitate nucleation and growth mechanism, strongly

suggested by the two known precipitation conditions, i.e. irradiation with energetic particles

and thermal ageing.

The small Cu precipitates have been well characterized as having a bcc structure. Our

calculation of the lattice parameter and energy of this lattice using Voter’s potential yielded

Embedded atom potential for Fe–Cu interactions

27

0.288 nm for the former, the same value obtained by Osetsky and Serra [2] using a pair

potential approach. Results of LMTO calculations conducted by Ackland et al [3] allowed

for a comparison with two hypothetical intermetallic phases in the L12 structure, Fe3 Cu and

Cu3 Fe, with excellent agreement, rendering additional reliability to the potential developed

here. The cohesive energy of bcc Cu yielded 3.494 eV, very close to the value of 3.496 eV

obtained by Ackland et al. The cohesive energy favours the fcc over the bcc phase by

46 meV, this difference being larger than Osetsky and Serra’s reported value of 37 meV by

24% [2]. The results obtained here are thus seen to be in fair agreement with those obtained

by other authors. The small lattice misfit with α-Fe requires a relatively low strain energy

to immerse the spherical precipitate with a coherent interface into the α-Fe matrix.

Simulations of some low-index coherent interfaces between the bcc Fe matrix and the

bcc Cu phase performed here yielded the fact that the more compact planes are favoured.

The magnitude of the interface energy for the spherical precipitate is of the same order

as that of a coherent fcc/bcc interface in pure Fe as calculated for the (12̄1)f k(31̄2)b

coherent interface, 178 mJ m−2 . Comparison with experimental observations, however,

is not straight-forward since the spherical precipitates have been observed in ferritic steels

where the presence of other alloying elements may stabilize a spherical interface rather than

a faceted one [1].

Our calculation of the relaxation of an edge dislocation in a Cu-containing Fe matrix

showed a tendency of the Cu atoms to segregate to the core, as could be expected from

the strong repulsive interaction between Cu and Fe. A similar calculation for a mixed

dislocation running through the precipitate yielded no difference in the dislocation core

structure between the two regions, thus indicating that such a dislocation has the same

features as in pure α-Fe.

Our studies of phase stability showed onset of a phase transformation in the precipitate

at the size of 6 nm. It is worth underlining that no vacancy presence was required for

such instability. Our results are at variance with those of Osetsky and Serra who performed

molecular dynamics simulations of the phase instability of spherical bcc Cu precipitate.

In their studies a 6% vacancy concentration was required to induce structural changes,

adding a diffusional contribution to the transformation mechanism [10]. In our calculations,

such a contribution does not appear as necessary at the above-mentioned size. Adding

vacancies at a 3% level in a smaller precipitate did not prompt any transformation in our

static calculations. The relaxation of a 7.5 nm precipitate shows additional displacements

as compared to the 6 nm precipitate, clearly revealing the size effect upon the instability of

the bcc phase.

In summary, the results obtained in this work indicate that the potential developed here

is reliable to conduct further simulations on both point defect and extended defect behaviour

in the Fe–Cu system.

Acknowledgments

This work was supported by the German Bundesministerium für Bildung, Wissenschaft,

Forschung und Technologie (BMBF) under grant No 150102, and by the US National

Science Foundation, FAW program.

References

[1] Othens P J, Jenkins M L and Smith G D W 1994 Phil. Mag. A 70 1

[2] Osetsky Y N and Serra A 1996 Phil. Mag. A 73 249

28

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

M Ludwig et al

Ackland G J, Bacon D J, Calder A F and Harry T 1997 Phil. Mag. 75 713

Daw M S and Baskes M I 1984 Phys. Rev. B 29 6443

Farkas D 1994 Modelling Simulation Mater. Sci. Eng. 2 975

Simonelli G, Pasionot R and Savino E J 1993 Mater Res. Soc. Proc. 291 567

Voter A F 1993 Los Alamos Unclassified Technical Report 93-3901 Los Alamos National Laboratory

Rose J H, Smith J R, Guinea F and Ferrante J 1984 Phys. Rev. B 29 2963

Johnson R A 1990 Implication of the EAM format Many atom interaction in solids (Springer Proceedings in

Physics 48) (Berlin: Springer) p 85

Osetsky Y N and Serra A 1997 Phil. Mag. 75 1097

Kraft T, Marcus P M, Methfessel M and Scheffler M T 1993 Phys. Rev. B 48 5886

Brauer G and Popp K 1987 Phys. Status Solidi a 102 79

Hultgren R, Desai P D, Hawkins D T, Gleiser M and Kelley K K 1973 Selected Values of the Thermodynamic

Properties of Binary Alloys (Metals Park, OH: ASM)

Farkas D and Rodriguez P L 1994 Scripta Met. 30 921

Farkas D, Schon C G, deLima M S F and Goldenstein H 1996 Acta Met. 44 409

Chen J K, Farkas D and Reynolds W T Jr 1994 Solid–State Phase Transformations ed W C Johnson et al

(Warrendale, PA: The Minerals, Metals and Materials Society) p 1097