Rinsing with Less Water

advertisement

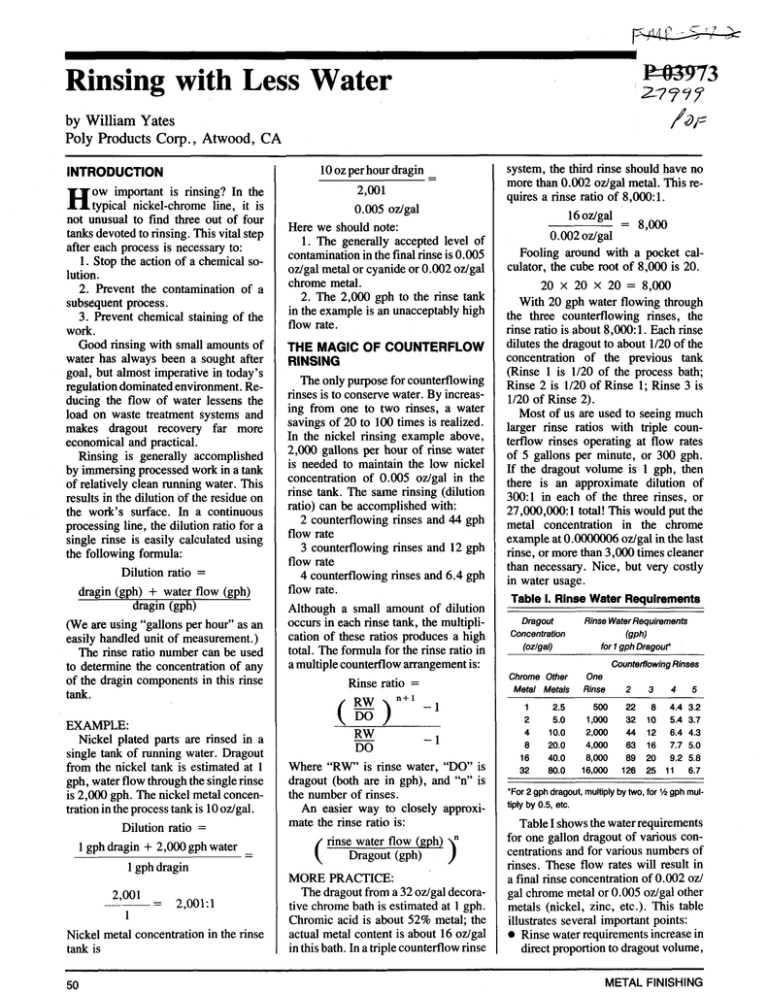

EKW-73 Rinsing with Less Water 2-77?y by William Yates Poly Products Corp., Atwood, CA INTRODUCTION ow important is rinsing? In the typical nickel-chrome line, it is not unusual to find three out of four tanks devoted to rinsing. This vital step after each process is necessary to: 1. Stop the action of a chemical solution. 2. Prevent the contamination of a subsequent process. 3. Prevent chemical staining of the work. Good rinsing with small amounts of water has always been a sought after goal, but almost imperative in today’s regulationdominatedenvironment. Reducing the flow of water lessens the load on waste treatment systems and makes dragout recovery far more economical and practical. Rinsing is generally accomplished by immersing processed work in a tank of relatively clean running water. This results in the dilution bf the residue on the work’s surface. In a continuous processing line, the dilution ratio for a single rinse is easily calculated using the following formula: Dilution ratio = dragin (gph) water flow (gph) dragin (gph) (We are using “gallons per hour” as an easily handled unit of measurement.) The rinse ratio number can be used to determine the concentration of any of the dragin components in this rinse tank. H + EXAMPLE: Nickel plated parts are rinsed in a single tank of running water. Dragout from the nickel tank is estimated at 1 gph, water flow through the singlerinse is 2,000 gph. The nickel metal concentration in the process tank is 10 oz/gal. Dilution ratio = 1 gph dragin 2,000 gph water - + 1 gph dragin 2,001 ~- - 2,001:l 1 Nickel metal concentration in the rinse tank is 50 10oz per hour dragin 2,001 0.005 odgal Here we should note: 1. The generally accepted level of contamination in the final rinse is 0.005 odgal metal or cyanide or 0.002 ozlgal chrome metal. 2. The 2,000 gph to the rinse tank in the example is an unacceptably high flow rate. THE MAGIC OF COUNTERFLOW RINSING The only purpose for counterflowing rinses is to conserve water. By increasing from one to two rinses, a water savings of 20 to 100 times is realized. In the nickel rinsing example above, 2,000 gallons per hour of rinse water is needed to maintain the low nickel concentration of 0.005 ozlgal in the rinse tank.The same rinsing (dilution ratio) can be accomplished with: 2 counterflowing rinses and 44 gph flow rate 3 counterflowing rinses and 12 gph flow rate 4 counterflowing rinses and 6.4 gph flow rate. Although a small amount of dilution occurs in each rinse tank, the multiplication of these ratios produces a high total. The formula for the riilse ratio in a multiple counterflow arrangement is: Rinse ratio = Where “RW’ is rinse water, “DO’ is dragout (both are in gph), and “n” is the number of rinses. An easier way to closely approximate the rinse ratio is: rinse water flow Dragout (gp;yh) ( MORE PRACTICE: The dragout from a 32 oz/gal decorative chrome bath is estimated at 1 gph. Chromic acid is about 52% metal; the actual metal content is about 16 oz/gal in this bath. In a triple counterflowrinse system, the third rinse should have no more than 0.002 ozlgal metal. This requires a rinse ratio of 8,000:l. 16oz/gal = 8,000 0.002 oz/gal Fooling around with a pocket calculator, the cube root of 8,000 is 20. 20 x 20 x 20 = 8,000 With 20 gph water flowing through the three counterflowing rinses, the rinse ratio is about 8,000:l. Each rinse dilutes the dragout to about 1/20 of the concentration of the previous tank (Rinse 1 is 1/20 of the process bath; Rinse 2 is 1/20 of Rinse 1; Rinse 3 is 1/20 of Rinse 2). Most of us are used to seeing much larger rinse ratios with triple counterflow rinses operating at flow rates of 5 gallons per minute, or 300 gph. If the dragout volume is 1 gph, then there is an approximate dilution of 300:l in each of the three rinses, or 27,000,000:l total! This would put the metal concentration in the chrome example at 0.0000006ozlgal in the last rinse, or more than 3,000 times cleaner than necessary. Nice, but very costly in water usage. Table 1. Rinse Water Requirements Dragout Rinse Water Requirements Concentration (ozlgal) (gph) for 1 gph Dragout. CountetflowingRinses Chrome Other Metal Metals 1 2 4 8 16 32 2.5 5.0 10.0 20.0 40.0 80.0 One Rinse 2 500 1,000 2,000 4,000 8,000 16,000 22 32 44 63 89 126 3 4 8 4.4 10 5.4 12 6.4 16 7.7 20 9.2 25 11 5 3.2 3.7 4.3 5.0 5.8 6.7 ‘For 2 gph dragout, muitiply by two, for 1h gph multiply by 0.5, etc. Table I shows the water requirements for one gallon dragout of various concentrations and for various numbers of rinses. These flow rates will result in a final rinse concentration of 0.002 OZ/ gal chrome metal or 0.005 oz/gal other metals (nickel, zinc, etc.). This table illustrates several important points: 0 Rinse water requirements increase in direct proportion to dragout volume, METAL FINISHING regardless of the number of rinse stations. 0 Rinse water requirements for a single rinse station increase in direct proportion to dragout concentration. 0 Rinse water flow rate requirements drop off dramatically with the addition of counterflow rinse stations. 0 In this table, the greatest change in flow rate is between one and two rinses; the smallest change is between 4 and 5 rinses. 0 When using multiple counterflowing rinses, it is more beneficial to reduce dragout volume than dragout concentration. All these figures and calculationsdepend on the complete mixing of the dragout (or dragin) with the water in each rinse station. AIR AGITATION One way to achieve good mixing of rinse water and dragin is to use air agitation to keep the water in motion within the rinse tank. Place the air agitation pipe across the bottom of the tank and close to the wall or partition on the water inlet side. This will provide a rolling motion to the rinse water, pushing any floating films across to the discharge side of the tank. When processing barrels or parts that entrap solution, special care in rinsing is required. It is important to flush out the interiors of barrels and entrapping parts with several immersions in each rinse station. SPRAYS Spray rinses can be added to the processing line to increase the number of counterflowing stations. Sprays may be positioned to rinse racked parts as they leave any rinse station or as they emerge from the plating or processing tank. Each set of sprays should be supplied with water pumped from the following rinse tank. There are two advantages of spraying over the final rinse tank: city water line pressure eliminates the need for a pump, and any overspray beyond the rinse tank is free of dragout. Pumps or city water pressure should be activated only when processed parts are actually in the spray zone. This will conserve water and allow the use of higher flow rate nozzles. factor of 10. This was done by using several counterflowing rinses after each of the processes: cleaner, acid, nickel and chrome. This made evaporative recovery possible of all nickel and chrome dragout, with savings of chemical and waste treatment costs. More water was saved by re-using the acid rinse water in rinses after the cleaner. THE REAL WORLD One large nickel-chrome plating shop cut their water consumption by a CONCLUSION Taking a little time to study your MAY 1989 rinsing needs, and devising ways to minimize water usage will pay great dividends. MF Biography Bill Yates is President of Poly Products Corp., a manufacturer of atmospheric evaporators and rinse water controlling devices. For the last 27 years, he has been involved in engineering and marketing of plating equipment. He attended Wayne State University and the University of Detroit. 51