Offshore Steel Wire Ropes

advertisement

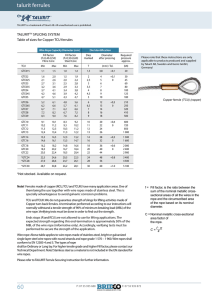

OFFSHORE DIVISION Offshore Steel Wire Ropes www.lankhorstropes.com Member of the Royal Lankhorst Euronete Group, a WireCo WorldGroup company OFFSHORE DIVISION 2 PROVEN STRENGTH 0413 More than 200 years of experience in development and manufacturing of synthetic and steel wire ropes have proven the strength of Lankhorst www.lankhorstropes.com OFFSHORE DIVISION 3 OFFSHORE DIVISION 4 COMPANY INFORMATION STEEL WIRE ROPE SOLUTIONS FOR: 6 • MOORING AND ANCHOR LINES 8 • TOWING ROPES 10 • OFFSHORE CRANE ROPES 14 • RISER TENSIONER LINES 16 • A&R WINCH ROPES AND PLOUGH ROPES 18 • DRILLING LINES 19 TERMINATIONS 0413 QUALITY SYSTEM & CERTIFICATION www.lankhorstropes.com 4 OFFSHORE DIVISION COMPANY INFORMATION Lankhorst Ropes is a member of the Royal Lankhorst Euronete Group. With more than 200 years of experience and 1,250 employees we are a worldwide innovative group with fully equipped production sites and R&D departments, located in The Netherlands, Portugal, Greece and Brasil, equipped for the production of a wide range of products in maritime and offshore ropes, technical yarns, fishing gear, Pure® composites, recycling and moulding material. In July 2012, the Royal Lankhorst Euronete Group was acquired by WireCo WorldGroup, of Kansas City, Mo, USA. WireCo WorldGroup is the global leader in manufacturing, engineering, and distributing wire rope, wire rope assemblies, synthetic rope and electromechanical cable with production units in Portugal, Germany, Poland, USA and Mexico. With true global reach, WireCo WorldGroup can deliver the right products for your equipment and application no matter where your worksite might be. Lankhorst Ropes is divided into three divisions: • Maritime Division with sales offices in The Netherlands, United Kingdom, Spain, United Arab Emirates, Brasil and Australia. In order to support the business, Lankhorst Ropes carries strategic stock in Houston (USA), New York (USA), Los Angeles (USA), Fujairah & Dubai (UAE), Cape Town & Durban (South Africa), Rotterdam (Holland), Panama and Singapore, and has service points in Bilbao (Spain), Brisbane (Australia) and Rio de Janeiro (Brasil); • Offshore Division which trades synthetic ropes in the name of Lankhorst Euronete Portugal S.A. and operates from Maia and Viana do Castelo (Portugal), and steel wire ropes for offshore applications produced by WireCo WorldGroup manufacturing units in the name of Lankhorst Ropes; • Heaving Lifting Division which brings its expertise in rope construction to meet the demand for high performance, offshore lifting slings. Lankhorst Ropes continuously strives for improved product performance, customer satisfaction and product innovation. Lankhorst Ropes has been certified according to ISO 9001:2000. 0413 This brochure covers Steel Wire Ropes for offshore applications. www.lankhorstropes.com OFFSHORE DIVISION 5 Lankhorst Ropes combines more than two centuries of experience with a strong innovative ability and modern production techniques. In close cooperation with clients world-wide, the company develops innovative solutions for specific applications in the maritime and offshore industry. These solutions can be either new products or optimised existing techniques. Casar is a global brand, consisting of specialty wire rope and hoisting cables, characterized by advanced engineering, innovation, and high technology. Casar delivers superior performance for mission critical applications in construction, industrial, and OEM markets. Union produces wire rope and delivers exceptional service and unmatched support worldwide – in the field, on the rig, and in the mine. In addition to oil, gas, and mining applications, Union products are used in construction, logging, industrial, and OEM arenas. Oliveira produces high performance synthetic and wire rope products, serving core markets including deepwater mooring line and towing applications, and aftermarket wire rope for cranes. Camesa specializes in high quality electromechanical cable for the oil and gas market as well as rope for almost any application. The Camesa high carbon wire products are used in tire bead wire, upholstery springs and music wires. Pre-stressed concrete strand from Camesa is used throughout the western hemisphere for buildings and bridges. 0413 Drumet is a leading manufacturer of wire rope, steel wire, and steel wire band in Eastern Europe. Drumet provides high quality, low cost wire production to support customers’ needs. www.lankhorstropes.com 6 OFFSHORE DIVISION MOORING AND ANCHOR LINES PRODUCTS: • 6x36 WS+IWRC 0413 • Spiral Strand www.lankhorstropes.com 7 OFFSHORE DIVISION 6x36 WS+IWRC Standard wire rope with higher breaking strength. Used for all kinds of purposes, i.e. luffing, mooring, towing, anchoring and coupling push barges. The independent wire rope core provides more strength and stability to the wire rope compared to fibre core. Construction according to ISO standard. Spiral Strand Diameter Weight (mm) (kg/m) MBF (kN) 32 34 36 38 40 42 44 46 48 50 51 52 54 56 58 60 62 64 66 68 70 72 74 76 80* 84* 88* 90* 94* 98* 100* 102* 715 807 904 1008 1116 1231 1351 1476 1608 1744 1815 1887 2030 2188 2350 2512 2680 2858 3039 3226 3419 3617 3821 4030 4466 4923 5403 5652 6165 6701 6978 7259 4,19 4,73 5,30 5,91 6,54 7,22 7,92 8,65 9,42 10,2 10,6 11,1 11,9 12,8 13,8 14,7 15,8 17 17,9 19 20 21,2 22,4 23,6 26,2 28,9 31,7 33,1 36,1 39,3 41,0 43,0 MBF (MT) 72,9 82,3 92,2 103 114 126 138 151 164 178 185 192 207 223 240 256 273 292 310 329 349 369 390 411 455 502 551 576 629 684 712 740 * construction 6x49 More details and specifications are available on request. These data are for guidance purposes only and are subject to change without prior notice. A586 Galvanized Structural Spiral Strand Grade 2 Class A Coating Throughout Diameter Metallic (mm) area (mm) Weight (kg/m) MBF (kN) 38 41 44 48 51 54 57 60 64 67 70 73 76 79 83 86 89 92 95 98 102 7,05 8,27 9,59 11,02 12,52 14,15 15,86 17,67 19,58 21,57 23,68 25,88 28,18 30,58 33,07 35,66 38,36 39,65 43,98 46,96 50,09 1415 1655 1922 2206 2509 2838 3176 3523 3843 4270 4626 5044 5507 5978 6397 6886 7411 7856 8407 8985 9466 871 1026 1187 1361 1548 1748 1961 2181 2419 2665 2929 3200 3484 3781 4090 4406 4742 5084 5439 5806 6194 More details and specifications are available on request. 0413 These data are for guidance purposes only and are subject to change without prior notice. www.lankhorstropes.com MBF (MT) 144 169 196 225 256 289 324 359 392 436 472 515 562 610 652 702 756 801 858 917 966 This rope is used where high strength and high modulus is required in a stationary structure/application. 8 OFFSHORE DIVISION TOWING ROPES PRODUCTS: 0413 • 6x36 WS+IWRC www.lankhorstropes.com OFFSHORE DIVISION 9 Diameter Weight (mm) (kg/m) MBF (kN) 32 34 36 38 40 42 44 46 48 50 51 52 54 56 58 60 62 64 66 68 70 72 74 76 80* 84* 88* 90* 94* 98* 100* 102* 715 807 904 1008 1116 1231 1351 1476 1608 1744 1815 1887 2030 2188 2350 2512 2680 2858 3039 3226 3419 3617 3821 4030 4466 4923 5403 5652 6165 6701 6978 7259 4,19 4,73 5,30 5,91 6,54 7,22 7,92 8,65 9,42 10,2 10,6 11,1 11,9 12,8 13,8 14,7 15,8 17 17,9 19 20 21,2 22,4 23,6 26,2 28,9 31,7 33,1 36,1 39,3 41,0 43,0 MBF (MT) 72,9 82,3 92,2 103 114 126 138 151 164 178 185 192 207 223 240 256 273 292 310 329 349 369 390 411 455 502 551 576 629 684 712 740 * construction 6x49 More details and specifications are available on request. 0413 These data are for guidance purposes only and are subject to change without prior notice. www.lankhorstropes.com 6x36 WS+IWRC Standard wire rope with higher breaking strength. Used for all kinds of purposes, i.e. luffing, mooring, towing, anchoring and coupling push barges. The independent wire rope core provides more strength and stability to the wire rope compared to fibre core. Construction according to ISO standard. 10 OFFSHORE DIVISION OFFSHORE CRANE ROPES PRODUCTS: • 6x36 WS+IWRC • 6x36WS+IWRC Compacted • Lanko®pack • Lanko®lift Compacted • Lanko®top 0413 • Lanko®top Compacted www.lankhorstropes.com 11 OFFSHORE DIVISION 6x36 WS+IWRC Standard wire rope with higher breaking strength. Used for all kinds of purposes, i.e. luffing, mooring, towing, anchoring and coupling push barges. The independent wire rope core provides more strength and stability to the wire rope compared to fibre core. Construction according to ISO standard. Diameter Weight (mm) (kg/m) MBF (kN) 32 34 36 38 40 42 44 46 48 50 51 52 54 56 58 60 62 64 66 68 70 72 74 76 80* 84* 88* 90* 94* 98* 100* 102* 715 807 904 1008 1116 1231 1351 1476 1608 1744 1815 1887 2030 2188 2350 2512 2680 2858 3039 3226 3419 3617 3821 4030 4466 4923 5403 5652 6165 6701 6978 7259 4,19 4,73 5,30 5,91 6,54 7,22 7,92 8,65 9,42 10,2 10,6 11,1 11,9 12,8 13,8 14,7 15,8 17 17,9 19 20 21,2 22,4 23,6 26,2 28,9 31,7 33,1 36,1 39,3 41,0 43,0 MBF (MT) 72,9 82,3 92,2 103 114 126 138 151 164 178 185 192 207 223 240 256 273 292 310 329 349 369 390 411 455 502 551 576 629 684 712 740 * construction 6x49 More details and specifications are available on request. 0413 These data are for guidance purposes only and are subject to change without prior notice. Diameter Metallic (mm) area (mm) Weight (kg/m) MBF (kN) 32 34 35 36 38 40 42 44 46 48 50 52 4,61 5,22 5,56 5,85 6,35 7,23 7,91 8,80 9,55 10,40 11,27 12,24 891 1012 1076 1132 1261 1402 1530 1702 1847 2012 2179 2364 540 614 653 687 765 850 928 1032 1121 1221 1322 1434 MBF (MT) 90,9 103 110 115 129 143 156 174 188 205 222 241 6x36WS+IWRC Compacted More details and specifications are available on request. Can be used for all hoist and pulling applications when a higher MBL instead of 6 strands conventional ropes is required. Manufacturing of slings with a high MBL. These data are for guidance purposes only and are subject to change without prior notice. Also available in 2160 N/mm2. www.lankhorstropes.com 12 OFFSHORE DIVISION Lanko®pack Can be used for all cranes and high performance lifting applications where non-rotating and high MBL ropes are required. Recommended for offshore, deck cranes and marine environment. Diameter Metallic (mm) area (mm) Weight (kg/m) MBF (kN) 22 23 24 25 26 27 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 2,34 2,56 2,79 3,03 3,25 3,54 3,80 4,38 4,97 5,59 6,30 7,01 7,74 8,52 9,40 10,36 11,32 11,98 13,21 14,13 15,82 17,06 18,25 474 520 567 612 660 717 772 887 1006 1132 1281 1419 1568 1727 1911 2094 2294 2437 2673 2868 2854 3078 3293 271 297 324 350 377 410 441 507 575 647 732 811 896 987 1092 1197 1311 1393 1528 1639 1797,9 1938,7 2074,1 MBF (MT) 48,3 53,0 57,8 62,4 67,3 73,1 78,7 90,5 103 115 131 145 160 176 195 214 234 249 273 293 291 314 336 More details and specifications are available on request. These data are for guidance purposes only and are subject to change without prior notice. Diameter Metallic (mm) area (mm) Weight (kg/m) MBF (kN) 22 24 26 28 30 32 34 35 36 38 40 41 42 44 46 48 50 52 54 56 58 60 2,28 2,75 3,20 3,71 4,24 4,80 5,48 5,78 6,13 6,78 7,64 8,04 8,37 9,17 9,95 10,94 12,56 13,75 14,63 15,82 17,06 18,25 433 526 610 706 808 935 1047 1109 1165 1295 1429 1498 1573 1714 1862 2055 2292 2436 2632 2578 2780 2974 263 317 370 427 490,1 551,2 629,5 665 705 779 879 921 967 1053 1144 1263 1427,1 1563 1662,1 1797,9 1938,7 2074,1 More details and specifications are available on request. 0413 These data are for guidance purposes only and are subject to change without prior notice. www.lankhorstropes.com MBF (MT) 44,2 53,7 62,2 72,0 82,4 95,4 107 113 119 132 146 153 160 175 190 210 234 248 268 263 284 303 Lanko®lift Compacted Is recommended for intensive use and severe hoist applications where rotation resistance property is required like e.g. tower cranes. Marine and offshore cranes when rotation resistance is required. 13 OFFSHORE DIVISION Lanko®top Can be used for all applications when a very high MBL is not required and can be used for flexible slings. The special feature of Lanko®top is that in the production process the core is covered by an especially designed HDPE extruded cover. This gives the wire rope stability, avoids point to point contact between wires of the outer and inner strands and stops corrosion and wear of the core. When the high breaking strength is added, this luffing wire rope is surpassed. Diameter Metallic (mm) area (mm) Weight (kg/m) MBF (kN) 22 24 26 28 30 32 34 35 36 38 40 41 42 44 46 48 50 52 54 56 58 60 62 2,066 2,466 2,86 3,369 3,868 4,35 4,901 5,335 5,553 6,205 6,829 7,169 7,495 8,23 9,26 10,18 11,08 11,97 12,89 13,69 14,65 15,75 16,81 391 469 541 637 733 824 925 1008 1052 1173 1292 1353 1419 1558 1749 1924 2093 2263 2440 2591 2774 2975 3177 240 288 332 391 450 506 569 620 646 721 794 832 872 958 1075 1183 1286 1391 1500 1593 1705 1828 1953 MBF (MT) 39,9 47,8 55,2 65,0 74,8 84,0 94,4 103 107 120 132 138 145 159 178 196 213 231 249 264 283 303 324 More details and specifications are available on request. These data are for guidance purposes only and are subject to change without prior notice. Diameter Metallic (mm) area (mm) Weight (kg/m) MBF (kN) 22 24 26 28 30 32 34 36 38 40 41 42 44 46 48 50 52 54 56 58 60 2,173 2,548 3,054 3,554 4,128 4,694 5,261 5,969 6,612 7,298 7,579 7,978 9,001 9,78 10,66 11,69 12,59 13,54 14,59 15,69 16,71 419 510 589 686 794 905 1018 1148 1271 1410 1464 1538 1736 1883 2055 2253 2427 2607 2805 3021 3224 251 305 353 411 476 543 610 688 762 845 878 922 1040 1129 1232 1350 1455 1563 1681 1811 1932 More details and specifications are available on request. 0413 These data are for guidance purposes only and are subject to change without prior notice. www.lankhorstropes.com MBF (MT) 42,7 52,0 60,1 70,0 81,0 92,3 104 117 130 144 149 157 177 192 210 230 248 266 286 308 329 Lanko®top Compacted When rotation resistant ropes are not required (twin hoist systems with right and left ropes, small heights). Hoist for steel mill cranes, container cranes, floating cranes and boom hoist for deck cranes, luffing and mobile cranes, grab cranes. The special feature of Lanko®top is that in the production process the core is covered by an especially designed HDPE extruded cover. This gives the wire rope stability, avoids point to point contact between wires of the outer and inner strands and stops corrosion and wear of the core. Compacting the wire rope provides more strength, due to higher steel content, and better abrasion resistance due to larger area of contact between wire rope and sheave. 14 OFFSHORE DIVISION RISER TENSIONER LINES PRODUCTS: • 6x36 WS+IWRC 0413 • Lanko®top Compacted www.lankhorstropes.com 15 OFFSHORE DIVISION 6x36 WS+IWRC Standard wire rope with higher breaking strength. Used for all kinds of purposes, i.e. luffing, mooring, towing, anchoring and coupling push barges. The independent wire rope core provides more strength and stability to the wire rope compared to fibre core. Construction according to ISO standard. Diameter Weight (mm) (kg/m) MBF (kN) 32 34 36 38 40 42 44 46 48 50 51 52 54 56 58 60 62 64 66 68 70 72 74 76 80* 84* 88* 90* 94* 98* 100* 102* 715 807 904 1008 1116 1231 1351 1476 1608 1744 1815 1887 2030 2188 2350 2512 2680 2858 3039 3226 3419 3617 3821 4030 4466 4923 5403 5652 6165 6701 6978 7259 4,19 4,73 5,30 5,91 6,54 7,22 7,92 8,65 9,42 10,2 10,6 11,1 11,9 12,8 13,8 14,7 15,8 17 17,9 19 20 21,2 22,4 23,6 26,2 28,9 31,7 33,1 36,1 39,3 41,0 43,0 MBF (MT) 72,9 82,3 92,2 103 114 126 138 151 164 178 185 192 207 223 240 256 273 292 310 329 349 369 390 411 455 502 551 576 629 684 712 740 * construction 6x49 More details and specifications are available on request. These data are for guidance purposes only and are subject to change without prior notice. Diameter Metallic (mm) area (mm) Weight (kg/m) MBF (kN) 22 24 26 28 30 32 34 36 38 40 41 42 44 46 48 50 52 54 56 58 60 2,173 2,548 3,054 3,554 4,128 4,694 5,261 5,969 6,612 7,298 7,579 7,978 9,001 9,78 10,66 11,69 12,59 13,54 14,59 15,69 16,71 419 510 589 686 794 905 1018 1148 1271 1410 1464 1538 1736 1883 2055 2253 2427 2607 2805 3021 3224 251 305 353 411 476 543 610 688 762 845 878 922 1040 1129 1232 1350 1455 1563 1681 1811 1932 More details and specifications are available on request. 0413 These data are for guidance purposes only and are subject to change without prior notice. www.lankhorstropes.com MBF (MT) 42,7 52,0 60,1 70,0 81,0 92,3 104 117 130 144 149 157 177 192 210 230 248 266 286 308 329 Lanko®top Compacted When rotation resistant resistantropes ropesare arenot notrequired required(twin (twinhoist hoistsystems When rotation systems with right and left ropes, small heights). Hoist forcranes, steel with right and left ropes, small heights). Hoist for steel mill mill cranes, container cranes, floating cranes and boom hoist container cranes,luffing floating cranes andcranes, boom grab hoistcranes. for deckThe cranes, for deck cranes, and mobile luffing mobile cranes, grab special feature of specialand feature of Lanko®top is cranes. that in The the production process the core is covered especiallyprocess designed extruded Lanko®top is that inby thean production theHDPE core is covered cover. This gives designed the wire rope avoids to point by an especially HDPEstability, extruded cover.point This gives the contact between wires of the outer and inner strands and stops wire rope stability, avoids point to point contact between wires of corrosion and wear of the core. Compacting the wire rope the outer and inner strands and stops corrosion and wear of the provides more strength, due to higher steel content, and better core. Compacting the wire provides strength, duewire to abrasion resistance due torope larger area of more contact between rope and sheave. higher steel content, and better abrasion resistance due to larger area of contact between wire rope and sheave. 16 OFFSHORE DIVISION A&R WINCH ROPES AND PLOUGH ROPES PRODUCTS: 0413 • Lanko®pack www.lankhorstropes.com 17 OFFSHORE DIVISION Lanko®pack Can be used for all cranes and high performance lifting applications where non-rotating and high MBL ropes are required. Recommended for offshore, deck cranes and marine environment. Diameter Metallic (mm) area (mm) Weight (kg/m) MBF (kN) 22 23 24 25 26 27 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 2,34 2,56 2,79 3,03 3,25 3,54 3,80 4,38 4,97 5,59 6,30 7,01 7,74 8,52 9,40 10,36 11,32 11,98 13,21 14,13 15,82 17,06 18,25 474 520 567 612 660 717 772 887 1006 1132 1281 1419 1568 1727 1911 2094 2294 2437 2673 2868 2854 3078 3293 271 297 324 350 377 410 441 507 575 647 732 811 896 987 1092 1197 1311 1393 1528 1639 1797,9 1938,7 2074,1 MBF (MT) 48,3 53,0 57,8 62,4 67,3 73,1 78,7 90,5 103 115 131 145 160 176 195 214 234 249 273 293 291 314 336 More details and specifications are available on request. 0413 These data are for guidance purposes only and are subject to change without prior notice. www.lankhorstropes.com 18 OFFSHORE DIVISION DRILLING LINES PRODUCTS: • 6x19S+IWRC 0413 • 6x26WS+IWRC www.lankhorstropes.com 19 OFFSHORE DIVISION 6x19S+IWRC & 6x26WS+IWRC 6x19S+IWRC Diameter (mm) Metric Weight MBF MBF (kg/m) (kN) (MT) 1960 N/mm2 22 26 28 30 32 34 36 38 40 44 48 52 1,94 2,70 3,14 3,60 4,10 4,62 5,18 5,78 6,40 8,25 9,67 11 338 472 547 628 715 807 904 1008 1116 1351 1608 1887 34,5 48,1 55,8 64,1 72,9 82,3 92,2 103 114 138 164 192 More details and specifications are available on request. These data are for guidance purposes only and are subject to change without prior notice. TERMINATIONS All different types of sockets, thimbles and soft eyes are available on request. Casted, swaged, talurit or superpressed. 0413 Open Spelter Socket Closed Spelter Socket www.lankhorstropes.com CR-Socket Type S04 6x26WS+IWRC Diameter (in) Imperial Weight MBF MBF (lb/ft) (tons of 2000 lbs) XIP XXIP 7/8* 1* 1 1/8** 1 1/4** 1 3/8** 1 1/2** 1 5/8* 1 3/4* 1 7/8* 2* 1,42 1,85 2,34 2,89 3,5 4,16 4,88 5,67 6,5 7,39 39,8 51,7 65 79,9 96 114 132 153 174 198 43,8 56,9 71,5 87,9 106 125 146 169 192 217 * 6x26WS RRL IWRC ** 6x19S RRL IWRC All sizes available in PFV coating. More details and specifications are available on request. These data are for guidance purposes only and are subject to change without prior notice. LANKHORST ROPES – Offshore Division Prinsengracht 2 8607 AD Sneek P.O. Box 203 8600 AE Sneek The Netherlands T: F: E: +31 (0)515 487647 +31 (0)515 487478 offshoresteelwire@lankhorstropes.com Quality system Certification www.lankhorstropes.com Member of the Royal Lankhorst Euronete Group, a WireCo WorldGroup company