Case Study

Embreak* Chemistry Saves Refinery

Over $350,000(USD)/year

… and improves environmental footprint as well

The Challenge

A North American refinery was experiencing

frequent brine quality issues in one of its crude

units, with 10-20% oil in the brine leaving the

desalter. A GE multifunctional technical team went

to the site to assess the root cause of the problem

and develop an action plan to restore brine quality.

Root cause analysis included investigation of

mechanical and operating conditions, as well as

assessment of oil and water feed quality. Testing

to identify potential chemical treatment alternatives

was also conducted, both on-site and at GE’s

Technology Laboratory in The Woodlands, Texas.

The team determined that several factors were

contributing to the brine quality issues. For one,

solids loading in the feed to the desalter had

recently increased. Additionally, an extended shut

down earlier in the year left the refinery with an

inventory of reduced crude that needed to be

reprocessed through the desalter. Finally, the

emulsified oil in the brine was identified as a solidsstabilised emulsion, requiring a shift in approach to

the desalter operation to restore performance.

Testing for alternate chemicals included

Embreak* 2W2030E, the latest innovation in GE’s

demulsifier chemistry portfolio. This patent pending

technology is part of GE’s line of products developed

to reduce potential environmental impact by eliminating nonylphenol ethoxylates (NPE’s). The new

chemistry clearly showed improved performance

in bench simulations and the refinery agreed to a

field evaluation.

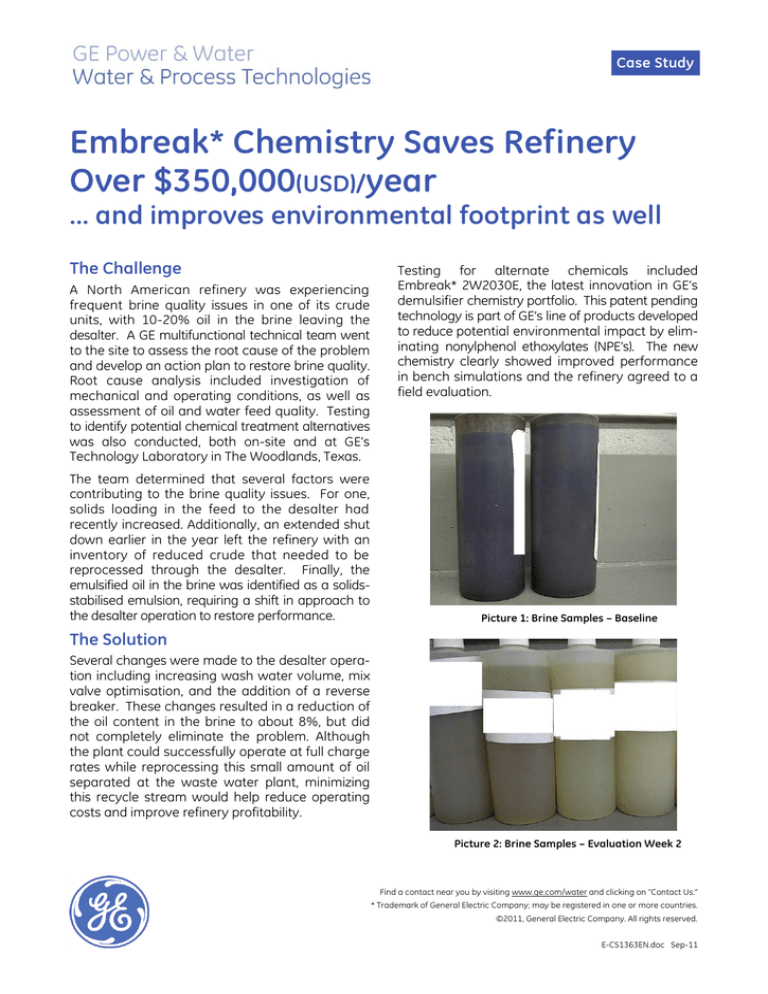

Picture 1: Brine Samples – Baseline

The Solution

Several changes were made to the desalter operation including increasing wash water volume, mix

valve optimisation, and the addition of a reverse

breaker. These changes resulted in a reduction of

the oil content in the brine to about 8%, but did

not completely eliminate the problem. Although

the plant could successfully operate at full charge

rates while reprocessing this small amount of oil

separated at the waste water plant, minimizing

this recycle stream would help reduce operating

costs and improve refinery profitability.

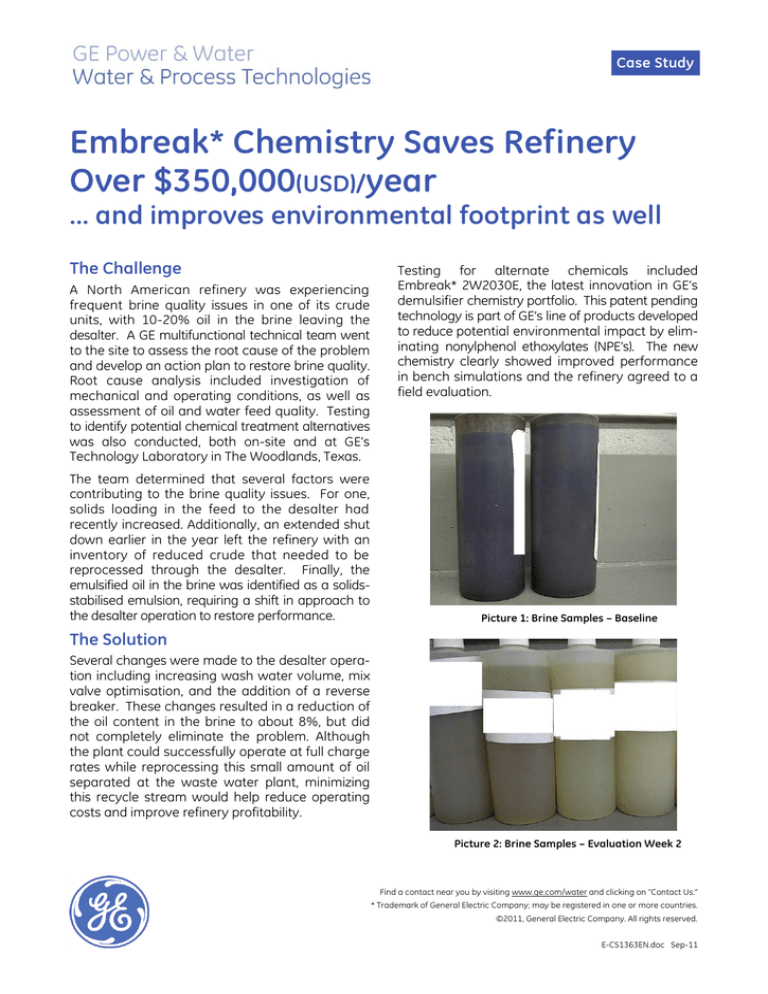

Picture 2: Brine Samples – Evaluation Week 2

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us.”

* Trademark of General Electric Company; may be registered in one or more countries.

©2011, General Electric Company. All rights reserved.

E-CS1363EN.doc Sep-11

Performance Summary

Solids Removal

Brine quality improvements can be clearly seen in

Pictures 1 and 2 on page 1. The savings associated

with eliminating the oil recycle and cutting back

on chemical injection exceeded $350,000 (USD)

per year.

Additionally, the plant maintains an on-line TOC

(Total Organic Carbon) analyser in the wastewater

influent stream. Although this meter measures

the TOC of several mixed water streams, there

was a marked reduction in influent TOC directly

related to the change in desalter chemistry.

Salt and solids removal were also improved as a

result of the change in chemistry – a 33% reduction

in salts and 56% improvement in solids removal

from the desalter.

Salt (ptb)

Desalted Crude Salt

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

1.8

1.2

Baseline

Page 2

Embreak 2W2030E

70

Percent Removal

The new chemistry was initially injected at dosage

rates equal to the previous treatment program. It

was quickly determined that both the desalting

performance and the brine quality improved

enough to justify optimising the new chemical

dosage rate. After trimming back chemical by 19%,

all performance targets were still being met.

67

60

50

43

40

30

Baseline

Embreak 2W2030E

Based on the success of this new chemistry, the

refiner converted the second crude unit at the

plant to the same program.

Environmental Impact

The demulsifier product used in this case contains

no nonylphenol ethoxylates (NPE).

In the 1990s, scientists began to raise concerns

regarding the environmental persistence of NP and

NPE-related compounds as well as their toxicity.

For NPE surfactants, research showed that, while

the ethoxylate part breaks down quickly, the parent

NP breaks down more slowly. Consequently,

nonylphenol has been found in sediments and

there is concern that NP could accumulate to

harmful levels in the environment. Additionally,

NP was found to be a weak estrogen (“endocrine

disruptor”) in both lab animals and fish.

GE is committed to not only improving performance,

but also reducing potential environmental impacts.

In this light, GE has committed aggressive research

activities to reduce or eliminate NP and NPE compounds from its products, regardless of use or

fate and effects. This new line of Embreak products

is a result of such research.

Case Study