12 Point Flange Screws (Ferry Cap), Alloy, Plain Specification

advertisement

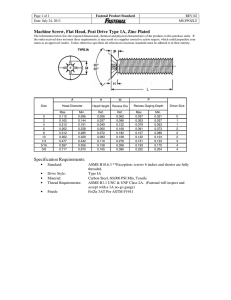

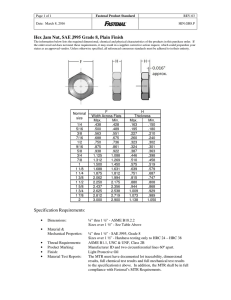

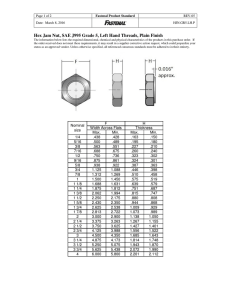

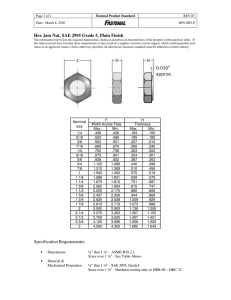

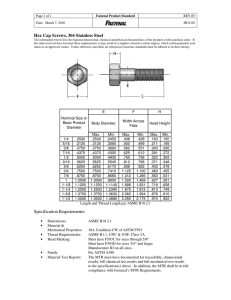

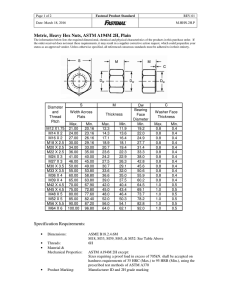

Page 1 of 1 REV-07 Fastenal Product Standard Date: February 23, 2016 FCS.ALLOY.P 12 Point Flange Screws (Ferry Cap), Alloy, Plain The information below lists the required dimensional, chemical and physical characteristics of the products in this purchase order. If the order received does not meet these requirements, it may result in a supplier corrective action request, which could jeopardize your status as an approved vendor. Unless otherwise specified, all referenced consensus standards must be adhered to in their entirety. D Size Body Diameter 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 1 1 1/8 1 1/4 1 1/2 C F Flange Diameter Max. Min. Max. .2500 .2435 .375 .3125 .3053 .469 .3750 .3678 .562 .4375 .4294 .656 .5000 .4919 .750 .6250 .6163 .938 .7500 .7406 1.125 .8750 .8647 1.312 1.000 .9886 1.500 1.125 1.1086 1.688 1.250 1.2336 1.875 1.500 1.4818 2.250 Min. .365 .457 .550 .642 .735 .921 1.107 1.293 1.479 1.665 1.652 2.224 H K J T Socket Width Across Wrench Head Flange Wrenching Thread Flats Size Height Thickness Height Length Max. Min. .252 .244 .315 .306 .377 .368 .438 .429 .502 .493 .627 .618 .752 .743 .877 .866 1.003 .991 1.128 1.115 1.253 1.240 1.503 1.489 Nom. 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 1 1 1/8 1 1/4 1 1/2 Max. .260 .312 .375 .438 .500 .625 .750 .875 1.000 1.125 1.250 1.500 Min. .058 .074 .095 .109 .129 .166 .200 .234 .268 .310 .350 .433 Min. .15 .18 .21 .26 .29 .36 .44 .51 .60 .66 .73 .87 Specification Requirements: • Dimensions: • • • Material: Mechanical Properties: Thread Requirements: • • • Product Marking: Finish: Material Test Reports: • Quality Assurance Provisions: IFI-115 (Note required mechanical properties below.) Medium Carbon Alloy Steel Properties shall comply with all requirements of ASTM A574 ASME B1.1, UNC or UNF Class 3A (#0 through 1”). ASME B1.1, UNC or UNF Class 2A (Over 1” through 1 ½”). Manufacturer’s ID on nominal diameters ¼” and larger Light Protective Oil The MTR must have documented lot traceability, dimensional results, full chemical test results and full mechanical test results to the specification(s) above. In addition, the MTR shall be in full compliance with Fastenal’s MTR Requirements. Category 3 of ASME B18.18 Basic 1.000 1.125 1.250 1.375 1.500 1.750 2.000 2.250 2.500 2.750 3.000 3.500