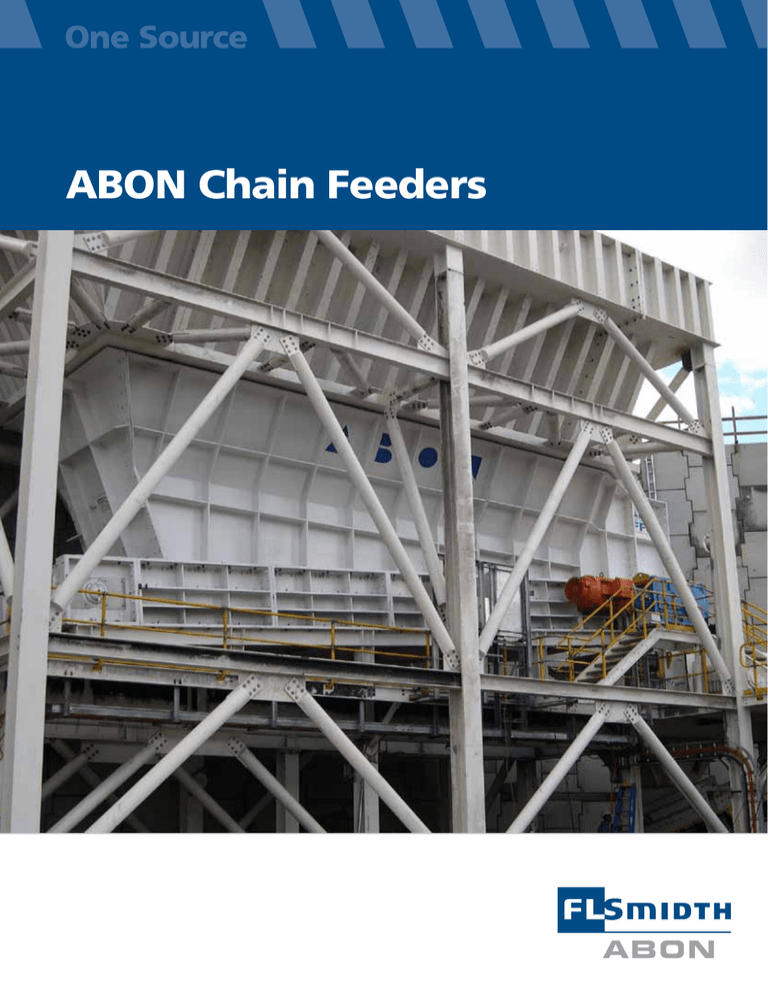

ABON Chain Feeders

2

Introduction

Features

• Via modular construction

and design, a wide range of

lengths can be accommodated

to reduce retaining wall height

• A large throat opening

encouraging free flow

• Exceptionally low conveyor

speeds minimise wear

• Insensitive to clay and sticky

materials

• All oil lubrication

• Robust chain design

• Electric Variable Speed Drive

is operationally clean and low

maintenance

FLSmidth ABON Pty Ltd has

manufactured Sizing, Crushing and

Screening equipment in excess of 45

years for an ever expanding range of

industries in the broad sphere of

minerals handling and minerals

processing by-product activities.

In 2002 we added the Flight Bar

Chain Feeder to our range of product

to compliment our robust, heavy duty

Sizers and Rollerscreens.

Our Chain Feeders can be offered

with a horizontal, inclined or “Z” deck

configuration, to suit any Hopper or

Reclaim design or retrofit.

3

ABON Feeders

Description of Equipment:

The ABON Chain Feeder is designed

to transfer material from the feed side

towards the discharge “Head Chute”

side of the Feeder at a constant

volumetric rate.

The feeder electric motor drives the

Feeder head shaft via a torque limiting

coupling and bevel helical reducer.

Sprockets on the head shaft mesh

with two strands of the Feeder Chain,

each strand is situated on either side

of the deck.

Flightbars are attached between the

two Feeder chains. These flightbars

transfer the material constant

volumetric rate to the discharge end.

ABON Feeders have several unique

features to exploit over other Feeder

models:

The modular design of the feeder

allows the unit to be easily broken

down into components, no more than

10 tonne, allowing the unit to be

easily barged to site and easily

assembled in situ. All modules are

keyed and bolted, and when

connected will hold it’s own load.

FLSmidth ABON’s heavy, robust build

has been designed for a life in excess

of 20 years.

4

ABON Feeder Sizer

The ABON Chain Feeder and Sizer are

easily coupled together to become an

ABON Feeder Sizer.

(1) The ABON Feeder and Sizer

concept has no restriction in the flow

of material, which prevents blockages,

therefore a constant flow is provided.

(2) There are no jolting effects on the

chain should larger rock boulders with

compressive strengths of up to 250

Mpa be encountered.

(3) The ABON Sizer will provide a

cubical / non slabby product, which

could result in less wear and tear on

the discharge conveyor.

(4) Due to it’s low roll speed the ABON

Primary Sizer is suitable for minimising

fines (minus 0.5 mm).

(5) The ABON Feeder and Sizer

concept is maintenance friendly and

will provide a cost saving in the years

to come.

(6) Replacement of the Sizer teeth can

easily be carried out with the Sizer

withdrawn to the maintenance

position.

5

Construction Features

Modular Robust Design

ABON’s heavy, robust build has been

designed for a life in excess of 20

years. The modular design allows the

unit to be easily broken down into

components. All modules are keyed

and bolted. The top deck will

withstand dumping of full loads from

side tippers without destruction.

Chain

ABON’s standard chain has a 6” pitch.

Chain breakage is practically designed

out as chain pull is 240 tonne per

strand. The ABON Chain Feeder

operates at low speeds (0.08 - 0.35

metres per second) which promote

long wear life of chain, sprockets and

flight bars .

Maintenance

Top and bottom decks are 600mm

apart to enable visual inspections.

Access for inspections is via inspection

hatches along bottom deck. Daily

service is limited to visual inspection

only of sight glasses fitted to oil baths.

More Features

• The top deck will withstand

dumping of full loads

from side tippers without

destruction.

• ABON’s standard chain has

a 6” pitch

• All oil lubrication

warranties (express or implied), and information and data contained in this brochure are for general reference only and may change at any time.

FLSmidth ABON Pty Ltd

24-28 Marshall Road

Airport West, Victoria

Australia 3042

Tel: 61-3-9338 7011

Fax: 61-3-9338 3765

Email: aboninfo@flsmidth.com

www.flsmidthabon.com

Rev: 4/27/2011 al-us

Copyright ©2010 FLSmidth A/S. ALL RIGHTS RESERVED. FLSmidth is a (registered) trademark of FLSmidth A/S. This brochure makes no offers, representations or