Series VQ - Allied Electronics

advertisement

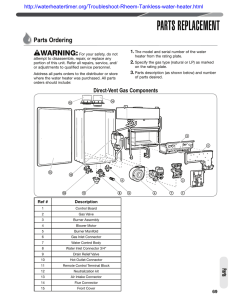

Base Mounted

Metal Seal/Rubber Seal

Series VQ

Space-saving profile

Unprecedented high speed

response and long service life

All pilot valves are compactly mounted on one side.

The space-saving design of mounting all fittings on

one side permits mounting in three directions.

(Metal seal, single, with indicator light/surge voltage suppressor)

VQ0000

10 ms

Space-saving ·········· 45% less

VQ1000

10 ms

Capacity-saving ······ 50% less

VQ2000

20 ms

VQC

SQ

VQ0

200 million cycles

VQ4

Dispersion accuracy ±2 ms

VQ5

VQZ

VQ0000

(VV5Q05)

Locking type (Manual)

Locking type

manual override

Built-in silencer,

direct exhaust

Regulator unit

Thin compact design

with large flow capacity

VQD

Flow characteristics

Manifold

pitch

(mm)

C [dm /(s·bar)]

C [dm /(s·bar)]

VQ0000

10.7

0.44

0.53

Up to ø40

VQ1000

10.5

0.72

1.0

Up to ø50

VQ2000

16

2.6

3.2

Up to ø80

Ejector unit

Model

Blanking

plate assembly

Metal seal

3

Rubber seal

3

Cylinder

size

∗ Flow characteristics: 4/2 5/3 (A/B R1/R2)

VQ1000

(VV5Q11)

Dual flow fitting

DIN rail

Elbow fitting assembly

(Top entry connector)

Elbow fitting assembly

(Bottom entry connector)

Port plug

Individual SUP spacer

Individual EXH spacer

∗ The photo does not show an actual use example.

VQ2000

(VV5Q21)

A variety of options

Innovative

mounting methods

The non-bias, one-clamp structure

permits easy valve replacement.

(Plug-in unit)

A variety of common wiring

methods are standardized.

F

G

Built-in One-touch

fittings for easy piping.

kit

(D-sub connector)

Number of pins: 15, 25

P

kit

(Flat ribbon cable connector)

Number of pins: 10, 16, 20, 26

Top entry

Side entry

Top entry

Side entry

kit

(Flat ribbon cable

with terminal block)

Number of pins: 20

kit

(Terminal box)

kit

(Lead wire)

kit

(Serial transmission

unit)

T

L

S

J

kit

(Flat ribbon cable connector)

Number of pins: 20

(PC Wiring System compliant)

Top entry

M

Side entry

kit

(Multi-connector kit)

(VQ2000 only)

2-4-113

Valve Specifications

Sonic

conductance

Type of actuation

Voltage

Electrical entry

Manual override

Rubber seal

VQ200

2.6

2.0

Metal seal

VQ201

3.2

2.2

Base Mounted

(F/L kit only)

Series

VQ2000

P. 2-4-128

Rubber seal

VQ050

0.44

0.32

Metal seal

P. 2-4-124

VQ051

0.53

0.44

Series

P. 2-4-186

Rubber seal

P. 2-4-182

VQ110

0.72

0.72

Metal seal

Plug lead

VQ0000

VQ111

1.0

0.65

Series

VQ1000

P. 2-4-184

2-4-114

P. 2-4-186

Locking type (Manual)

Locking type

Push type, Tool required

Double

Plug-in

(F/L kit only)

Plug-in

P. 2-4-128

P. 2-4-120

M plug connector

0.65

Series

VQ1000

L plug connector

1.0

12 V 100 V 200 V

24 V 110 V 220 V

DC AC AC

50/60 50/60

Hz Hz

Grommet

VQ101

Pressure center

0.72

Exhaust center

3 position

Closed center

0.72

Closed center

Double

Single

Rubber seal

VQ00

Metal seal

4/2 5/3

(A/B R1/R2)

Single

C [dm3/(s·bar)]

External pilot

D-sub connector 15P

Except L kit

Negative common specifications

For S, G kit, please contact SMC.

One-touch fitting

Inch size

Except L kit

Option

Except L kit

For S, G kit, please contact SMC.

P. 2-4-177

Except L kit

For S kit, please contact SMC.

P. 2-4-177

P. 2-4-215

P. 2-4-215

For S kit, please contact SMC.

Flat ribbon cable 10P 16P 20P

For special wiring spec.

Blanking plate

Individual SUP/EXH

SUP/EXH passage spacer

Name plate

DIN rail mounting style

Standard

P. 2-4-166

P. 2-4-172

P. 2-4-208

P. 2-4-210

Built-in silencer

Silencer for EXH port

Elbow fitting for cylinder port

Two stations matching

fittings for double flow rate

Plug for cylinder port

Regulator unit

Ejector unit mounted

Double check block

Manifold Option

Back pressure check valve

2-4-115

VQC

SQ

VQ0

VQ4

VQ5

VQZ

VQD

Series VQ/Base

Mounted: Variations

Manifold Variations

F

P

J

G

kit

kit

kit

kit

D-sub connector

Conforming to MIL D-sub connector

Flat ribbon cable

Flat ribbon cable

connector

connector

(26, 20, 16, 10 pins)

(20 pins)

Flat ribbon cable

with power supply

terminal block

Conforming to MIL flat ribbon Conforming to MIL flat ribbon Conforming to MIL flat ribbon cable

cable connector

cable connector

connector

PC Wiring System compatible

Applicable to OMRON’s serial transmission

unit

PC Wiring System compatible

Plug-in

Series

VQ1000

P. 2-4-130

P/J kit

P. 2-4-134

P. 2-4-142

P. 2-4-130

P/J kit

P. 2-4-134

P. 2-4-142

P. 2-4-188

P kit only

P. 2-4-192

P. 2-4-188

P kit only

P. 2-4-192

Series

VQ2000

Plug Lead

Series

VQ0000

Series

VQ1000

2-4-116

P. XXX

Manifold Variations

T

L C

S

M

kit

kit

kit

kit

Terminal block box

(Terminal block)

Lead wire

Serial transmission unit

Circular connector

Direct electrical entry type

Enables single-wire solenoid

valve-PLC operation

IP65 (Dusttight/Low jetproof type)

Terminal blocks are compactly

arranged on one side.

VQC

SQ

VQ0

L

VQ4

kit

VQ5

VQZ

VQD

Terminal block box

P. 2-4-146

P. 2-4-150

L

P. 2-4-154

Enclosure

IP65 compliant

kit

Enclosure

IP65 compliant

P. 2-4-146

Enclosure

IP65 compliant

P. 2-4-150

P. 2-4-154

P. 2-4-200

P. 2-4-204

P. 2-4-200

P. 2-4-204

W type only

P. 2-4-158

C

kit

Terminal block

P. 2-4-196

C

kit

Terminal block

P. 2-4-196

2-4-117

2-4-118

Cylinder Speed Chart

Use as a guide for selection.

Please confirm the actual conditions with

SMC Sizing Program.

Bore size

Series

Series CJ2

Pressure 0.5 MPa

Load factor 50%

Stroke 60 mm

Average

speed

(mm/s)

ø6

VQ0151

Port size:

One-touch fitting for ø4

VQ1101

Port size:

One-touch fitting for ø6

VQ2101

Port size:

One-touch fitting for ø8

ø10

Series CM2

Pressure 0.5 MPa

Load factor 50%

Stroke 300 mm

ø16

ø20

ø25

Series MB, CA1

Pressure 0.5 MPa

Load factor 50%

Stroke 500 mm

ø32

ø40

ø40

800

700

600

500

400

300

200

100

0

800

700

600

500

400

300

200

100

0

800

700

600

500

400

300

200

100

0

ø50

VQC

ø63

ø80

ø100

Perpendicular,

upward actuation

Horizontal

actuation

VQ0151

VQ1101

VQ2101

Conditions

VQ4

VQZ

VQD

Conditions

Tube bore x Length

Speed controller

Silencer

Tube bore x Length

Speed controller

Silencer

Tube bore x Length

Speed controller

Silencer

VQ0

VQ5

∗ It is when the cylinder is extending that is meter-out controlled by speed controller which is directly connected with cylinder, and its needle valve

with being fully open.

∗ The average velocity of the cylinder is what the stroke is divided by the total stroke time.

∗ Load factor: ((Load weight x 9.8)/Theoretical force) x 100%

Series

SQ

Series CJ2

Series CM2

Series MB, CA1

T0425 x 1 m

AS2001F-04

AN103-X233

T0604 x 1 m

AS3001F-06

AN103-X233

T0806 x 1 m

AS3001F-08

AN200-KM8

2-4-119

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

VQ1000

Base Mounted

Series

Plug-in Unit

How to Order Manifold

VV5Q 1 1 08 C6 F U1

Series

1

VQ1000

Option

Symbol

Nil

2

B

D

G1

G2

G3

J

K

N

R

S

Manifold

1 Plug-in unit

Stations

01

1 station

···

···

The maximum and minimum

number of stations are

varied depending on kit.

(Refer to the table below.)

Note 1) When two or more symbols are specified, indicate

them alphabetically. Example) -BRS

Note 2) Models with a suffix “-B“ have check valves for

prevention of back pressure at all manifold

stations. If not all stations need this check valve,

specify the stations where check valves are

installed by using the manifold specification sheet.

Note 3) Specify the mounting position in the manifold

specification sheet.

Note 4) Refer to page 2-4-170 for the details of ejector

mounted styles. A combination of “J“ and “N“ is

unavailable.

Note 5) Specify the wiring by means of the manifold

specification sheet. (Except L kit)

Note 6) Indicate “R“ for the valve with external pilot.

Cylinder port

Port size

Symbol

Symbol

With One-touch fitting for ø3.2

C3

With One-touch fitting for ø4

C4

With One-touch fitting for ø6

C6

M5 thread

M5

With mixed size/with port plug (1)

CM

L3 W/ elbow One-touch fitting ø3.2 for top piping

L4 W/ elbow One-touch fitting ø4 for top piping

Option

None

200/220 VAC models (Applicable to F and L kits)

With back pressure check valve (2)

DIN rail mounting

1 set of regulator unit (3)

2 sets of regulator unit (3)

3 sets of regulator unit (3)

With vacuum ejector unit (4)

Special wiring specifications (Not double wiring) (5)

With name plate

External pilot (6)

Built-in silencer, direct exhaust

Port size

L6 W/ elbow One-touch fitting ø6 for top piping

Elbow M5 thread for top piping

L5

B3 W/ elbow One-touch fitting ø3.2 for bottom piping

B4 W/ elbow One-touch fitting ø4 for bottom piping

B6 W/ elbow One-touch fitting ø6 for bottom piping

Elbow M5 thread for bottom piping

B5

Mixed size for elbow piping

LM

Note 1) Specify “Mixed size/with port plug” in the manifold specification sheet.

Note 2) Inch-size One-touch fittings are also available. For details, refer to page 2-4-179.

Note 3) M5 fittings for M5 thread are attached without being incorporated.

Simple specials are available with SMC Simple Specials System.

For details about applicable models, please contact SMC.

Kit/Electrical entry/Cable length

F

kit

(D-sub connector)

P

Top entry

kit

(Flat ribbon cable

connector)

J

kit

(Flat ribbon cable

connector (20P))

Top entry

Note 1)

G

Top entry

The valve is equipped with

Compatible only with 24

VDC valves.

Order separately

SI unit made by

OMRON Corp.

Note 1)

25P

Note 1)

26P

Side entry

Connector entry direction

P. 2-4-130

26P

Side entry

Connector entry direction

P. 2-4-134

Side entry

Connector entry direction

P. 2-4-138

Top entry Side entry

Top entry Side entry

Top entry Side entry

U0

U0

U0

U0

S0 Without cable

S0 Without cable

S0 Without cable

(2)

(2)

(2)

Kit U1 Kit S1 With cable (1.5 m) 2 to 24 Kit U1 Kit S1 With cable (1.5 m) 2 to 24 Kit U1 Kit S1 With cable (1.5 m) 2 to 16 Kit U1

F U2 F S2 With cable (3 m) stations P U2 P S2 With cable (3 m) stations J U2 J S2 With cable (3 m) stations G U2

U3

U3

U3

U3

S3 With cable (5 m)

S3 With cable (5 m)

S3 With cable (5 m)

Note 1) Besides the above, F and P kits with different number of pins are available. Refer to page 2-4-177 for details.

Note 2) For details, refer to page 2-4-178.

2-4-120

Kit

(Flat ribbon cable

connector with power

supply terminal block)

P. 2-4-142

Without cable

With cable (1.5 m)

With cable (3 m)

With cable (5 m)

(2)

2 to 16

stations

Base Mounted

Plug-in Unit Series

How to Order Valves

VQ 1 1 0 0 Y

How to Order Manifold Assembly

Example

5

S

··

1

Metal

Seal

Rubber

0

1

2 position double

Light/Surge

voltage suppressor

Metal seal

Rubber seal

3 position closed center

Symbol

3 position exhaust center

4

5

4 position dual 3 port valve

2

1

D-sub connector

DC

AC

Nil

Standard type

(1.0 W)

Note)

H

High pressure

type

(1.5 W)

—

Y

Low wattage

type

(0.5 W)

—

1

2 Note)

3

4 Note)

5

6

100 VAC (50/60 Hz)

200 VAC (50/60 Hz)

110 VAC (50/60 Hz)

220 VAC (50/60 Hz)

24 VDC

12 VDC

Note) 200/220 VAC

models

are

applicable to F

and L kits.

VQ0

Cylinder ports

C6: With One-touch fitting for ø6

F kit

(D-sub connector)

Manifold base (9 stations)

VV5Q11-09C6FU2

VV5Q11-09C6FU2 ···· 1 set (F kit 9 station manifold base no.)

∗VQ1100-5 ·········· 4 sets (Single solenoid part no.)

∗VQ1200-5 ·········· 4 sets (Double solenoid part no.)

∗VV1000-10A-1 ······ 1 set (Blanking plate part no.)

The asterisk denotes the symbol for assembly.

Prefix it to the part nos. of the solenoid valve, etc.

Specify the part numbers for valves and options together

beneath the manifold base part number. Besides, when the

arrangement will be complicated, specify them by means of

the manifold specification sheet.

Note) For external pilot and negative

COM specifications, refer to

“Option” on pages 2-4-178 to 24-179.

A

5

N.C

Specifications

Note) For power consumption

of AC type, refer to page

2-4-129.

3 position pressure center

SQ

Coil voltage

Function

3

VQC

C: Locking type

(Manual)

Nil

Yes

E Note) None

Note) Inapplicable

to the S kit.

2 position double

4

Blanking plate

VQ1000-10A-1 (1 set)

1 Ds

2 id

3 e

···

···

··

2 position single

Note) (A)

ta

VQ1000

tio U

ns sid

e

Nil: Non-locking B: Push-locking

slotted type

push type

(Tool required)

Type of actuation

2

Double solenoid (24 VDC)

VQ1200-5 (4 sets)

Single solenoid (24 VDC)

VQ1100-5 (4 sets)

Manual override

Series

1

VQ1000

3

N.C

4 position dual 3 port valve

4

2

Note) (B)

B

5

N.O

1

3

N.O

4 position dual 3 port valve

Note) (C)

4

2

Note) Rubber seal type only.

C

5

N.C

T

1

3

N.O

kit

(Terminal box)

L

kit

(Lead wire cable)

S

kit

(Serial transmission unit)

The valve is equipped with an

indicator light and surge voltage

suppressor, and the voltage is 24

VDC. The dust proof SI unit is also

available. Refer to page 2-4-154 for

details.

P. 2-4-154

P. 2-4-146

Kit T

O Terminal block box 2 to 24 stations (2)

Kit

L

0

1

2

0

A

Without SI unit

With general type SI unit (Series EX300)

B

Mitsubishi Electric Corp.:

MELSECNET/MINI-S3 Data Link System

(2)

C

OMRON Corp.: SYSBUS Wire System

Max.16

D

SHARP Corp.: Satellite I/O Link System

stations

E Matsushita Electric Works: MEWNET-F System

F1 NKE Corp.: Uni-wire System (16 output points)

Kit

G Rockwell Automation: Allen Bradley Remote I/O (RIO) System

S

H

NKE Corp.: Uni-wire H System

J1 SUNX Corp.: S-LINK System (16 output points)

Max. 8 stations

J2 SUNX Corp.: S-LINK System (8 output points)

K

Fuji Electric Co.: T-LINK Mini System

Max.16

P. 2-4-150

Q

DeviceNet, CompoBus/D (OMRON Corp.)

stations

R1 OMRON Corp.: CompoBus/S System (16 output points)

With cable (0.6 m)

1 to 8

R2 OMRON Corp.: CompoBus/S System (8 output points) Max. 8 stations

With cable (1.5 m)

stations

Max. 16 stations

V

Mitsubishi Electric Corp.: CC-LINK System

With cable (3 m)

2-4-121

VQ4

VQ5

VQZ

VQD

Base Mounted

Series

VQ1000

Manifold Option

Blanking plate assembly

VVQ1000-10A-1

P. 2-4-208

SUP block plate

VVQ1000-16A

2 stations matching fitting assembly Blanking plug

VVQ1000-52A-C8

KQ2P-

Double check block

VQ1000-FPG-

23

04

06

08

T

CY o

Lp

ort

Individual SUP spacer

VVQ1000-P-1-C6

EXH block base assembly

C3

F

C6

VVQ1000-19A- PL - C4

M5

Elbow fitting assembly

C3

C6

VVQ1000-F-L C4

M5

Silencer (For EXH port)

AN200-KM8/AN203-KM8

C6 (SUP port)

One-touch fitting for ø6

Individual EXH spacer

VVQ1000-R-1-C6

Connector assembly

Back pressure check valve assembly [-B] DIN rail mounting bracket [-D]

VVQ1000-18A

VVQ1000-57A

Regulator unit

VVQ1000-AR-1

• For cylinder port fittings

part no., refer to page 2-4175.

• For replacement parts,

refer to page 2-4-227.

C6 (EXH port)

One-touch fitting for ø6

With vacuum ejector unit

[-J]

Port plug

VVQ0000-58A

Built-in silencer,

Name plate [-N]

N -Station (1 to Max. stations) direct exhaust [-S]

VVQ1000- NC

Exhaust port

2-4-122

Blanking plate with connector

VVQ1000-1C-

2-4-123

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

VQ2000

Base Mounted

Series

Plug-in Unit

How to Order Manifold

VV5Q 2 1

Option

08 C6 F U1

Symbol

Series

2

Manifold

VQ2000

1

Plug-in unit

Kit type

Cylinder port

Stations

01

1 station

···

···

The maximum and

minimum number of

stations are varied

depending on kit.

(Refer to the table

below.)

Symbol

Port size

With One-touch fitting for ø4

With One-touch fitting for ø6

With One-touch fitting for ø8

With mixed size/with port plug (1)

Symbol

C4

C6

C8

CM

L4 W/ elbow One-touch fitting ø4 for top piping

L6 W/ elbow One-touch fitting ø4 for top piping

Port size

W/ elbow One-touch fitting ø8 for top piping

L8

B4 W/ elbow One-touch fitting ø4 for bottom piping

B6 W/ elbow One-touch fitting ø6 for bottom piping

B8 W/ elbow One-touch fitting ø8 for bottom piping

Mixed size for elbow piping

LM

Option

Nil

None

B

Back pressure check valve (2)

D

DIN rail mounting style

K Special wiring specifications (Except double wiring) (3)

N

With name plate

R

External pilot (4)

S

Built-in silencer, direct exhaust

Enclosure: Dust tight/splashproof type

W

(IP65) [T, L, S and M kits only]

Note 1) Specify “Mixed size/with port plug” on the manifold specification

sheet.

Note 2) Inch-size One-touch fittings are available. For details, refer to page

2-4-179.

Simple specials are available with SMC Simple Specials System.

For details about applicable models, Contact SMC.

Note 1) When two or more symbols are

specified,

indicate

them

alphabetically. Example) -DNR.

Note 2) Models with a suffix “-B” have check

valves for prevention of back pressure

at all manifold stations. If not all

stations need this check valve, specify

the stations where check valves are

installed by manifold specification

sheet.

Note 3) Specify the wiring specifications in

the manifold specification sheet.

(Except L kit)

Note 4) Indicate “R” for the valve with

external pilot.

Kit/Electrical entry/Cable length

F

kit

(D-sub connector)

P

kit

(Flat ribbon cable

connector)

J

kit

(Flat ribbon cable

connector (20P))

Side entry

Side entry

Note 1)

Note 1)

25P

Connector entry direction

P. 2-4-130

Compatible only

with 24 VDC valves.

26P

Top entry

Top entry

Connector entry direction

Connector entry direction

P. 2-4-134

P. 2-4-138

Top entry Side entry

Top entry Side entry

Top entry Side entry

U0

U0

U0

U0

S0 Without cable

S0 Without cable

S0 Without cable

(2)

(2)

(2)

Kit U1 Kit S1 With cable (1.5 m) 2 to 24 Kit U1 Kit S1 With cable (1.5 m) 2 to24 Kit U1 Kit S1 With cable (1.5 m) 2 to16 Kit U1

F U2 F S2 With cable (3 m) stations P U2 P S2 With cable (3 m) stations J U2 J S2 With cable (3 m) stations G U2

U3

U3

U3

U3

S3 With cable (5 m)

S3 With cable (5 m)

S3 With cable (5 m)

2-4-124

kit

(Flat ribbon cable

connector with power

supply terminal block)

Note 1)

26P

Top entry

G

P. 2-4-142

Without cable

With cable (1.5 m)

With cable (3 m)

With cable (5 m)

(2)

2 to 16

stations

Base Mounted

Plug-in Unit Series

How to Order Valves

VQ 2 1 0 0 Y

How to Order Manifold Assembly

Example

5

Double solenoid (24 VDC)

VQ2200-5 (4 sets)

Series

Enclosure

VQ2000

Nil

Dust-protected

W Dusttight/Low jetproof type (IP65)

Type of actuation

Blanking plate

VQ2000-10A-1 (1 set)

S

VQC

·

sid

3

N.C

3

D

2

1

ta

Nil: Non-locking B: Push-locking

push type

slotted type

(tool required)

A

5

N.C

U

tio si

ns de

4 position dual 3 port valve

4

2

(A)

···

Note)

e

2 position single

1

Single solenoid (24 VDC)

VQ2100-5 (3 sets)

Manual override

···

2

VQ2000

Metal

B

2 position double

Rubber

2

Note)

4 position dual 3 port valve

4

2

(B)

Note)

C

5

N.O

1

1

2 position double

4 position dual 3 port valve

(C)

4

2

5

N.C

1

3

N.O

Function

Symbol Specifications DC

Standard (1.0 W)

Nil

type

Seal

4

3 position pressure center

0 Metal seal

1 Rubber seal

5

H

Y

Note ) For sub-plate single

unit type, refer to page

2-4-165.

AC

Note)

VQ0

VQ4

D-sub connector

AXT100-DS25-030

F kit

(D-sub connector)

Coil voltage

3

3 position exhaust center

C: Locking type

(Manual)

Nil

Yes

None

E Note)

Note) Inapplicable

to the S kit.

Note) Rubber seal

type only.

3 position closed center

SQ

Light/Surge

voltage suppressor

3

N.O

1

2 Note)

3

4 Note)

5

6

100 VAC (50/60 Hz)

200 VAC (50/60 Hz)

110 VAC (50/60 Hz)

220 VAC (50/60 Hz)

24 VDC

12 VDC

Note) 200/220 VAC

models

are

applicable to F

and L kits.

(1.5 W)

High

—

pressure type

Low wattage (0.5 W)

—

type

Note) For power consumption

of AC type, refer to

page 2-4-129.

Note) For external pilot and negative COM specifications,

Cylinder ports

C8: With One-touch

fitting for ø8

Manifold base (8 stations)

VV5Q21-08C8FU2

VV5Q21-08C8FU2 ··· 1 set (F kit 8 station manifold base no.)

∗VQ2100-5 ········· 3 sets (Single solenoid part no.)

∗VQ2200-5 ········· 4 sets (Double solenoid part no.)

∗VVQ2000-10A-1 ·· 1 set (Blanking plate part no.)

The asterisk denotes the symbol for assembly.

Prefix it to the part nos. of the solenoid valve, etc.

Specify the part numbers for valves and options together

beneath the manifold base part number. Besides, when the

arrangement will be complicated, specify them by means of

the manifold specification sheet.

refer to “Option” on page 2-4-178 to 2-4-179.

T

kit

(Terminal box)

L

kit

(Lead wire cable)

S

kit

(4)

(Serial transmission unit)

The valve is equipped with an indicator light and

surge voltage suppressor, and the voltage is 24

VDC. The dusttight SI unit is available. Refer to

page 2-4-154 for details. Dusttight/splashproof

type (IP65) is also available. (Except SE and SG.)

M

kit

(Multi-connector)

P. 2-4-154

O

A

B

Dust tight/Low jetproof type

(IP65) available P. 2-4-146

Kit T O

Terminal

block box

Note 1)

Note 2)

Note 3)

Note 4)

Without SI unit

With general type SI unit (Series EX300)

Mitsubishi Electric Corp.:

MELSECNET/MINI-S3 Data Link System

(2)

Max.16

stations

(4)

Dust tight/

Mitsubishi Electric Corp.:

jetproof type

BB MELSECNET/MINI-S3 Data Link System(2 power supply lines) Low

Max.16 stations

(IP65) only available

OMRON Corp.: SYSBUS Wire System

C

SHARP Corp.: Satellite I/O Link System

D

(2)

E Matsushita Electric Works: MEWNET-F System

Kit F1 NKE Corp.: Uni-wire System (16 output points) Max.16

S G Rockwell Automation: Allen Bradley Remote I/O (RIO) System stations

NKE Corp.: Uni-wire H System

H

J1 SUNX Corp.: S-LINK System (16 output points)

J2 SUNX Corp.: S-LINK System (8 output points) Max. 8 stations

Dust tight/Low jetproof type

Fuji Electric Co.: T-LINK Mini System

K

(IP65) available P. 2-4-150

Max.16

DeviceNet, CompoBus/D (OMRON Corp.)

Q

stations Kit

0 With cable (0.6 m)

OMRON

Corp.:

CompoBus/S

System

(16

output

points)

R1

1 to 8

Kit

Max.

8 stations M

1 With cable (1.5 m)

R2 OMRON Corp.: CompoBus/S System (8 output points)

stations

L

2 With cable (3 m)

V Mitsubishi Electric Corp.: CC-LINK System Max. 16 stations

2 to 20

stations (2)

Besides the above, F and P kits with different number of pins are available. Refer to page 2-4-177 for details.

For details, refer to page 2-4-178.

Refer to the pages on respective kits for IP65 type. (T, L and S kits)

Kits with IP65 enclosure applicable to input/output are also available. Refer to page 2-4-162 for details.

P. 2-4-162

Without cable

0

(2)

1 With cable (1.5 m) 2 to 24

2 With cable (3 m) stations

3 With cable (5 m)

2-4-125

VQ5

VQZ

VQD

Base Mounted

Series

VQ2000

Manifold Option

P. 2-4-210

Blanking plate assembly

VVQ2000-10A-1

SUP block plate

VVQ2000-16A

DIN rail mounting bracket [-D]

VVQ2000-57A

Port plug

VVQ1000-58A

Individual SUP spacer

VVQ2000-P-1-C8

EXH block plate

VVQ2000-19A

Built-in silencer,

direct exhaust [-S]

Blanking plug

04

08

KQ2P- 06

10

Exhaust port

C8 (SUP port)

One-touch fitting for ø8

Individual EXH spacer

VVQ2000-R-1-C8

Name plate [-N]

VVQ2000-N-Station (1 to Max. stations)

Silencer (For EXH port)

AN200-KM10

• For cylinder port fittings part

no., refer to page 2-4-175.

• For replacement parts, refer to

page 2-4-227.

C8 (EXH port)

One-touch fitting for ø8

Back pressure check valve assembly [-B]

VVQ2000-18A

Elbow fitting assembly

VVQ2000-F-L (C4, C6, C8)

2 stations matching fitting assembly

VVQ2000-52A-C10

Double check block

VQ2000-FPG-

To

CY

Lp

ort

2-4-126

VQC

SQ

VQ0

VQ4

VQ5

VQZ

VQD

2-4-127

VQ1000/2000

Base Mounted

Series

Plug-in Unit

Model

Flow characteristics (1)

4 position

VQ2000

3 position

2 position

4 position

VQ1000

3 position

2 position

Series

Number of

solenoids

1 2/4 (P A/B)

Model

Response time (ms) (2)

2/4 3/5 (A/B R1/R2)

Standard : 1 W Low wattage:

0.5 W

H : 1.5 W

b

Cv

C [dm3/(s·bar)]

b

Cv

VQ1100

0.70

0.15

0.16

0.72

0.25

0.18

12 or less

15 or less

29 or less

Rubber seal

VQ1101

0.85

0.20

0.21

1.0

0.30

0.25

15 or less

20 or less

34 or less

Metal seal

VQ1200

0.70

0.15

0.16

0.72

0.25

0.18

10 or less

13 or less

13 or less

Rubber seal

VQ1201

0.85

0.20

0.21

1.0

0.30

0.25

15 or less

20 or less

20 or less

Closed

center

Metal seal

VQ1300

0.68

0.15

0.16

0.72

0.25

0.18

20 or less

26 or less

40 or less

Rubber seal

VQ1301

0.70

0.20

0.16

0.65

0.42

0.18

25 or less

33 or less

47 or less

Exhaust

center

Metal seal

VQ1400

0.68

0.15

0.16

0.72

0.25

0.18

20 or less

26 or less

40 or less

Rubber seal

VQ1401

0.70

0.20

0.16

1.0

0.30

0.25

25 or less

33 or less

47 or less

Pressure Metal seal

center

Rubber seal

VQ1500

0.70

0.15

0.16

0.72

0.25

0.18

20 or less

26 or less

40 or less

VQ1501

0.85

0.20

0.21

0.65

0.42

0.18

25 or less

33 or less

47 or less

Dual

Rubber seal

3 port valve

A

VQ1B 01

C

0.70

0.20

0.16

0.70

0.20

0.16

25 or less

33 or less

47 or less

Metal seal

VQ2100

2.0

0.15

0.46

2.6

0.15

0.60

22 or less

29 or less

49or less

Rubber seal

VQ2101

2.2

0.28

0.55

3.2

0.30

0.80

24 or less

31 or less

51or less

Metal seal

VQ2200

2.0

0.15

0.46

2.6

0.15

0.60

15 or less

20 or less

20 or less

Rubber seal

VQ2201

2.2

0.28

0.55

3.2

0.30

0.80

20 or less

26 or less

26 or less

Closed

center

Metal seal

VQ2300

2.0

0.15

0.46

2.0

0.18

0.46

29 or less

38 or less

58 or less

Rubber seal

VQ2301

2.0

0.28

0.49

2.2

0.31

0.60

34 or less

44 or less

64 or less

Exhaust

center

Metal seal

VQ2400

2.0

0.15

0.46

2.6

0.15

0.60

29 or less

38 or less

58 or less

Rubber seal

VQ2401

2.0

0.28

0.49

3.2

0.30

0.80

34 or less

44 or less

64 or less

Pressure Metal seal

center

Rubber seal

VQ2500

2.4

0.17

0.57

2.0

0.18

0.46

29 or less

38 or less

58 or less

VQ2501

3.2

0.28

0.80

2.2

0.31

0.60

34 or less

44 or less

64 or less

1.8

0.28

0.46

1.8

0.28

0.46

34 or less

44 or less

64 or less

Metal seal

Single

Double

Single

Double

Dual

Rubber seal

3 port valve

A

VQ2 B 01

C

Note 1) Cylinder port size C6: (VQ1000), C8: (VQ2000) without check valve option for prevention of back pressure.

Note 2) As per JIS B 8375-1981 (Supply pressure; 0.5 MPa; with indicator light/surge voltage suppressor; clean air)

The response time is subject to the pressure and quality of the air. The values at the time of ON are given for double types.

2-4-128

AC

C [dm3/(s·bar)]

Weight

(g)

64

78

90

110

Base Mounted

Plug-in Unit Series

VQ1000/2000

Standard Specifications

Valve specifications

Metal

2 position single

Rubber

Metal seal

Rubber seal

Fluid

Air/Inert gas

Air/Inert gas

Maximum operating pressure

0.7 MPa (High pressure type: 0.8 MPa)

Valve construction

JIS Symbol

2 position double

2 position double

Minimum

operating pressure

Single

0.1 MPa

0.15 MPa

Double

0.1 MPa

0.1 MPa

3 position

0.1 MPa

Push type/Locking type (Tool required, Manual type) Option

Manual override

Impact/Vibration resistance

(2)

12 , 24 VDC, 100, 110, 200, 220 VAC (50/60 Hz)

Coil rated voltage

Solenoid

3 position pressure center

Allowable voltage fluctuation

±10% of rated voltage

Coil insulation type

Class B or equivalent

Power

consumption

(Current)

24 VDC

1 W DC (42 mA), 1.5 W DC (63 mA)

12 VDC

1 W DC (83 mA), 1.5 W DC (125 mA)

, 0.5 W DC (21 mA)

(4)

(3)

, 0.5 W DC (42 mA) (4)

100 VAC

Inrush 1.2 VA (12 mA), Holding 1.2 VA (12 mA)

110 VAC

Inrush 1.3 VA (12 mA), Holding 1.3 VA (12 mA)

200 VAC

Inrush 2.4 VA (12 mA), Holding 2.4 VA (12 mA)

220 VAC

Inrush 2.6 VA (12 mA), Holding 2.6 VA (12 mA)

Porting specifications

Base model

(2)

Port size

Type of connection

Port location

(1)

1(P), 3(R)

4(A), 2(B)

C8 (ø8)

C3 (ø3.2)

Option

C4(ø4)

Built-in

silencer,

direct exhaust

M5 (M5 thread)

Applicable

stations

Applicable

solenoid valve

5 station

weight

(g)

F kit–D-sub connector

P kit–Flat ribbon cable connector

J kit–Flat ribbon cable connector (20P)

VQ1000 VV5Q11-

G kit– Flat ribbon cable connector

with terminal block

T kit–Terminal box

Side

L kit–Lead wire cable

C6 (ø6)

F, P, T kits

2 to 24 stations

J, G, S kit

2 to 16 stations

VQ100

VQ101

L kit

1 to 8 stations

628

(Single)

759

(Double,

3 position)

S kit–Serial transmission unit

F kit–D-sub connector

F, P kits

2 to 24 stations

P kit–Flat ribbon cable connector

C10 (ø10)

J kit–Flat ribbon cable connector (20P)

Option

G kit– Flat ribbon cable connector

with terminal block

Built-in

Side

VQ2000 VV5Q21-

silencer,

T kit–Terminal box

direct exhaust

L kit–Lead wire cable

S kit–Serial transmission unit

M kit–Multi-connector

Note 1) Inch-size One-touch fittings are also available. For details, refer to page 2-4-179.

Note 2) For details, refer to page 2-4-178.

C4 (ø4)

C6 (ø6)

C8 (ø8)

J, G, S kit

2 to 16 stations

L kit

1 to 8 stations

T kit

2 to 20 stations

VQ200

VQ201

1051

(Single)

1144

(Double,

3 position)

R port

R port

P port

Type of connection

P port

A, B port

VQ0

VQ4

(3)

Note 1) Use dry air to prevent condensation when operating at low temperatures.

Note 2) Impact resistance ··· No malfunction occurred when it is tested with a drop tester in the axial direction

and at the right angles to the main valve and armature in both energized and deenergized states every once for each condition. (Values at the initial period)

Vibration resistance ··· No malfunction occurred in a one-sweep test between 45 and 2000 Hz. Test was

performed at both energized and de-energized states in the axial direction and at

the right angles to the main valve and armature. (Values at the initial period)

Note 3) Value for high voltage type (1.5 W)

Note 4) Value for low voltage type (0.5 W)

Note 5) Dusttight/Low jetproof type (IP65) is available on T, L, S and M kits of VQ2000.

Manifold Specifications

Series

SQ

150/30 m/s2

Dust-protected, Dust tight/Low jetproof type (IP65) (5)

Enclosure

3 position exhaust center

VQC

Not required

Lubrication

3 position closed center

0.2 MPa

–10 to 50°C (1)

Ambient and fluid temperature

A, B port

Type of connection

2-4-129

VQ5

VQZ

VQD

F

VQ1000/2000

Kit (D-sub connector)

VV5Q11

The D-sub connector reduces installation labor for electrical

connections.

Using the D-sub connector (25P), (15P as an option) conforming to

MIL standard permits the use of connectors put on the market and

gives a wide interchangeability.

Top or side receptacle position can be selected in accordance with

the available mounting space.

Maximum stations are 24.

VV5Q21

Manifold Specifications

Porting specifications

Series

Applicable

stations

Port size

Port

locaition 1(P), 3(R) 4(A), 2(B)

VQ1000

Side

C8

VQ2000

Side

C10

C3, C4, C6, M5 Max. 24 stations

C4, C6, C8

Max. 24 stations

D-sub Connector (25 pins)

Cable Assembly 015

AXT100-DS25- 030

050

Wire Color by Terminal No. of

D-sub Connector Cable Assembly

The D-sub connector cable assembly can be ordered individually or

included in a specific manifold model no. Refer to How to Order Manifold.

Electric

D-sub Connector Cable Assembly (Option) Characteristics

Multi-core vinyl cable

0.3 mm2 x 25C

Cable

length (L)

1.5 m

3m

5m

L

~

= ø10

Assembly part no.

Note

AXT100-DS25-015

AXT100-DS25-030

AXT100-DS25-050

Cable 25 core

x 24AWG

8

44

∗ For other commercial connectors, use a 25 pins type

with female connector conforming to MIL-C-24308.

Connector manufacturers’ example

Socket side

25

16

14

• Fujitsu Limited

• Japan Aviation Electronics Industry, Ltd.

• J.S.T. Mfg. Co., Ltd.

• Hirose Electric Co., Ltd.

2-M2.6 x 0.45

55

13

1

Item

Characteristics

Conductor

65 or

resistance

less

Ω/km, 20°C

Voltage limit

1000

V, 1 min, AC

Insulation

5 or

resistance

more

MΩkm, 20°C

Note) The min. bending

radius of D-sub

cable assembly is

20 mm.

Terminal no.

47.04

Note) Types with 15 pin are also available. Refer to page 2-4-177 for details.

Terminal no. Lead wire color Dot marking

1

None

Black

2

None

Brown

3

None

Red

4

None

Orange

5

None

Yellow

6

None

Pink

7

None

Blue

8

White

Purple

9

Black

Gray

10

Black

White

11

Red

White

12

Red

Yellow

13

Red

Orange

14

Black

Yellow

15

Black

Pink

16

White

Blue

17

None

Purple

18

None

Gray

19

Black

Orange

20

White

Red

21

White

Brown

22

Red

Pink

23

Red

Gray

24

White

Black

25

None

White

How to Order Manifold

VV5Q 1 1

08 C6

F

U 1

Option

N

Symbol

Nil

B

Series

1

2

D

VQ1000

VQ2000

Connector entry

direction

U

S

Top entry

Side entry

Cable (Length)

0

1

2

3

G1

Without cable

G2

With cable (1.5 m)

G3

J

With cable (3 m)

With cable (5 m)

Cylinder port

Manifold

1

Plug-in unit

02

2 stations

···

···

Stations

24

24 stations

Note) For details,

refer to page

2-4-178.

2-4-130

Symbol

C3

C4

C6

C8

M5

CM

Port size

VQ1000

VQ2000

With One-touch fitting for ø3.2

With One-touch fitting for ø4

With One-touch fitting for ø6

M5 thread

With mixed size/with port plug

N

R

S

With One-touch fitting for ø8

K

(3)

Note 1) Insert “L” (top piping) or “B” (bottom

piping) for elbow type. Example) B6

(Elbow One-touch fittings for ø6,

bottom piping.)

Note 2) Indicate “LM” for models with elbow

fittings and mixed cylinder port sizes.

Note 3) Specify “Mixed size/with port plug” in

the manifold specification sheet.

Note 4) Inch-size One-touch fittings are

available. For details, refer to page 2-4179.

VQ1000 VQ2000 Note

Option

None

(2)

With back pressure check valve DIN rail mounting style

1 set of regulator unit

(3)

2 sets of regulator unit

3 sets of regulator unit

(4)

With vacuum ejector unit

Special wiring specifications

(5)

(Not double wiring)

With name plate

(6)

External pilot

Built-in silencer, direct exhaust

Note 1) When two or more symbols are specified,

indicate them alphabetically. Example) -BRS

Note 2) Models with a suffix “-B” have check

valves for prevention of back pressure at

all manifold stations. If not all stations

need this check valve, specify the stations

where check valves are installed by using

the manifold specification sheet.

Note 3) Specify the mounting position in the

manifold specification sheet.

Note 4) Refer to page 2-4-170 for the details of

ejector mounted styles. A combination of

“J” and “N” is unavailable.

Note 5) Specify the wiring by using of the

manifold specification sheet.

Note 6) Indicate “R” for the valve with external pilot.

Base Mounted

Plug-in Unit Series

VQ1000/2000

ta U s

tio ide

ns

VQC

2

3

D

sid

···

e

···

·

S

SQ

1

Electrical

wiring specifications

D-sub connector assembly

015

AXT100-DS25- 030 Wire color

050

D-sub connector

Terminal no.

{

2 stations

{

3 stations

{

4 stations

{

5 stations

{

6 stations

{

Connector

terminal no.

7 stations

{

As the standard electrical wiring

specifications, double wiring 8 stations {

(connected to SOL. A and SOL.

9 stations

{

B) is adopted for the internal

wiring of each station for 12 10 stations

{

stations or less, regardless of

11 stations

valve and option types.

{

Mixed single and double wiring is

available as an option. For details, 12 stations {

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

SOL.A

SOL.B

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

refer to page 2-4-178.

COM.

13

1 station

ns

1

2

3

D

···

VV5Q21

Note) When using the negative common

specifications, use valves for negative

common. (Refer to page 2-4-178.)

For details, refer to “Option” on page 2-4-178.

The total number of stations is tabulated

starting from station one on the D side.

How to Order Valves

5

Manual override

VQ1000

VQ2000

Nil Non-locking push type (Tool required)

Locking type (Tool required)

B

Locking type (Manual)

C

Type of actuation

2 position single

Light/Surge voltage suppressor

2 position double

3 position closed center

Nil

3 position exhaust center

E

Yes

None

Rubber seal

VV5Q11-09C6FU2 ···· 1 set –Manifold base no.

*VQ1100-5 ············· 2 sets–Valve part no. (Stations 1 to 2)

*VQ1200-5 ············· 4 sets–Valve part no. (Stations 3 to 6)

*VQ1300-5 ············· 2 sets–Valve part no. (Stations 7 to 8)

*VVQ1000-10A-1 ······ 1 set–Blanking plate part no. (Station 9)

Prefix the asterisk to

the part nos. of the

solenoid valve, etc.

High

(1.5 W) —

pressure type

Low wattage (0.5 W) —

Y

type

Note) For power consumption of

AC type, refer to page 2-4129.

U

S side

ta

tio

ns

···

e

···

100 VAC (50/60 Hz)

200 VAC (50/60 Hz)

110 VAC (50/60 Hz)

220 VAC (50/60 Hz)

24 VDC

12 VDC

sid

Symbol Specifications DC

AC

Standard (1.0 W) Note)

Nil

type

1

2

3

4

5

6

Write sequentially from the

1st station on the D side.

When part nos. written

collectively

are

complicated, specified by

using

the

manifold

specification sheet.

3

Function

H

Note) For external pilot and

negative

COM

specifications, refer to

“Option” on pages 2-4178 to 2-4-179.

Note)

<Example>

D-sub connector kit with cable (3 m)

D

Metal seal

None

Black

None

Black

None

White

None

None

None

None

None

Black

None

White

White

White

Black

Red

Black

Red

Red

White

Red

None

Red

2

0

1

Positive common Negative common

specifications

specifications

Coil voltage

3 position pressure center

Seal

Black

Yellow

Brown

Pink

Red

Blue

Orange

Purple

Yellow

Gray

Pink

Orange

Blue

Red

Purple

Brown

Gray

Pink

White

Gray

White

Black

Yellow

White

Orange

Specify the part numbers for valves and options

together beneath the manifold base part number.

Series

1

2

3

4

5

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(+)

(–)

How to Order Manifold Assembly

VQ 1 1 0 0 Y

1

2

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(–)

(+)

VQ4

Lead wire color Dot marking

1

sid

e

···

···

···

S

ta

tio

U

sid

e

VV5Q11

Polarity

VQ0

2-4-131

VQ5

VQZ

VQD

F

VQ1000/2000

Kit (D-sub connector)

VQ1000

The broken lines indicate the DIN rail mounting style [-D] and the side entry connection [-FS].

Applicable connector:

D-sub connector

(Conforming to MIL-C-24308)

P = 10.5

Indicator light

Manual

override

~

=2

Mounting hole for M4

Stations

D side

1

2

3

4

5

6

7

8

n

U side

3(R) EXH port

DIN rail clamp screw

2n-C3, C4, C6, M5

C3: One-touch fitting for ø3.2

C4: One-touch fitting for ø4

C6: One-touch fitting for ø6

M5: M5 thread

< >: AC

1(P) SUP port

< >: AC

Dimensions

n

L

L1

L2

(L3)

(L4)

2

65.5

83.5

112.5

123

3

76

94

125

135.5

4

86.5

104.5

125

135.5

5

97

115

137.5

148

6

107.5

125.5

150

160.5

7

118

136

162.5

173

8

128.5

146.5

175

185.5

9

139

157

187.5

198

10

149.5

167.5

187.5

198

11

160

178

200

210.5

12

170.5

188.5

212.5

223

Formula L1 = 10.5n + 44.5, L2 = 10.5n + 62.5

n: Station (Maximum 24 stastions)

13

181

199

225

235.5

20

254.5

272.5

300

310.5

Vacuum ejector unit style: Formula L1 = 10.5n + 28.7 + (Number of ejector units x 26.7)

L2 = 10.5n + 46.3 + (Number of ejector units x 26.7)

L4 is L2 plus about 30.

2-4-132

14

191.5

209.5

237.5

248

15

202

220

250

260.5

16

212.5

230.5

250

260.5

17

223

241

262.5

273

18

233.5

251.5

275

285.5

19

244

262

287.5

298

21

265

283

312.5

323

22

275.5

293.5

325

335.5

23

286

304

325

335.5

24

296.5

314.5

337.5

348

Base Mounted

Plug-in Unit Series

VQ1000/2000

VQ2000

The broken lines indicate the DIN rail mounting style [-D] and the side entry connection [-FS].

VQC

SQ

Applicable connector: D-sub connector (25P)

(Conforming to MIL-C-24308)

VQ0

Indicator light

VQ4

Manual

override

VQ5

VQZ

VQD

~

=4

Mounting hole for 4-M5

D side

Stations

1

2

3

4

5

6

7

8

n

U side

3(R) EXH port

DIN rail clamp screw

< >: AC

Dimensions

n

L

L1

L2

(L3)

(L4)

P = 16

2n-C4, C6, C8

C3: One-touch fitting for ø3.2

C4: One-touch fitting for ø4

C6: One-touch fitting for ø6

C8: One-touch fitting for ø8

1(P) SUP port

Formula L1 = 16n + 53, L2 = 16n + 73

2

85

105

137.5

148

3

101

121

150

160.5

4

117

137

162.5

173

5

133

153

187.5

198

6

149

169

200

210.5

7

165

185

212.5

223

8

9

181 197

201 217

225 250

235.5 260.5

10

213

233

262.5

273

11

229

249

275

285.5

12

245

265

300

310.5

13

261

281

312.5

323

14

277

297

325

335.5

15

293

313

337.5

348

16

309

329

350

360.5

17

325

345

375

385.5

18

341

361

387.5

398

19

357

377

400

410.5

n: Station (Maximum 24 stations)

20

373

393

412.5

423

21

22

389 405

409 425

437.5 450

448 460.5

23

24

421 437

441 457

462.5 487.5

473 498

2-4-133

P

VQ1000/2000

Kit (Flat ribbon cable connector)

VV5Q11

VV5Q21

Manifold Specifications

MIL flat ribbon cable connector reduces installation labor for

electrical connection.

Using the connector for flat ribbon cable (26P) conforming to MIL

standard permits the use of connectors put on the market and

gives a wide interchangeability.

Top or side receptacle position can be selected in accordance with

the available mounting space.

Maximum stations are 24.

Porting specifications

Series

Port size

Port

location 1(P), 3(R)

4(A), 2(B)

Side

C8

VQ2000

Side

C10

C3, C4, C6, M5 Max. 24 stations

C4, C6, C8

Max. 24 stations

···

D

1

2

3

Cable assembly ···

sid

·

e

S

ta

tio

Flat Ribbon Cable (26 pins)

ns

U

sid

e

VQ1000

Applicable

stations

1

AXT100-FC26-to3

Flat ribbon cable connector assembly can be ordered individually or

included in a specific manifold model no. Refer to How to Order Manifold.

Red

1

2

3

D

···

sid

···

e

···

···

···

·

Terminal no.

S

ta

tio

ns

U

sid

e

VV5Q11

Flat Ribbon Cable Connector Assembly (Option)

Cable length (L)

Assembly part no.

Note

1.5 m

3m

5m

AXT100-FC26-1

AXT100-FC26-2

AXT100-FC26-3

Cable 26 core

x 28AWG

∗ For other commercial connectors, use a 26 pins type with strain

relief conforming to MIL-C-83503.

VV5Q21

Connector manufacturers’ example

• Hirose Electric Co., Ltd.

• Sumitomo 3M Limited

• Fujitsu Limited

• Japan Aviation Electronics Industry, Ltd.

• J.S.T. Mfg. Co., Ltd.

• Oki Electric Cable Co., Ltd.

The total number of stations is tabulated starting from

one on the D side.

How to Order Manifold

VV5Q 1 1 08 C6

Connector entry

direction

VQ1000

VQ2000

U

S

Plug-in unit

02

2 stations

···

···

Stations

24 24 stations

Note) For details, refer

to page 2-4-178.

2-4-134

Top entry

Side entry

0

1

2

3

Without cable

With cable (1.5 m)

With cable (3 m)

With cable (5 m)

Cylinder port

Manifold

1

Option

N

Cable (Length)

Series

1

2

P

U 1

Symbol

Port size

VQ1000 VQ2000

C3 With One-touch fitting for ø3.2

C4

With One-touch fitting for ø4

C6

With One-touch fitting for ø6

C8

With One-touch fitting for ø8

M5

M5 thread

(3)

CM With mixed size/with port plug

Note 1) Insert “L” (top piping) or “B” (bottom

piping) for elbow type.

Example) B6 (Elbow One-touch fittings for

ø6, bottom piping.)

Note 2) Indicate “LM” for models with elbow

fittings and mixed cylinder port sizes.

Note 3) Specify “Mixed size/with port plug” in the

manifold specification sheet.

Note 4) Inch-size One-touch fittings are available.

For details, refer to page 2-4-179.

Symbol

Option

VQ1000 VQ2000 Note

None

Nil

(2)

Back pressure check valve

B

DIN rail mounting style

D

1 set of regulator unit

G1

(3)

2 sets of regulator unit

G2

3 sets of regulator unit

G3

(4)

J With vacuum ejector unit

K

Special Wiring Specifications

(Not double wiring)

N

R

S

With name plate

External pilot

Built-in silencer, direct exhaust

(5)

(6)

Note 1) When two or more symbols are specified,

indicate them alphabetically. Example) -BRS

Note 2) Models with a suffix “-B” have check valves

for prevention of back pressure at all

manifold stations. If not all stations need this

check valve, specify the stations where

check valves are installed by using the

manifold specification sheet.

Note 3) Specify the mounting position in the manifold

specification sheet.

Note 4) Refer to page 2-4-170 for the details of

ejector mounted styles. A combination of “J”

and “N” is unavailable.

Note 5) Specify the wiring specifications in the

manifold specification sheet.

Note 6) Indicate “R” for the valve with external pilot.

Base Mounted

VQ1000/2000

Plug-in Unit Series

VQC

SQ

VQ0

VQ4

Electrical wiring specifications

Terminal no.

SOL.A 1

SOL.B 2

SOL.A 3

SOL.B 4

SOL.A 5

SOL.B 6

SOL.A 7

SOL.B 8

SOL.A 9

SOL.B 10

SOL.A 11

SOL.B 12

SOL.A 13

SOL.B 14

SOL.A 15

SOL.B 16

SOL.A 17

SOL.B 18

SOL.A 19

SOL.B 20

SOL.A 21

SOL.B 22

SOL.A 23

SOL.B 24

COM. 25

COM. 26

Electrical wiring specifications

Note) When using the negative common

specifications, use valves for negative

common. (Refer to page 2-4-178.)

For details, refer to “Option” on page 2-4178.

How to Order Valves

How to Order Manifold Assembly

Manual override

Nil Non-locking push type (Tool required)

B Locking type (Tool required)

C

Locking type (Manual)

Light/Surge voltage suppressor

Coil voltage

Function

Seal

0

1

Yes

None

Metal seal

Rubber seal

Symbol Specifications DC

AC

Note)

Standard (1.0 W)

Nil

type

(1.5 W)

H High pressure type

Note) For external pilot and negative

COM specifications, refer to

“Option” on pages 2-4-178 to

2-4-179.

Prefix the asterisk to

the part nos. of the

solenoid valve, etc.

1 100 VAC (50/60 Hz)

3 110 VAC (50/60 Hz)

24 VDC

5

12 VDC

6

e

E

sid

Nil

U

2 position single

2 position double

3 position closed center

3 position exhaust center

3 position pressure center

sid

1

2

3

4

5

Y

—

Write sequentially from the

1st station on the D side.

When part nos. written

collectively are complicated,

specified by using the

manifold

specification

sheet.

tio

Type of actuation

VV5Q11-09C6PU2 ··· 1 set–Manifold base no.

∗VQ1100-5 ············ 2 sets–Valve part no. (Stations 1 to 2)

∗VQ1200-5 ············ 4 sets–Valve part no. (Stations 3 to 6)

∗VQ1300-5 ············ 2 sets–Valve part no. (Stations 7 to 8)

∗VVQ1000-10A-1 ······ 1 set–Blanking plate no. (Station 9)

ta

VQ1000

VQ2000

D

1

2

<Example>

Flat ribbon cable kit with 3 m cable

S

Series

ns

5

··

VQ 1 1 0 0 Y

Specify the part numbers for valves and options

together beneath the manifold base part number.

e

Triangle mark

indicator position

VQD

···

Connector

terminal no.

VQZ

As the standard electrical wiring specifications,

double wiring (connected to SOL. A and SOL. B) is

adopted for the internal wiring of each station for 12

stations or less, regardless of valve and option types.

Mixed single and double wiring is available as an

option.

For details, refer to page 2-4-178.

3

2 stations

2

{

{

3 stations {

4 stations {

5 stations {

6 stations {

7 stations {

8 stations {

9 stations {

10 stations {

11 stations {

12 stations {

1 station

VQ5

Polarity

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(–)

(+)

(+)

(–)

(+)

(–)

Note)

Positive

Negative

common

common

specifications specifications

1

Flat ribbon cable connector

Low wattage (0.5 W) —

type

Note) For power consumption of AC

type, refer to page 2-4-129.

2-4-135

P

VQ1000/2000

Kit (Flat ribbon cable connector)

VQ1000

The broken lines indicate the DIN rail mounting style [-D] and the side entry connection [-PS].

Applicable connector: Flat ribbon cable connector (26P)

(Conforming to MIL-C-83503)

P = 10.5

Indicator light

Manual

override

≅2

Mounting hole for M4

D side

Stations ···· 1 ···· 2 ···· 3 ···· 4 ···· 5 ····6 ····7 ···· 8 ···· n

U side

3(R) EXH port

DIN rail clamp screw

2n-C3, C4, C6, M5

C3: One-touch fitting for ø3.2

C4: One-touch fitting for ø4

C6: One-touch fitting for ø6

M5: M5 thread

< >: AC

Dimensions

n

L

L1

L2

(L3)

(L4)

Formula L1 = 10.5n + 44.5, L2 = 10.5n + 57.5

2

65.5

78.5

112.5

123

3

76

89

125

135.5

4

86.5

99.5

125

135.5

5

97

110

137.5

148

6

107.5

120.5

150

160.5

7

118

131

162.5

173

8

128.5

141.5

175

185.5

9

139

152

187.5

198

10

149.5

162.5

187.5

198

11

160

173

200

210.5

12

170.5

183.5

212.5

223

13

181

194

225

235.5

Vacuum ejector unit style: Formula L1 = 10.5n + 28.7 + (Number of ejector units x 26.7)

L2 = 10.5n + 41.3 + (Number of ejector units x 26.7)

L4 is L2 plus about 30.

2-4-136

1(P) SUP port

14

191.5

204.5

225

235.5

15

202

215

237.5

248

16

212.5

225.5

250

260.5

17

223

236

262.5

273

18

233.5

246.5

275

285.5

19

244

257

287.5

298

n: Station (Maximum 24 stations)

20

254.5

267.5

287.5

298

21

265

278

300

310.5

22

275.5

288.5

312.5

323

23

286

299

325

335.5

24

296.5

309.5

337.5

348

Base Mounted

Plug-in Unit Series

VQ1000/2000

VQ2000

The broken lines indicate the DIN rail mounting style [-D] and the side entry connection [-PS].

Applicable connector: Flat ribbon cable connector (26P)

(Conforming to MIL-C-83503)

VQC

P = 16

SQ

Indicator light

Manual

override

VQ0

VQ4

VQ5

VQZ

VQD

Mounting hole for 4-M5

D side

Stations ···· 1 ····· 2 ····· 3 ····· 4 ····· 5 ····· 6 ·····7 ····· 8 ····· n

U side

3(R) EXH port

DIN rail clamp screw

2n-C4, C6, C8

C4: One-touch fitting for ø4

C6: One-touch fitting for ø6

C8: One-touch fitting for ø8

< >: AC

Dimensions

n

L

L1

L2

(L3)

(L4)

1(P) SUP port

Formula L1 = 16n + 53, L2 = 16n + 68

2

85

100

125

135.5

3

101

116

150

160.5

4

117

132

162.5

173

5

133

148

175

185.5

6

149

164

187.5

198

7

165

180

212.5

223

8

181

196

225

235.5

9

197

212

237.5

248

10

213

228

262.5

273

11

229

244

275

285.5

12

245

260

287.5

298

13

261

276

300

310.5

14

277

292

312.5

323

15

293

308

337.5

348

16

309

324

350

360.5

17

325

340

362.5

373

18

341

356

387.5

398

n: Station (Maximum 24 stations)

19

357

372

400

410.5

20

373

388

412.5

423

21

389

404

425

435.5

22

405

420

450

460.5

23

421

436

462.5

473

24

437

452

475

485.5

2-4-137

J

VQ1000/2000

Kit (Flat ribbon cable connector)

VV5Q11

MIL flat ribbon cable connector reduces installation labor for electrical

connection.

The use of flat ribbon cable connectors (20P) conforming to MIL

standards provides a wide range of compatibility with conventional

connectors.

Top or side receptacle position can be selected in accordance with the

available mounting space.

Maximum stations are 16.

VV5Q21

Manifold Specifications

Porting specifications

Series

Applicable

stations

VQ1000

Side

C8

C3, C4, C6, M5

Max. 16 stations

VQ2000

Side

C10

C4, C6, C8

Max. 16 stations

2

3

···

···

·

D

Cable assembly S

sid

ta

e

tio

ns

U

sid

e

Flat Ribbon Cable (26 pins)

Port size

Port

location 1(P), 3(R)

4(A), 2(B)

1

1

AXT100-FC20- to3

Flat ribbon cable connector assembly can be ordered individually or

included in a specific manifold model no. Refer to How to Order Manifold.

Red

ns

1

2

3

D

···

sid

e

···

···

···

···

···

··

Terminal no.

S

ta

tio

19

U

20

sid

e

30

VV5Q11

Flat Ribbon Cable Connector Assembly (Option)

Cable length (L)

Assembly part no.

Note

1.5 m

3m

5m

AXT100-FC20-1

AXT100-FC20-2

AXT100-FC20-3

Cable 20 core

x 28AWG

∗ For other commercial connectors, use a 20 pins with strain relief

conforming to MIL-C-83503.

VV5Q21

Connector manufacturers’ example

• Hirose Electric Co., Ltd.

• Sumitomo 3M Limited

• Fujitsu Limited

• Japan Aviation Electronics Industry, Ltd.

• J.S.T. Mfg. Co., Ltd.

• Oki Electric Cable Co., Ltd.

The total number of stations is tabulated starting from

one on the D side.

How to Order Manifold

VV5Q 1 1 08 C6

VQ1000

VQ2000

U

S

Plug-in unit

Stations

···

2 stations

···

02

16

16 stations

Note) For details, refer

to page 2-4-178.

2-4-138

Top entry

Side entry

Option

N

Cable (Length)

0

1

2

3

Without cable

With cable (1.5 m)

With cable (3 m)

With cable (5 m)

Cylinder port

Manifold

1

U 1

Connector

entry direction

Series

1

2

J

Symbol

C3

C4

C6

C8

M5

CM

Port size

VQ1000 VQ2000

With One-touch fitting for ø3.2

With One-touch fitting for ø4

With One-touch fitting for ø6

With One-touch fitting for ø8

M5 thread

(3)

With mixed size/with port plug

Note 1) Insert “L” (top piping) or “B” (bottom

piping) for elbow type.

Example) B6 (Elbow One-touch fittings for

ø6, bottom piping.)

Note 2) Indicate “LM” for models with elbow

fittings and mixed cylinder port sizes.

Note 3) Specify “Mixed size/with port plug” in the

manifold specification sheet.

Note 4) Inch-size One-touch fittings are available.

For details, refer to page 2-4-179.

Symbol

Option

VQ1000 VQ2000

Nil

None

B Back pressure check valve

DIN rail mounting style

D

1 set of regulator unit

G1

2 sets of regulator unit

G2

3 sets of regulator unit

G3

With vacuum ejector unit

J

K

Special Wiring Specifications

(Not double wiring)

Note

(2)

(3)

(4)

(5)

With name plate

N

(6)

External pilot

R

S Built-in silencer, direct exhaust Note 1) When two or more symbols are specified,

indicate them alphabetically. Example) BRS

Note 2) Models with a suffix “-B” have check valves

for prevention of back pressure at all

manifold stations. If not all stations need

this check valve, specify the stations

where check valves are installed by using

the manifold specification sheet.

Note 3) Specify the mounting position in the

manifold specification sheet.

Note 4) Refer to page 2-4-170 for the details of

ejector mounted styles. A combination of

“J” and “N” is unavailable.

Note 5) Specify the wiring specifications in the

manifold specification sheet.

Note 6) Indicate “R” for the valve with external

pilot.

Base Mounted

VQ1000/2000

Plug-in Unit Series

VQC

SQ

VQ0

VQ4

Electrical wiring specifications

VQ5

Terminal no.

Flat ribbon cable connector

20

18

16

14

12

10

8

6

4

2

19

17

15

13

11

9

7

5

3

1

1 station

SOL.A

SOL.B

2 stations

SOL.A

SOL.B

3 stations

SOL.A

SOL.B

4 stations

SOL.A

SOL.B

Triangle mark

indicator position 5 stations

SOL.A

SOL.B

6 stations

SOL.A

SOL.B

7 stations

SOL.A

SOL.B

8 stations

SOL.A

SOL.B

Connector terminal no.

Polarity

20

18

(–)

(–)

(+)

(+)

16

14

12

10

(–)

(–)

(+)

(+)

(–)

(–)

(+)

(+)

8

6

(–)

(–)

(+)

(+)

19

17

(–)

(–)

(+)

(+)

15

13

(–)

(–)

(+)

(+)

11

9

7

5

(–)

(–)

(+)

(+)

(–)

(–)

(+)

(+)

(+)

(+)

(–)

(–)

As the standard electrical wiring specifications, double wiring (connected to SOL. A

and SOL. B) is adopted for the internal wiring of each station for 12 stations or less,

regardless of valve and option types.

Mixed single and double wiring is available as an option.

For details, refer to page 2-4-178.

Note) When using the negative common specifications, use valves for

negative common. (Refer to page 2-4-178.)

For details, refer to “Option” on page 2-4-178.

4

3

COM

COM

2

1

Note)

Positive common Negative common

specifications

specifications

How to Order Valves

How to Order Manifold Assembly

VQ 1 1 0 0 Y

Specify the part numbers for valves and options

together beneath the manifold base part number.

5

Manual override

Series

Nil Non-locking push type (Tool required)

B Locking type (Tool required)

C

Locking type (Manual)

VQ1000

VQ2000

Type of actuation

Light/Surge voltage suppressor

2 position single

Nil

2 position double

E

3 position closed center

Coil voltage

Function

Note) For external pilot and negative

COM specifications, refer to

“Option” on pages 2-4-178 to

2-4-179.

Y

Low wattage (0.5 W)

type

···

High pressure (1.5 W)

type

e

H

·

S

ta

U

sid

tio e

ns

When ordering, specify the part

nos. in order from the 1st.

station in the D side. When part

nos. written collectively are

complicated, specify by using

the manifold specification sheet.

···

Rubber seal

sid

Seal

Metal seal

24 VDC

Symbol Specifications DC

Standard (1.0 W)

Nil

type

D