FLIR Technical Series

Application Note for Research & Science

NDT in Composite Materials

with Flash, Transient, and Lockin Thermography

Markus Tarin and Ralph Rotolante

MoviTHERM, Inc.

Abstract

Composites are now used in everything from aircraft to prosthetics.

This paper will discuss three thermographic NDT techniques currently in

use for the detection and measurement of defects in composites such

as impact damage, delamination, voids, inclusions, and stresses. The

particular technique that should be employed for optimum results, whether

pulsed flash, pulsed transient, or lock-in, will depend upon the sample

material and thickness, and the test environment. Choice of camera type

also varies widely, from cooled to uncooled, with large format 640 × 480

pixels now available.

Introduction

Infrared cameras are used in a wide variety of military and civil

applications. These cameras typically operate with a temperature

sensitivity of about 15 mK for cooled and 80 mK for uncooled, certainly

sensitive enough for most applications.

Occasionally, and especially in many NDT applications, a more sensitive

measurement is needed. Infrared Pulse and Lock-In Thermography give a

much better sensitivity—100 times to 1000 times better.

Pulse and Lock-In Thermography are in use for NDT applications worldwide:

for defect imaging, stress imaging, solar-cell shunt imaging, solar-cell

carrier-density/lifetime imaging, and semiconductor photo- and electroluminescence imaging.

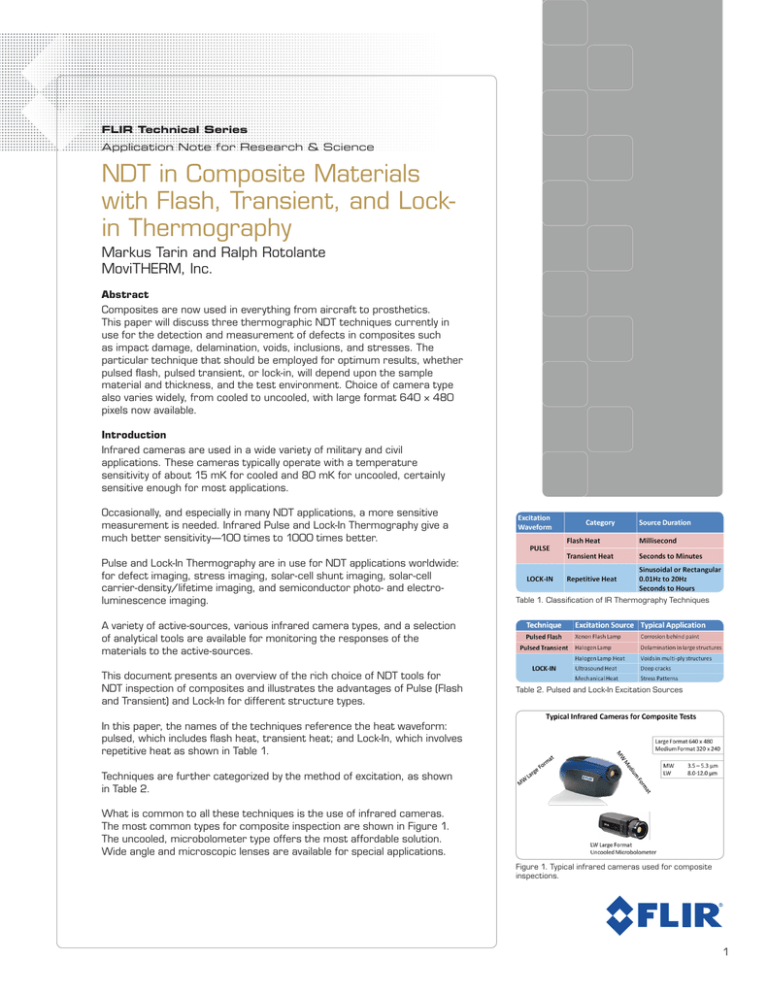

Table 1. Classification of IR Thermography Techniques

A variety of active-sources, various infrared camera types, and a selection

of analytical tools are available for monitoring the responses of the

materials to the active-sources.

This document presents an overview of the rich choice of NDT tools for

NDT inspection of composites and illustrates the advantages of Pulse (Flash

and Transient) and Lock-In for different structure types.

Table 2. Pulsed and Lock-In Excitation Sources

In this paper, the names of the techniques reference the heat waveform:

pulsed, which includes flash heat, transient heat; and Lock-In, which involves

repetitive heat as shown in Table 1.

Techniques are further categorized by the method of excitation, as shown

in Table 2.

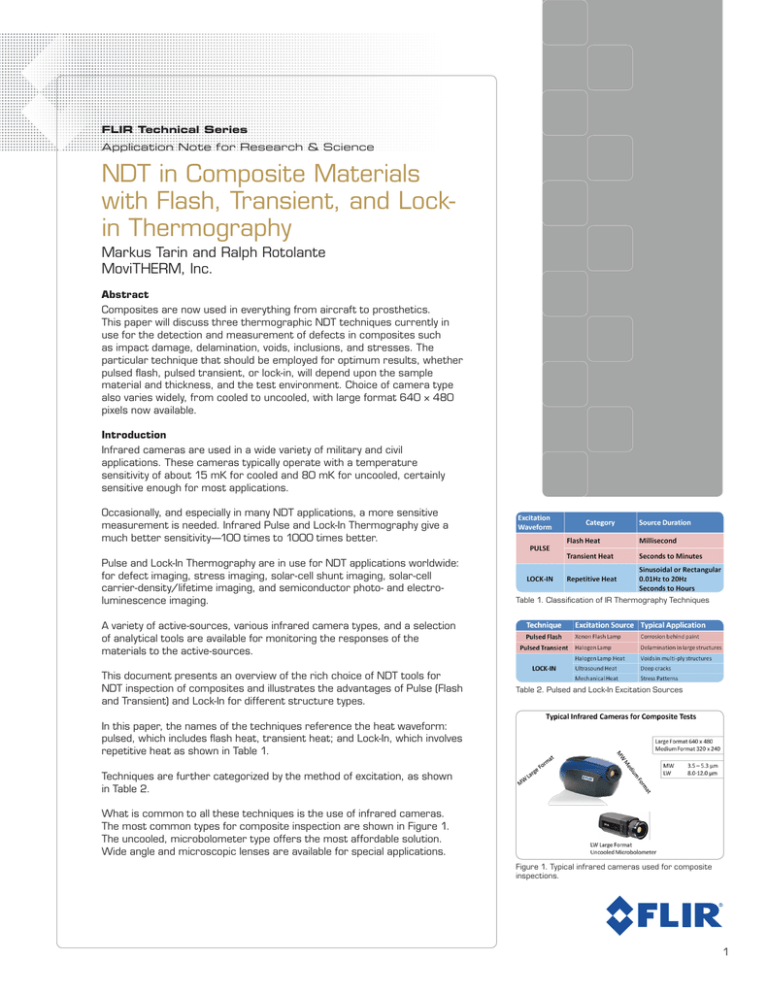

What is common to all these techniques is the use of infrared cameras.

The most common types for composite inspection are shown in Figure 1.

The uncooled, microbolometer type offers the most affordable solution.

Wide angle and microscopic lenses are available for special applications.

Figure 1. Typical infrared cameras used for composite

inspections.

1

Pulsed Thermography – Principles of Operation

In pulsed thermography, the stimulus is applied with a xenon flash lamp for

a flash pulse or with a halogen lamp in the transient case. In both cases,

the equipment set-up is as indicated in Figure 2.

Figure 2. Equipment set-up for Pulse Thermography—

Flash or Transient

Solving the Heat Conduction Equation tells us that the thermal propagation

time to the depth of 2 mm to a subsurface defect is about 40 ms in

aluminum and for 2 mm of graphite epoxy is about 30s. This means Flash is

better for materials of high thermal diffusivity, e.g., metals. Materials with

a low thermal diffusivity, e.g., composites, have a long thermal propagation

time, which limits flash thermography to the detection of shallow defects.

The Heat Conduction Equation gives us the curve fit in Figure 3 for the

surface temperature of a sample with a defect after a heat pulse.

A good treatment of the underlying mathematics is given by Maldague1.

Figure 3. Typical temperature signal of one pixel at the

surface of a part after applying a heat pulse.

The reconstructed profiles in black are from an analytic approximation

function. Common analytical functions that are used include a rootapproximation-model, an exponential-approximation-model, and a pulsephase calculation which performs a Fourier Transform of the recorded

signal and gives the phase spectrum as a function of the frequency. The

first and second derivatives of these curves often yield the best images.

The main advantages of the flash thermography are short measuring

times and the ability to perform depth-resolved inspections, providing

excellent performance for inspection of thin layers and for the detection

of shallow defects.

Figure 4. Transient is best for composite samples that

are large in area and/or thick.

The main disadvantages of flash thermography are a limited inspection

area due to the energy of the flash lamps, a depth range limited to shallow

defects, and a high-thermal loading on the sample.

The main advantages of transient thermography are that it is applicable for

large-area measurements, halogen lamps are affordable heat-sources, and

the low thermal load on the inspected component.

The main disadvantage of transient thermography is that it is not suited for

thick samples.

A rough rule-of-thumb for composite defect inspection is up to 3 mm for

flash thermography (see Shepard2), up to 6 mm for transient thermography

(and up to 12 mm for Lock-In thermography, discussed below). Of course,

many material and configuration variables are present, so each application

must be evaluated individually.

Figure 5. Flash thermography is well-suited for very thin

samples.

Pulsed Thermography – Examples

Flash thermography with a high-power xenon lamp is a powerful tool for

thin samples with shallow defects, such as corrosion under paint. Typical

lamps are 6 kJ with 2 ms pulses. A dramatic example is shown in Figure 5,

a helicopter panel with corrosion under the paint. This is a situation where

transient or lock-in thermography would not work.

Figure 6. Inspection of dashboards for voids.

Transient thermography becomes important for large structures, as shown

in the auto factory image in Figure 6. Depending upon the minimum defect

size to be investigated, sections of an airplane fuselage or an AWACS dome

as large as 4 ft by 6 ft, can be imaged in a single shot, as shown in Figure

7. Typical set-ups will have two to four halogen lamps (1 kW each), used

with a 10 sec pulse and a 20 sec cool-down.

Figure 7. AWACS dome showing (a) Photograph of the

dome and workstation technician (b) Phase image of

damaged region (not visually seen) (c) Normal region of

the dome.

2

Lock-In Thermography – Principles of Operation

In lock-in thermography, the dynamic stimulus can be applied from a wide

variety of sources. For composite inspection, this includes halogen lamps,

ultrasound, and mechanical stimulation. In all cases, the equipment setup is

as shown in Figure 8.

Mathematically, in the lock-in case, the recorded temperature information

is transformed into the frequency domain. In each pixel, the measured

temporal evolution of the temperature is Fourier-transformed for all images

of the recorded sequence. Phase and amplitude information are derived

and presented as an image.

Figure 8. Schematic of equipment setup for lock-in

measurements.

Advantages of the lock-in method include:

• The summation causes a noise-filtering which enhances the contrast in

the resulting images.

• Depth range for the phase information is twice that of the pulse mode,

~ 2µ with µ =. 2 K

ρC pω

•L

ock-in allows detection of thermal waves with a sensitivity of 100 to

1,000 greater than the best thermal camera – down to µ-Kelvin range.

• The phase image is insensitive to external effects, such as sunlight,

reflections, dirt, and emissivity differences – problems common to

conventional thermography.

• The phase information is insensitive to uneven distribution of the

applied heat.

• Large areas can be examined within a few minutes from a distance via

non-contact measurement.

• An un-cooled IR-camera is normally sufficient.

• Affordable heat sources are widely available (e.g. halogen lamps).

• Visualization of deeper defects is possible than with pulse thermography.

Figure 9. Example of the lock-in measurement principle

measurements.

Figure 9 shows the measuring principle, using CFRP material with a

sinusoidal excitation. The curves are the typical temperature signals at the

surface. Curves are shown for pixels with and without delamination. Note

that the signal is evident in both amplitude and phase.

Lock-In Thermography – Examples

The most common excitation source for lock-in is the affordable halogen

lamp. Figure10 shows an example of voids in a new composite honeycomb.

Other defects like delaminations or inclusions also can be detected reliably

with lock-in.

Figure 10. Voids in composite Al-honeycomb structure.

This challenging measurement of Figure 10 was done at a frequency of

0.05 Hz, and for two periods - a forty second measurement acceptable for

many applications. The panel is 1-inch thick with defects on the front and

back sides.

An important source of heat is ultrasound. Typical settings are 100 W at

20 KHz with a 200 ms burst frequency for synchronization. A disadvantage

of the ultrasound technique is that it can be destructive—care is required

in the temperature rise.

Figure 11 shows a test of Carbon-fiber Reinforced Ceramic (CFRC) with

cracks originating from drilled holes.

A powerful tool for laboratory and factory is the use of mechanical excitation

for heat generation through the thermoelastic effect, shown in Figure 12.

Applications of this technique include measurement of fatigue limits,

imaging of stress patterns, crack propagation studies, and imaging of

Figure 11. Top: Visible image. Bottom: Phase image.

Fine cracks originating from the drilled holes are clearly

evident.

3

Figure 12. Compression and expansion give temperature

changes proportional to the stress.

Figure 14. Stress patterns on a polymer sample.

vibration patterns, as shown with turbine blades in Figure 13. The stress

images of Figure 13 are equivalent to having 320 x 240 = 77,000 strain

gages on the sample. Engineers often compare results such as these to

FEA calculations.

Figure 15. Time, power, and temperature regimes for

pulsed flash, pulsed transient and lock-in.

Polymers present a challenge for thermography because they are often

orientation-dependent, as shown in Figure 14. The different thermal

characteristics of the fibers are evident in the figure. Features of 1 mm

size are evident. A standard microscope lens could be used with this FLIR

MW camera to examine detail as small as 5 µm.

Summary

It is evident from the discussion above that pulsed flash, pulsed transient

and lock-in thermography are important tools for research and for quality

assurance in most areas of manufacturing. The particular technique used

must be determined on a case-by-case basis. A starting point for the

choice is shown in Figure 15 - do you need a blink…a glance…or a stare.

717 Hz – 1st Mode

References

1.X. Maldague, Theory and Practice of Infrared Technology for

Nondestructive Testing, John Wiley & Sons, 2001.

2.S. Shepard, “Understanding Flash Thermography,” Materials Evaluation,

454 (2006).

About the Authors

2136 Hz – 2nd Mode

Markus Tarin is President and CEO of MoviTHERM.

Ralph Rotolante heads the East Coast Operations of MoviTHERM

BOSTON

FLIR Systems, Inc.

25 Esquire Road

North Billerica, MA 01862

USA

PH: +1 866.477.3687

PH: +1 978.901.8000

PORTLAND

Corporate Headquarters

FLIR Systems, Inc.

27700 SW Parkway Ave.

Wilsonville, OR 97070

USA

PH: +1 866.477.3687

CANADA

MEXICO/LATIN AMERICA

FLIR Systems, Ltd.

920 Sheldon Ct.

Burlington, ON L7L 5L6

Canada

PH: +1 800.613.0507

FLIR Systems Brasil

Av. Antonio Bardella

320 - B. Boa Vista- Cep:

18085–852 - Sorocaba – SP - Brazil

PH: +55 15 3238 8070

©2011 FLIR Systems, Inc. All rights reserved. (Rev. 8/11)

www.flir.com

NASDAQ: FLIR

3418 Hz – 3rd Mode

5911 Hz – 4th Mode

Tests performed on shake table.

Figure 13. Vibration mode on a turbine blade tested on

a shake table.

4