Pulling Tension (1)

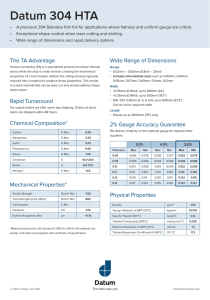

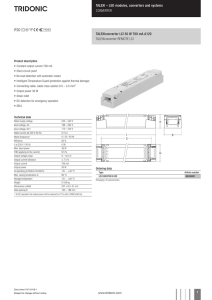

advertisement

Pulling Tension (1) In setting out a cable route, numbers of angles and bends should be kept to a minimum for ease in pulling. Recommended limits on pulling tensions are given below: a. With stocking grip 0.12xD Newtons (kN), where D = the overall diameter of the cable (mm) subject to a maximum of: unarmored cables with lead sheath • 10 N per mm2 of lead sheath. unarmored cables with no lead sheath • • • 70 N per mm2 on stranded copper. 50 N per mm2 on stranded aluminium. 30 N per mm2 on solid aluminium. GSW armored cables • 100 N per mm2 of galvanised steel wire armour. Steel tape armoured cables are not suitable for stocking grip because of a tendency for the steel tape to unravel. In this case the best procedure is to strip the armour and apply a stocking over the next layer, or to attach a pulling eye to the conductor. b. With pulling eye on conductor 70 Newtons per mm2 on stranded copper. 50 Newtons per mm2 on stranded aluminium. 30 Newtons per mm2 on solid aluminium. On Armour: 100 Newtons per mm2 on galvanised steel wire armour. Caution: • Installers are advised to review actual pulling tensions, taking into account the maximum sidewall pressures, cable minimum bending radius and other installations restrictions. • Pulling different conductor sizes at the same time is not recommended if the conductor size or other cable characteristics are significantly different. • When pulling in ducts, a maximum pulling tension of 20kN is recommended.