Insulation

tester

for substations

Limiting

catastrophes

Cable

faults

see page 3

see page 5

see page 7

ELECTRICAL

TESTER

Published by Megger

July 2013

The industry’s recognised information tool

Phase evaluation in power networks

Dr Frank Petzold and Alexander Stanischa

Megger Baunach

The spread of green micro-generation systems

and other market forces mean that power

utilities increasingly have to allow third-party

access to their networks. At the same time,

staffing levels have in many cases been

reduced dramatically. This means that the

days when individual employees were

specialists in a particular area of work are

gone. Today’s employees are expected to

cover a wide range of activities, and simply

don’t have the time to develop in-depth

expertise.

Of course no compromises can ever be made

in matters of safety, even when human

resources are scarce.

Achieving and maintaining the highest levels

of safety is made even more complicated for

network operators by the restructuring of

networks that is now carried out almost

continuously to optimise operating efficiency.

In particular, the constant changes make it

difficult to ensure that documentation is up to

date and correct.

This means that it is now more important

than ever to be able to easily and reliably

determine the absolute phase of busbars in

switching equipment, transformer feeders and

substations, crossing points of overhead cables,

cable end closures and various parts of the

low-voltage network.

To meet this requirement, new phase evaluation

test instruments have been developed which

take advantage of modern technologies such

as the GSM mobile phone network and the

GPS satellite system that is most commonly

used for satellite navigation in vehicles.

Correctly used, these instruments will prevent

the occurrence of costly and often dangerous

errors during the commissioning and maintenance of electrical power systems, thereby

ensuring that high network reliability and

economic efficiency are achieved.

PRACTICAL PHASE MEASUREMENT

To explore the way that the new instruments

operate and how they are used, it is easiest

to consider a specific product, in this case

the new SebaKMT PVS100, but the functionality

described can be taken as a guide to what

users should expect from any modern phase

evaluation system.

The absolute phasing at any point in a

transmission or distribution network can

only be determined when the measurement

is made with respect to a known reference

phase. This means that for making phase

measurements in the field, a mobile unit that

is capable of being used with a reference

device (base station) is needed in order to

It’s another

world!

Nick Hilditch

Group marketing services manager

www.megger.com

edition

perform the necessary synchronisation. In the

PVS100, this requirement has been met by

designing the instrument as two identical units,

one of which acts as the base station while the

other is used as the mobile unit in the field.

A precise time base for synchronisation is

established using signals from the GPS satellites,

while for transmission of synchronisation data,

each unit incorporates a GSM module. This

can operate in the normal CSD data transmission mode or alternatively in GPRS mode.

When the voltage of the phase to be measured

is less than 400 V, it is connected directly to

the mobile unit. Direct connection can also be

used for measurements at capacitive test points

of switching equipment or angle plugs (elbow

connectors).

For higher voltages, a high-voltage measurement

sensor is used, and this communicates with

the base unit via an 866 MHz wireless link.

The sensor, which is attached to an insulating

rod approved for use at the appropriate voltage,

incorporates a high-intensity LED, visible even

in direct sunlight, which signals that the

measurement has been completed and the

phase identified successfully.

This arrangement means that the operator can

give their full attention to the positioning of

the sensor while the measurement is being

made, without being distracted by having to

look at the mobile unit. The mobile unit stores

the measurement data for later downloading

and analysis.

PHASE CORRECTION

If the base station is not connected to L1 as

the reference phase, the appropriate correction

angle of either +120º or -120º must be entered.

Depending on the application, there can be

transformers with the same or different vector

groups between the base station and the

mobile device. Each of the vector groups leads

to a specific resultant phase shift, which must

be entered on the mobile unit to obtain the

correct absolute phase indication. If the

correction values are not entered, only the

phase angle relative to the reference phase

can be determined.

Correction values are also needed for

measurements taken at capacitive voltage

test points. These values are restored in the

instrument for the most common types of

capacitive sensor, and there is provision for

entering the correction values for an almost

unlimited number of additional sensor types.

MEASURING MODES AND APPLICATION

EXAMPLES

Because conditions in the field vary in terms

of access to mains power and the availability

of GPS and GSM signals, the best phase

evaluation test sets offer multiple measuring

There can be no doubt that Megger employs

some very talented engineers but it’s easy to

forget that they don’t leave their talents behind

them when, at the end of a long working day,

they leave their desks and head homeward.

So what do these gifted engineers get up to in

their spare time?

Some might say that’s a question best left

unanswered but, in the case of Mark Hadley,

who is new product research manager at the

company’s Dover site, it’s already too late!

Thanks to recent press reports, Mark’s spare

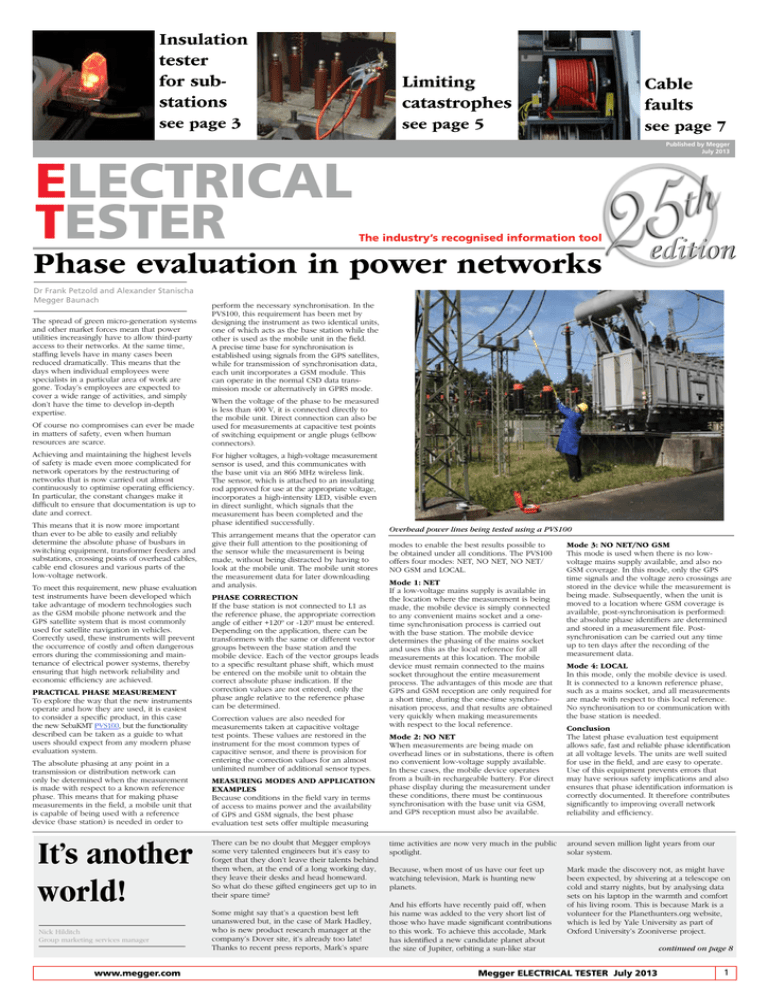

Overhead power lines being tested using a PVS100

modes to enable the best results possible to

be obtained under all conditions. The PVS100

offers four modes: NET, NO NET, NO NET/

NO GSM and LOCAL.

Mode 1: NET

If a low-voltage mains supply is available in

the location where the measurement is being

made, the mobile device is simply connected

to any convenient mains socket and a onetime synchronisation process is carried out

with the base station. The mobile device

determines the phasing of the mains socket

and uses this as the local reference for all

measurements at this location. The mobile

device must remain connected to the mains

socket throughout the entire measurement

process. The advantages of this mode are that

GPS and GSM reception are only required for

a short time, during the one-time synchronisation process, and that results are obtained

very quickly when making measurements

with respect to the local reference.

Mode 3: NO NET/NO GSM

This mode is used when there is no lowvoltage mains supply available, and also no

GSM coverage. In this mode, only the GPS

time signals and the voltage zero crossings are

stored in the device while the measurement is

being made. Subsequently, when the unit is

moved to a location where GSM coverage is

available, post-synchronisation is performed:

the absolute phase identifiers are determined

and stored in a measurement file. Postsynchronisation can be carried out any time

up to ten days after the recording of the

measurement data.

Mode 4: LOCAL

In this mode, only the mobile device is used.

It is connected to a known reference phase,

such as a mains socket, and all measurements

are made with respect to this local reference.

No synchronisation to or communication with

the base station is needed.

Mode 2: NO NET

When measurements are being made on

overhead lines or in substations, there is often

no convenient low-voltage supply available.

In these cases, the mobile device operates

from a built-in rechargeable battery. For direct

phase display during the measurement under

these conditions, there must be continuous

synchronisation with the base unit via GSM,

and GPS reception must also be available.

Conclusion

The latest phase evaluation test equipment

allows safe, fast and reliable phase identification

at all voltage levels. The units are well suited

for use in the field, and are easy to operate.

Use of this equipment prevents errors that

may have serious safety implications and also

ensures that phase identification information is

correctly documented. It therefore contributes

significantly to improving overall network

reliability and efficiency.

time activities are now very much in the public

spotlight.

around seven million light years from our

solar system.

Because, when most of us have our feet up

watching television, Mark is hunting new

planets.

Mark made the discovery not, as might have

been expected, by shivering at a telescope on

cold and starry nights, but by analysing data

sets on his laptop in the warmth and comfort

of his living room. This is because Mark is a

volunteer for the Planethunters.org website,

which is led by Yale University as part of

Oxford University’s Zooniverse project.

And his efforts have recently paid off, when

his name was added to the very short list of

those who have made significant contributions

to this work. To achieve this accolade, Mark

has identified a new candidate planet about

the size of Jupiter, orbiting a sun-like star

Megger ELECTRICAL TESTER July 2013

continued on page 8

1

The industry’s recognised information tool

Contents

Phase evaluation in power

networks............................................. 1

Dr Frank Petzold, Alexander Stanischa,

Banuanch Germany

Don’t take a chance

on your CAT!

Simon Wood

UK wholesale and distribution

sales manager

ELECTRICAL

TESTER

History is

never static!

HV Supply

It’s another world!.............................. 1

Nick Hilditch, group marketing services manager

Stina Flogell Ostlundh

General manager,

Megger Sweden

Don’t take a chance on your CAT!...... 2

Simon Wood, UK wholesale and distribution sales

manager

History is never static!........................ 2

From time to time, Electrical Tester has included

brief histories of some of the well-known

companies that now form part of the Megger

group. Several years ago, we wrote in this

vein about the Swedish company, Programma.

History is never static and the story we told

then is now rather behind the times, so let’s

bring it up to date.

Stina Flogell Ostlundh, general manager,

Megger Sweden

Insulation tester for substations........ 3

Clive Pink, product manager

Measuring on a roll!........................... 3

Josef Hollweck, sales engineer, Megger Germany

Interoperability and IEC61850

Goose.................................................. 4

Andrea Bonetti, technical specialist in protection

and relay test

The secret to limiting substation

catastrophes....................................... 5

Gary Wright, consultant

Multiple current injection................... 6

Marius Pitzer, sales manager, Megger South Africa

Safeguard those services!................... 6

Mr Jörg Schubert, manager, line locating and

inspection department, Banuanch Germany

Explaining the art of testing.............. 7

Elsa Cantu, marketing communications manager,

Megger Dallas

Cable fault.......................................... 7

Peter Herpertz, product manager, power

My resistance is low!.......................... 8

Keith Wilson, electrical engineer

It’s another world continued from page 1....................... 8

Q&A.................................................... 8

The rights of the individuals attributed in Electrical Tester to

be identified as authors of their respective articles has been

asserted by them in accordance with the Copyright, Designs

and Patents Act 1988.

© Copyright Megger. All rights reserved. No part of Electrical

Tester may be reproduced in a retrieval system, or transmitted

in any form or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior written

permission of Megger.

To request a licence to use an article in Electrical Tester,

please email ElectricalTester@Megger.com, with a brief

outline of the reasons for your request.

All trademarks used herein are the property of their respective

owners. The use of any trademark in this text does not imply

trademark ownership rights in such trademarks, nor does use

of such trademarks imply any affiliation with or endorsement

of Electrical Tester by such owners.

A printed newsletter is not as interactive as its email

equivalent so to help you find items quickly on

www.megger.com, we have underlined key search words in

blue.

Note from the Editor

Time for your say.

We have introduced a ‘Questions and Answers’ section and

would like your input. If you have any questions or stories

that you think we could use, then please email

electricaltester@megger.com

‘Views expressed in Electrical Tester are not necessarily the

views of Megger.’

The word ‘Megger’ is a registered trademark

Editor Nick Hilditch.

T +44 (0)1304 502232

E nick.hilditch@megger.com

www.megger.com

Megger Limited

Archcliffe Road Dover Kent CT17 9EN

T +44 (0)1304 502100

E electricaltester@megger.com

www.megger.com

2

EN 61010-1 categories

When testing electrical systems of any kind,

it’s essential to make sure that the test

equipment being used is suitable for the task

in hand. If it’s not, there is a significant risk

not only of damage to the test equipment

and the installation, but also of injury to the

user. That probably seems so obvious that it’s

hardly worth mentioning. After all, how many

technicians or engineers would use unsuitable

equipment for testing? The answer is that few

would do so knowingly, but many may be

doing so every day without even realising

that there’s a problem. And that problem

relates to transients. All electrical installations

experience transients, which are voltage

spikes that are super-imposed on the normal

supply. Although these spikes are usually of

very short duration – typically they last just

a few microseconds – their amplitude can

be thousands of volts. These transients come

from a variety of sources, but one source that

is surprisingly common even in temperate

climes is lightning strikes. Note that a direct hit

on the installation doesn’t have to be involved,

nor even a hit on the power lines supplying it;

a nearby strike is often enough to produce a

large transient.

But what have transients got to do with

testing and safety? To answer this question,

let’s examine what happens if you’re carrying

out a test – which could be something as

simple and routine as checking the voltage

of an LV supply – when it experiences a

transient. If the instrument in use has not been

specifically chosen to be suitable for the type

of work being carried out, there’s a very real

risk that the transient will cause a flash over

inside the instrument and set up an arc.

Because its duration is very short, the transient

itself is unlikely to have enough energy to do

a lot of damage. Unfortunately though, once

it is established, the arc provides a low

impedance path for current from the mains

supply. That current flow releases a lot of

energy inside the instrument. Of course, the

circuit’s protective device, whether it’s a fuse

or circuit breaker, will quickly disconnect the

supply and interrupt the fault current.

Before this has time to happen, however,

the energy released within the instrument is

enough to cause real problems. In the worst

cases, the instrument may explode, injuring or

even killing the person who is using it. Even

in less severe cases there is a definite risk of

fire and damage to the equipment under test

as well as to the instrument itself.

It’s clearly important, therefore, to choose an

instrument that has been designed to withstand the level of transients it’s likely to

encounter in use. But how can you tell? The

answer is to look at the instrument’s category

rating, which is more commonly called its CAT

rating.

CAT ratings are defined in the IEC 61010-1

standard, and are specifically intended to

Megger ELECTRICAL TESTER July 2013

address the issue of transients in the testing of

low-voltage installations. To understand how

the ratings work, it’s necessary to look at what

happens to transients as they pass through a

typical electrical installation.

Outside the building and at the point where

the mains supply enters the building, the

transients have their highest amplitude. For

testing in these locations, only instruments

with a CAT IV rating are suitable.

Transients are, however, quickly attenuated by

the wiring and equipment in an electrical

installation. Once the supply has passed

through the main switchboard, therefore, the

amplitude of the transients is much lower, and

instruments with a CAT III rating (or higher)

can be safely used. At the final circuit outlets,

the transient levels are lower still, and CAT

II or higher instruments can be used without

problems.

What about CAT I instruments? These are

for use within appliances such as VDUs and

photocopiers. In practice, major suppliers of

instruments designed for professional use are

unlikely to offer CAT I or CAT II instruments,

as their area of safe usage is so limited.

That’s not quite the whole story, as CAT

ratings must always include a voltage – for

example, CAT IV 300 V. This voltage is the

maximum RMS phase-to-earth voltage of the

system on which the instrument is suitable for

use. This means, for example, that instruments

with a 300 V rating can be used on singlephase systems up to 300 V and three-phase

systems up to 520 V, making them suitable for

the vast majority of low-voltage applications.

There’s one final point to mention. It would

be easy to think that insulation testers and

other instruments designed for use on dead

circuits didn’t need a CAT rating. Remember,

however, that these instruments could be

accidentally connected to a live supply, and

also that many of them incorporate facilities

for some live circuit tests, such as measuring

the supply voltage. The CAT rating is, therefore, still relevant for these types of

instruments.

Once the significance of the CAT rating system

is understood, it’s not difficult to choose an

instrument that’s appropriate for the type of

work being undertaken. As a general rule of

thumb, a CAT III 300V rating is likely to be

the minimum acceptable for general use.

It is, however, well worth considering

investing in CAT IV instruments, as these can

be used without restrictions anywhere within

a normal installation. Many utility companies

and other major purchasers of instruments are,

in fact, now specifying CAT IV instruments as

standard, since they deliver an extra level of

safety in return for a very modest additional

investment.

Programma was founded in 1976 by two

friends who saw designing and manufacturing

electronic products as an attractive business

opportunity. Their first idea was to produce

an electronic programmer for washing

machines, which explains the choice of

company name. Unfortunately, the washing

machine manufacturers weren’t interested,

as they develop their own programmers inhouse.

Fortunately, the brother of one of the friends

had been working as a protection relay test

engineer and had developed a small portable

relay tester for his own use. He suggested that

this could be commercialised, and estimated

that there would be a market for perhaps 20

of these instruments. In fact, including the

successors to the original design, more than

20,000 have been sold!

Programma was so successful that it became

a takeover target. It was purchased by GE

Energy and in an attempt to reduce

manufacturing costs, manufacturing was

transferred to China. By 2007, however,

GE Energy had decided to rationalise its

operations by divesting itself of non-core

businesses, and Programma found itself up

for sale.

Knowing that Programma had an excellent

reputation for quality, expertise and innovation,

as well as a product range that complemented

its own, this was an opportunity too good for

Megger to miss and in June 2007, it brought

the company into the group. One of its first

actions was to bring manufacturing back inhouse, as this restored the close control over

product quality and performance that can

only be achieved when the manufacturing

site is close to the design and development

facility.

Just a year later, in 2008, Megger acquired

another Swedish company, PAX Diagnostics,

a specialist in power transformer test and

diagnostics with industry-leading expertise

in sweep frequency response analysis and

dielectric frequency response analysis. Before

long, the PAX operations were moved to

share the Programma site in Taby, where they

benefitted from access to a much wider range

of resources.

Now operating under the Megger name, both

the Programma and PAX operations in

Sweden have continued to flourish, and are

producing a wide range of innovative power

test instruments that are sold all over the

world. In fact, the Swedish operations have

forged ahead so strongly that the latest update

in this story is another change of location.

After 30 years in Täby, all of the Swedish

operations moved to a much bigger and more

modern premises in Danderyd, Stockholm in

April 2013. The new premises provide a greatly

enhanced environment for the development

and manufacturing teams, as well as the

facilities needed to ensure that as its business

continues to grow, the company will be able

to maintain and enhance its already renowned

level of customer service well into the future.

www.megger.com

ELECTRICAL

TESTER

The industry’s recognised information tool

Clive Pink

Product manager

In distribution and transmission substations

and switchyards – as in almost every other

kind of electrical power installation – dc

insulation resistance testing (IRT) is an

invaluable tool for assessing the condition

of equipment and for diagnosing faults.

Unfortunately, however, obtaining dependable

insulation resistance measurements in Extra

High Voltage (EHV) substations and switchyards can be challenging, not least because

of the high levels of electrical noise that are

present.

Insulation tester for substations

In fact, an instrument with 3 mA noise

immunity will often be a good choice for

general applications, but in EHV substations

and switchyards it’s a very different story

as noise levels are frequently much higher.

The right choice here is the new S1–Series of

products from Megger that have been purpose

designed and built for use in these very

challenging environments.

A very effective solution would be to arrange

for all nearby equipment to be de-energised

while tests are carried out so as to minimise

noise levels, but in the real world this is rarely

possible. A more practical approach to tackling

the noise problem is to use the shortest

possible test leads and to route these near

earthed objects such as the casing of a transformer, or to use test leads that are screened.

The best of these instruments offer 8 mA

noise immunity, which is an exceptionally

high figure, and that’s not all. They also

incorporate powerful software-base filtering

that further reduces the effect of electrical

noise on measurements. The level of filtering

is user selectable as the highest levels extend

the time needed to perform a test, although

they do make it possible to obtain dependable

results in situations where measurements

would have previously been impossible.

These measures are effective in reducing high

frequency noise pick up on the test leads, and

this may sometimes be enough for dependable

measurements to be made, but they can do

nothing about noise picked up by the test

object itself or from noise currents flowing in

the ground. The only way to tackle this is to

use an insulation tester that offers high noise

immunity.

These new instruments have been tested in

the field and proved their worth in field trials.

Tests carried out with a Megger S1-1068 10 kV

test set in 765 kV substations in India yielded

accurate and repeatable results without even

needing to use the highest level of filtering.

This is a particularly notable achievement as

no other insulation test set had ever been able

to operate successfully in these locations.

Of course, all manufacturers of insulation testers

claim that their products offer high noise

immunity and, indeed, all test sets sold in the

EU must meet the EMC requirements of IEC

61326-1. Experience has shown, however, that

in environments like substations and switchyards, the levels of electrical noise are often

much higher than those laid down in this

standard.

While their exceptionally high noise immunity

is undoubtedly the key characteristic of the

new S1-Series, these leading models have

many other desirable features. They’re robust

yet lightweight, easy to transport and, because

low-voltage power is not always conveniently

available in substations and switchyards, they

incorporate rapid-charge Li-ion batteries that

allow hours of testing to be carried out even

when a mains an AC supply is not available.

It is, therefore, necessary to go beyond simple

claims of high noise immunity or IEC 61326

compliance and to look at quantitative data

about the noise immunity of an instrument.

This is usually specified in mA, and a typical

specification might be that a particular

instrument has an immunity of 3 mA at 50/

60 Hz. In simple terms, this means that if

the noise current induced in the test circuit

at power frequency is 3 mA or less, the

instrument will give reliable results.

These test sets also deliver a high short-circuit

current – typically up to 6 mA – to allow rapid

charging of items under test, and they have

a CAT IV 600 V safety rating up to 3000 m in

line with IEC 61010, to help ensure operator

safety. A further important feature is provision

for remote operation via a fully isolated interface, which again can help to enhance

operator safety when carrying out tests in

difficult environments.

USB beacon which enables remote operation from a PC

As would be expected, these instruments have

internal storage for date- and time-stamped

test results, which can be recalled to the

display or downloaded to external devices for

inclusion in reports or later analysis. Downloading is performed via a USB or Bluetooth®

interfaces.

There is no doubt that high voltage and EHV

substations and switchyards will always be

challenging environments in which to carry

out electrical testing. As we’ve seen, when it

comes to insulation resistance testing, the

challenges have now been very effectively

addressed. For successful results it is essential

to use a test set that’s been designed for the

job: attempting to get by with a generalpurpose instrument is all too likely to lead to

frustration and wasted time.

Measuring on a roll

Josef Hollweck

Sales engineer, Megger Germany

There are many cases when using a TDR for

cable length measurement is not only convenient,

but also an excellent way of guarding against

problems.

Construction companies, for example, often

hire submersible pumps to remove water

from deep excavations and these pumps are

usually delivered with power cables on drums.

Although the required cable length will have

been specified, mistakes happen and a short

cable can make it impossible to install the

pump at the required depth, which is likely to

delay the project and incur unnecessary costs.

A quick check on the cable length with a TDR

will ensure that this doesn’t happen.

TDR1000/3 being used to measuring the length of cable left on a drum

Most engineers and technicians who regularly

work with power cables will at some time,

have used a time domain reflectometer (TDR)

– one of those handy little instruments that

feeds an electrical pulse into a cable, then

measures the time it takes for reflections of

that pulse to return. Since the pulse is reflected

not only by the end of the cable, but also by

many kinds of cable fault, the TDR is an

invaluable tool for determining fault locations.

www.megger.com

For those who think creatively, this is not the

only application of these useful instruments.

For example, instead of tediously measuring

cable lengths by hand, why not use a TDR? In

fact, why not use a TDR to measure the length

of a cable coiled on a drum or a cable reel?

With this technique, it isn’t even necessary to

unroll the cable, which saves a lot of time and

effort.

For companies that stock and sell power

cable, using a TDR to measured cable lengths

on the drum is a particularly attractive option.

To check stocks, it is no longer necessary to

unroll the cable and measure it by hand – all

that’s needed is access to one end of the cable

and the measurement can be made in seconds,

with very little effort.

Of course, not every TDR is well suited to

this type of application. What’s needed is

an easy-to-use instrument that has good

resolution to ensure that the length measurements are accurate. Fortunately, convenient

and cost-effective handheld instruments that

meet these requirements are now readily

available.

The best incorporate an auto set-up feature

that instantly recognises the type of cable,

ensuring reliable and accurate results. In

addition, the pulse they send into the cable

is very short – around 2 ns – and so they can

measure cable lengths with an accuracy of

around 100 mm.

Finally, they have high-resolution screens

and a trace hold feature that make it easy

to interpret the results, and they feature robust

construction to handle the rough-and-tumble

of on-site use. These instruments are modestly

priced considering the benefits they offer and,

if you really want to, you can even use them

for cable fault location!

So, next time you want to know how much

power cable is on a reel or drum, don’t reach

for a tape measure and spend ages struggling

with tangles as you unreel the cable, reach

instead for your trusty TDR and, with you’ll

have the answer in seconds, effortlessly!

Megger ELECTRICAL TESTER July 2013

3

ELECTRICAL

TESTER

The industry’s recognised information tool

Interoperability

and IEC 61850

GOOSE

Andrea Bonetti

Technical specialist in protection relay test

Introduction

In general terms, interoperability is the ability

of diverse systems to work together effectively

and efficiently. Interoperability is a property

of a product or system whose interfaces are

completely understood to work with other

products or systems, present or future, without restrictions on access or implementation.

Interoperability helps to decrease complexity

and makes it easier to manage heterogeneous

environments while enhancing choice and

innovation in the market. Importantly, the

interoperability requirement of the IEC

61850 standard has beneficially increased the

“interoperability among different engineers”

working for companies that are nominally in

competition. This increased communication

among different vendors has contributed to

the fact that GOOSE messaging can today be

considered a working technology, even if

problems still arise, as they do in any

technology.

With more than six years of field experience

with IEC 61850 GOOSE communication in

protection and control applications, it is now

possible to list the main reasons for interoperability problems in multi- and singlevendor systems. However, a comprehensive

list would be unmanageably long, especially if

cases found in the early days of using GOOSE

messages were included.

case, the receiving relay may fail to receive the

signal. This is a frequent situation during the

commissioning of substations, and the usual

solution is to replace the binary input card of

the receiving relay. Finding this problem and

identifying its cause are time-consuming jobs

because the test engineer usually believes that

the problem is located in other parts of the

system and the real cause is identified only

after other “more probable causes” have been

eliminated.

Interoperability with IEC 61850 GOOSE

With IEC 61850 GOOSE technology, the

situation is very similar. The problem is

identified after a time-consuming investigation

concludes that the signal is not being correctly

received by the receiving IED. Relay engineers

usually describe interoperability failures by

saying something like:

A typical example is illustrated where,

depending on its own VLAN settings, the

switch (or switches) removes the VLAN tag of

the GOOSE message.

As the VLAN tag is a mandatory part of the

GOOSE message, an IED “has the right” to

refuse the GOOSE message if the tag is

missing.

One IEC 61850 TISSUE (nr.290, VLAN ID) has

been dedicated to this problem and the

decision taken – in essence – is that the IEDs

are allowed to receive GOOSE messages with

or without VLAN tag.

A sending relay has its binary output

polarized by the battery voltage at 110 V dc,

and the receiving relay has a binary input

card with nominal voltage of 220 Vdc. In this

Megger ELECTRICAL TESTER July 2013

From what has been seen in the field to date,

unless there is a design fault (bug) in the IEC

61850 GOOSE stack of one of the IEDs, this

problem almost always occurs when using

non-standard ASCII characters like ä or ö in

the SCL description of the GOOSE message.

The use of space characters has also created

problems. Not all engineering tools are very

robust when checking that only valid

characters have been used, and the definition

of “valid character” has to be found in the

XML file specification, as SCL files are XML

files. This interoperability problem has been

identified in multi-vendor applications.

Experience has shown that the best way of

avoiding these problems is to always use basic

ASCII characters and never use spaces when

defining GOOSE messages in the engineering

tools.

This problem has usually been found in the

sender IED, and if this is the case, the

consistency check method against the SCL file

detects the difference.

This type of interoperability problem is mainly

due to the different interpretation by individual

vendors of the default values that must be

assigned to the various attributes of the

GOOSE message, when information is missing

in the SCL file describing it. This interoperability problem has been seen in multi-vendor

applications.

Even this simple connection can produce

“interoperability” problems. Consider, for

example:

Different interpretation of “default

values”

GOOSE messages modified by other IEDs

in the network

Interoperability “before”

Interoperability is a word that commonly

refers to numerical technology or numerical

relays. Interoperability problems did and do

exist even within the so-called conventional

technology, where communication between

different protection relays is based on Boolean

signals expressed in terms of dc voltage level.

In other words, the binary output (contact

or similar) from one relay is connected to a

binary input of another relay. The connecting

medium is a couple of wires.

4

Depending on the switches used, they may

have problems in handling the VLAN 0, but

they should always be able to handle any

VLAN other than zero. If all GOOSE messages

have the same VLAN (001 for instance), it is

always possible to set all the ports of all the

switches to handle VLAN 1, with consequence

that the VLAN tags of the messages should

neither be removed nor modified.

The remaining part of this article looks at

some of the most common sources of

interoperability problems with IEC 61850

GOOSE.

This interoperability problem can occur in

both single- and multi-vendor applications.

Different interpretation of SCL (xml)

information (file importing/exporting)

It is also recommended to always use the

VLAN tag, even if in the horizontal

communication different VLANs are not used,

to make sure that all GOOSE messages are on

the same VLAN (for instance VLAN 1).

“The GOOSE message appears on the network.

It can be seen with any network analyzer or

dedicated GOOSE visualizer … But the IED

does not receive it.”

In order to commission substations with the

new IEC 61850 technology, there is a need to

use new tools and methods. The key to these

tools and methods is – paradoxically –

implicitly available in the IEC 61850 standard

itself.

What is interoperability in IEC 61850

communication?

The IEC 61850 standard clearly aims for

communication interoperability among IEDs

from different manufacturers and defines the

interoperability as “… the ability to operate

on the same network or communication path

sharing information and commands...”. When

data sent by Device A is not fully understood

or received by Device B, an interoperability

failure occurs. This situation was common

before the IEC 61850 standard, as most

numerical relays from different vendors had

their own proprietary communication

protocols. When the communication was

not required to perform real time tasks (like

handling protection signals for protection

schemes), it was possible to solve this

problem by using protocol converters.

This means that, depending on whether the

firmware of the IED was issued before or

after the TISSUE had been approved, some

IEDs may receive the message with an altered

VLAN tag, and others may refuse it. The

simplest solution to this problem is to set the

substation switches in such a way that the

VLAN tags are neither removed nor modified.

If the problem is in the receiving IED, the

consistency check method doesn’t help because

the GOOSE message on the network is the

same as the message in the SCL file. But in

this case, everything points to the receiving

IED and the manufacturer should be contacted

to help in the investigation.

Problems created by the IEC 61850

engineering process

Even where the standard is quite clear on the

default values, this type of interoperability

problem has often appeared; the solution is

usually a new firmware release for the IED.

The problem could be in the sender IED

(which sends the wrong default value) or in

the receiving IED that is not able to understand that the default value received on the

network is correct, even if its description on

the SCL file for that value is empty.

This non-interoperability can be detected by

comparing the SCL GOOSE information with

the GOOSE information available on the network (consistency check method).

The best way of avoiding this problem is to

always set all the possible attributes when

defining the GOOSE message with the IEC

61850 engineering tool, and to not leave any

fields empty.

Typically, this type of interoperability problem

is the result of a difference in the configuration

revision of the GOOSE message. For example,

in the SCL file there is Configuration Revision

3, but the published GOOSE has Configuration

Revision 2.

This means that the IEC 61850 horizontal

communication has been modified at SCL file

level, but maybe for that particular GOOSE

message nothing has been changed. The

engineering tool has nevertheless incremented

the configuration revision, but the sender IED

has not been updated with the new SCL file

and continues to work with the previous one.

This interoperability problem can occur in

single- and multi-vendor applications, but in

single-vendor applications the IEC 61850

engineering process is usually simplified by

the vendor tool, and the risk is minor. With

this problem, engineers typically say, “everything was working fine previously”. This is a

good indication of where the problem lies.

The use of several SCL files (for example,

several CID files for different IEDs rather

than a single SCD file) also increases the

probability of generating this type of interoperability problem, not only related to

different configuration revisions.

www.megger.com

ELECTRICAL

TESTER

The industry’s recognised information tool

The secret to limiting

substation catastrophes

By properly maintaining switches and

connections, technicians can avoid costly

and time-consuming failures and outages.

Gary Wright, Consultant

Gary Wright (gwright@forestgrove-or.

gov) consults for McMinnville Water &

Light and Forest Grove Light & Power

in Oregon. He started out in the power

industry in 1977, and recently worked for

Clark Public Utilities in charge of substations, metering and relaying, and is

now retired.

When you work inside a substation, many

problems will sneak in without your knowledge and some of them may be catastrophic.

As utility professionals know, a catastrophic

substation failure can bring a lot of attention

— the kind you don’t want.

Unfortunately, no silver-bullet solutions are

available to prevent substation failure. These

failures can be caused by a variety of factors,

including power transformers, batteries,

breakers or protection schemes that fail or

weren’t set correctly. But one of the most

common issues revolves around problems

with disconnect switches and bus connections.

attention to the condition of the contacts in

regards to pitting or loss of silver. Make sure

you have good contact pressure and then

apply a thin coat of Dow Corning® 1292 white

grease or similar. One benefit of this grease is

that it will stay soft, so when you are back in

three to five years for routine maintenance, it

will wipe off with a rag.

These types of problems can take down substations and inflict major damage. In addition,

they can require switching plans to be halted

because switches won’t open, won’t close, are

raining down sparks when asked to carry load

or are flashing over when asked to interrupt

load.

If the switch happens to be a load break type,

it’s important to test the interrupter. Load

break switches work by making a parallel

between the switch contacts and the interrupter

unit as the switch is starting to open. Normally,

most switch manufacturers don’t want any

current in the interrupter unit when the switch

is closed. If this is the case, test for the proper

clearances or the interrupter can burn up

under normal load.

Scanning with infrared

When evaluating the state of utility substations,

switches and connections should top the list.

In-house crews can perform switch maintenance

with just a little training. And, once the switches

and connections are operating properly, this

will eliminate one large opportunity for a

catastrophic failure and also make all future

switching go smoothly and predictably.

Infrared scanning helps technicians spot

problems. It’s beneficial to conduct infrared

scanning of all substations and some transmission lines every year. Also, when possible,

it’s best to schedule the work in times of

heavier loads.

When doing the infrared scanning, it’s

important to note that infrared is crucial but

not perfect. For example, infrared is not

effective for switches that sit open normally or

for switches feeding ‘out of service’ loads on

the day you scan. Wires may still burn down

even though they passed an infrared scan,

even if they were carrying load during the

scan.

If a connection does fail shortly after passing

an infrared scan, a utility could be looking at

a connection failure cycle. In this situation,

the connection can get so hot carrying load

that it will melt and then weld together. This

weld makes a good connection, at least for the

amount of current at the time, and the infrared

scan of the weld may show nothing. Then,

at a later date, the current is raised beyond

the capabilities of the weld area and the wire

burns in two.

Making preparations

To successfully guard against untimely outages,

substation technicians should not rely on

infrared technology alone. Instead, they should

also consider adding resistance-based tests in

the substation. These tests also can be applied

to transmission and distribution switches or

selected line connections.

Resistance-based testing involves using a

micro-ohm meter, which measures tiny

amounts of resistance (such as what would be

the resistance of a few feet of bus). After this

test is applied to all switches and connections

in a station, the tester can be sure the tested

items will not heat up under rated loads

because every switch is included, even the

ones that are normally open.

To begin, you’ll need some basic tools and

maintenance parts for this testing. First, and

most important, you’ll need a good micro-ohm

www.megger.com

A technician runs a diagnostic test using a micro-ohmmeter

meter such as the Megger DLRO200-115. This

is a meter that puts out 200 A of filtered dc

current. The advantage of filtered DC current

is that you can avoid a false trip. If you have

a differential scheme and the relays are still

connected to the current transformer (CT) of

the device you are testing, you can run this

filtered dc through the CT and the dc will not

be sensed in the differential circuit.

In addition, you should have upgraded bolts

for the connection pads and bimetal pads in

all three sizes (two-hole, 3 inch four-hole, and

4 inch four-hole). The reason for the bimetal

pads is that sometimes when connections fail,

it’s due to someone improperly making them

up, putting copper against aluminum. These

can be redone installing the bimetal pads

between the dissimilar metals. It’s a good

idea to upgrade the bolt system for the

connections. Normally, it’s only necessary

to change the bolts if a connection fails the

micro-ohm test.

The preferred connection system for bolted

pad type connections consists of a stainless

steel bolt (long enough so at least two threads

protrude through the nut), two stainless steel

³/16-inch-thick flat washers, one on each side

of the connection, one 3,500 lb stainless

steel Belleville washer on the nut side and a

silicon bronze nut. The bolts are ½ inch and

should be tightened to a torque of 45 ft. This

will compress the 3,500 lb Belleville washer

to about 60% compression, which will mean

the connection can expand and contract with

heating and cooling cycles and not stretch the

bolt. And the connection will maintain

constant tension through the years.

The last trick is to clean up the mating

surfaces with Scotch Bright® or whatever

cleaner is needed to get them clean. Then coat

the surfaces with an oxidation inhibitor like

DE-OX, a non-gritted ‘green’ inhibitor from

Ilsco®. There’s no reason to use a gritted

inhibitor because the parts are de-energized

and can be completely cleaned. If the Scotch

Bright can’t get the old dried inhibitor off, try

a scraper. As a general rule, you should avoid

sanding or filing because if the terminals are

tin-plated you could go through the tin very

easily.

Testing the equipment

After cleaning and preparing the surfaces, it’s

time to test with a micrometer. Technicians

should put the clamp around the entire switch

assembly, including all connections associated

with the switch. It’s important to clean the bus

to bare metal for this connection using a wire

brush and some light sanding.

When talking about micro-ohms, you cannot

have any resistance. It’s often effective to run

the maximum current of 200 A, provided the

components are rated for it. It’s important that

at least one side of the switch — or whatever

part you are testing — is not grounded.

One way to do it is to take a reading on the

entire assembly, and then if it passes, you are

done. The values you get will vary with switch

quality and materials, but a typical 1,200 A

copper switch (along with the switch pads at

both ends and the bus to terminal connections

at both ends) might be in the 350 micro-ohm

range. It doesn’t take long to develop a feel

for what to expect. You must look for things

that stand out. If you’re testing a different kind

of switch and you’re not sure what to expect,

if all three poles match, chances are you are

in good shape. If one or two poles stand out,

you probably should work on the higher poles

to see if you can get them to match the lower

poles.

If you run into a problem pole using this

connection across everything, then leave the

200-A current connections across the whole

switch but move your voltage leads across the

individual connections. For example, you can

measure the resistance of just one end of the

switch contacts, the bolted pads, the clamp to

the bus or the hinged end of the switch. This

will allow you to isolate your problem quickly

so you know what needs attention. All of this

is done by just moving along with the voltage

probes, and the 200 A current source stays

connected across the entire switch.

Checking equipment

Checking through all the switches with the

micro-ohm meter should be done in

conjunction with switch maintenance. The

contacts should be cleaned, being careful to

not scratch through the silver plating on the

contacts. You must check for proper alignment

of poles and contacts, and pay particular

As the switch opens, load current is paralleled

between the main contacts and the interrupter.

This parallel has to be maintained as you

continue to open the switch until a sufficient

gap exists between the main contacts to avoid

re-strike as the load is interrupted. The interruption will occur either using a vacuum

bottle or an expulsion-type snuffer device. In

either case, you’ll need to test that the closed

interrupter has low resistance. In most cases,

anything less than an ohm can be used for a

go/no-go.

After you have proven you can pass current

through the closed interrupter, the next step is

to prove the interrupter can interrupt the

current at full voltage. If the interrupter is of

the snuffer type, there’s no real test you can

do. If the interrupter is of the vacuum type,

verify with the manufacturer that the vacuum

bottle can be tested with a hi-pot. Applying

voltage to the open vacuum bottle is the only

way to prove the vacuum exists and the

interrupter will interrupt load at line voltage.

If all these procedures are followed on all

connections and switches in the station during

a three- to five-year cycle, you should have

eliminated at least one looming source for

serious catastrophic substation problems.

Insider Tips for maintenance

Gary Wright, has been responsible for the

maintenance of more than 100 sub-stations

over the last 35 years.

Infrared: Often some of the transmission

lines can be scanned as you drive to each

station. It’s usually beneficial to hire an

infrared contractor to scan transmission lines

and the most important distribution feeders.

Nuts: It’s important to use a silicon bronze

for the nut, because if you use a stainless

steel nut, the nut can gall and stick. This

means you can’t get the connection tight.

Unfortunately, it will appear tight, and you

might not be able to get the nut back off.

Grounding: There can only be one ground

connected anywhere on the conductor

you are testing. If there is a second ground

installed anywhere, it will become a parallel

current path and make your reading useless.

Megger ELECTRICAL TESTER July 2013

5

ELECTRICAL

TESTER

The industry’s recognised information tool

Multiple current injection

Figure 1: Two SMRT36’s and two SMRT1’s

interconnected together

Figure 3: Sixteen bay bus-zone stable condition while

injecting sixteen currents

The number of current outputs that users

require from protection relay test sets

seems to be constantly increasing and of

course, test sets are evolving to meet these

requirements. Some of the latest models

are capable of injecting ten test currents

simultaneously from a single test set.

Sometimes even this isn’t quite enough, and,

in certain applications, more are needed.

This application-based need was most

definitely apparent when a customer in South

Africa wanted to test a new bus-zone

protection panel, manufactured by one of the

world’s best-known relay manufacturers. The

panel was to be installed as an upgrade in one

of the South African 400 kV substations. This

particular bus-zone panel had 16 protection

relays, and, to test the bus-zone scheme

effectively, the most convenient solution was

to inject current into all of the relays

simultaneously. Unfortunately, there is no

single relay test set available that supports 16

current channels.

Safeguard

those services!

Mr. Jörg Schubert

Manager, line locating and inspection

Megger Baunach

It only takes a short walk or drive through

any town centre to confirm that excavations

– holes in the road – are common. In fact,

they’re very common. And, with every one

of those excavations goes a very real concern:

will the digging lead to costly and disruptive

accidental damage to underground services?

Of course in an ideal world, the routes of

buried cables and pipes should be properly

documented, which would make avoiding

them relatively straightforward. In the real

world however, plans are often missing or

just plain wrong.

6

Ingenious engineers came up with a thoughtprovoking alternative. Instead of using a

single test set, why not interconnect multiple

relay test sets to provide the required number

of current channels? The engineers from the

customer and the relay manufacturer found

this suggestion interesting, and so arrangements were made for it to be evaluated.

Largely because of equipment availability,

the test sets chosen for the exercise were two

SMRT36 three-phase units and two SMRT1

single-phase configured as shown in Figure 1.

The three-phase unit had three current

channels and three voltage channels, but

the voltage channels could be converted to

current channels to give six currents at one

time out of one test set. The single-phase unit

had one current channel and one voltage

channel and the voltage channel could be

converted to a current channel to give two

current channels.

Fortunately, this no longer needs to be a

problem, as convenient and dependable line

location systems for determining the position of

underground services are now available, like

the EasyLoc.

Comprising of two separate components – a

transmitter and a handheld receiver – which

are capable of tracing the routes of energised

and dead power cables and of metallic pipes.

When tracing energised cables, the receiver is

used on its own and looks for power frequency

signals radiated by the cable. The user simply

scans the likely route of the cable with the

receiver until a clear signal is indicated, and

then determines the cable location even more

accurately by carefully adjusting the position

of the receiver until the highest signal strength

is achieved.

Typically, the signal is indicated audibly via

a built-in loudspeaker, and also visually on a

backlit display panel. With the best instruments,

once the location of the cable has been

determined, its depth can be measured and

displayed simply by pressing a button on the

receiver.

Megger ELECTRICAL TESTER July 2013

Marius Pitzer

Sales manager, Megger South Africa

Figure 2: Three SMRT36’s interconnected together

Figure 4: Sixteen bay bus-zone Zone 1 fault while

injecting sixteen currents

The four test sets were interconnected via

Ethernet cable (RJ45) so that they could be

operated as if they were one single test set,

and overall control was provided for some of

the time with a touch-screen interface unit,

and on other occasions with a dedicated software package running on a PC.

The test equipment performed exactly as

required, and the simulation of different

zone faults went smoothly when a simple

pre-fault/fault test was run. In the pre-fault

stage, a stable bus-zone condition was

simulated as shown in Figure 3. After a

predetermined time period, a fault was

injected and the time taken to clear the fault

was measured. Figure 4 shows a Zone 1 fault

that tripped in 12.5 ms. After the zone timing

tests were completed successfully, breaker fail

testing was performed using seven stages and

once again this proved to be problem free.

At the end of the testing, both the customer

and the relay manufacturer’s engineers

agreed that this novel approach offered major

The procedure for tracing pipes and unenergised cables is very similar, but in this

instance the transmitter is used to inject a

unique test signal, usually at a frequency of

33 kHz, into the pipe or cable. This can be

done by direct connection of the transmitter,

or by using induction to couple the test signal.

With some instruments, the transmitter has an

output that’s protected against mains voltages,

allowing it to be used with energised cables

to improve accuracy in difficult operating

conditions.

The latest line location systems incorporate

automatic sensitivity control, which makes

them particularly easy to operate; together

with a self-calibration check routine that saves

on maintenance costs. Some also offer accessories

to further increase their usefulness. These

accessories may, for example, include pipeline

transmitters for locating non-metallic pipes,

transmitter clamps for coupling the transmitter

signal into energised cables without the need

for direct connections, house connection sets

for connecting the transmitter signal via a

standard socket outlet, and headphones to

enable the receiver’s audible output to be

monitored in noisy environments.

benefits, not the least of which was that it had

allowed the testing of the new bus-zone panel

to be completed in less than a day when

similar panels had in the past typically taken

three days to test using traditional test

techniques. Using the traditional test techniques, the customer would sectionalize the

bus-zone and test the panel using six test

currents at a time and would therefore, have

to go through a prolonged process to simulate

all possible faults in the bus-zone.

Since the initial test, the customer has bought

another SMRT36 three-phase test set and is

now using three of these to inject up to 18

currents, as shown in Figure 2. No end-user

is ever satisfied for very long, however, and

it is already being suggested that the next

challenge will be to test a protection system

that requires 32 currents to be injected

simultaneously!

Line location systems of the type described

here are readily portable, easy to use and

modestly priced. All in all, they’re an excellent

investment – they safeguard services and

thereby provide peace of mind by eliminating

one of the biggest concerns associated with

excavations of every kind.

When the location of the cable has been

determined, its depth can be measured and

displayed simply by pressing a button on the

receiver

www.megger.com

ELECTRICAL

TESTER

The industry’s recognised information tool

Explaining

the art of

testing

Elsa Cantu

Marketing communication manager,

Megger Dallas

Cable fault

Peter Herpertz

Product manager, power

In the first of a series of articles on cable

fault location, Peter Herpetz looks at the

construction of modern power cables and

examines the most common types of fault

that affect them.

The importance of cable testing

Fault location on power cables is a very

special area of electrical technology, and the

results obtained depend very much on good

logistics and knowledge. Accurate prelocation

is the foundation for fast and reliable fault

location, because it means that pinpointing

procedures only need to be carried out on a

short section of cable.

The importance of cable testing, cable fault

diagnosis and partial discharge analysis are

certain to become increasingly important in

the future, as condition-based maintenance

of cable networks more and more displaces

event-oriented maintenance.

A prime requirement for testing electrical

power systems is without doubt to have access

to the right equipment – the latest test sets

deliver levels of convenience and performance

that simply cannot be achieved with their

predecessors. But the right test equipment on

its own does not offer a complete solution;

adoption of the correct test techniques is also

essential if the most accurate and reliable

results are to be obtained.

Test techniques do not however, stand

still. On the contrary, they are continuously

developing, which is why NETA, the

InterNational Electrical Testing Association,

regularly invites papers on developments in

test techniques and associated subjects for

presentation at its annual PowerTest Electrical

Maintenance and Safety Conference.

The papers are carefully selected to highlight

significant advances and, at the end of the

conference, the best of them, which are

chosen through a searching judging and

evaluation process carried out by NETA,

receive awards. These coveted and prestigious

awards recognise not only the expertise of

the papers’ authors, but also the valuable

contribution that their work has made to the

power test community. Among the awards

made at PowerTest 2013, which was held in

New Orleans in February, were:

A good, detailed knowledge about the cable

network, cable types and cable accessories

greatly simplifies the evaluation of test results

and, in many cases, such knowledge is an

essential prerequisite for making correct

decisions. Among the most important things

that technicians need to know are the types of

cable faults and the steps needed to carry out

cable fault location and diagnosis.

Construction of power cables

The function of power cables is the

distribution of electrical energy, and they

must carry out this function reliably and safely

for very long periods. Depending on the

application, the external environment and

local conditions, such as the presence of

ground water and the type of ground voltages,

different types of cable are used. Cables with

impregnated insulation, such as PILC (paper

insulated lead covered) types were widely

used until the late 1960s and are still in

service in some areas. These cables have,

however, mostly been replaced by cables

with PVC (polyvinylchloride), EPR (ethylenepropylene rubber), PR, or XLPE (cross-linked

polyethylene) insulation. As a result of these

changes in the type of insulation used, cable

faults and cable testing techniques have also

changed considerably.

The following sections cannot cover all of the

possible types of cables, insulating materials

and cable construction, so they focus on the

most important variants. In many cases, details

are explained primarily as an aid to understanding the terminology used in the later

sections of this guide to cable fault location.

Best Relay Presentation: ‘Utilising Ground

Fault Resistance to Accurately Test Distance Element’ by Jason Buneo, Applications Engineer

n

n

Best Circuit Breaker Presentation: ‘Testing

and Troubleshooting of Low to Medium

Voltage Circuit Breakers’ by Bret Hammond

and Robert Foster, Technical Support Engineers

n

Best Safety Paper: ‘Electrical Safety Through

Design, Installation and Maintenance’ by Dennis Neitzel

All the authors of these award-winning papers,

with the exception of Dennis Neitzel are

Megger employees. Dennis Neitzel is Director

Emeritus of AVO Training Institute Inc., which

is a Megger subsidiary. Megger also won two

marketing awards at PowerTest 2013, for Best

in Show Trade Show Marketing, and Most

Entertaining Hospitality Night.

www.megger.com

As well as these typical materials, there are

many other types of insulation.

Semiconducting layers (at nominal

voltages above 6 kV)

The purpose of semiconducting layers is to

reduce the strength of electric fields within the

cable, and to eliminate partial discharge. Semiconducting layers reduce the electric field that

develops around the conductors, and thereby

eliminate the potentially damaging discharges

associated with high electric field strengths.

On modern cables, another type of semiconducting layer is sometimes integrated with

the outer insulating sheath/jacket. The purpose

of this type of layer is to aid the location of

sheath faults on cables that are installed in

ducts, where there is no return path through

the earth for fault currents.

Sheath/jacket

Shield/screen

Semi conductor

Flashing fault (parallel fault)

This is a very high resistance fault, and can

be present when the cable is charged.

Typically, the flashover occurs at several kV,

and is very often located in cable joints. The

cable behaves in the same way as an arc gap,

where the distance between the electrodes

determines the breakdown voltage. The

resistance of this type of fault is typically

infinity up to the breakdown voltage.

Open-circuit fault (series fault)

Faults of this type can be very high resistance,

up to infinity if the conductor is completely

severed. Very often, this type of fault is a

combination of series and parallel resistances.

The reason for this is that if the conductor is

completely cut or pulled out of a joint, this not

only produces a complete open circuit, but

also allows all possible variations of flashover.

If the conductor is partially burned, this type

of fault is called a longitudinal fault.

Insulation/dielectric

Inner semi conductor

Core/conductor

Metallic sheath

The metallic sheath performs multiple

functions. It seals the cable against the entry

of humidity, it provides a conductive path for

leakage and earth-fault currents, it provides

potential equalisation and it can be used as

either an earth conductor or a concentric

neutral conductor. For cables used in critical

or subsea applications, the metallic sheath

can be designed to provide robust mechanical

protection.

Shield (for MV and HV cables)

The shield provides electric field control, and

also offers a conductive path for leakage and

earth fault currents.

Armour

The armour provides mechanical protection.

It may consist of steel bands, flat steel wire,

round steel wires, etc. In some cases, the

armour may be made up of several different

layers.

Plastic sheath

The plastic sheath provides outer protection

for the cable, and usually consists of either

PVC or polyethylene.

Cable faults

When diagnosing and locating cable faults, the

procedure depends on the type of cable fault.

Cable faults are generally divided into the

types listed here.

Earth faults and sheath faults

These are faults between the metallic shield

and the surrounding soil for plastic-insulated

cables, or between the conductor and the

surrounding soil for LV and plastic-insulated

cables. Great care must be taken when using

high voltages to test for or locate this type of

fault, as the voltage discharges directly into the

earth, creating shock hazards for people and

animals.

Humid/wet faults

On multicore cables, all conductors are often

affected by this type of fault, but the flashovers

do not always occur at the point where the

water entered the cable. Impedance changes

occur at the fault position. Depending on the

cable construction (for example, the type of

longitudinal water sealing), these faults can

be confined to a single point or widespread

throughout the cable. Humidity/wet faults are

the most difficult faults to locate. They have

a tendency to change during the fault location

procedure, often very considerably. Particularly

in joints, this means that the fault becomes

highly resistive after one or two discharges, as

the water is blown out of the joint and dries

up. When this happens, the fault can no

longer be localised. Underwater faults are

another form of wet fault. With these, the

water pressure prevents effective ignition of

the fault when high voltage is applied. These

faults can be very difficult to localise.

Conductor-to-conductor fault (parallel

fault)

Unwanted connection between two or more

conductors. The resistance of the fault may be

anywhere between zero ohms (low resistance)

and several megohms (high resistance).

n

Best Reliability Presentation: ‘Detecting Common Power Quality Issues’ by Andrew Sagl, Product Manager

propylene rubber (EPR)

n above 60 kV: paper with oil or gas, cross-

linked polyethylene (XLPE)

Conductor

The conductor is the part of the cable that

transmits current, and is usually soft electrolytic copper or pure aluminium. The conductor

can be round or sector-shaped, and made of

single wire or multi-stranded.

Insulation

The purpose of the insulation is to prevent the

flow of current between the conductors in the

cable, and from the conductors to the cable’s

metallic outer covering, which may be armour

or a lead sheath. Typical insulating materials

are:

n 1 to 10 kV: mass impregnated paper (PILC), polyvinylchloride (PVC)

n 1 to 30 kV: mass impregnated paper (PILC), cross-linked polyethylene (XLPE), ethylene Conductor-to-shield fault (parallel fault)

Connection between a conductor and the

shield or between multiple conductors and

the shield. The resistance of the fault may be

anywhere between zero ohms (low resistance)

and several megohms (high resistance).

Experience shows that the majority of faults

fall into this category.

CONCLUSION

A clear distinction must be made between

short-circuit, resistive and high-resistance

faults, because this distinction has a significant

influence on the procedures that should be

used for fault location. These procedures will

be described in future articles in this series.

Megger ELECTRICAL TESTER July 2013

7

ELECTRICAL

TESTER

The industry’s recognised information tool

Q&A

Q: How should transformer winding resistance

test results be evaluated?

A: Evaluation can be carried out by comparing

the test results with original factory measurements

or with previous measurements that have been

made in the field. Alternatively, the results can

be evaluated by comparing the phases with

each other. In most cases, phase-to-phase

comparisons are sufficient.

Q: How much difference between measurements

is acceptable?

A: The industry standard for factory tests

permits a maximum difference of 0.5% from

the average resistance of the three phase

windings. Measurements made in the field

may vary slightly more than this because there

are more variables, but if the measurements

are within 1% of each other, they can be

considered acceptable. Note that comparing

absolute resistance values measured in the

field with factory values can be difficult,

principally because of the difficulty of estimating