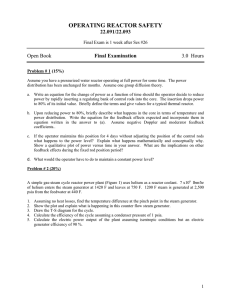

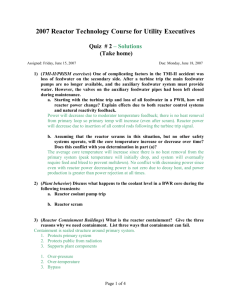

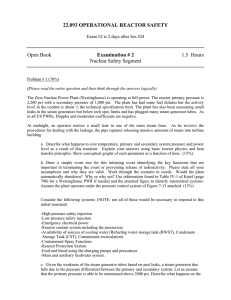

Fault Studies to Discuss Deterministic Analysis, PSA and Fault

advertisement