Computer Science and Engineering 2013, 3(2): 15-23

DOI: 10.5923/j.computer.20130302.01

Application of the Structural Analysis on a Three Axis

Manipulator Robot

Yasmine Derdour1,* , Hafid Haffaf1 , Kheireddine Bouazza2

1

Department of Computer, University of Oran, Faculty of Science, Oran, 31000, Algeria, Riir

Department of Computer, University of Oran, Faculty of Science, Oran, 31000, Algeria, Litio

2

Abstract The main objective is to show the efficiency of the structural analysis in the field of the mon itoring and the

fault detection by taking into account the constraints of the real world, and consequently, to know exact ly at wh ich level

and at which mo ment it will be necessary to intervene. The problem of fault detection (FD) is to check for the presence of

crash. When no fault is present in the system, it is in the safe mode, otherwise it is in the faulty mode. In the first case, the

analytical residual redundancy relations (ARRs) vanish, in the second case, they are different fro m zero if some fault arises,

and we have to decide among a nu mber of fau lty modes, wh ich mode is incriminated, this is the isolation process (FI) Th is

paper presents a three axis manipulator robot on which we apply the structural analysis for fault diagnosis purpose.

Structural analysis offers the opportunity to transform an analytical model into a structural model, so we can describe it

using an incidence matrix which allows representing components of the system. Fro m the structural graph obtained, we

apply the matching algorith m to extract analytical redundancy relations gathered in a signature failures table. Based on

“detectability” and “localizab ility” properties, the aim of the method is to identify the main variables which are influential

and dependent on the evolution of the system.

Keywords Structural Analysis, Monitoring, Fau lt Detection and Isolation, Matching, Bipart ite Graph, Incidence Matrix,

Table of Signature, Residue, Analytical Relations of Redundancies

1. Introduction

At present, the competition between manufacturers

became more and more rough to satisfy the requirements of

their customers in order to offer the best quality of products

and services which exists. This competition obliges

increasingly to integrate the concept of monitoring at every

level. In order to achieve this objective, manufacturers try

today more than ever to increase the productivity of their

companies; this by reducing the costs and production time

and by improving manufacturing quality. The ceaseless

modernizat ion of production tools makes industrial systems

increasingly co mplex and sophisticated. In parallel, a

greater request of reliability, availability, reconfigurability

and safety became real challenges in the third millenniu m

that industrial system ought to verify.

The development of co mputing, financial accessibility and

co mp u t in g p o wer o f co mp u t ers mad e p o s s ib le t h e

develop ment of diagnosis methods such as the structural

analysis. Ho wever, industrial systems are designed much

more co mp lex and the failure of one co mponent can lead to

dysfunction of the whole system. Th is can have major effects

* Corresponding author:

derdouryasmine@yahoo. fr (Yasmine Derdour)

Published online at http://journal.sapub.org/computer

Copyright © 2013 Scientific & Academic Publishing. All Rights Reserved

on the availability and performance of the system so leading

industry efforts to failure. It can even cause damage

tomachines or hu man especially when these systems appear

in many processes with risk such as nuclear and chemical

ones. The improvement of their safety is based on the Fault

detection and isolation (FDI) procedures[1]. A fault in a

system may affect the actuators, the sensors or the

components. Different approaches for the design of FDI

procedures have been developed, on the basis of the kind of

knowledge used to describe the plant. The FDI methodology,

when applied to detect the failures by using the structural

analysis, is the use of the structural model. The later

represents only relationships between components

neglecting the values of variables and parameters[2][3]. The

structural model of a system is an abstraction of its

behavioural model in the sense that only the structure of the

system is important. Among those properties, we can cite:

controllability, observability, fault detectability or

monitorability, sensor placement objectives,[4]. The FDI

procedure is essentially based on generating Analytical

Redundancy Relations (ARRs) in order to compare the

actual behaviour with reference behaviour in monitoring

process[5]. In the other hand, control of robot is topical issue

in automat ic process, and the ability of monitoring sensitive

components is a main object ive in design process. For this

raison, the estimate of a process state quality and its

dependability are h ighly conditioned by the number and

16

Yasmine Derdour et al.: Application of the Structural Analysis on a Three Axis M anipulator Robot

distribution of measurements over it. The instru mentation

architecture design of a system represents a very important

step. The used analytical model can be given under structural

or state space equation form [6]. A bipart ite graph is then

generated from the mathematical model corresponding to the

three axis robot in order to perform structural analysis, which

in turn, boils down to matching characterizat ion.

The innovative interest of this paper is to apply this

structural method in robotics, a three axis manipulator robot

is considered, on which all the steps of structural analysis are

carried out: we apply the matching on a bipart ite graph, and

thus, generate ARRs fro m this matching which are gathered

on signature table. After giving the model of the robot

(section 5), the basic concepts of structural analysis are

recalled in section 6, and then in section 7 and 8, the

application of the analytical redundancy relations generation

steps.

These redundancy relations are then satisfied in the

normal mode, and not satisfied in the case of presence of

failure[6].

2. Monitoring Concepts

To detect locate errors, the anomalies and dysfunctions,

the surveillance includes all the tools allo wing to control the

evolution of the behavior of production system with regard

to its normal functioning. The surveillance is the base of an

excellent safety of functioning of technological processes, it

constitutes an interface between the operator and the

physical installat ion. Its role is to provide information on the

actual state (correct or incorrect) of mon itored devices, to

validate the in formation fro m the sensors and to locate the

failing co mponents. The FDI based methodology is divided

in two stages: design phase to obtain ARRs fro m the

structural (graphical) model, and the explo itation phase

where these residuals are on line analy zed.

Let us now introduce some basic concepts of

SURVEILLA NCE (SUPERVISION)[7]

Failure. (undesirable) : functional ano maly in a physical

system. A failure is a consequence of a risk that materializes.

Error or dysfunction : this is the part of the system that no

longer meets the need required, and can eventually cause

failure.

Breakdown :inability of a device to perform its function.

Safety of functioning : It is the technical and human

reliability of a process. The design of a system sure must

assess the risk of hardware failu re, software and human, and

environmental conditions.

Reliability: ability to adequately perform the task in

normal conditions, during a given time interval.

Availability: (at any time) the availability is defined as

"the ability of an entity to be able to accomplish required

function in given conditions, at a given time or during a

given time interval, assuming the provision of external

resources necessary maintenance is assured.

Maintainability or possibility of restoring: according to

the AFNOR standard is "in the given conditions of use, the

ability of an entity to be maintained or restored, on a given

time interval, in a state in which it can perform a required

function, when maintenance is performed under given

conditions, with prescribed procedures and resources."

Security: the system's ability to avoid appear, in g iven

conditions, catastrophic events or the insurance system to

resist unauthorized or incorrect entrance and to be able to

report them.

3. Conception of a Monitoring System

The variables are of two kinds needed in the system:

a) The entrances

• Knowledge of the operation of the system to monitor

• Monitoring System Specifications

b) The outputs

• Detection, localization, diagnosis of failures

• Algorith ms variables that must be acquired to enable it

to fulfill the specifications

• Characterization of the system designed to assess its

performance[7].

In the monitored system, the decision-making between the

presence or absence of the errors is a problem of fau lt

detection (FD). When no error has been made in the system,

this last one is called " in normal mode ", otherwise it is

called " in degraded mode". The problem of fau lts isolation

is to determine the presence of degraded mode between

modes and possible states of the system.

4. Principle of Fault Detection and

Isolation (FDI)

For thirty years, the fault detection and isolation (FDI)

continues to grow in importance as a research topic,

especially within the co mmun ities of Automat ic Co mmand

and Artificial intelligence[8][9]. The FDI is based on the

following steps:

The diagnosis bases on an explicit model of the normal

behavior of the system.

The faults isolation is based on the analysis of sets

components (faults) involved in each detected incoherencies.

• A defect is detected fro m the incoherence between the

observed behavior and the behavior predicted by the model

• The faults isolation is based on the analysis of sets

components (faults) involved in each detected incoherence.

Nu merous methods are on the basis of the works of

detecting and locating defects, and there are constantly new

methods proposed in the literature[10]. Most of these

methods can be viewed as variations or imp rovements of

previous ones. This section is intended as a not exhaustive

review o f these methods, among which it is sometimes

difficult to determine which it is better necessary to use[7].

Nevertheless, we can retain three operations:

• Detection: decide if the system is faulty.

Computer Science and Engineering 2013, 3(2): 15-23

• Localization: to determine which part of the system is

affected.

• Identification: determine the extent of the defect.

The FDI methods differs not only in the way in wh ich

knowledge about the process being monitored is used but

also on[7] the nature the required knowledge. In general, the

methods are divided into two major families fo llo wing:

4.1. Approaches Based on Models

They are based on knowledge we get of the normal

behavior of the system represented by a specific model,

which can be quantitative or qualitative. The first model is

based on fundamental physical princip les expressed in the

form of mathemat ical equations, while the second is based

on the system structure and the links between co mponents,

expressed for examp le in the form of logical relat ions. The

principle of these approaches consists in comparing the

informat ion fro m the system in real time with those from the

model to detect differences.

4.2. Approaches wi th Historical Data (or wi thout

Models)

They are based on knowledge obrained from past

experiences (we shall also take into account superficial

knowledge based on the history story of the process). In

these approaches, an analysis is made on the records of the

past experiences in order to extract the characteristics of the

system to be monitored to ach ieve the observed symptoms

lin ked to the corresponding defects.

Techniques based model and techniques without model

make both use of redundancy information relative to the

system. This can be obtained fro m data of the system during

previous functioning in normal mode, either fro m the

knowledge wh ich we have on the system (analyt ical model).

The redundancy can result thus either fro m entrances. We are

interested in this article to structural analysis that is a

method-based model.

The structural analysis is a tool o f a collective reflect ion. It

offers the possibility of translating an analytical model into

structural model then it describes this model using an

incidence matrix linking all the co mponents of this system.

Fro m there, the structural graph can be obtained. We make

then the matching to be able to loosen analytical redundancy

relations which we shall classify in the signature failures

table. And at the end, we can apply the FDI. Leav ing of this

description, this method has for object to create the main

influential and dependent variables and thus the essential

variables in the evolution of the system.

We shall discuss the approaches which are interested in

the fault detection and isolation of the defects ( FDI) in a

system, especially the methods which use a behavioral

model. This model consists of a representation of system

behavior in the form of mathematical relations ( analytical

model).

17

5. Modelling of Dynamic Model of the

Robot[11]

The model is represented by the following equation:

𝛤𝛤 = 𝑀𝑀 (𝑞𝑞) 𝑞𝑞̈ + 𝐶𝐶(𝑞𝑞, 𝑞𝑞̇ )𝑞𝑞̇ + 𝐺𝐺 (𝑞𝑞) + 𝑓𝑓𝑣𝑣 𝑞𝑞̇ + 𝑓𝑓𝑠𝑠 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 ( 𝑞𝑞̇ ) (1)

Where𝑞𝑞̈ is the n×1 accelerat ions vector, 𝑞𝑞̇ is the n×1

velocities vector, q is the n×1 coordinates vector and 𝛤𝛤 is

the n×1 external torques vector. 𝑀𝑀 (𝑞𝑞) represents the n×n

positive definite inertial matrix, 𝐶𝐶 (𝑞𝑞, 𝑞𝑞̇ ) is the n×n Coriolis

and centrifugal fo rces matrix and G(q) is the n×1

gravitational torques vector. fv is the n×n viscous frictions

diagonal matrix, and fs is the Coulo mb frictions diagonal

matrix, but these matrix will be ignored throughout our work.

And therefore we obtain the following model:[11]

𝛤𝛤 = 𝑀𝑀 (𝑞𝑞) 𝑞𝑞̈ + 𝐶𝐶(𝑞𝑞, 𝑞𝑞̇ )𝑞𝑞̇ + 𝐺𝐺 (𝑞𝑞)

(2)

Without loss of generality, the inert ial matrix of the robot

is given by:

0

𝑀𝑀11 𝑀𝑀12

0 �

𝑀𝑀 = �𝑀𝑀21 𝑀𝑀22

0

0

𝑀𝑀33

With:

▪ 𝑀𝑀11 = 𝑚𝑚1 𝑎𝑎21 + 𝑚𝑚2 (𝑙𝑙 21 + 𝑎𝑎22 + 2 𝑎𝑎2 𝑙𝑙 1 𝑐𝑐2) +

𝑚𝑚3 ( 𝑙𝑙 21 + 𝑙𝑙 22 + 2 𝑙𝑙 1 𝑙𝑙2 𝑐𝑐2 ) + 𝐼𝐼1𝑧𝑧𝑧𝑧 + 𝐼𝐼2𝑧𝑧𝑧𝑧 + 𝐼𝐼3𝑧𝑧𝑧𝑧

▪ 𝑀𝑀12 = +𝑀𝑀21 = 𝑚𝑚2 ( 𝑎𝑎22 + 𝑎𝑎2 𝑙𝑙1 𝑐𝑐2 ) + 𝑚𝑚3 (𝑙𝑙 22 +

𝑙𝑙1 𝑙𝑙2 𝑐𝑐 2+𝐼𝐼2𝑧𝑧𝑧𝑧+𝐼𝐼3 𝑧𝑧𝑧𝑧

▪ 𝑀𝑀22 = 𝑚𝑚2 𝑎𝑎22 + 𝑚𝑚3 𝑙𝑙 22 + 𝐼𝐼2𝑧𝑧𝑧𝑧 + 𝐼𝐼3𝑧𝑧𝑧𝑧

▪ 𝑀𝑀22 = 𝑚𝑚3

Where :

𝑚𝑚𝐼𝐼 : Mass of axis 𝑖𝑖

𝑠𝑠𝑖𝑖 : Sinus ( 𝑞𝑞𝑖𝑖 )

ci : Cosinus ( 𝑞𝑞𝑖𝑖 )

𝐼𝐼𝑖𝑖𝑖𝑖𝑖𝑖 : Inertia mo ment of joint 𝑖𝑖

The mat rix of Corio lis and Centrifugal forces is:

𝐶𝐶11 𝐶𝐶12 0

𝐶𝐶 = � 𝐶𝐶21 0 0 �

0

0 0

with

𝐶𝐶11 = −2 𝑙𝑙 1 𝑠𝑠2 ( 𝑚𝑚2 𝑎𝑎2 + 𝑚𝑚3 𝑙𝑙 2 )𝑞𝑞̇ 2

𝐶𝐶12 = −𝑙𝑙 1 𝑠𝑠2 (𝑚𝑚2 𝑎𝑎2 + 𝑚𝑚3 𝑙𝑙 2 )𝑞𝑞̇ 2

𝐶𝐶21 = 𝑙𝑙 1 𝑠𝑠2 (𝑚𝑚2 𝑎𝑎2 + 𝑚𝑚3 𝑙𝑙 2 )𝑞𝑞̇ 1

And the gravitational vector is: 𝑞𝑞̇

𝐺𝐺 = ( 0 0 − 𝑚𝑚3 𝑔𝑔) 𝑇𝑇

l1

a1

a2

l2

c2

c1

d2

Figure 1. The robot under study

18

Yasmine Derdour et al.: Application of the Structural Analysis on a Three Axis M anipulator Robot

In order to min imize, the nu mber of parameters (without

rank deficiency on observation matrix) and also to avoid the

probable cumulat ive errors in identification of each

parameter, we proceed to several grouping:[11]

𝑃𝑃1 = 𝑚𝑚1 𝑎𝑎21 + ( 𝑚𝑚2 +𝑚𝑚3 )𝑙𝑙 21 + 𝑚𝑚2 𝑎𝑎22 + 𝑚𝑚3 𝑙𝑙 22

+ 𝐼𝐼1𝑧𝑧𝑧𝑧 + 𝐼𝐼2𝑧𝑧𝑧𝑧 + 𝐼𝐼3𝑧𝑧𝑧𝑧

𝑃𝑃2 = 𝑚𝑚2 𝑎𝑎22 + 𝑚𝑚3 𝑙𝑙 22 + 𝐼𝐼2𝑧𝑧𝑧𝑧 + 𝐼𝐼3𝑧𝑧𝑧𝑧

𝑃𝑃3 = 𝑙𝑙 1 (𝑚𝑚2 𝑎𝑎2 + 𝑚𝑚3 𝑙𝑙 2 )

𝑃𝑃4 = 𝑚𝑚3

Then, we can write:

𝑝𝑝1 + 2𝑝𝑝3 𝑐𝑐2 𝑝𝑝2 + 𝑝𝑝3 𝑐𝑐2 0

𝑝𝑝2

0 � 𝑞𝑞̈ +

𝛤𝛤 = � 𝑝𝑝2 + 𝑝𝑝3 𝑐𝑐2

0

0

𝑝𝑝4

0

−2𝑝𝑝3 𝑠𝑠2 𝑞𝑞̇ 2 −𝑝𝑝3 𝑠𝑠2 𝑞𝑞̇ 2 0

� 𝑝𝑝3 𝑠𝑠2 𝑞𝑞̇ 1

(3)

0

0� 𝑞𝑞̇ + � 0 �

−𝑝𝑝4 𝑔𝑔

0

0

0

With the parameters presented in the table below:

Table 1. Robot parameters

p1

p2

p3

p4

19.1337

2.8522

4.1214

1.2568

• The Relati ons for Model of the Robot

The components of the robot are described by the

following relat ions:

−𝐶𝐶1 : 𝑞𝑞̈ 1 =

𝑎𝑎 𝛤𝛤1 + 𝑏𝑏 𝛤𝛤2 + 𝑐𝑐 𝛤𝛤3 + 𝑞𝑞̇ 1 (𝑎𝑎 8,2428 𝑠𝑠𝑠𝑠𝑠𝑠 𝑥𝑥(3) 𝑥𝑥(4) −

𝑏𝑏 4,1214𝑠𝑠𝑖𝑖𝑛𝑛 𝑥𝑥3 𝑥𝑥 2+ 𝑐𝑐𝑚𝑚3𝑔𝑔 (4)

−𝐶𝐶2 : 𝑞𝑞̈ 2 = 𝑑𝑑 𝛤𝛤1 + 𝑒𝑒 𝛤𝛤2 + 𝑓𝑓 𝛤𝛤3 + 𝑞𝑞̇ 2

(𝑏𝑏 4,1214 𝑠𝑠𝑠𝑠𝑠𝑠 𝑥𝑥 (3) 𝑥𝑥 (4) + 𝑓𝑓𝑚𝑚3 𝑔𝑔)

(5)

(6)

−𝐶𝐶3 : 𝑞𝑞̈ 3 = 𝑔𝑔 𝛤𝛤1 + ℎ 𝛤𝛤2 + 𝑖𝑖( 𝛤𝛤3 +𝑚𝑚3 𝑔𝑔)

(7)

−𝑚𝑚1 : 𝑦𝑦1 (𝑡𝑡) = 𝑞𝑞1 (𝑡𝑡)

(8)

−𝑚𝑚2 : 𝑦𝑦2 (𝑡𝑡) = 𝑞𝑞2 (𝑡𝑡)

(9)

−𝑚𝑚3 : 𝑦𝑦3 (𝑡𝑡) = 𝑞𝑞3 (𝑡𝑡)

𝑑𝑑 𝑞𝑞1 (𝑡𝑡)

−𝑑𝑑 1 : 𝑞𝑞̇ 1 (𝑡𝑡) =

(10)

−𝑑𝑑 2 : 𝑞𝑞̈ 1 (𝑡𝑡) =

−𝑑𝑑 3 : 𝑞𝑞̇ 2 (𝑡𝑡) =

−𝑑𝑑 4 : 𝑞𝑞̈ 2 (𝑡𝑡) =

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞̇ 1 (𝑡𝑡)

−𝑑𝑑 6 : 𝑞𝑞̈ 3 (𝑡𝑡) =

(12)

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞3 𝑡𝑡)

(14)

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞̇ 2 (𝑡𝑡 )

−𝑑𝑑 5 : 𝑞𝑞̇ 3 (𝑡𝑡) =

(11)

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞2 (𝑡𝑡 )

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞̇ 3 (𝑡𝑡)

𝑑𝑑𝑑𝑑

(13)

(15)

The analytical model of the robot is a set of:

-Three constraints: 𝐶𝐶1 , 𝐶𝐶2 and 𝐶𝐶3

-Three measures: 𝑚𝑚1 , 𝑚𝑚2 and 𝑚𝑚3

-Six derivations : 𝑑𝑑 1 , 𝑑𝑑 2 , 𝑑𝑑 3 , 𝑑𝑑 4 , 𝑑𝑑 5 and 𝑑𝑑 6

This model connects nine unknown variables; it implies

that we can generate three relations of analytical redundancy.

It includes the follo wing co mponents:

-The inputs 𝛤𝛤1 , 𝛤𝛤2 and 𝛤𝛤3 of the three axis of robot.

-The position, the speed and acceleration ( 𝑞𝑞1 , 𝑞𝑞̇1 and 𝑞𝑞1̈ )

for axis1, and so on for axis 2 and axis 3.

- 𝑦𝑦: output,

- 𝑎𝑎, 𝑏𝑏, 𝑐𝑐, 𝑑𝑑 , 𝑒𝑒, 𝑓𝑓, 𝑔𝑔, ℎ, 𝑖𝑖: coefficients,

- 𝑔𝑔 : gravity.

Industrial systems like those in Robotic much more

complex designed and the failure o f one component can lead

to the dysfunction of the whole system. This can have major

effects on the availab ility and performance o f the system

leading the industrialists’ efforts to failure. It can even cause

damage to machines or human.

The need for safety of functioning and monitoring became

crucial to meet the performance objectives and above all

safety of technological processes such as robots especially

for critical systems such as nuclear, aeronautical systems...

This is why there are several methods to overcome these

problems and ensure proper monitoring.

6. Structural Analysis

The structural analysis is a method of the pretreatment;

this pretreatment is effective even for the most co mplex

automated systems. This method is concerned with the

properties of the system structure model, and it’s considered

as a powerful tool which determinates these properties.

Thanks to graph theory, these properties are obtained

starting from the only knowledge of the existence of links

(constraints) between variables, without need the parameters

values[12].

The structural analysis, by the knowledge of the structural

conditions of observability or o f co mmandability, allo ws the

detection and localizat ion of the failures or the study of

reconfigurability.

The structural properties under study are[2]:

• The identification of the mon itorable part of the system

that is the subset of the system components of this system of

whose faults can be detected and isolated.

•The possibility to design the residuals which meet some

specific fau lt diagnosis requirements, namely which are

simp ly robust, (insensitive to disturbances and uncertainties),

and structured (sensitive to certain faults and insensitive to

others).

• The existence of reconfiguration possibilities in order to

estimate (respectively to control) some variable o f interest

in case of sensor, actuator or system component failures[2].

Answers to these questions are provided by the analysis of

the structural graph of the system.

The main purpose of representing the system as a

structural graph is to obtain the knowledge of the subsystem

with inherent redundant informat ion that exists within the

system. Th is part can be analy zed in detail, and redundant

informat ion can then be used for fault detection and isolation

(FDI) purpose.

6.1. Structural Model Representati on

The structural model of a system as a bi-partite graph

which represents the links between a set of variables and a

set of constraints . It is an abstraction of the behavior model,

because it merely describes which variab les are connected by

which constraints, but it doesn’t say how these constraints

look like. Hence, the structural model p resents the basic

Computer Science and Engineering 2013, 3(2): 15-23

features and properties of a system that are independent of its

parameters.

The system’s structural model is[13] represented by the

set of relations F= {f1 ,f2 ….fm } and the set of variables Z=

K∪X = {z1 ,z2 ….zn }.X is the set of unknown variables and

K=U ∪Y is the set of known variables where input/reference

signals (U),and measured signals(Y) [13].

The set of constraints F is separated into Fk, wh ich we only

apply to known variables, and Fx=F/Fk that is the set of those

constraints that include at least one unknown variable.

The types of variables in a diagnostic context are: the

known variab les corresponding to measurements and

controller input. The unknown variables, typically internal

states and unknown inputs should not influence the residual,

and the faults to be detected. Formally, the structural model

of the system is defined as follows:

R = {R1 , R2 ,..., Rm }a set of structural equations.

K = {k1 , k 2 ,..., k c } the set of the known variab les.

X = {x1 , x2 ,..., xn } the set of the unknown variables.

Z = X ∪ K is the set of all the variab les. Z = n + c A

constraint R impose a relation between variables and

parameters, belonging to

R j z1 , z 2 ,...z Z = 0

Z:

; j = 1, m.

These relations can represent dynamic, static, linear or

non-linear relat ions[13].

This model is then represented graphically by

bipartite graph or in an equivalent way, by an incidence

(

)

19

matrix.

6.2. Bi-Partite Graph

The structural model of the system (C, Z) is a bi-part ite

graph (C, Z, ℰ ) where ℰ ⊂ C × Z is the set of edges defined

by: �ci , zj � ∈ ℰ if the variable zj appers in the constraint ci .

Note that the bi-partite graph is an undirected graph,

which can be interpreted as follows: all variables and

parameters connected with a g iven constraint vertex has to

satisfy the equation or rule this vertex presents. This graph

allo ws representing the structure of the system rather general

models including both differential and algebraic constraints.

6.3. Inci dence Matri x

An incidence matrix is a matrix that shows the relat ionship

between two classes of objects. If the first class is C and the

second is 𝑍𝑍, the matrix has one row for each element of C

and one column for each element of 𝑍𝑍[14].The entry in row

c and column z is 1 if c and z are related (called incident in

this context) and 0 if they are not.

With C: Constraint, 𝑑𝑑 : Derivation and 𝑚𝑚: Measure

-The matching edges are indicated by gray boxes.

- 𝑥𝑥: is used to forbid the integral causality because the

initial values of variables are unknown.

-The arrows indicate the constraints not saturated by the

matching which are 𝐶𝐶1 , 𝐶𝐶2 and 𝐶𝐶3.

Table 2. Incidence matrix of the robot

𝐶𝐶1

𝐶𝐶2

𝐶𝐶3

𝑑𝑑1

Γ1

1

Γ2

1

Γ3

1

1

1

1

1

1

1

𝑞𝑞1

𝑞𝑞2

x

𝑞𝑞̈ 1

1

𝑞𝑞̈ 2

𝑞𝑞̈ 3

𝑦𝑦1

𝑦𝑦2

𝑦𝑦3

1

x

x

1

1

x

𝑑𝑑5

𝑚𝑚3

𝑞𝑞̇ 3

1

𝑑𝑑4

𝑚𝑚2

1

𝑞𝑞̇ 2

1

𝑑𝑑3

𝑚𝑚1

𝑞𝑞̇ 1

1

𝑑𝑑2

𝑑𝑑6

𝑞𝑞3

x

1

1

x

1

1

1

1

1

1

1

20

Yasmine Derdour et al.: Application of the Structural Analysis on a Three Axis M anipulator Robot

6.4. The Matching Concept[13]

The ultimate aim of representing the system in terms of

structured graph is to obtain knowledge about the

parts/subsystems with inherent redundant information that

exists within the system. These parts can be analyzed in

detail and the redundant informat ion can then be

man ipulated for FDI purpose[13]. A matching is a causal

assignment which associates unknown system variab les with

the system constraints fro m wh ich they can be calculated.

Unknown variables which cannot be matched cannot be

calculated. Variables which can be matched in several ways

can be determined in different (redundant) manners, which

provide a means for fault detection and possibility for

reconfiguration[2].

Definition[2]: Let (𝐶𝐶, 𝑍𝑍, ℰ ) be a bi-partite graph, 𝑒𝑒 ∈ ℰ ,

𝑒𝑒 = (𝛼𝛼, 𝛽𝛽) be an edge which lin ks the constraint 𝛼𝛼 and the

variable 𝛽𝛽, and 𝑝𝑝𝑐𝑐 and 𝑝𝑝𝑧𝑧 be two projections.

𝑝𝑝𝑐𝑐 : ℰ → 𝐶𝐶

𝑒𝑒 ⟼ 𝑝𝑝𝑐𝑐 (𝑒𝑒) = 𝛼𝛼

𝑝𝑝𝑧𝑧 : ℰ → 𝑍𝑍

𝑒𝑒 ⟼ 𝑝𝑝𝑍𝑍 (𝑒𝑒) = 𝛽𝛽

The projection of the edge on the constraint set is

𝑝𝑝𝑐𝑐 (𝑒𝑒 ) = 𝛼𝛼 (the constraint node of the edge 𝑒𝑒 ) and the

projection of the edge on the variable set is

𝑝𝑝𝑍𝑍 (𝑒𝑒) = 𝛽𝛽 (the variable node of the edge 𝑒𝑒);

A matching 𝑀𝑀 is a subset of such that the restriction of

𝑝𝑝𝑐𝑐 and 𝑝𝑝𝑧𝑧 to 𝑀𝑀 are inject ive,

∀ 𝑒𝑒1 , 𝑒𝑒2 ∈ 𝑀𝑀: 𝑒𝑒1 ≠ 𝑒𝑒2 ⇒ 𝑝𝑝𝑐𝑐 ( 𝑒𝑒1 ) ≠ 𝑝𝑝𝑐𝑐 ( 𝑒𝑒2 ) ⋀𝑝𝑝𝑍𝑍 ( 𝑒𝑒1 )

≠ 𝑝𝑝𝑧𝑧 ( 𝑒𝑒2 )

This means that a matching is a subset of edges such that

any two edges have no common node (neither in 𝐶𝐶nor in 𝑍𝑍).

There are two types of matching maximal and co mplete.

is only one in the co lu mn). It is obviously possible to define

matchings, maximal matchings, and complete matchings by

considering either the whole structure of the system or only

subgraphs of its structural graph, i.e. subsets of the

constraints and variables instead of the whole set. As know

variables need not to be determined by some constraint, the

matching is accomp lished in the following for the subgraph

containing all unknown variab les rather than the whole

structure graph.

𝛤𝛤1

𝛤𝛤2

𝛤𝛤3

𝑦𝑦1

6.4.1. Maximal Matching

A maximal matching is a matching 𝑀𝑀 such that ∀𝑁𝑁 ∈

2𝜀𝜀 𝑤𝑤𝑤𝑤𝑤𝑤ℎ 𝑀𝑀 ⊂ 𝑁𝑁, 𝑁𝑁 is not a matching.

Thus,a maximal matching is a matching such that no edge

can be added without violating the no co mmon node

property. Since the set of matchings 𝑀𝑀 is only part ially

ordered, it fo llo ws that there is in general more than one

maximal matching[2].

6.4.2. Co mp lete Matching[2]

𝑦𝑦2

𝑦𝑦3

C1

d1

C2

d2

C3

d3

m1

d4

m2

d5

m3

𝑞𝑞 1

𝑞𝑞̇ 1

𝑞𝑞̈ 1

𝑞𝑞 2

𝑞𝑞̇ 2

𝑞𝑞 2̈

𝑞𝑞 3

𝑞𝑞̇ 3

A matching is called co mplete with respect to 𝐶𝐶 if

|𝑀𝑀| = |𝐶𝐶 | holds. A matching is called complete with respect

𝑞𝑞 3̈

d6

to 𝑍𝑍 if |𝑀𝑀| = |𝑍𝑍| holds.

For a co mplete matching 𝑀𝑀 on 𝐶𝐶(respectively on 𝑍𝑍),each

constraint (respectively each variab le) belong to exactly one

edge of the matching:

∀ 𝑐𝑐 ∈ 𝐶𝐶: ∃𝑧𝑧 ∈ 𝑍𝑍 𝑠𝑠𝑠𝑠𝑠𝑠ℎ 𝑡𝑡ℎ𝑎𝑎𝑎𝑎 (𝑐𝑐, 𝑧𝑧) ∈ 𝑀𝑀

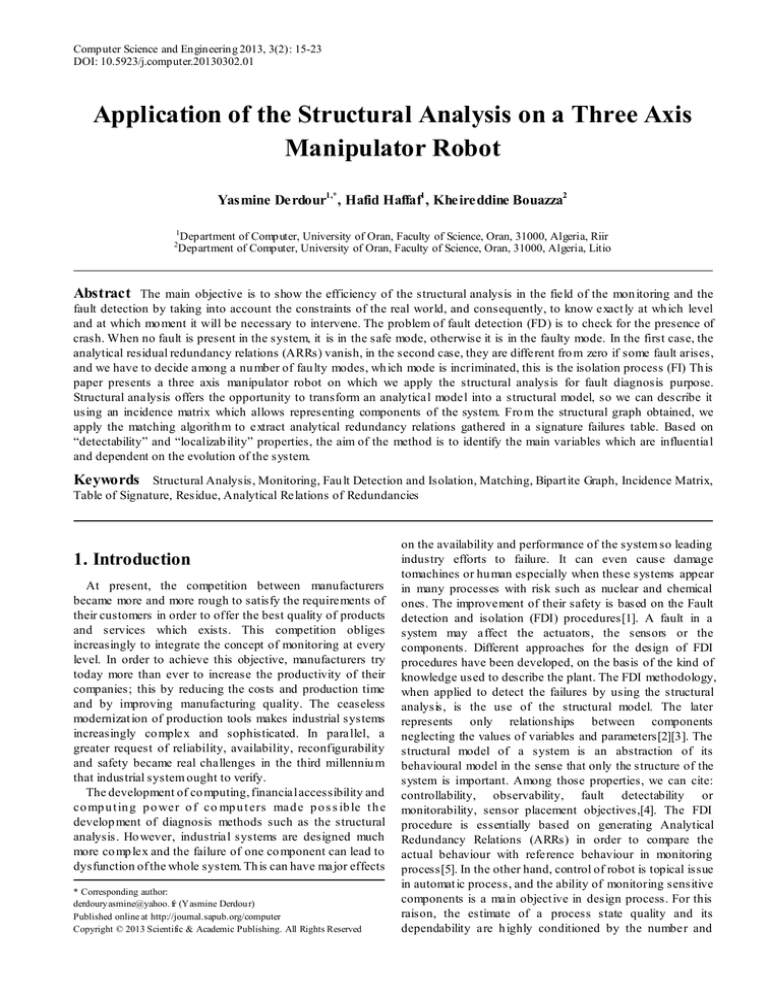

Figure 2. The graph of the structural model of the robot

∀ 𝑧𝑧 ∈ 𝑍𝑍: ∃𝑐𝑐 ∈ 𝐶𝐶 𝑠𝑠𝑠𝑠𝑠𝑠ℎ 𝑡𝑡ℎ𝑎𝑎𝑎𝑎 (𝑐𝑐, 𝑧𝑧) ∈ 𝑀𝑀

However, the incidence matrices and the graphical

A matching can be represented by selecting at most one”1”

in each row and each column in the incidence matrix of the representations are usually given for the co mplete structure

bi-partite graph. Each selected “1” represents an edge of the graph.

-The structural graph corresponding to our matrix of

matching. No other edge should contain the same variab le

(thus the only one in the row) or the same constraint (thus it incidence is shown in the Fig 2. Every colu mn of the matrix

Computer Science and Engineering 2013, 3(2): 15-23

corresponds to a circle-vertex and every row to a bar-vertex.

This matching is maximal and co mplete with respect to the

variables. For FDI considerations i.e to obtain a signature

table that could give all the colu mns disjoint two by two, we

tried to obtain the "best" matching. If we cannot obtain this

property, the system is not structurally monitorable and we

have to place some additional sensors [15].

The chosen matching is drawn by dark lines.

6.5. Relations after Matching

𝐶𝐶1 : 0 = 𝑎𝑎 𝛤𝛤1 + 𝑏𝑏 𝛤𝛤2 + 𝑐𝑐 𝛤𝛤3 + 𝑞𝑞̇ 1 (𝑎𝑎 8,2428 𝑠𝑠𝑠𝑠𝑠𝑠 𝑥𝑥 (3) 𝑥𝑥 (4) −

𝑏𝑏 4,1214𝑠𝑠𝑖𝑖𝑛𝑛 𝑥𝑥3 𝑥𝑥 2+ 𝑐𝑐𝑚𝑚3𝑔𝑔− 𝑞𝑞1

(16)

𝐶𝐶1 (𝑞𝑞̇ 1 , 𝑞𝑞̈ 1 ) → 𝑧𝑧𝑧𝑧𝑧𝑧𝑧𝑧 = 𝑑𝑑 1 � 𝑚𝑚1 (𝑦𝑦1 ) , 𝐶𝐶1 �𝑑𝑑 1 �𝑚𝑚1 (𝑦𝑦1 )��� (17)

𝐶𝐶2 : 0 = 𝑑𝑑 𝛤𝛤1 + 𝑒𝑒 𝛤𝛤2 + 𝑓𝑓 𝛤𝛤3 + 𝑞𝑞̇ 2

(4,1214 𝑠𝑠𝑠𝑠𝑠𝑠 𝑥𝑥(3) 𝑥𝑥(4) + 𝑓𝑓𝑚𝑚3 𝑔𝑔) − 𝑞𝑞̈ 2

(18)

𝐶𝐶2 (𝑞𝑞̇ 2 , 𝑞𝑞̈ 2 ) → 𝑧𝑧𝑧𝑧𝑧𝑧𝑧𝑧 ⟹ 𝑑𝑑 3 � 𝑚𝑚2 ( 𝑦𝑦2 ), 𝐶𝐶2 � 𝑑𝑑 3 �𝑚𝑚2 (𝑦𝑦2 ) ��� (19)

𝐶𝐶3 : 0 = 𝑔𝑔 𝛤𝛤1 + ℎ 𝛤𝛤2 + 𝑖𝑖 ( 𝛤𝛤3 +𝑚𝑚3 𝑔𝑔) − 𝑞𝑞̈ 3

𝐶𝐶3 (𝑞𝑞̈ 3 ) → 𝑧𝑧𝑧𝑧𝑧𝑧𝑧𝑧 ⟹ 𝐶𝐶3 �𝑑𝑑 6 (𝑑𝑑 5 �𝑚𝑚3 (𝑦𝑦3 ) ��

𝑚𝑚1 : 𝑞𝑞1 (𝑡𝑡) = 𝑦𝑦1 (𝑡𝑡) ⟶ 𝑚𝑚1 ( 𝑦𝑦1 ) ⟶ 𝑞𝑞1

𝑚𝑚2 : 𝑞𝑞2 (𝑡𝑡) = 𝑦𝑦2 (𝑡𝑡) ⟶ 𝑚𝑚2 (𝑦𝑦2 ) ⟶ 𝑞𝑞2

𝑚𝑚3 : 𝑞𝑞3 (𝑡𝑡) = 𝑦𝑦3 (𝑡𝑡 ) ⟶ 𝑚𝑚3 (𝑦𝑦3 ) ⟶ 𝑞𝑞3

𝑑𝑑 𝑞𝑞 (𝑡𝑡 )

𝑑𝑑 1 : 𝑞𝑞̇ 1 (𝑡𝑡) = 1

⟶ 𝑑𝑑 1 (𝑞𝑞1 ) ⟶ 𝑞𝑞̇ 1

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞̇ 1 (𝑡𝑡)

𝑑𝑑 2 : 𝑞𝑞̈ 1 (𝑡𝑡) =

𝑑𝑑 3 : 𝑞𝑞̇ 2 (𝑡𝑡) =

𝑑𝑑 4 : 𝑞𝑞̈ 2 (𝑡𝑡) =

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞2 (𝑡𝑡)

𝑑𝑑 5 : 𝑞𝑞̇ 3 (𝑡𝑡) =

𝑑𝑑 6 : 𝑞𝑞̈ 3 (𝑡𝑡) =

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞̇ 2 (𝑡𝑡)

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞3 𝑡𝑡)

𝑑𝑑𝑑𝑑

𝑑𝑑𝑞𝑞̇ 3 (𝑡𝑡 )

𝑑𝑑𝑑𝑑

⟶ 𝑑𝑑 2 (𝑞𝑞̇ 1 ) ⟶ 𝑞𝑞̈ 1

(20)

(21)

(22)

(23)

(24)

(25)

(26)

⟶ 𝑑𝑑 3 (𝑞𝑞2 ) ⟶ 𝑞𝑞̇ 2

(27)

⟶ 𝑑𝑑 5 (𝑞𝑞3 ) ⟶ 𝑞𝑞̇ 3

(29)

⟶ 𝑑𝑑 4 (𝑞𝑞̇ 2 ) ⟶ 𝑞𝑞̈ 2

⟶ 𝑑𝑑 6 ( 𝑞𝑞̇ 3 ) ⟶ 𝑞𝑞̈ 3

21

values.

• Structured: this insures that in the presence of a given

fault, only a subset of the ARRs is not satisfied, th is allows to

recognize (satisfied and not satisfied ARRs subset) the faulty

mode.

Applying the previous method in our case by

characterizing the ARRS in the bipartite graph, three

Analytical redundancy relations are obtained for this model.

• The first ARR model results following constraints:

C1 , d1 , d2 and m1.

𝐀𝐀𝐀𝐀𝐀𝐀𝐀𝐀 : 0 =

d q (t )

𝑎𝑎𝛤𝛤 1+𝑏𝑏𝛤𝛤 2 +𝑐𝑐𝛤𝛤 3+ 1 (𝑎𝑎8.2428 𝑠𝑠𝑠𝑠𝑠𝑠 𝑥𝑥 (3) 𝑥𝑥 (4) −

dt

𝑏𝑏4.1214 𝑠𝑠𝑖𝑖𝑛𝑛𝑥𝑥3 𝑥𝑥 2+𝑐𝑐𝑚𝑚3 𝑔𝑔− dq1(t)dt

(31)

− d1 (m1 ( y 1 ), C1 (d1 (m1 (y 1 )))) ⟶ Zéro. (32)

• The second ARR model results following

constraints: C2 , d3 , d4 and m2 .

ARR2 : 0 =

𝑑𝑑 𝑞𝑞2 (𝑡𝑡)

(4.1214𝑠𝑠𝑠𝑠𝑠𝑠 𝑥𝑥(3) 𝑥𝑥(4) + 𝑓𝑓𝑚𝑚3 𝑔𝑔) −

𝑑𝑑𝛤𝛤1+𝑒𝑒𝛤𝛤 2 +𝑓𝑓𝛤𝛤 3+

𝑑𝑑𝑑𝑑

d q̇ 2 (t )

(33)

(34)

− d3 (m2 (y 2 ) , C2 (d3 (m2 ( y 2 ))))⟶ Zéro.

• The third ARR model results following constraints:

C3 , d5 , d6 and m3

𝑑𝑑𝑞𝑞̇ (𝑡𝑡)

ARR3 : 0 = 𝑔𝑔 𝛤𝛤1 + ℎ 𝛤𝛤2 + 𝑖𝑖( 𝛤𝛤3 +𝑚𝑚3 𝑔𝑔) − 3 (35)

𝑑𝑑𝑑𝑑

(36)

− C3 (d6 (d5 (m3 (y 3 ) ))) ⟶ Zéro.

dt

7.1. Defini tion of Residue

(28)

(30)

The form, under which the equations are presented above,

translate exactly the matching selected in the incidence

matrix.

7. Analytical Redundancy Relations of

Robot (ARRs)[2]

Analytical redundancy relations are static or dynamic

constraints which link the time evolution of the known

variables when the system operates according to its normal

operation model.

An analytical relation of redundancy (ARR) is a relat ion

resulting fro m the equations of the nominal model (without

disturbances, failures), building the input output variables

and the successive derivative of these variables until a given

order.

Moreover, in order to the fault diagnosis procedure works

properly, ARR should have the follo wing properties:[2]

• Robust, i.e. insensitive to unknown input and unknown

parameters. Th is insures that they are satisfied when no fault

is present.

• Sensitive to faults: this insures that they are not satisfied

when faults are present, so that there is no missed detection.

At least in this case, one of the residual differs fro m vanishes

A residue is a signal conceived as indicator of functional

or behavioral anomalies. The princip le of a residue fo r the

supervision is that it connects only what is known[2].

With regard to a given matching, Analytical Redundancy

Relation is a relat ion not saturated by the matching and

which is either a relation wh ich is connected only to known

variables (sensors, actuators) or a relation which is

connected to variables unknown but already saturated by the

matching (Or both at the same time).

When the occurrence of a defect is detected, the procedure

of localization or insulation is used to determine the origin of

this defect (the defective component).

In order to establish the insulation, it is necessary to use a

set (or a vector) of residues, which must react differently and

predefined manner to various defects.

For this, two methods are possible[16]:

• The direct ional residues.

• The structured residues.

a) Directional residues

The idea of this method[16] is to generate a residue as a

vector of standard ideally zero in the case of the proper

functioning of the system. In case of defect, this vector is

directed in a direct ion which depends on the defect in the

system. The faults insulation step is then to determine which

of the different predefined directions which is the closest to

the residue observed. So the objective of design of the

generator of residue, in this approach, is to predefine the

directions of the most distinct defects possible to obtain good

22

Yasmine Derdour et al.: Application of the Structural Analysis on a Three Axis M anipulator Robot

insulation performance thereafter.

b) Structured residues

This approach is widely used in the field of the defects

insulation because the principle o f the method[16] is very

simp le and applies to a wide variety of systems (linear, not

linear ..). The principle of this method consists in having a

group of residues in which each residue is sensitive to a

subset of defects monitored.

8. The Signature Failures Table

In the signature failure table, every line corresponds to a

residue and every column to a failure. The analysis of the

signature table of the residuals enables us to check the

structural detectability and localizability property[17],[12].

A failure is detectable if its signature comprises at least

one ‘’1’’, two failures are localizable, or identifiab le if their

signatures are different.

The structural analysis gives only the structural

proprieties.

Fro m the signature failures table we can deduct the

structural properties.

The signatures surrounded by a circle are different fro m

the others.

Table 3. The signature failures

- Concerning the isolability, only the violation of variables

associated in (𝑞𝑞̇ 3 , 𝑞𝑞̈ 3 ) are structurally isolable.

- All other defects possess the same signature, a fact that

makes them not structurally localizab le.

- Concerning the Γ1 , Γ2 , Γ3 commands possess the same

signature thus they are neither mon itorable nor detectable.

- As for the measures y 1 , y 2 , y 3 they are impossible to

monitor (not detectable and not isolable).

- Since the positions q1 , q2 , q3 have the same

structuralization then they are not monitorable and not

isolable. We can’t detect failu re if it affect one of these

variables; so some additional sensors have to be placed in the

system to make it monitorab le.

rules, look-up tables)·

This methodology helps to highlight the monitorable parts

of system by using informat ion included in the model itself,

without extra or physical redundancy requirement and also

allo ws building the strong structured residues for the FDI.

When applied to the model robot, we have been able to see

which of the state variables are mon itorable and which are

not. The approach presented, when applied to the robot

model, it provides a powerful tool for analy zing systems at

any stage of the design process, providing the designer to

correct in early stage, the system (robot) by adding

sensors[18].

Analyzing disturbances and errors of estimates will be the

subject of future work. It will be interesting to compare these

results with the diagnosis approach on the basis of observer

theory.

In future work, the co mbinatorial problem related to

which is the best matching for monitoring, will be

investigated as well as how to make the reconfigurat ion by

structural analysis.

REFERENCES

[1]

H.Haffaf, B. Ould Bouamama, “Cycle Algorithm in Tripartite

Graph for FDI.”.Journal of the Franklin Institute, Vol 349

(Isuue 1), pages:112-125.M arch 2008.

[2]

M .Blanke, M .Kinnaert, J.Lunze et M . Staroswiecki

“Diagnosis and Fault-Tolerant Control”,2nd edition with

contributions by Jochen Schroder,Berlin Heidelberg,may

2006.

[3]

D. Dustgor . “Aspects Algorithmics of the Structural Analysis

for the M onitoring”, PhD of the University of the Sciences

and the Technologies of Lille,2005.

[4]

M . Krysander,E.Frisk, E. Sensor placement for fault

diagnosis, IEEE systems and humans, p 1398-1410,

1083-4427 vol.38 NO.6,2008.

[5]

V.de Flaugergues, V.Cocquempot, M . Bayart,M.Pengov.

“Structural Analysis for FDI, a M odified, Invertibility,based

Canonical Decomposition”. Proceedings of the 20th

International Workshop on principles of Diagnosis, p59—66,

2009.

[6]

D. Dustegor and al. Automated graph-based methodology for

fault detection and location in power systems, IEEE

Transactions on power delivery, pp-638-646, VOL.25,

NO.2,2010.

[7]

M . Belaguid . Optimization Algorithms Generating RRAS in

Structural Analysis for M onitoring, M agister Thesis in

Computer Science University of es Senia, October 2004.

[8]

J.Ph. Cassar and M . Staroswiecki . A Structural Approach for

the Design of Failure Detection and Identification Systems.

Proceedings IFAC-IFIP-IM ACS Conference on Control of

Industrial Processes (Berfort, France), Année 1997

[9]

R. Carpentier, Litwak, and J.Ph. Cassar .Criteria Evaluation

of FDI Systems Application to Sensors Location. Proceedings

9. Conclusions

The results show the efficiency and simp licity of structural

analysis for fau lts detection and isolation for either a linear or

nonlinear system because it bases on the graph theory. The

structural analysis displays the relations between constraints

and variables, and identifies the observable and monitorab le

parts in terms of decomposition. Th is method applies to

complex systems with hundreds of variables and equations.

Thanks to the structural analysis we can represent different

types of modelling (qualitat ive, quantitative, static, dynamic,

Computer Science and Engineering 2013, 3(2): 15-23

of IFAC/Safeprocess, Année 1997.

[10] M . KRYSANDER.,M .NYBERG, Structural Analysis for

Fault Diagnosis of DAE Systems Using M SS Sets, IFAC

World Congress, 2002

[11] K.E

Bouazza,

M .Ouali,

M .Boutayeb.”M odelling,

Identification and Control of Three A xis M anipulator robot”.

Journal of Automation and System Engineering, Volume3,

Issue4,2009.

[12] H.Haffaf, M .Belaguid.”Algorithm of the Cycles in Structural

Analysis for the M onitoring”. M aghrebian conference ,

Agadir, M orocco ,2007.

[13] R.l.Zamanabadi.“Structural Analysis Approach to Fault

Diagnosis with Application to fixed-wing Aircraft M otion”.

Department of control engineering ,Intelligent Autonomous

Systems(IAS).Aalborg University, Denmark,2002.

23

[14] D.Reinhard,

Graph Theory, Graduate Texts

in

M athematics,173(3rd ed),Springer-Verlag,ISBN 3-540-2618

3-4,2005.

[15] M . Khemlich , B.Ould Bouamama and H. Haffaf Sensors and

actuators A,«Sensor placement for Component diagnosability

using Bond-graph». Elsevier pp 547-556. January 2006

[16] J. Gertler. Analytical Redundancy M ethods in Fault Detection

and Isolation, Survey and Synthesis. IFAC Fault Detection,

Supervision end Safety for Technical Processes, Germany,

pp.43-55. 26, Année 1991.

[17] M .Gondran , M.M inoux. “Graphs and Algorithms“ . Edition

EROYLLES ,1995.

[18] D. Dustegor .Automated graph-based methodology for fault

detection and location in power systems, IEEE Transactions

on power delivery, pp-638-646, Vol.25, No.2,april 2010.