Dust Collection Technical Handbook

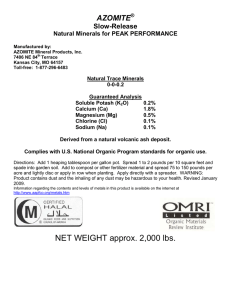

advertisement