Designed to perform... built to last

advertisement

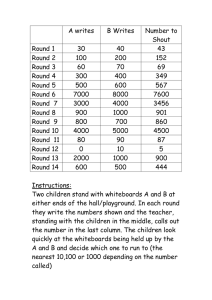

FD/FG40NT FD/FG45NT FD/FG50CNT FD/FG50NT FD/FG55NT (The information in this document may be subject to change pending final release) Preliminary Specifiations Diesel and Petrol/LPG Counterbalance 4 Wheel Pneumatic Tyres • 4.0 – 5.5 tonnes Designed to perform... built to last The effectiveness and legendary reliability of Mitsubishi 4 and 5 tonne IC engine forklift trucks has been proved over many years in the most demanding of applications. Generations of forklift truck owners have grown to love and depend upon these tough and highly capable machines. GRENDIA EX builds on those exceptional qualities. Environmentally friendly, and with the quality, reliability and investment value you would associate with diamonds, its name – meaning ‘Green Diamond’ – is truly deserved. Low noise and vibration, a comfortable operating environment and the latest ErgoCentric developments in steering, hydraulic and other controls will all be welcomed by operators. Meanwhile, the IPS2 Integrated Presence System and advanced brake systems will help ensure that they stay safe. And as always, every system and component has been designed and chosen to minimise downtime and maintenance costs. Frame and body ● Stylish, purposeful design reflects this machine’s power to work productively, non-stop, whatever the conditions. ● Robust construction provides high stability, rigidity and protection, with no exposed wires or hoses. Mast and fork assembly ● Strong, high-visibility mast allows handling of heavy loads in tough environments with total confidence. ● Wide range of high-quality masts and attachments delivers precise compatibility and an ideal configuration for each application. Drive ● Industrially proved diesel engine is ultra-reliable and durable, as well as smooth and economical, and easily complies with emission control regulations. ● Fully floating powertrain with twospeed forward and one-speed reverse transmission maximises gradeability and travel speed, minimises noise and vibration, and uses maintenance-free gears instead of belts to lower running costs. ● Adjustable transmission shift timing increases versatility, for optimum performance in a wide variety of applications. ● Large diameter drive axle shafts are extremely durable and require little maintenance. ● Low-noise air intake connects directly to intake filter for easy flow and quiet performance. Diesel Counterbalance 4 Wheel Pneumatic Tyres • 4.0 – 5.5 tonnes 1.1 1.2 1.3 1.4 1.5 1.6 1.8 1.9 2.1 2.2 2.3 3.1 3.2 3.3 3.5 3.6 3.7 4.1 4.2 4.3 4.4 4.5 4.7 4.8 4.12 4.19 4.20 4.21 4.22 4.23 4.24 4.31 4.32 4.33 4.34 4.35 4.36 4.41 5.1 5.2 5.3 5.5 5.7 5.9 5.10 6.4 7.1 7.2 7.3 7.4 7.5 8.1 8.2 8.3 8.4 8.5 Characteristics Manufacturer (abbreviation) Manufacturer’s model designation Power source: (battery, diesel, LP gas, petrol) Operator type: pedestrian, (operator)-standing, -seated Load capacity Load center distance Load distance, axle to fork face Wheelbase Weight Truck weight, without load / including battery (simplex mast, lowest lift height) Axle loading with maximum load, front/rear (simplex mast, lowest lift height) Axle loading without load, front/rear (simplex mast, lowest lift height) Wheels, Drive Train Tyres: V=solid, L=pneumatic, SE=solid pneumatic - front/rear Tyre dimensions, front Tyre dimensions, rear Number of wheels, front/rear (x=driven) Track width (center of tyres), front Track width (center of tyres), rear Dimensions Mast tilt, forwards/backwards Height with mast lowered (see tables) Free lift (see tables) Lift height (see tables) Overall height with mast raised Height to top of overhead guard Seat height Tow coupling height Overall length Length to fork face (includes fork thickness) Overall width Fork dimensions (thickness, width, length) Fork carriage to DIN 15 173 A/B/no Fork carriage width Ground clearance under mast, with load Ground clearance at center of wheelbase, with load (forks lowered) Working aisle width with 1000 x1200 mm pallets, crosswise Working aisle width with 800 x1200 mm pallets, crosswise Turning circle radius Minimum distance between centers of rotation Performance Travel speed, with/without load Lifting speed, with/without load Lowering speed, with/without load Rated drawbar pull, with/without load Gradeability, with/without load Acceleration time (10 metres) with/without load Service brakes (mechanical/hydraulic/electric/pneumatic)o VDI 60 cycle IC Engine Manufacturer / Type Rated / Nominal output to ISO 1585** Rated speed to DIN 70 020 Number of cylinders / cubic capacity Fuel consumption according to VDI 60 cycle Miscellaneous Type of drive control Maximum operating pressure for attachments Oil flow for attachments Noise level, value at operator’s ear (EN 12053) Towing coupling design / DIN type, ref. Continuing improvement may lead to changes in these specifications. * Fuel consumption and noise data available upon request. ** Net power according 97/68/EC: 52kW Q c x y kg (mm) (mm) (mm) Mitsubishi FD40NT Diesel Seated 4000 500 577 1850 Mitsubishi FD45NT Diesel Seated 4500 500 577 2000 kg kg kg 5920 8960/960 2630/3290 6330 9710/1130 2780/3550 L/L 8.25-15-14PR 7.00-12-14PR 2x/2 1175 1180 L/L 300-15-18PR 7.00-12-14PR 2x/2 1175 1180 6/10 2320 150 3300 3920 2296 1280 395 4220 3000 1415/1965 50/150/1220 3A 1190 150 227 4357 4157 2580 836 6/10 2320 150 3300 3920 2296 1280 395 4350 3130 1460/1965 50/150/1220 3A 1190 150 227 4507 4307 2730 903 21.5/22.0 0.55/0.61 0.5/0.5 25000/17400 26.9/26.4 4.20/3.70 Hydraulic 21.0/22.0 0.55/0.61 0.5/0.5 25000/18700 24.4/26.7 4.52/3.87 Hydraulic Mitsubishi / S6S 57.4 2300 6 / 4996 * Mitsubishi / S6S 57.4 2300 6 / 4996 * Powershift 2/1 191 * * Pin Powershift 2/1 191 * * Pin b10 b11 (mm) (mm) ␣/ h1 h2 h3 h4 h6 h7 h10 l1 l2 b1/b2 s/e/l ° (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) b3 m1 m2 Ast Ast Wa b13 (mm) (mm) (mm) (mm) (mm) (mm) (mm) m/s km/h m/s m/s N % s kW rpm cm3 l/h / kg/h bar l/min dB(A) Mitsubishi FD50CNT Diesel Seated 5000 500 582 2000 Mitsubishi FD50NT Diesel Seated 5000 600 602 2150 Mitsubishi FD55NT Diesel Seated 5500 600 602 2150 6850 10600/1250 2900/3950 7300 11020/1280 3220/4080 7640 11740/1400 3170/4470 L/L 300-15-18PR 7.00-12-14PR 2x/2 1175 1180 L/L 300-15-18PR 7.00-12-14PR 2x/2 1175 1180 SE/SE 300-15-18PR 7.00-12-14PR 2x/2 1175 1180 6/10 2400 150 3300 4000 2296 1280 395 4390 3170 1460/1965 50/150/1220 3A 1190 150 227 4542 4342 2760 903 6/10 2400 160 3300 4000 2296 1280 395 4530 3310 1460/1965 60/150/1220 4A 1190 150 227 4692 4492 2890 971 6/10 2400 160 3300 4000 2296 1280 395 4580 3360 1460/1965 60/150/1220 4A 1190 150 227 4742 4542 2940 971 21.0/22.0 0.47/0.53 0.5/0.5 24700/19400 22.0/25.7 4.52/3.87 Hydraulic 21.0/22.0 0.47/0.53 0.5/0.5 24500/21800 20.8/26.8 4.52/3.87 Hydraulic 21.0/22.0 0.47/0.53 0.5/0.5 24200/21300 19.3/25.0 4.52/3.87 Hydraulic Mitsubishi / S6S 57.4 2300 6 / 4996 * Mitsubishi / S6S 57.4 2300 6 / 4996 * Mitsubishi / S6S 57.4 2300 6 / 4996 * Powershift 2/1 191 * * Pin Powershift 2/1 191 * * Pin Powershift 2/1 191 * * Pin Clear-view overhead guard Robust mast assembly Informative LCD display Fully hydrostatic steering THE GREEN DIAMOND The green colour of our trucks is a sign of our commitment to protecting the environment. The diamond shapes in our logo are a reminder that – like a diamond – a Mitsubishi forklift truck guarantees quality, reliability and a sound investment. LPG Counterbalance 4 Wheel Pneumatic Tyres • 4.0 – 5.5 tonnes 1.1 1.2 1.3 1.4 1.5 1.6 1.8 1.9 2.1 2.2 2.3 3.1 3.2 3.3 3.5 3.6 3.7 4.1 4.2 4.3 4.4 4.5 4.7 4.8 4.12 4.19 4.20 4.21 4.22 4.23 4.24 4.31 4.32 4.33 4.34 4.35 4.36 4.41 5.1 5.2 5.3 5.5 5.7 5.9 5.10 6.4 7.1 7.2 7.3 7.4 7.5 8.1 8.2 8.3 8.4 8.5 Characteristics Manufacturer (abbreviation) Manufacturer’s model designation Power source: (battery, diesel, LP gas, petrol) Operator type: pedestrian, (operator)-standing, -seated Load capacity Load center distance Load distance, axle to fork face Wheelbase Weight Truck weight, without load / including battery (simplex mast, lowest lift height) Axle loading with maximum load, front/rear (simplex mast, lowest lift height) Axle loading without load, front/rear (simplex mast, lowest lift height) Wheels, Drive Train Tyres: V=solid, L=pneumatic, SE=solid pneumatic - front/rear Tyre dimensions, front Tyre dimensions, rear Number of wheels, front/rear (x=driven) Track width (center of tyres), front Track width (center of tyres), rear Dimensions Mast tilt, forwards/backwards Height with mast lowered (see tables) Free lift (see tables) Lift height (see tables) Overall height with mast raised Height to top of overhead guard Seat height Tow coupling height Overall length Length to fork face (includes fork thickness) Overall width Fork dimensions (thickness, width, length) Fork carriage to DIN 15 173 A/B/no Fork carriage width Ground clearance under mast, with load Ground clearance at center of wheelbase, with load (forks lowered) Working aisle width with 1000 x1200 mm pallets, crosswise Working aisle width with 800 x1200 mm pallets, crosswise Turning circle radius Minimum distance between centers of rotation Performance Travel speed, with/without load Lifting speed, with/without load Lowering speed, with/without load Rated drawbar pull, with/without load Gradeability, with/without load Acceleration time (10 metres) with/without load Service brakes (mechanical/hydraulic/electric/pneumatic)o VDI 60 cycle IC Engine Manufacturer / Type Rated / Nominal output to ISO 1585** Rated speed to DIN 70 020 Number of cylinders / cubic capacity Fuel consumption according to VDI 60 cycle Miscellaneous Type of drive control Maximum operating pressure for attachments Oil flow for attachments Noise level, value at operator’s ear (EN 12053) Towing coupling design / DIN type, ref. Continuing improvement may lead to changes in these specifications. * Fuel consumption and noise data available upon request. Q c x y kg (mm) (mm) (mm) Mitsubishi FG40NT Petrol Seated 4000 500 577 1850 Mitsubishi FG45NT Petrol Seated 4500 500 577 2000 kg kg kg 5860 8940/920 2610/3250 6270 9680/1090 2750/3520 L/L 8.25-15-14PR 7.00-12-14PR 2x/2 1175 1180 L/L 300-15-18PR 7.00-12-14PR 2x/2 1175 1180 6/10 2320 150 3300 3920 2296 1280 395 4220 3000 1415/1965 50/150/1220 3A 1190 150 227 4357 4157 2580 836 6/10 2320 150 3300 3920 2296 1280 395 4350 3130 1460/1965 50/150/1220 3A 1190 150 227 4507 4307 2730 903 22.0/22.5 0.57/0.60 0.5/0.5 26000/17200 27.8/25.9 5.02/3.65 Hydraulic 22.0/22.5 0.57/0.60 0.5/0.5 26000/18500 25.3/26.2 5.02/3.65 Hydraulic TB45 60.8 2450 6 / 4500 * TB45 60.8 2450 6 / 4500 * Powershift 2/1 191 * * Pin Powershift 2/1 191 * * Pin b10 b11 (mm) (mm) ␣/ h1 h2 h3 h4 h6 h7 h10 l1 l2 b1/b2 s/e/l ° (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) b3 m1 m2 Ast Ast Wa b13 (mm) (mm) (mm) (mm) (mm) (mm) (mm) m/s km/h m/s m/s N % s kW rpm cm3 l/h / kg/h bar l/min dB(A) Mitsubishi FG50CNT Petrol Seated 5000 500 582 2000 Mitsubishi FG50NT Petrol Seated 5000 600 602 2150 Mitsubishi FG55NT Petrol Seated 5500 600 602 2150 6790 10570/1210 2870/3920 7240 10990/1250 3190/4050 7570 11710/1360 3130/4440 L/L 300-15-18PR 7.00-12-14PR 2x/2 1175 1180 L/L 300-15-18PR 7.00-12-14PR 2x/2 1175 1180 SE/SE 300-15-18PR 7.00-12-14PR 2x/2 1175 1180 6/10 2400 150 3300 4000 2296 1280 395 4390 3170 1460/1965 50/150/1220 3A 1190 150 227 4542 4342 2760 903 6/10 2400 160 3300 4000 2296 1280 395 4530 3310 1460/1965 60/150/1220 4A 1190 150 227 4692 4492 2890 971 6/10 2400 160 3300 4000 2296 1280 395 4580 3360 1460/1965 60/150/1220 4A 1190 150 227 4742 4542 2940 971 22.0/22.5 0.49/0.52 0.5/0.5 25500/19200 22.7/25.2 5.02/3.65 Hydraulic 22.0/22.5 0.49/0.52 0.5/0.5 25500/21600 21.6/26.4 5.02/3.65 Hydraulic 21.5/22.5 0.49/0.52 0.5/0.5 25000/21000 19.9/24.6 5.02/3.65 Hydraulic TB45 60.8 2450 6 / 4500 * TB45 60.8 2450 6 / 4500 * TB45 60.8 2450 6 / 4500 * Powershift 2/1 191 * * Pin Powershift 2/1 191 * * Pin Powershift 2/1 191 * * Pin Auto-style controls Adjustable steering column Grip/horn for reversing (optional) High all-round visibility THE GREEN DIAMOND The green colour of our trucks is a sign of our commitment to protecting the environment. The diamond shapes in our logo are a reminder that – like a diamond – a Mitsubishi forklift truck guarantees quality, reliability and a sound investment. FD/FG40-45NT Models Mast Performance and Capacity FD/FG40NT Mast type Simplex Duplex Triplex FD / FG40NT & FD / FG45NT FD/FG40NT FD/FG45NT FD/FG45NT FD/FG40NT FD/FG40NT FD/FG45NT FD/FG45NT Q@ c=500mm Q@ c=600mm Q@ c=500mm Q@ c=600mm Q@ c=500mm Q@ c=600mm Q@ c=500mm Q@ c=600mm h3 mm 3000 3300 3700 4000 4500 5000 5500 6000 3000 3300 3700 4100 3700 4000 4360 4700 5050 5500 6000 6500 7000 h1 mm 2170 2320 2520 2700 3000 3250 3500 3750 2170 2320 2520 2700 1950 2050 2170 2285 2400 2550 2750 2950 3150 h4 mm 4130 4430 4830 5130 5630 6130 6630 7130 4130 4430 4830 5190 4830 5130 5490 5830 6180 6630 7130 7630 8130 h2 mm 150 150 150 150 150 150 150 150 - h5 mm 1090 1240 1440 1620 870 970 1090 1200 1320 1470 1670 1870 2070 (pneumatic) kg 4000 4000 4000 4000 4000 3850 3600 3500* 4000 4000 4000 4000 4000 4000 4000 3900 3800 3600* 3450* 3000* 2400* (pneumatic) kg 3500 3500 3500 3500 3500 3500 3400* 3300* 3500 3500 3500 3500 3500 3500 3500 3500 3500 3400* 3250* 3000* 2400* (pneumatic) (solid pneum.) (solid pneum.) (solid pneum.) (solid pneum.) kg kg kg kg kg 4000 4000 3500 4500 4000 4000 4000 4500 4000 3500 4000 4000 4500 3500 4000 4000 4000 3500 4500 4000 4000 4000 4500 4000 3500 4000 4500 4000 3500 4000 4000* 4000 3500 4400 3700 3900* 3900 4250 3600 3400 4000 4500 4000 3500 4000 4000 4000 3500 4500 4000 4000 4000 4500 3500 4000 4000 4500 4000 3500 4000 4000 4000 4500 4000 3500 4000 4000 4500 3500 4000 4000 4500 4000 3500 4000 4000 4000 3500 4500 4000 4000 4000 4500 3900 3500 4000* 4350 4000 3450 3700 3800* 3900 4200 3300 3550 3000* 3800* 4050* 3200 3350 2400* 3500* 3500* 3100* 3300* (pneumatic) kg 4500 4500 4500 4500 4500 4500 4300* 3900* 4500 4500 4500 4500 4500 4500 4500 4500 4500 4200* 4050* 3000* 2400* 6000 5500 Capacity (kg) FD/FG40-55NT Models Capacities at Various Load Centres Simplex - h3 = 4000 mm 5000 4500 FD/FG55NT FD/FG50NT FD/FG50CNT FD/FG45NT FD/FG40NT 4000 3500 3000 2500 500 600 700 800 900 1000 Load Centre (mm) Ast a/2 x l6 a/2 b2 e b12 b10 b11 b3 h4 b13 C h7 Working aisle width Turning radius Safety clearance = 2 x 100 mm Pallet length Pallet width Q s m1 l x y l2 l1 h10 = = = = = m2 Ast Wa a l6 b12 h5 Height with mast lowered Standard free lift Lift height Height with mast raised Full free lift Lifting capacity, rated load Load centre (distance) h2 h1 h2 h3 h4 h5 Q c h6 h1 h3 Wa FD/FG50CNT Models Mast Performance and Capacity FD / FG50CNT FD/FG50CNT FD/FG50CNT FD/FG50CNT FD/FG50CNT Mast type Simplex Duplex Triplex h3 mm 3000 3300 3700 4000 4500 5000 5500 6000 2970 3300 4100 3700 4040 4310 4750 5050 5500 6000 6500 7000 h1 mm 2250 2400 2600 2850 3100 3350 3600 3850 2250 2400 2850 2050 2170 2260 2400 2500 2650 2850 3050 3250 h4 mm 4130 4430 4830 5130 5630 6130 6630 7130 4100 4410 5210 4830 5170 5440 5880 6180 6630 7130 7630 8130 h2 mm 150 150 150 150 150 150 150 150 - h5 mm 1170 1320 1770 970 1090 1180 1320 1420 1570 1770 1970 2170 Q@ c=500mm Q@ c=600mm Q@ c=500mm (pneumatic) kg 5000 5000 5000 5000 5000 5000 4750* 3900* 5000 5000 5000 5000 5000 5000 5000 5000 4700* 4200* 3000* 2400* (pneumatic) (solid pneum.) (solid pneum.) kg kg kg 4500 5000 4500 4500 5000 4500 4500 5000 4500 4500 5000 4500 4500 5000 4500 4500 5000 4500 4500* 4850 4500 3900* 4700 4400 4500 5000 4500 4500 5000 4500 4500 5000 4500 4500 5000 4500 4500 5000 4500 4500 5000 4500 4500 5000 4500 4500 5000 4500 4450* 4800 4500 4200* 4600 4350 3000* 4450* 4200* 2400* 3500* 3500* Q@ c=600mm Fingertip hydraulic controls (optional) Front LED working lights FD/FG50-55NT Models Mast Performance and Capacity Stylish, robust design FD / FG50NT & FD / FG55NT FD/FG50NT FD/FG55NT FD/FG50NT Mast type Simplex Duplex Triplex h3 mm 3000 3300 3700 4000 4500 5000 5500 6000 3000 3300 4100 3700 4040 4310 4750 5050 5500 6000 6500 7000 h1 mm 2250 2400 2600 2850 3100 3350 3600 3850 2250 2400 2850 2050 2170 2260 2400 2500 2650 2850 3050 3250 h4 mm 4280 4580 4980 5280 5780 6280 6780 7280 4250 4560 5360 4980 5320 5590 6030 6330 6780 7280 7780 8280 h2 mm 160 160 160 160 160 160 160 160 - h5 mm 1030 1180 1630 830 950 1040 1180 1280 1430 1630 1830 2030 FD/FG55NT Q@ c=600mm Q@ c=600mm Q@ c=600mm Q@ c=600mm (pneumatic) kg 5000 5000 5000 5000 5000 5000 4900* 4100* 5000 5000 5000 5000 5000 5000 5000 5000 4900* 4300* 3150* 2500* (pneumatic) (solid pneum.) (solid pneum.) kg kg kg 5500 5000 5500 5500 5000 5500 5500 5000 5500 5500 5000 5500 5500 5000 5500 5500* 5000 5500 (4650)* 5000 5500 (3450)* 4900 5350* 5500 5000 5500 5500 5000 5500 5500 5000 5500 5500 5000 5500 5500 5000 5500 5500 5000 5500 5450 5000 5500 5500* 5000 5500 (4850)* 5000 5500 (3500)* 4800 5300* (2600)* 4650* (4400)* (2000)* 3900* (3050)* * Truck equipped with dual tyres. Consult your dealer for the maximum back-tilt allowed, to obtain the capacities specified. ( ) Capacities shown in brackets for the 5.5 tonnes model show lower capacities compared to 5.0 tonne model. Auto-style pedals when reliability is everything... Convenient handbrake button Steering system ● Fully hydrostatic steering is responsive, precise and effortless for the operator and requires only minimal maintenance. Brakes ● Powerful drum brake system gives excellent control with little effort and is easy to maintain. ● Electronically controlled parking brake allows safe, effective immobilisation of the truck with minimum effort – and without restricting knee and leg movement. Hydraulics ● Powerful hydraulic system is specifically designed to minimise noise in the operator's environment. Electrical and control systems ● Integrated Presence System 2 (IPS2) pioneered by Mitsubishi prevents all movement of the truck and its mast if the operator is not seated. ● Operator identification system can be activated – if owner wishes – to prevent unauthorised use of the truck. ● Onboard diagnostics and detailed fault diagnosis via laptop connection alerts operators and service engineers to problems, speeds up servicing and prevents damage. Strong, high-visibility mast Operator compartment and controls ● Market-leading ErgoCentric design results in easy on-off access, a unique, adjustable steering column with position memory, user-friendly controls, a practical layout and great all-round visibility – for maximum precision and productivity. ● Full-suspension seat with hip support keeps driver comfortable through the longest of shifts. User-friendly hydraulic levers Other features ● Long service interval and long life of components reduces downtime and associated costs. ● RapidAccess features give unequalled ease of entry to all areas for checks and maintenance. Options ● Oil-cooled wet disc brakes and FlexControl intelligent truck protection package ● Fingertip hydraulic controls ● Hydraulic control levers are easy to reach and easy to use. ● Rear grip with integrated horn button ● Optional fingertip hydraulic controls with integrated, fully adjustable, high-comfort armrest (an award-winning concept) allows effortless precision. ● Overload indicator ● Load weight indicator ● Speed limiter ● Automotive-style pedals with optimum pedal angle are easy to use and give good control without leg strain. ● Low noise level at operator’s ear and low vibration from powertrain increases comfort and reduces fatigue. Like any product bearing the Mitsubishi name, our materials handling equipment benefits from the huge resources and cutting-edge technology of one of the world’s largest corporations. So when we promise you quality, reliability and value for money, you know it’s a guarantee we have the power to deliver. Every model in our comprehensive, awardwinning range of forklift trucks and warehouse equipment is built to a high specification and is designed to keep on working for you... day after day... year after year... whatever the job... whatever the conditions. To ensure your truck stays in constant productive action, we have a network of local dealers – hand-picked for their commitment to customer care... and backed up by the Mitsubishi Forklift Trucks organisation. No matter where you are, we have a dealer close by – ready and willing to meet your needs. That friendly local service covers everything from identifying the perfect model and configuration for your application to providing competitive, flexible finance and maintenance packages, unbeatable warranties, long and short term hire, and highly responsive field service and repairs... as well as the industry’s quickest and most reliable parts supply. Only Mitsubishi can give you this combination of global engineering excellence and outstanding local support... only Mitsubishi offers you such a quality product at such an affordable price... and only Mitsubishi places reliability as high as you do in its priorities. Contact your local dealer now and see what Mitsubishi can do for you. You can find your nearest dealer at www.mitforklift.com ● Clear and comprehensive instrument panel with LCD display keeps operator and manager fully informed of, for example, speed, time, engine hours, service intervals and faults – to optimise productivity, truck life and safety. FlexControl intelligent truck protection: ? combined with oil-cooled wet disc brakes in an option package for high-intensity applications ? delivers dynamic performance with minimum wear of transmission components and tyres Integrated Presence System 2 (IPS2) provides: ? a hydraulic and travel interlock system that prevents all movement of the truck and its mast if the driver is not seated INTEGRATED PRESENCE SYSTEM II CESM1506AME (01/12) © 2013 MCFE Printed in The Netherlands mitforklift@mcfe.nl www.mitforklift.com ? a seat belt warning light ? an automatic parking brake with alarm The term ‘Integrated Presence System’ (IPS) is intended as a trading style, only to describe a number of design features on the Mitsubishi trucks to which IPS is applied. It does not imply that the truck can be driven without appropriate operator training and without due care and attention. The manufacturer (MCFE, Almere, the Netherlands) cannot accept any responsibility for any accidents or damage caused by incorrect or dangerous use of its equipment. NOTE: Performance specifications may vary depending on standard manufacturing tolerances, vehicle condition, types of tyres, floor or surface conditions, applications or operating environment. Trucks may be shown with non-standard options. Specific performance requirements and locally available configurations should be discussed with your distributor of Mitsubishi forklift trucks. Mitsubishi follows a policy of continual product improvement. For this reason, some materials, options and specifications could change without notice.