Explore the benefits of a new generation of fast reacting

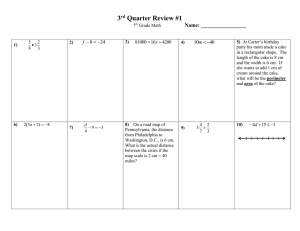

advertisement

we are e x p e r t s in e mul s i f i e rs and stabilizers for bakery, confectionery, dairy, ice cream, margarine and fine foods - and we happy to share our expertise. our company values can be defined are in just three words : loyalty, responsibility and we aim to be the preferred partner commitment. and supplier of quality products, application service and knowhow to regional and m u l t i - n a t i o n a l food companies. to Palsgaard l o y a l t y means that we act as a reliable and honourable business partner for our customers. we treat information confidentially and know how to keep a business secret. to Palsgaard r e s p o n s i b i l i t y means caring about the environment and being aware of our corporate social responsibility; we have a goal to be CO 2 neutral by 2020 and are members of SEDEX and RSPO. to Palsgaard c o m m i t m e n t means we are dedicated to getting the best results for our customers’ products - to the benefit of their customers. we care about our employees and have a declared aim that Palsgaard must be a pleasant place to work. Palsgaard we know that our most important resource is the k n o w - h o w and d e d i c a t i o n found in our employees. we are committed to getting the best results with our products in our pilot plants and in your facilities. at Palsgaard we don’t sell standard solutions - we start with your needs. Palsgaard - Heart Working heart work is the best way to achieve success - let us help you get it. our products are produced according to the Heart Working People strictest quality criteria. we are experts in emulsifiers and stabilizers and we are happy to share our expertise with you. let our pilot plants help you shorten the step between idea and your new product. heart work is the best way to succeed - let us help you do so. Explore the benefits of a new generation of fast reacting cake emulsifiers Palsgaard Technical Paper, April 2012 By Knud Erik Mogensen, M.Sc. Food Science, Business Unit Manager Bakery & Confectionery. Palsgaard A/S. New ways to lower costs Palsgaard is continuously seeking to improve performance and reduce costs of its solutions. Lower dosages and lower unit prices all contribute to lower cost-in-use, but increased capacity, less ingredient and product waste all contribute to lower costs and the latter can sometimes far outweigh pure ingredient factors. Palsgaard® SA 6610 is a good example of a product which has an effect on all these aspects which makes it an ideal choice for cake producers. Low dosage: With a dry matter content of more than 92 %, Palsgaard® SA 6610 has a higher emulsifier content than gels. In addition to the emulsifier part an activating medium is absolutely critical and necessary in order for Palsgaard® SA 6610 to act instantly in cake batters. This activating medium will have clear benefits in the cake batter and it will improve finished cake quality. The results are high quality cakes using low dosages leading to attractive costin-use calculations. Cake factories today are challenged by their customers to deliver high quality cakes produced rationally and consistently at low cost. Our activated cake emulsifier Palsgaard® SA 6610 can meet those challenges - the result being convenient, efficient and safe production of high quality cakes at low cost. New processes - convenience Direct addition: Food companies are increasingly automatizing their production lines for the purpose of improving productivity, quality and outputs. Often implementation of quality programmes such as HACCP leads to increased automation. Palsgaard® SA 6610 can be handled automatically as a powdered ingredient and it can be added directly to a cake batter without prehydration, prepatory steps or product loss. This is in contrast to handling of gels, shortenings and other cake emulsifiers in paste form. Easier product development: As Palsgaard® SA 6610 only consists of one active emulsifier and one food ingredient, it is now easier Palsgaard Technical Paper, April 2012 Explore the benefits of a new generation of fast reacting cake emulsifiers to make recipe adjustments when developing new products or making adjustments to existing ones. As you no longer have to consider multiple ingredients and effects, which is often contradictory or undesired, it makes for more safe and less costly product development work. No allergens: Palsgaard® SA 6610 has no allergens according to Directive 2000/13/EC. It contains neither milk, soya nor wheat proteins and therefore you need not consider possible allergens due to these raw materials. It is based on 100% vegetable raw materials and is both Kosher and Halal certified. 2 New processes - efficiency Faster premixing: The premixing step in industrial cake production is often time consuming and involves a number of separate steps. If premixing happens to be a bottleneck in your processing, changing to Palsgaard® SA 6610 could mean significantly increased outputs. We advice a very simple and efficient one stage procedure, where all ingredients except oil are added at the beginning of the mixing and just before finishing mixing, oil is added. This procedure guarantees the best functionality when using Palsgaard® SA 6610. The procedure is simple and effective. No product loss and precision: Automation means a minimum of manual handling and maximum security for correct dosages. The emulsifier will show constant performance over time and will improve overall cake quality for the benefit of company brand. Using Palsgaard® SA 6610 will mean less errors, less rework and no waste of emulsifier. Optimum performance: Full benefit of Palsgaard® SA 6610 is achieved by making sure, that the emulsifier is properly distributed in the cake batter. Figure 1 below illustrates potential cake volume as a function of work input. It shows a typical S-curve behaviour. At low energy input Palsgaard® SA 6610 is physically distributed and solubilised in the batter and as energy input is gradually increased by further mixing, the emulsifier is building an ideal emulsion and dispersion for further processing in the aerator. Palsgaard can offer alternative powdered cake emulsifiers suitable for different premix equipment. This guarantees full performance of the selected cake emulsifier. High quality cakes When using Palsgaard® SA 6610 it is possible to produce juicier cakes by substituting unhealthy hardened fats and trans fats for more healthy vegetable oils. Palsgaard® SA 6610 can carry high amounts of liquid oil making it a very flexible ingredient in relation to use in different product types such as sponge cakes, Swiss rolls, cup cakes, muffins and other cakes with a high fat content. The benefits of using oils in cakes instead of more saturated fats are much better juiciness and improved softness during storage. How to make a fast reacting cake emulsifier? Palsgaard has worked with cake emulsifiers for nearly 100 years and therefore we have a broad and practical experience in selecting the right type of emulsifier for the right purpose. Palsgaard has continuously been awarded new patents in the extruded cake emulsifier area and these patents make it possible to create new cake emulsifiers at reduced costs. Palsgaard produces many different types of polyglycerolesters and we have succeeded in developing specific types and active carriers for optimum performance in relation to aeration, stability and softness over time. Creating a cake emulsifier with only one active emulsifier type has only been possible due to our long experience in this specialized field. What is an activated cake emulsifier? Activated cake emulsifier is a term used to describe the instant properties of Palsgaard® SA 6610 when adding the product to the cake batter. The activation is achieved by placing the emulsifier on the surface of very small starch granules by means of an extrusion process. The emulsifier on the surface of Figure 1 illustrates potential cake volume as a function of work input. It low energy input Palsgaard® SA 6610 is physically distributed and solubilised in the batter and as the energy input Minimum mixing Potential cake volume shows a typical S-curve behaviour. At is gradually increased by further mixing, the emulsifier is building an ideal emulsion and dispersion for further processing in the aerator. Premixing time/-intensity Palsgaard Technical Paper, April 2012 Explore the benefits of a new generation of fast reacting cake emulsifiers 3 the starch granule has to be in a stable alpha crystal form as this special crystal form is essential for proper aeration of a cake batter. In Figure 2 a microphoto of a powder particle of Palsgaard® SA 6610 is shown. You can identify the individual small starch particles in the powder particle and each of these starch particles is covered by a monomolecular layer of polyglycerolester. This creation of a huge surface area is achieved by means of our special extrusion process. The result is very significant – one single carton of 15 kilos will have a surface area equal to 4 to 5 football fields. This fact is the background for the high efficiency of Palsgaard® SA 6610. The alpha crystal form in Palsgaard® SA 6610 is stable for min. 18 months - contrary to many gels which may recrystallize quickly during storage creating white spots. White spots in gels are not whipping active and will spread through the gel over time destroying whippability. This disadvantage will be avoided when using Palsgaard® SA 6610. Figure 2: Microphoto of a Palsgaard® SA 6610 powder particle. The total surface area of a 15 kilo carton of Palsgaard® SA 6610 equals 4 - 5 football fields. The benefit of a pilot plant A significant part of our know-how within industrial baking is based on trials performed on our industrial scale pilot plant and our practical experience. Our industrial scale pilot plant helps us make realistic trials which can be easily upscaled. Palsgaard offers theoretical and practical support which takes its starting point in your specific set up and working conditions. In this way the likelihood of success is higher, when working closely together on specific projects. Get your recipe adjusted As a dedicated supplier of ingredients to the cake industry, we offer extensive technical support covering all aspects in formulating new products and optimizing recipes and processes. As our Palsgaard® SA 6610 differs in important ways from traditional cake emulsifiers, recipe adjustments are necessary when changing emulsifier type. 2 basic changes are needed and Palsgaard can help you safely through the process: • Reduction in dosage of Palsgaard® SA 6610 of approx. 25 %, compared to gels. • Changes related to the difference in the composition between gel and Palsgaard® SA 6610 primarily the starch/flour level and the water content. Get your own cost-in-use calculations Should you be interested in getting your own cost-in-use calculations resulting from a possible change to Palsgaard® SA 6610, we shall be happy to assist you. Please contact Business Development Manager at kem@palsgaard.dk or Tel. +45 7682 7682 Palsgaard Technical Paper, April 2012 Explore the benefits of a new generation of fast reacting cake emulsifiers 4