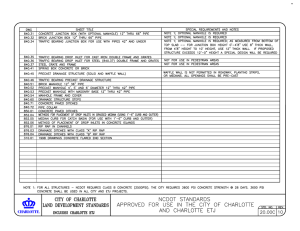

manhole rehabilitation

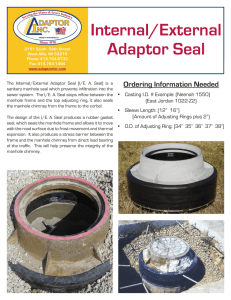

advertisement