NCP1650 - Power Factor Controller

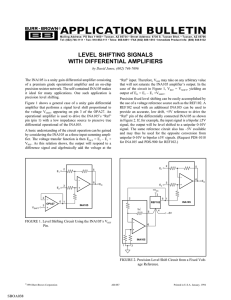

advertisement