electrical modification works at wood lab rubber board manganam

advertisement

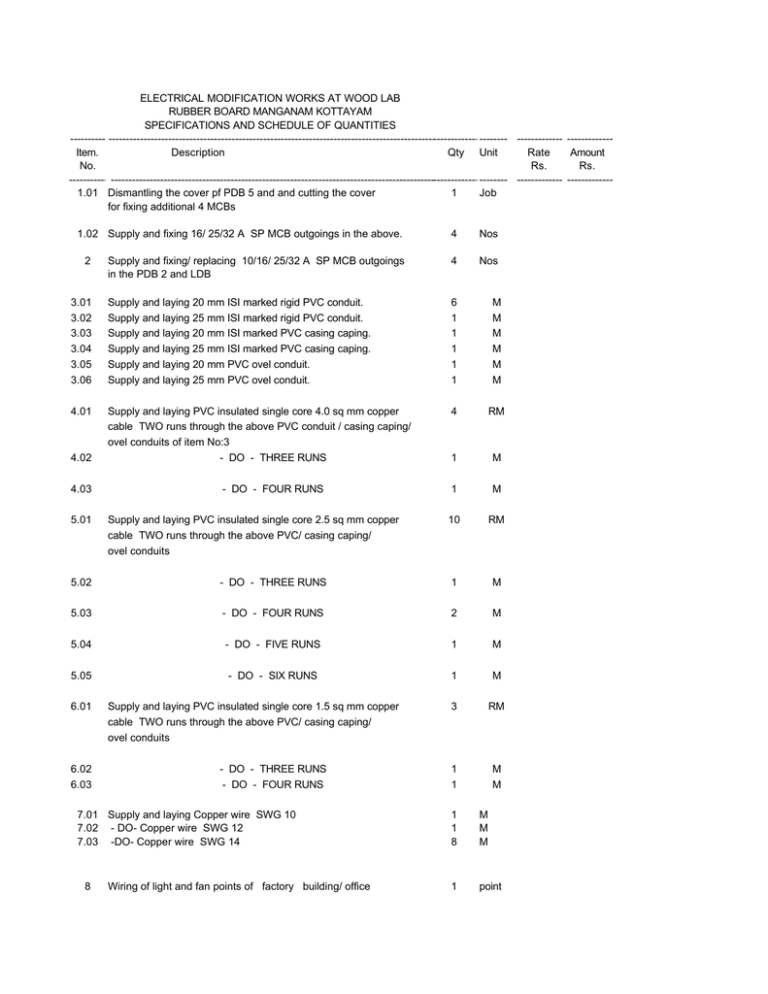

ELECTRICAL MODIFICATION WORKS AT WOOD LAB RUBBER BOARD MANGANAM KOTTAYAM SPECIFICATIONS AND SCHEDULE OF QUANTITIES ---------- ------------------------------------------------------------------------------------------------------------------- ----------------------------------------------------------------------------------------------Item. Description Qty Unit Rate Amount No. Rs. Rs. --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ----------------------------------------------------------------------------------------------1.01 Dismantling the cover pf PDB 5 and and cutting the cover 1 Job for fixing additional 4 MCBs 1.02 Supply and fixing 16/ 25/32 A SP MCB outgoings in the above. 4 Nos Supply and fixing/ replacing 10/16/ 25/32 A SP MCB outgoings in the PDB 2 and LDB 4 Nos 3.01 3.02 3.03 3.04 3.05 3.06 Supply and laying 20 mm ISI marked rigid PVC conduit. Supply and laying 25 mm ISI marked rigid PVC conduit. Supply and laying 20 mm ISI marked PVC casing caping. Supply and laying 25 mm ISI marked PVC casing caping. Supply and laying 20 mm PVC ovel conduit. Supply and laying 25 mm PVC ovel conduit. 6 1 1 1 1 1 M M M M M M 4.01 Supply and laying PVC insulated single core 4.0 sq mm copper cable TWO runs through the above PVC conduit / casing caping/ ovel conduits of item No:3 - DO - THREE RUNS 4 RM 1 M 1 M 10 RM 2 4.02 4.03 5.01 - DO - FOUR RUNS Supply and laying PVC insulated single core 2.5 sq mm copper cable TWO runs through the above PVC/ casing caping/ ovel conduits 5.02 - DO - THREE RUNS 1 M 5.03 - DO - FOUR RUNS 2 M 5.04 - DO - FIVE RUNS 1 M 5.05 - DO - SIX RUNS 1 M 3 RM 1 1 M M 6.01 6.02 6.03 Supply and laying PVC insulated single core 1.5 sq mm copper cable TWO runs through the above PVC/ casing caping/ ovel conduits - DO - THREE RUNS - DO - FOUR RUNS 7.01 Supply and laying Copper wire SWG 10 7.02 - DO- Copper wire SWG 12 7.03 -DO- Copper wire SWG 14 8 Wiring of light and fan points of factory building/ office 1 1 8 M M M 1 point for independant control using PVC insulated copper cable of 1.0 sq mm in ISI Marked rigid PVC conduits with independent switches in sheet steel enclosure. 9 -DO- Wiring of light and fan points of factory building/ office for independant control using PVC insulated copper cable of 1.5 sq mm in ISI Marked rigid PVC conduits. 1 point 1 sets 1 sets 1 sets 11.02 Supply and fixing 32 Amp DP MCB in enclosure on the walls 1 set 11.03 Supply and fixing 32 Amp DP switch in enclosure on the walls 1 set 10.01 Supply and fixing/ replacing 5 A plug socket 3 pin type with control switch on the existing MS box 10.02 Supply and fixing/ replacing 15 A power plug socket 5 in one type in the existing MS box 11.01 Supply and fixing 3 Nos 5 A plug socket 3 pin type with 3 Nos control switch on MS box including supply of all items. 12 Checking the existing power point line in the entomology lab and identifying the power line, rectification and balancing of power loads, AC unit power supply etc. 2 Labour 13 Supply and fixing/ replacing of damaged 40 A ELCB Four pole. 1 No 1 1 1 No No No 14.01 Supply and fixing/ replacing of damaged 50 Amp HRC fuse 14.02 Supply and fixing/ replacing of damaged 32 Amp HRC fuse 14.03 Supply and fixing/ replacing of damaged 25 Amp HRC fuse TOTAL I/We hereby tender for the execution of works refered to above in the aforesaid documents upon the terms and conditions contained or referred to therein and in accordance in all respects with the specifications, designs, drawings and other relevant details at the rates quoted by me/us. Signature of the Tenderer Date ......... Wood Lab Miscelleneous ------------------------ ------------------------