08TD0110 Braced Insulator Assemblies

advertisement

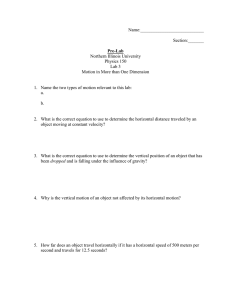

High Voltage Braced Insulator Assemblies Design & Application Panel Session PN23 2008 IEEE Transmission & Distribution Exposition & Conference April 24, 2008 Chicago, IL 1 High Voltage Braced Insulator Assemblies Design & Application A. C. Baker: Overview & general comments R. A. Bernstorf: Strength ratings D. G. Powell: Horizontal Vee stability R. K. Kihara: Construction 2 1 Armless Construction 3 Load Capacity Improvement α d θ d Maximum Allowable Vertical (Weight) Load Conventional Vertical String Porcelain Polymer Horizontal Line Post RTL RCL ( RTL = 0.5 M&E) (RCL = 0.4CS) RTL RCL (RTL = 0.5 SML) (RCL = 0.5 SCL) RTL range 7,500 – 25,000 lbs. RCL range 650 – 1,900 lbs. REFERENCES: 1) ANSI C29 STANDARDS, (C29.2, 29.7, C29.12, & C29.17) 2) IEEE STANDARD 987, “IEEE Guide for Application of Composite Insulators” 3) NEMA STANDARD PUB. HV-2, “Application Guide for Ceramic Insulators” Braced Post Assembly For α = 45º .707 RTL For α = 30º .500 RTL VMAX range 2,500 - 14,000 lbs. 4 2 Braced Insulator Assembly 5 8000 7000 230 Kv Horizontal Vee Vertical Load V lbs. 6000 Post: Max Working Loads Cantilever = 1,000 lbs. Tension/Compression = 7,500 lbs 5000 4000 Brace: Max .Working Load Tension = 12,500 lbs. 3000 2000 1000 0 0 500 1000 1500 2000 2500 3000 3500 4000 Horizontal Load H, lbs. Vertical Load Carrying Capacity vs. Transverse Loading 6 for a Typical 230 kV Horizontal Vee 3 Unbalanced Longitudinal Loads L1 ≠ L2 T = (V sin θ – H cos θ) tan ω 7 Horizontal Vee Longitudinal Displacement L1 L2 8 4 Horizontal Vee Lines • Wind stability limit can be lower than maximum wind speed usually considered. • HV assemblies subjected to unbalanced longitudinal loads will be displaced in direction of higher load. • Changes in sag will counteract the unbalancing load, establishing new equilibrium at each support point. • Iterative solution needed. 9 Horizontal Vee Wind Speed Stability Limit Wind Stability Limit, km/hr 350 300 250 200 150 100 50 0 0 10 20 30 40 50 Num ber of Spans 60 70 80 10 5 230 kV Horizontal Vee Line Ref. INMR Quarterly Review Quarter 1 2004 11 Rotated Horizontal Vee Ref. INMR Quarterly Review Quarter 1 2004 12 6 Braced Post Used as a Longitudinal Restraint Point Ref. INMR Quarterly Review Quarter 1 2004 13 Tripod Longitudinal Restraint Assembly 14 7 Other Loading Considerations • Suspension insulators: tension loads only. • Brace: no compression loads. • Polymer posts: combined loading effects • Some Porcelain posts designed for tension /compression only. Do not use for Braced Post Assemblies. • Posts : consider buckling strength • These subjects will be covered in detail in later presentations. 15 Electrical Design • Brace and Post insulator components must be properly coordinated. • Individual components must be adequate to withstand the power frequency and impulse electrical stresses in service. • Assembly Leakage Distance. • Assembly Dry Arc Distance. • Manufacturers should be consulted concerning need for corona rings. 16 8 Summary • Two types of Braced Insulator Assemblies: Braced Posts & Horizontal Vees (fixed or articulated posts) • • • • Different mechanical characteristics. Braced Posts primarily polymer. Consider Horizontal Vee wind stability limits. Longitudinal restraint assemblies can increase the wind stability limit for a Horizontal Vee line. • Installation of some Horizontal Vees may require special construction techniques. 17 9