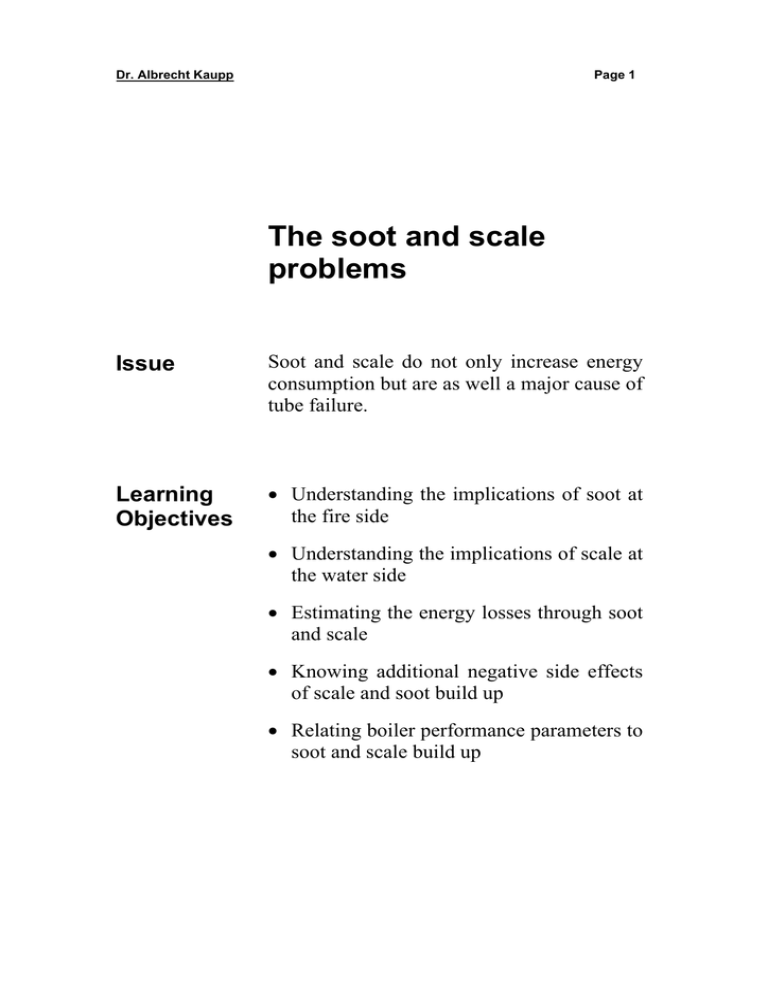

The soot and scale problems

advertisement

Dr. Albrecht Kaupp Page 1 The soot and scale problems Issue Soot and scale do not only increase energy consumption but are as well a major cause of tube failure. Learning Objectives Understanding the implications of soot at the fire side Understanding the implications of scale at the water side Estimating the energy losses through soot and scale Knowing additional negative side effects of scale and soot build up Relating boiler performance parameters to soot and scale build up The soot and scale problems Page 2 NOTES 1. Introduction Boilers are delivered clean with no soot, slag and scale. Consequently a soot and scale problem is a classic management and operational problem that has very little to do with boiler design. Soot and slag is a mixture of solid carbon, ash, and molten ash that sticks to the fire side of the tube and prevents heat transfer. Slag will also cause corrosion. Scale is a hard coating or layer of chemical materials on internal surfaces of the boiler exposed to the water side. Scale mitigates heat transfer and may lead to corrosion as well. Scale and soot prevention is one of the most important task of a boiler operator besides reducing stack gas losses. The cause of scale will be extensively discussed in lecture 15. Soot and slag deposits at boiler tube surfaces are mainly a firing problem and/or mismatch of the fuel and burners. 2. Soot and slag generation In any combustion process of a fuel there will be always some unburned carbon (soot) generated and some ash carried with the stack gas stream. Soot, ash, and molten ash (slag) will accumulate at the tube banks of the heat exchangers. Some ash will even melt down at the tube surface. The final result is a layer insulating the tubes against the hot combustion gases. Soot generation has various causes such as a) Freezing the chemical reaction The flame comes too close to the boiler walls, “freezing” the kinetic reaction. This effect is best demonstrated with a knife one passes through a candle flame. The flame will blacken the knife. Major causes are overfiring of the boiler, too much excess air, and worn out burner nozzles. The soot and scale problems Page 3 NOTES b) Insufficient atomization of fuel oil We talk about the three “T’s” in combustion, turbulence, temperature and time. Low oil line pressure and lack of turbulence will result in poor atomization of fuel oil, resulting in larger droplets leaving the flame envelope partially unburned. Major causes are low oil line pressure, lack of primary combustion air, or low fuel oil preheating temperature. c) High moisture content in the fuel Too much water in a fuel leads to a “cold” fire causing excessive smoke generation because there is not enough fuel energy available to generate a sufficiently high flame temperature. However some water helps to speed up kinetic reaction. It also shortens the flame length. Major cause of this type of soot generation is a combination of high moisture content and too much excess air. d) Erratic feeding of solid fuels Solid fuel firing is not as “smooth” as liquid or gaseous fuel firing. Excess air is changing constantly, causing cold pockets in the furnace, where too much fuel and not enough “fire” and air are present. The result is smoke generation. Major causes are bad combustion air distribution and malfunctioning or badly designed feeding mechanism. e) Dripping burner Occasionally liquid oil drips directly from the burner down into the fire tube and forms a pile of soot. This soot burns up and generates smoke. In particular in boilers with superheaters, soot and slag accumulates at the superheater tube banks first because the superheater is the first heat exchanger passed by the products of combustion. All superheaters have “soot blowers” that are activated periodically to blow off the soot with steam. The soot and scale problems Page 4 NOTES 3. Fire tube and water tube differences There is a basic difference between fire tube and water tube arrangements, with respect to the location of the soot and scale. Figure 1 shows a water or superheater tube with soot at the outside of the tube and scale at the inside. In a water tube boiler the hot combustion gases pass a bank of tubes at the outside and release their energy to the water or steam flowing inside the tube. Figure 1: Water tube with soot outside and scale inside The soot and scale problems Page 5 NOTES Figure 2: Fire tube with soot inside and scale outside Figure 2 shows a fire tube with soot inside the tube. In a fire tube boiler the hot combustion gases pass through a bundle of tubes and release part of their energy to the water at the outside. Fire tube boilers are usually smaller (1 to 25 t/h) and mostly in the 5 to 20 bar range. Soot cleaning is simple, requiring only to open the back and front door of the boiler to expose the horizontal fire tubes. Soot cleaning of water tube boilers is much more complicated, since they are larger and more complicated built. 4. Stack gas temperatures versus soot and scale deposits The rated heat output of a boiler is based on firing a specific fuel at a specific excess air factor. In a clean boiler this will result in a well defined stack gas temperature for a specific fuel firing rate. Stack gas temperatures depend very much on the firing rates. The stack gas temperature is usually lower at “low fire”, while it reaches its peak at “high fire”. Most manufacturers specify what stack gas temperature is to be expected at “low fire”, “high fire” or rated heat output. The stack gas temperature always refers to a point in the system where the combustion gases do not release heat any longer to the water-steam The soot and scale problems Page 6 NOTES circuit. This boiler specific stack gas temperature is our yardstick and the best we can achieve in the field. High stack gas temperatures are therefore a sure sign that boiler heat exchanger surfaces have accumulated soot and/or scale. A highly recommended method of reducing fuel consumption is to set a so called best stack gas temperature at “high fire” and to instruct operators to clean the boiler if stack gas temperatures exceed this value by 10 to 20 oC. This practice is in particular easy to implement with fire tube boilers, where cleaning of the fire side can be accomplished in half a day. Descaling of the water side is usually complicated and done yearly if necessary. Implementation of this practice would require to record stack gas temperatures about three times a day at the high fire setting. Note, that the stack gas temperature at a lower firing rate will be considerable lower. Also, increasing the excess air lowers stack gas temperature. Furthermore most in line temperature sensors get easily fouled, with soot deposits at the stem. Fouled temperature sensors show a lower temperature because the soot layer insulates the stem against the hot stack gas. As discussed, any 20 oC decrease of stack gas temperature could easily save 1 % fuel and is therefore worthwhile to consider. 5. A crash course in applied heat transfer In a fire tube boiler, the energy of hot combustion gases are transferred through the soot layer, the tube wall and the scale layer to the water. Both, the soot as well as the scale act as insulators. The effect is a hotter than usual stack gas temperature because the combustion gases were prevented from efficiently transferring their energy to the water side. Depending on the water chemistry, different types of scale exist. High density scale ( = 2,000-2,700, = 0.7-2.33) The soot and scale problems Page 7 NOTES Medium density scale Low density scale ( = 1,000-2,500, = 0.15-1.16) ( = 300-1,200, = 0.08-0.23) Roh, (), is the scale density in kg/m3, while Lambda, (), stands for the thermal conductivity in W/moC. The thermal conductivity of soot is between 0.03 and 1 W/moC, depending on how much slag has been accumulated at the surface. For comparison, good insulation of steam distributions line have = 0.05 to 0.3 W/moC. Boiler tube walls have a thermal conductivity of 50 to 60 W/moC and are very good heat conductors. An insulator causes a high temperature drop across its thickness, while a very good conductor causes a very small temperature drop across its thickness. Since on both sides of the tube we have a fluid flowing (stack gas, water, or steam) there are also two so called film heat transfer coefficients, hH2O, for the water or steam side and hgas for the gas side. The film heat transfer coefficient, hgas, describes how easily the gas transfers its energy to the metal or soot surface, while hH2O describes how easily the water or steam picks up the heat that penetrates through the metal tube or the scale surface. The combined effect is expressed in a well known equation describing heat transfer through tubes with three layers (scale, metal and soot). Q = Ta Tb r0 r1 r2 r3 ki L h0 h3 = = = = = = = = = = 2 L Ta Tb 1 ln r r ln r2 r1 ln r3 r2 1 1 0 k1 k2 k3 r3 h3 r0 h0 Watt temperature of the fluid (steam, water, stack gas) inside the tube, oC temperature of the fluid (gas, water) outside the tube, oC inner radius of the free cross section of the pipe, m outer radius of the first layer, m outer radius of the second layer, m outer radius of the third layer, m thermal conductivity of layer i, W/moC tube length, m inner film heat coefficient, W/m2 oC outer film heat coefficient, W/m2 oC To demonstrate some of the temperature and heat loss effects it is sufficient to assume the following: The soot and scale problems Page 8 NOTES Film heat transfer liquid water side, hH2O Film heat transfer steam side, hH2O Film heat transfer gas side, hgas of scale of soot of metal tube = 10,000 W/m2 oC = 1,000 W/m2 oC = 100 W/m2 oC = 1 W/m oC = 1 W/m oC = 50 W/m oC The above numbers are used in the exercise section. 6. Heat exchanger tube failures There is a specific set of circumstances, where you as a consultant, trying to reduce fuel consumption, may unintentionally contribute to premature tube failure in heat exchanger tubes. Some boiler operators neither care about soot nor scale and operate their boiler inefficiently. Recall that scale as well as soot are barriers to heat transfer. Your recommendation is to clean the fire side of the boiler and remove the soot regularly, while descaling of the water side can wait until the next major shutdown for overhauling of the boiler. Consequently one barrier for heat transfer is removed, but the other remains. Note that the barrier on the very hot combustion gas side was removed, and subsequently the metal surface temperature will go up significantly (thermal stress), depending on the scale thickness on the water or steam side. This phenomena would not happen to this extend if both barriers, scale and soot, are removed. Keep in mind that under certain circumstances cleaning the fire side without cleaning the water or steam side will increase the danger of thermal stress of boiler tubes. This happens in particular at the tube seats of the first pass of fire tube boilers. It is in general bad practice to frequently clean the fire side and totally ignore scale built up at the water side. This will reduce fuel consumption at the expense of more frequent retubing of boiler tubes. Tube corrosion is also accelerated at high temperatures. The costs of retubing and repairing water walls damaged by overheating are much higher than any additional fuel costs due to The soot and scale problems Page 9 NOTES reduced efficiencies. One should therefore always inquire about descaling practice and feedwater treatment. 7. Fuel reduction potential Only “rules of thumb” figures for scale and soot can be given as shown in Figure 3 and Figure 4. Losses are expressed in percent of fuel input as a function of the scale or soot thickness. Inaccuracies are not caused by rough estimates of film heat transfer coefficients. Their value has no significant impact on the result. More critical is the thermal conductivity of scale and soot layers that may vary widely. Nevertheless even very thin layers (0.5 to 1 mm) of soot and scale cause significant fuel losses. In addition scale built up causes thermal stress to the tubes and increases repair and maintenance costs. Effect of Soot on Fuel Consumption % Fuel Energy Loss 10 8 6 4 2 4 3.5 3 2.5 2 1.5 1 0.5 0 Thickness of Soot Layer, mm Figure 3: Fuel energy loss due to soot The soot and scale problems Page 10 NOTES Effect of Scale on Fuel Energy Losses 12 % Fuel Loss 10 8 High density 6 Medium Density Low Density 4 2 2 1.75 1.5 1.25 1 0.75 0.5 0.25 0 0 Scale Thickness,mm Figure 4: Fuel energy loss due to scale 8. Measurement techniques The stack gas temperature of a boiler, if continuously recorded over longer periods (weeks, months), gives very important information about the efficiency of a boiler and its operating hours. Temperature recording is accurate, inexpensive and easy to perform. In case a boiler requires closer observation one may first install automatic single channel data loggers that measure the temperature in 1 to 10 minute intervals over days and weeks. Equipment costs are US$ 350 only. A long term temperature profile of a boiler is like a electrocardiogram. It can show on a time scale the following: The temperature built up due to scale and soot formation The cycling behavior of the oil burner or solid fuel feeding system The low and high fire intervals The boiler operating hours Consultants are encouraged to continuously record boiler temperature in case they intend to engage in a long term contract to improve boiler efficiency. The soot and scale problems Page 11 NOTES EXERCISES Task 1 Assume there is a scale with = 1 W/moC at the inside of a boiler water tube (OD = 38.1 mm, wall thickness =3.4 mm). The steam and water mixture is at 40 bar and 250oC. The overall heat transfer is 400 kW/m2 inner pipe surface. Follow the steps to calculate the temperature increase across each of the surfaces from the inside to the outside (Water film, scale, tube wall). Step Input Data or Equation Result 250 250 °C 1) Steam temperature,TS, °C 2) Inner radius, r0, m 0.01905 2 3) Water film hWF, W/m °C 10,000 2 4) Heat input, qo, W/m 400,000 q0 h WF 5) Temperature difference across water film, Twater film, °C 6) Scale thickness, ts, m 0.001 7) Conductivity scale s, W/m °C 8) Temperature difference across scale, Tscale, °C 9) Tube wall thickness, tT, m 1 r0q0 r t ln 0 s r0 s 0.0034 10) Conductivity tube, T, W/m°C 50 11) Temperature difference across, tube, Ttube, °C r t t r0 q 0 ln 0 s T r0 t s 12) Tube surface temperature, Tsurface 13) Soot thickness, tsoot, m sum of rows 1, 5, 8, 11 0.001 14) Conductivity soot, soot, W/m°C 15) Temperature difference across soot layer, Tsoot, °C 1 r t t t r0 q 0 ln 0 s T soot r0 t s t T 16) Soot surface temperature, °C T soot sum of rows 12 and 15 The soot and scale problems Page 12 NOTES SA-210 Carbon steel shall not exceed an oxidation temperature of 450°C. This exercise gives a very educational insight view on the effect of scale and soot on wall temperatures of tubes. The case refers to the water wall in a furnace that receives its energy input mostly by radiation and not by convection. Note the rather high heat transfer of 400 kW/m2 . Task 2 Often an energy auditor is in no position to measure water or steam temperatures. Assume a situation where the temperature gages are missing or you don’t trust the reading, but you are able to measure the surface temperature of the bare pipe correctly ( 2 oC). Did you make a large error by assuming the fluid temperature is 2% higher than the measured surface temperature? Repeat this exercise under the assumption that there was a 1 mm scale inside the tube, you didn’t know about. Use the same procedure as in task 1. Asssume steam at 250°C and a film heat transfer coefficient of 1000 W/m2 °C. The ambient temperature is 35°C. Depending on the emissivity of the bare pipe surface (shiny or black) we may have a heat transfer of between 4.4 kW /m2 and 7.5 kW/m2 from the pipe surface to the ambient. Task 3 Measuring surface temperatures requires special surface temperature sensors and some skills. It is always advisable to apply enough pressure on the sensor and clean the surface, prior to measuring. Test the effect of paint at the pipe surface. Even a very thin layer of paint will change the surface temperature of a pipe carrying hot feedwater at 95 C by about 3-7 C. Does the temperature go up or down as compared to the surface temperature of the clean pipe?