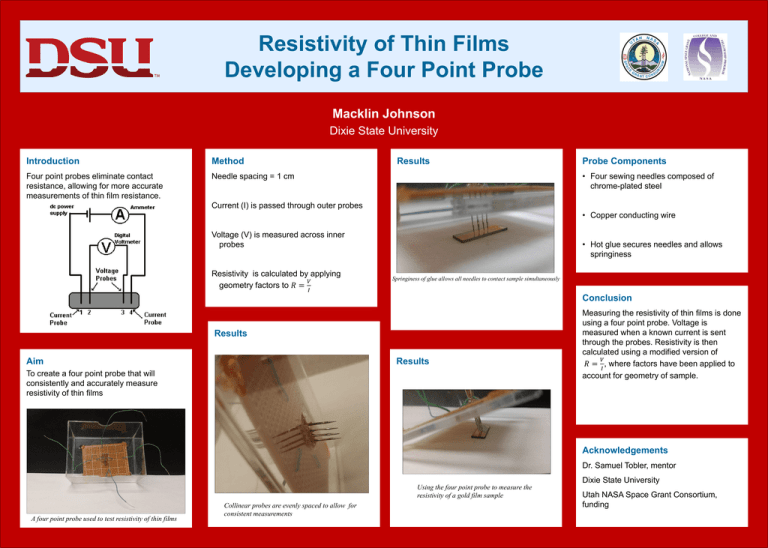

Resistivity of Thin Films Developing a Four Point Probe

advertisement

Resistivity of Thin Films Developing a Four Point Probe Macklin Johnson Dixie State University Introduction Method Four point probes eliminate contact resistance, allowing for more accurate measurements of thin film resistance. Needle spacing = 1 cm Results Probe Components • Four sewing needles composed of chrome-plated steel Current (I) is passed through outer probes • Copper conducting wire Voltage (V) is measured across inner probes Resistivity is calculated by applying 𝑉 geometry factors to 𝑅 = • Hot glue secures needles and allows springiness Springiness of glue allows all needles to contact sample simultaneously 𝐼 Conclusion Results Aim Results To create a four point probe that will consistently and accurately measure resistivity of thin films Measuring the resistivity of thin films is done using a four point probe. Voltage is measured when a known current is sent through the probes. Resistivity is then calculated using a modified version of 𝑉 𝑅 = , where factors have been applied to 𝐼 account for geometry of sample. Acknowledgements Dr. Samuel Tobler, mentor Dixie State University Using the four point probe to measure the resistivity of a gold film sample A four point probe used to test resistivity of thin films Collinear probes are evenly spaced to allow for consistent measurements Utah NASA Space Grant Consortium, funding