American Journal of Infection Control 41 (2013) S97-S104

Contents lists available at ScienceDirect

American Journal of Infection Control

American Journal of

Infection Control

journal homepage: www.ajicjournal.org

Original research article

The crucial role of wiping in decontamination of high-touch environmental

surfaces: Review of current status and directions for the future

Syed A. Sattar PhD a, *, Jean-Yves Maillard PhD b

a

b

Centre for Research on Environmental Microbiology, Faculty of Medicine, University of Ottawa, Ottawa, Ontario, Canada

Pharmaceutical Microbiology, Cardiff School of Pharmacy and Pharmaceutical Sciences, Cardiff University, Cardiff, UK

Key Words:

Wiping

Towelettes

Disinfection

Nosocomial pathogens

Infection control

The testing and label claims of disinfectants to wipe high-touch environmental surfaces rarely reflect

their field use where contact times are in seconds with only microliters of the disinfectant deposited on

a unit surface area. Therefore, such products must be properly assessed with mechanical/chemical action

combined. We critically review current wipe test methods and propose future approaches.

Copyright Ó 2013 by the Association for Professionals in Infection Control and Epidemiology, Inc.

Published by Elsevier Inc. All rights reserved.

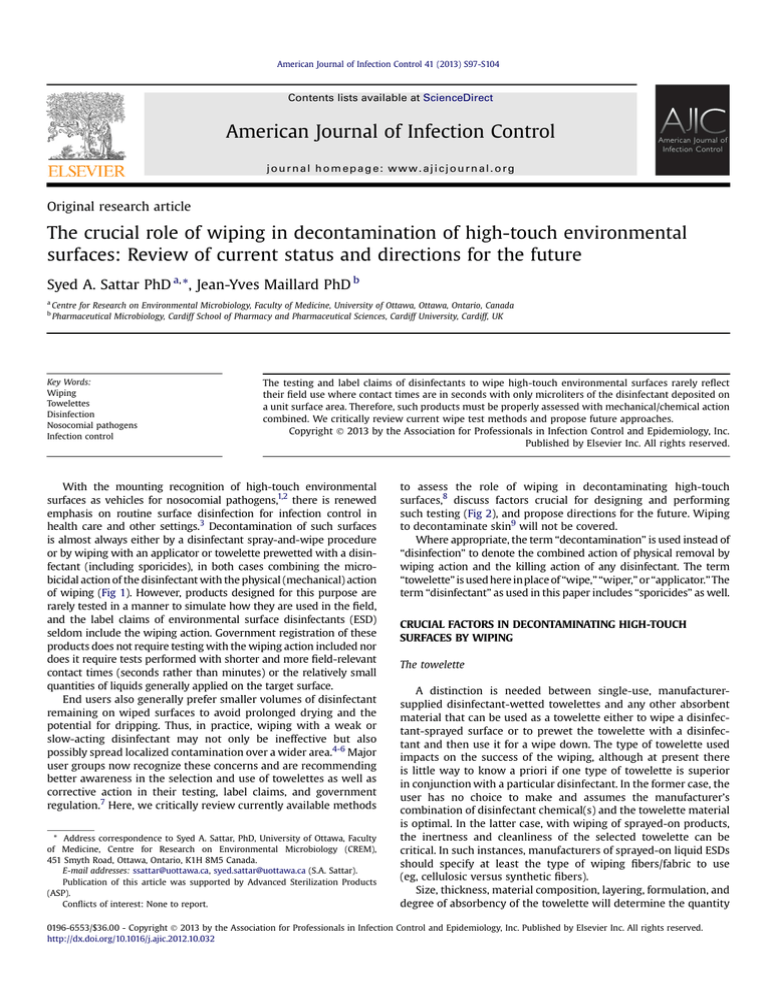

With the mounting recognition of high-touch environmental

surfaces as vehicles for nosocomial pathogens,1,2 there is renewed

emphasis on routine surface disinfection for infection control in

health care and other settings.3 Decontamination of such surfaces

is almost always either by a disinfectant spray-and-wipe procedure

or by wiping with an applicator or towelette prewetted with a disinfectant (including sporicides), in both cases combining the microbicidal action of the disinfectant with the physical (mechanical) action

of wiping (Fig 1). However, products designed for this purpose are

rarely tested in a manner to simulate how they are used in the field,

and the label claims of environmental surface disinfectants (ESD)

seldom include the wiping action. Government registration of these

products does not require testing with the wiping action included nor

does it require tests performed with shorter and more field-relevant

contact times (seconds rather than minutes) or the relatively small

quantities of liquids generally applied on the target surface.

End users also generally prefer smaller volumes of disinfectant

remaining on wiped surfaces to avoid prolonged drying and the

potential for dripping. Thus, in practice, wiping with a weak or

slow-acting disinfectant may not only be ineffective but also

possibly spread localized contamination over a wider area.4-6 Major

user groups now recognize these concerns and are recommending

better awareness in the selection and use of towelettes as well as

corrective action in their testing, label claims, and government

regulation.7 Here, we critically review currently available methods

* Address correspondence to Syed A. Sattar, PhD, University of Ottawa, Faculty

of Medicine, Centre for Research on Environmental Microbiology (CREM),

451 Smyth Road, Ottawa, Ontario, K1H 8M5 Canada.

E-mail addresses: ssattar@uottawa.ca, syed.sattar@uottawa.ca (S.A. Sattar).

Publication of this article was supported by Advanced Sterilization Products

(ASP).

Conflicts of interest: None to report.

to assess the role of wiping in decontaminating high-touch

surfaces,8 discuss factors crucial for designing and performing

such testing (Fig 2), and propose directions for the future. Wiping

to decontaminate skin9 will not be covered.

Where appropriate, the term “decontamination” is used instead of

“disinfection” to denote the combined action of physical removal by

wiping action and the killing action of any disinfectant. The term

“towelette” is used here in place of “wipe,” “wiper,” or “applicator.” The

term “disinfectant” as used in this paper includes “sporicides” as well.

CRUCIAL FACTORS IN DECONTAMINATING HIGH-TOUCH

SURFACES BY WIPING

The towelette

A distinction is needed between single-use, manufacturersupplied disinfectant-wetted towelettes and any other absorbent

material that can be used as a towelette either to wipe a disinfectant-sprayed surface or to prewet the towelette with a disinfectant and then use it for a wipe down. The type of towelette used

impacts on the success of the wiping, although at present there

is little way to know a priori if one type of towelette is superior

in conjunction with a particular disinfectant. In the former case, the

user has no choice to make and assumes the manufacturer’s

combination of disinfectant chemical(s) and the towelette material

is optimal. In the latter case, with wiping of sprayed-on products,

the inertness and cleanliness of the selected towelette can be

critical. In such instances, manufacturers of sprayed-on liquid ESDs

should specify at least the type of wiping fibers/fabric to use

(eg, cellulosic versus synthetic fibers).

Size, thickness, material composition, layering, formulation, and

degree of absorbency of the towelette will determine the quantity

0196-6553/$36.00 - Copyright Ó 2013 by the Association for Professionals in Infection Control and Epidemiology, Inc. Published by Elsevier Inc. All rights reserved.

http://dx.doi.org/10.1016/j.ajic.2012.10.032

S98

S.A. Sattar, J.-Y. Maillard / American Journal of Infection Control 41 (2013) S97-S104

Fig 1. Possible scenarios for decontaminating high-touch environmental surfaces by

wiping (modified from Sattar and Springthorpe29).

of a disinfectant retained in and released from it. The physical

structure of the towelette also influences the degree of contact it

makes with the surface as well as its cleaning/abrasion of that

surface and the capacity it has to pick up and hold soils, microbes,

and particles as the surface is wiped. It can, therefore, also influence

the level of redeposition of any previously accumulated microbes or

soil onto the most recently wiped surface area. Its chemical structure as well as prior use history and the degree of soil load it carries

influence whether and to what extent the towelette interacts with

the disinfectant chemicals. Such interactions weaken the disinfecting power by partial or complete neutralization of the disinfectant(s). The more surface contacted and the more soil acquired,

the weaker the disinfectant becomes. Towelettes employed in the

wiping of disinfectant-sprayed surfaces are often used for repeated

wiping with no or only cursory washing/decontamination in

between. Even those towelettes marketed as single use are often

used repeatedly and beyond their capacity to disinfect the surface

they are wiping. Thus, the level of the active(s) brought in contact

with the target surface and the inherent ability of the towelette

to react with and neutralize the active(s) in the disinfectant10 are

key factors that must be considered to prevent spread of microbial

contamination over wider areas. In specific settings, the use of

prewetted towelettes was shown to be better than a spray-andwipe procedure in decreasing bioburden from surfaces.11

Target nosocomial pathogens

In health care settings in particular, the types and levels of

pathogen contamination on high-touch environmental surfaces is

often unknown. Also, nosocomial pathogens vary widely in their

susceptibility to ESD depending on their biology, growth phase,

environmental conditions such as relative humidity (RH) and air

temperature, nature of the surface, and type and level of the

associated soil. Therefore, for routine wiping to be effective, it must

be designed and executed to cover as wide a variety of commonly

encountered pathogens as possible. The advent of sporulating

Clostridium difficile as an important nosocomial pathogen is now

a significant challenge for environmental decontamination in general12,13; the higher microbicide resistance of its spores14 requires

the use of towelettes with sporicidal chemicals.6

Regulatory agencies in North America (US Environmental

Protection Agency [EPA]; Health Canada)15,16 and Europe (European

Committee for Standardization [CEN])17 accept, with some exceptions (EPA and viruses), the use of surrogates of nosocomial pathogens to permit label claims for ESD. The criteria for choosing

a surrogate in testing towelettes would be the same as those

Fig 2. The combined effect of various factors impacting the outcome of decontamination of high-touch surfaces by wiping with a towelette.

currently employed in carrier testing of ESD, and the surrogate to be

selected should withstand the initial drying of the inoculum on the

carrier to be used for wiping. Safety, ease of handling, and ready

quantitation of viability are also important considerations. In

addition, the surrogate must be reasonably resistant to common

types of ESD to make label claims meaningful.18,19 Table 1 is a list of

recommended surrogates with justifications for inclusion in the

testing of towelettes. The listed surrogates represent all 5 major

groups of nosocomial pathogens and belong to biosafety levels 1

and 2.20 Several of those are already widely accepted in testing

chemical microbicides in general.21

The wiping action

The type and frequency of wiping action as well as the pressure

exerted during wiping can profoundly influence the outcome of

decontamination, and they also are among the more difficult

variables to control in the field. However, any standardized testing

of towelettes and wiping action must precisely control all these

factors for reproducible data on towelette performance and assess

all tested products under the same test conditions.

Surface to be wiped

A combination of use history, topography, accessibility, orientation, and inherent disinfectant demand of the target surface will

determine the efficiency of wiping and also the level of contact

between the target pathogen(s) and ESD. The surface to be wiped

must not only permit direct contact between the target pathogen(s)

and ESD but also allow for a sufficiently long dwell time to achieve

the desired level of decontamination. In general, the ease of

decontamination by wiping is directly related to the degree of

smoothness of the surface. However, if a representative environmental surface is to be selected for standardized evaluation of

wiping performance and decontamination efficacy, it should be one

with an uneven topography and also widely available.22

S.A. Sattar, J.-Y. Maillard / American Journal of Infection Control 41 (2013) S97-S104

S99

Table 1

Surrogates recommended for the testing of towelettes

Organism (ATCC number)

Category

Biosafety

level

Nosocomial

pathogen?

Staphylococcus aureus (6538)

Gram-positive

coccus

2

Yes

Acinetobacter baumannii (19606)

Gram-negative

bacillus

2

Yes

Candida albicans (10231)

Nonfilamentous or

yeast-like fungus

2

Yes

Aspergillus niger (64958)

Filamentous fungus

2

Yes

Mycobacterium terrae (15755)

Environmental

mycobacterium

2

Rare cases of

human infections

Bacillus subtilis (19659)

Aerobic spore former

1

No

Clostridium difficile (43598)

Anaerobic spore

former

2

Yes

Feline calicivirus (VR-782)

Small, nonenveloped

virus

2

No

Comment(s)

A common nosocomial pathogen; frequently used as a surrogate for

testing microbicides against vegetative bacteria (ASTM 2011).21,40

Survives well on drying of inocula on carriers.

Higher intrinsic resistance to microbicides than other gram negatives

and also withstands drying well. Increasingly important as

a nosocomial pathogen.41

An opportunistic nosocomial pathogen. Widely used as a surrogate

for testing ESD and topicals against nonfilamentous fungi

(ASTM 2011).21

Aspergillus42 and other species of filamentous fungi are emerging

nosocomial pathogens. The conidia of A niger are used in testing ESD

against filamentous fungi (ASTM 2011).21

Several species of nontuberculous or environmental mycobacteria are

increasingly being incriminated in health care-acquired infections.43

Mycobacteria in general also show a higher resistance to ESD.

M terrae is now widely accepted as a surrogate for testing the

mycobactericidal activity of microbicides (ASTM 2011).21,44

Commonly used as a surrogate to test chemicals against aerobic

spore-forming bacteria.

Now a significant nosocomial pathogen. EPA now requires ESD to be

tested against nontoxigenic strains of these spores for label claims of

sporicidal activity.45

Safe and relatively easy to culture and assay for infectivity in vitro;

withstands drying well,46 and also shows relatively high resistance to

ESD; a good surrogate for nosocomial viral pathogens including

human noroviruses.29

ATCC, American Type Culture Collection.

Contact time between ESD and target pathogen(s)

Product performance criterion

As mentioned above, the contact time between the towelette

and the target surface during normal wiping is often no longer than

a few seconds.4,23 Therefore, the desired level of reduction in

microbial contamination with a combination of wiping and disinfection must be achieved within that brief period for the decontamination to be effective under actual use conditions.

For government registration, an ESD should achieve a 3- to

5-log10 reduction in the viability of tested organisms (except for

bacterial spores), depending on the test method acceptable to the

target regulatory agency. This level of product performance is based

more on practicality than on any documented links between log10

kill and reductions in the rates of nosocomial infections spread via

high-touch environmental surfaces. A recent study of environmental surfaces in patient wards found the highest counts

of heterotrophic bacteria to be about 2.0 103 colony-forming

units/in2 (3 102 colony-forming units/cm2) on the bedrails24;

the numbers of nosocomial pathogens such as methicillin-resistant

Staphylococcus aureus were barely detectable on the bedrails at the

same site. These numbers are of the same level of magnitude as

those previously reported in the literature.25

Should an ESD assessed in a towelette test achieve the same

level of performance for registration without wiping or a higher

level because of the combined action of disinfection and the

physical action of wiping? As stated before, wipe testing is generally more demanding because of the much shorter contact times as

well as the lower volumes of disinfectant deposited over a unit

surface area. This critical issue should perhaps be discussed

together with the regulatory community once sufficient data from

well-designed and standardized wipe-testing studies become

available. For wiping of food-contact surfaces, the EPA requires

a 5-log10 reduction in the viability of the tested bacteria.26

Disinfectant

Whereas environmental surfaces in health care facilities may

be wiped down after terminal fumigation of a ward, or after

applying a disinfectant powder for a spill, most commonly used

ESDs are liquids. The speed and spectrum of microbicidal action of

any such liquid are both crucial for successful decontamination by

wiping. A combination of the chemical action of ESD and the

physical action of wiping must achieve the desired level of

reduction in contamination ideally against common nosocomial

vegetative bacteria, mycobacteria, viruses, and fungi. For spray-on

products, it may be feasible to wait for the label-recommended

contact time of several minutes before wiping is initiated. For

products that are applied with a single-use, manufacturer

supplied towelette, the wiping and contact occur simultaneously,

and so it is critical that the ESD act within a few seconds. Towelettes claiming residual microbicidal activity on the wiped surface

will require careful evaluation and potential benefits as well as

any risks the long-term use of such products may entail in

promoting antimicrobial resistance.

As mentioned above, effective wiping of surfaces suspected of

contamination with spore formers such as Clostridium difficile

would require sporicidal ESD.6 The relationship between detergent activity and microbicidal efficacy in the formulation is critical; an imbalance will lead to inefficient bioburden removal from

surfaces and the release of pathogens from the towelette.6

Recovery of test organism(s) from the carrier

Efficient recovery of the organism used for experimental

contamination of the carrier is critical for a quantitative and

reproducible assessment of the combined effect of disinfection and

wiping. Flat and relatively small carriers are the most desirable for

ease of wiping and complete immersion of the carrier into

S100

S.A. Sattar, J.-Y. Maillard / American Journal of Infection Control 41 (2013) S97-S104

a relatively small volume of eluent-neutralizer; this is especially

important when testing against viruses. The eluent and disinfectant

neutralizer must first be tested for efficiency as well as safety to the

test organism(s) and cell cultures when working with viruses.22

The human factor

Even when the most effective product is used, the degree of

diligence on the part of the housekeeping staff will ultimately

determine the success of the wiping action. It is now well documented that the wiping of high-touch environmental surfaces is

either neglected altogether or carried out in too cursory a manner

to be effective.27 Improper wiping can be counterproductive by

spreading localized contamination over a wider area.5,6 It should be

noted that wiping is a generic term that means different things to

different individuals. Properly conducted wipe testing should give

guidance on the types and extent of wiping that might be valuable

inclusions in product labeling.

contamination and may spread it over a wider area during the

decontamination if not killed effectively at the point of contact.

Therefore, it is imperative that the combined action of disinfection

and wiping be fast and efficient enough to reduce the pathogen

load to as low a level as possible to avoid spreading the pathogen

over a wider area.4,5 The potential for such pathogen spread over

a wider area during wiping is particularly high with inappropriate

detergent/microbicide ratio and the ability of certain towelette

materials to release microbial contamination.6

CURRENTLY AVAILABLE PROTOCOLS FOR TESTING OF

TOWELETTES

RH and air temperature together can determine the rate of loss

of wetness on the towelette itself and, therefore, the amount of ESD

delivered to the point of contact with the contaminated surface.

This points to the need for proper packaging of towelettes by

manufacturers and appropriate care in the storage and use of the

packaged towelettes by the end user. RH and air temperature can

also influence the rate of evaporation of liquids from environmental

surfaces, thus affecting microbicidal efficacy on surfaces.

Table 2 lists the available wipe test protocols with their attributes in relation to the critical factors listed above and summarizes

the information from 4 peer-reviewed studies published thus far.

With some exceptions (EPA 2001),26 test protocols currently available to assess disinfecting towelettes for regulatory purposes are

semiquantitative at best, and they also do not incorporate crucial

and field-relevant factors such as pressure and the relatively short

contact during wiping nor can they properly control for the ratio

between the volume of the disinfectant applied and the unit surface

area being wiped.

Currently, AOAC International and ASTM International are the

only 2 standards-setting organizations with published methods for

testing towelettes for their microbicidal activity (Table 2). They are

similar in their basic design and also subject to the same limitations. There is also a dearth of towelette test methods in peerreviewed literature.

Disinfectant/towelette ratio

A LOOK AT THE FUTURE

Marketed single-use towelettes generally have a relatively

constant ratio between an individual towelette and the volume of

disinfectant soaked in it as long as the canister or pouch is properly

closed, stored, and used within its recommended shelf life. Much

greater variability occurs when a dry towelette is wetted with

a disinfectant on site or when a disinfectant is first sprayed on a

surface and it is then wiped. For economy and for environmental

and human safety,8 the most desirable approach would be to have

just enough disinfectant to wet the towelette and to deliver moisture to the surface to be decontaminated without it dripping. How

long the towelette remains damp enough during use would depend

on the type and level of volatile organics (eg, ethanol) the ESD

contains but also on the end user for those towelettes that need

activation with water prior to use.

Any future attempts at developing standardized protocols to

assess the decontaminating potential of towelettes should consider

the following:

Should towelettes be tested against individual types and species

of pathogens? We consider such an approach unnecessary and

impractical. Instead, carefully chosen surrogates should be used

to maintain the cost of product development competitive while

keeping the product label uncomplicated and user-friendly. In

particular, the “fear-factor” should never be the basis for selecting

a pathogen for testing and label claims, especially in the absence of

any credible evidence for its ability to survive on and be transmitted

by high-touch environmental surfaces.19 It should be noted that it is

also possible to evaluate ESD against defined cocktails of microorganisms,28 a somewhat more complex but necessarily more realistic approach.

If and what type of soil load should be used in testing the decontaminating activity of towelettes? Pathogens discharged by infected

hosts are always contained in body fluid of one kind or another.

The organic and inorganic materials in such body fluids represent

the “soil load,” which not only affords protection to the pathogen but

can also react with the disinfectant and quench its microbicidal

activity. In addition, even brand new environmental surfaces often

exert a demand on ESD, and those frequently cleaned also contain

residual amounts of soil. Therefore, the decontaminating potential of

towelettes should be tested in the presence of a reasonable amount

of added soil load to better simulate the impact of the factors noted

above. The ingredients of any soil load selected should be available

readily and widely at a reasonable cost from reputable sources; they

also must be compatible with any organism used in the testing.29

Should test organisms be recovered from the towelette used for

decontamination? Recovering the test organism from the contaminated towelette is neither easy nor needed. Efficient elution of

microbes from towelettes is often difficult because of their porous

Relative humidity and air temperature

Ratio between disinfectant volume and surface area to be wiped

In addition to the volume of disinfectant soaked in a towelette,

the efficiency of surface decontamination is related to the total area

rubbed with a given towelette. As a towelette moves over the

surface there is depletion of the disinfectant in it and also simultaneous accumulation of microbial and other contamination from

the surface being wiped. In other words, a towelette could rapidly

lose its decontaminating potential if used beyond its “capacity.”

Therefore, label directions must provide the user with guidance

on the surface area to be decontaminated with a given towelette

for optimal effectiveness.

Potential for microbial transfer

Surface contamination is rarely uniform and is likely to be

concentrated in certain “spots.” Wiping a contaminated surface

for infection control inevitably dislodges wet or dried microbial

Table 2

Listing of available methods to test towelettes for decontamination of high-touch, hard, nonporous surfaces

Source

Standards-setting organizations

AOAC International’s Standard 961.0235

Comments

A bacterial inoculum, with or without an added soil load, is dried on several

microscope slides. Depending on the test, 10-60 slides are then sprayed

individually with a disinfectant. At the end of the contact time, each slide

is separately placed in a neutralizer-containing recovery medium. For a “pass,”

10/10 slides must show no growth, and no more than 1 “failure” allowed with 60

slides.

Can be used to generate data to register aerosol/trigger-sprayed disinfectants in the

United States. Requires additional details, eg, better standardization of the

starting bacterial inocula and conditions for drying them on the carriers, to

reduce variability in results. The volume of the liquid sprayed per unit surface

areas may be higher than that normally used in the field. The recommended

contact time of 10 minutes is also not in line with normal use. The large number

of carriers required in each test makes the procedure time-consuming and labor

intensive. The carrier surface is relatively smooth and thus easier to disinfect.

This method cannot differentiate between mechanical bacterial removal by wiping

and the killing action of the disinfectant in the towelette. It is also subject to

individual variations in the wiping procedure.

Designed for use with vegetative bacteria, mycobacteria, and filamentous fungi for

testing precleaned or soiled surfaces. Although the contact time is not specified,

wiping of 10 carriers with 1 towelette would extend it well beyond what is

relevant in the field. The carrier surface is relatively smooth.

ASTM International’s Work Item 3290836

This quantitative method, which uses Petri plates as carriers for dried inocula of

vegetative bacteria, is soon expected to become a standard of ASTM.

ASTM International’s standard E236237

To wipe carriers (glass slides) with towelettes impregnated or presaturated with

a disinfectant. After specified contact time, each carrier is placed in a neutralizercontaining recovery medium and incubated. As an option, the used towelette, or

a portion of the liquid expressed from it, is also cultured for surviving test

organisms.

This phase 2, step 2 test incorporates a back and forth wiping procedure across 4 test

areas, simulating in-use conditions. It also aims to evaluate the sustained activity

of various disinfectant ingredients on surfaces.

Four-field test: CEN test under

development38

Peer-reviewed publications

Three stage-test4-6,11

US Environmental Protection Agency

US EPA39

Draft Interim Guidance for Nonresidual

Sanitization of Hard Inanimate Food

Contact Surfaces Using Presaturated

Towelettes26

This test is currently being considered, and the final details are not available yet;

thus, comments cannot be made on how the wiping process and the transfer of

microbial contamination are strictly controlled.

This “three-step” method to test removal, killing, and transfer of bacteria was

designed after close observations of the use of commercial towelettes on hightouch surfaces in an intensive care unit of a hospital. Control or test towelettes are

mounted on the tip of a drill to wipe a metal disk; the drill rotation (set at 60

rpm), contact time (set at 10 seconds), and contact pressure (set from 100 g to

300 g) are controlled. The used towelette is brought into contact with an agar

medium containing a neutralizer to assess the extent of transfer of viable

organisms to a clean surface.

The method originally described by Williams et al4 was used to measure the

efficacy of a number of different towelettes against MRSA. This quantitative

method incorporates a reasonably short contact time of 10 seconds based on

field use of wiping. The starting inoculum on each disk usually >6-log10 of cfu

represented a high level of contamination. Also, contacting the used towelette

with an already moist surface of agar, potentially over-estimated the extent of

bacterial transfer.

Whereas Williams et al.4,5 compared the efficacy of different commercially

available towelettes against MRSA, Panousi et al11 compared the efficacy of

prewetted towelettes with that of disinfectant spray-on towelettes. Siani et al6

measured the sporicidal activity of a number of towelettes against C difficile

spores. In this study, towelettes varied widely in their ability to remove the

spores. None showed the required level of sporicidal action even after a 5minute contact. There was repeated transfer of the spores from all but 1 type of

towelette. In fact, the detergency in the towelettes released more cfu of the

spores.

This quantitative study with a relatively short contact time points to the

importance of proper testing of “sporicidal” claims of towelettes to avoid

enhancing the risk of spread of the spores over a wider area during wiping.

Overall, used towelettes with weak disinfection activity can transfer viable bacteria

upon as many as 8 consecutive adpressions.

Uses the feline calicivirus as a surrogate for human norovirus to assess virucidal

activity of presaturated or impregnated towelettes on hard, nonporous surface

disinfection. Virus suspension, with an added soil load, is spread on inside bottom

surface of glass Petri plates and dried. Ten carriers (Petri dishes) are wiped with 1

towelette. Product effectiveness criterion is a 4-log10 reduction in virus viability

as compared with the controls.

AOAC standard 961.0235 adapted to wiping glass, metallic, plastic, or ceramic

carriers contaminated with either Staphylococcus aureus or Escherichia coli, with

a soil load. Other organisms to be listed on label could also be tested. Product

performance criterion is 99.999% (5 log10) in viability of test organism.

Acceptable for data submission to EPA for registration of a product as a virucide.

Although the contact time is not specified, wiping of 10 carriers with 1 towelette

would extend it well beyond what is relevant in the field. The carrier surface is

relatively smooth and thus easier to disinfect.

S.A. Sattar, J.-Y. Maillard / American Journal of Infection Control 41 (2013) S97-S104

Summary of procedure

The method is quite flexible and based on a reasonably short contact time of 30

seconds. It is also quantitative because it clearly specifies the level of microbial

load on the carriers at the start and gives a clear product performance criterion.

Inclusion of E coli as a test organism may be inappropriate because it does not

withstand drying well.

S101

(Continued on next page)

CFU, Colony-forming units; MRSA, methicillin-resistant Staphylococcus aureus.

Can be used to generate data to register presaturated towelettes in the United

States. Requires additional details, eg, better standardization of the starting

bacterial inocula and conditions for drying them on the carriers, to reduce

variability in results. Individual variations in wiping procedure may also impact

the results.

Method for Disinfection Using

Presaturated Towelettes26

AOAC standard 961.02 method35 adapted for work with Mycobacterium bovis (BCG).

Glass slides inoculated with the test organism (with soil load) and dried. Ten

slides are then wiped with 1 towelette. The glass slides are then placed in

a neutralizer-containing recovery medium and incubated.

A bacterial inoculum, with or without an added soil load, is dried on several

microscope slides. Depending on the test, 10-60 slides are then wiped with

a disinfectant-soaked towelette. At the end of the contact time, each slide is

separately placed in a neutralizer-containing recovery medium. For a “pass,”

10/10 slides must show no growth, and no more than 1 “failure” is allowed with

60 slides.

Summary of procedure

Source

Table 2

Continued

Towelette test for mycobacteria15

Comments

S.A. Sattar, J.-Y. Maillard / American Journal of Infection Control 41 (2013) S97-S104

Suggested contact time is 10 minutes which is too long for the way towelettes are

used in the field. The test may take as long as 60 days to complete because of the

slow growth of M bovis. The carrier surface is relatively smooth.

S102

nature and the potential for irreversible microbial attachment to

individual fibers30; applying strong shearing forces may cause

microbial inactivation. Furthermore, relatively large volumes of an

eluent/neutralizer are required to properly immerse the entire

towelette for microbial recovery. Sufficiently large volumes of such

eluates are generally difficult to process when working with

viruses. Properly discarding used towelettes, even if they contain

residual levels of contamination, should pose virtually no threat to

patients and staff. The approach of squeezing out the disinfectant

from the test towelette before or/and after use and testing a portion

of the properly neutralized liquid for its microbicidal activity has

been used, but its relevance and practicability remain questionable.

Should product labels not specify the ratio between disinfectant

volume and the surface area to be decontaminated by wiping? The

volume of disinfectant in individual presoaked towelettes marketed commercially remains fairly constant. However, the end user

is hardly ever provided with guidance on how large a surface area

to be decontaminated with a given towelette. Such information is

crucial because the disinfecting power of a towelette is rapidly

depleted during its application with the accumulation of soil and

also because of the evaporation of any liquid disinfectant in it.

There are additional factors to consider when dealing with

towelettes to be used for decontaminating surfaces prewetted with

a disinfectant. Towelettes used in such situations may vary widely in

their nature, absorbency, degree of cleanliness, and potential to react

with and neutralize the disinfectant. These factors individually or in

combination could impact the outcome of decontamination. Here

also, an end user is not provided with clear guidance on the type of

towelette to be used and the unit surface area to be decontaminated

with it. The testing and label claims of presoaked towelettes as well

as those for decontaminating prewetted surfaces must take these

factors into consideration to better inform the end user and thus

ensure greater success in infection prevention and control.

What controls should be included in testing the decontaminating

activity of towelettes: Apart from the usual sterility checks on culture

media and reagents, a wipe test must include the following controls:

(1) the number of viable organisms placed on each carrier to be

wiped; (2) assessment of loss in viability of the test organism during

the initial drying of the carriers; (3) physical removal of the test

organism from the carrier by a control or blank towelette; this control

is needed to differentiate between the microbicidal action of the

disinfectant and the simple removal of the contamination by the

wiping action alone. However, obtaining towelettes without the

disinfectant already soaked in them may be difficult. In case such

“blanks” become available, the challenge will also be to soak them

in a control fluid because of the strong hydrophobicity of the fabric.

Addition of a mild detergent and overnight soaking may help

provided the control fluid is proven to be safe for the test organism(s).

Alternatively, the disinfectant-soaked test towelette can be brought

into contact with the contaminated carrier for 5 to 10 seconds

without any wiping action to assess the effect of exposure to the

disinfectant alone in the towelette.31 Although only relatively small

volumes of test disinfectant may be left on wiped carriers, it still

is necessary to confirm that its microbicidal activity has been effectively neutralized immediately at the end of the contact time.

DISCUSSION

Even though high-touch environmental surfaces may on occasion introduce pathogens directly into patients, more commonly

bare or gloved hands become the vehicles after contact with hightouch environmental surfaces.12 Towelettes used for the decontamination of high-touch surfaces have a role to play in decreasing

microbial bioburden from surfaces if they can demonstrate they can

remove and/or kill target microorganisms from surfaces and

S.A. Sattar, J.-Y. Maillard / American Journal of Infection Control 41 (2013) S97-S104

prevent the transfer of microbial contamination. The use of sporicidal towelettes combined with appropriate education of the end

users and proper auditing can substantially decrease the nosocomial spread of C difficile.32

However, the label claims of disinfectants for wiping of hightouch environmental surfaces are not tenable either on scientific

or practical grounds. Such claims are based on unrealistically long

contact times, absence of wiping action, and testing against a limited

number of relatively disinfectant-sensitive nosocomial pathogens.

This situation continues to generate a false sense of security and loads

the environment with potentially unsafe chemicals while exposing

patients and caregivers to undue health risks.9 In spite of the

mounting evidence for the spread of nosocomial pathogens through

high-touch environmental surfaces13 and the benefits of decontaminating such surfaces12,33 for infection prevention and control,

the frequency and quality of such decontamination remain woefully

inadequate.27 Indeed, cursory wiping of high-touch surfaces with

weak or slow-acting ESD may spread localized contamination over

a wider area, thus making routine housekeeping counterproductive.

Pathogens can be readily transferred between hands and hightouch environmental surfaces.12,34 Therefore, effective infection

control requires both regular hand hygiene as well as the decontamination of high-touch surfaces.3 Although towelettes are also

marketed for the decontamination of hands,9 they are excluded

from consideration here because of fundamental differences in test

protocols for their evaluation.

Some disinfectants in towelettes may damage hands on

repeated contact. Manufacturers provide instructions for suitable

gloves to be worn when wiping. Also, any sharps or pieces of broken

glass must first be safely removed from any surface to be wiped.

This critical review of the current situation is meant to focus on

the urgent need for better protocols to test towelettes to ensure the

development/marketing of more efficient products and thus aid in

improved infection prevention. Whereas the convenience of use is an

important factor in the increasing popularity of disinfectant-wetted

towelettes, they also contribute to workplace safety and reduce the

use of disinfectant chemicals. In certain applications, prewetted

towelettes offer better bioburden control compared with spray-on

towelettes.11 Vertical surfaces (eg, light switches) and round ones

(eg, bedrails) can be more readily and conveniently decontaminated

using towelettes than by spraying of disinfectants. On the other hand,

prespraying then wiping of surfaces has the advantage of being able

to extend the contact time and to provide a larger amount of ESD per

unit area. Proper testing protocols are required to back up claims of

either product type and to provide adequate instructions for use

in preventing the spread of pathogens.

Here, we reviewed the use of towelettes mainly against bacterial

pathogens, viruses, and endospores based on the available literature. There is no information on the efficacy of towelettes against

bacterial biofilms.

Acknowledgment

The authors thank Susan Springthorpe of CREM for her critical

review of the manuscript and Jason Tetro of CREM for providing

much assistance in the search for relevant literature.

References

1. Otter JA, Yezli S, French GL. The role played by contaminated surfaces in the

transmission of nosocomial pathogens. Infect Control Hosp Epidemiol 2011;32:

687-99.

2. Shaughnessy MK, Micielli RL, DePestel DD, Arndt J, Strachan CL, Welch KB, et al.

Evaluation of hospital room assignment and acquisition of Clostridium difficile

infection. Infect Control Hosp Epidemiol 2011;32:201-6.

3. Dancer SJ. The role of environmental cleaning in the control of hospitalacquired infection. J Hosp Infect 2009;73:378-85.

S103

4. Williams GJ, Denyer SP, Hosein IK, Hill DW, Maillard J-Y. The development of

a new three-step protocol to determine the efficacy of disinfectant wipes on

surfaces contaminated with Staphylococcus aureus. J Hosp Infect 2007;67:329-35.

5. Williams GJ, Denyer SP, Hosein IK, Hill DW, Maillard J-Y. Limitations of the

efficacy of surface disinfection in the healthcare setting. Infect Control Hosp

Epidemiol 2009;30:570-3.

6. Siani H, Cooper C, Maillard J-Y. Efficacy of “sporicidal” wipes against Clostridium

difficile. Am J Infect Control 2011;39:212-8.

7. Royal College of Nursing. The selection and use of disinfectant wipes. London, 2011. Available from: http://www.rcn.org.uk/__data/assets/pdf_file/0011/

382538/003873.pdf. Accessed September 24, 2012.

8. Huslage K, Rutala WA, Sickbert-Bennett E, Weber DJ. A quantitative approach

to defining “high-touch” surfaces in hospitals. Infect Control Hosp Epidemiol

2010;31:850-3.

9. Larson EL, Cohen B, Baxter KA. Analysis of alcohol-based hand sanitizer

delivery systems: efficacy of foam, gel, and wipes against influenza A (H1N1)

virus on hands. Am J Infect Control 2012;40:806-9.

10. Goldsmith MT, Latlief MA, Friedl JL, Stuart LS. Adsorption of available chlorine

and quaternary by cotton and wool Fabrics from disinfecting solutions. Appl

Microbiol 1954;2:360-4.

11. Panousi MN, Williams GJ, Girdlestone S, Maillard J-Y. Use of alcoholic wipes

during aseptic manufacturing. Lett Appl Microbiol 2009;48:648-51.

12. Kundrapu S, Sunkesula V, Jury LA, Sitzlar BM, Donskey CJ. Daily disinfection of

high-touch surfaces in isolation rooms to reduce contamination of healthcare

workers’ hands. Infect Control Hosp Epidemiol 2012;33:1039-42.

13. Weber DJ, Rutala WA, Miller MB, Huslage K, Sickbert-Bennett E. Role of hospital

surfaces in the transmission of emerging health care-associated pathogens:

norovirus, Clostridium difficile, and Acinetobacter species. Am J Infect Control

2010;38:S25-33.

14. Perez J, Springthorpe VS, Sattar SA. Activity of selected oxidizing microbicides

against the spores of Clostridium difficile: relevance to infection control. Am J

Infect Control 2005;33:320-5.

15. US Environmental Protection Agency. 2012 Antimicrobial testing methods &

procedures (ATMP). Available from: http://www.epa.gov/pesticides/methods/

atmpindex.htm. Accessed on February 08, 2013.

16. Health Canada Guidance Document. Disinfectant drugs. 2007. Public Works

and Government Services Canada. Available from: http://www.hc-sc.gc.ca/dhpmps/alt_formats/hpfb-dgpsa/pdf/prodpharma/disinf_desinf-eng.pdf. Accessed

September 22, 2012.

17. European Commission. Technical guidance document in support of the directive

98/8/EC concerning the placing of biocidal products on the market: guidance on

data requirements for active substances and biocidal products. European

Commission, Brussels, Belgium. Available from: http://ihcp.jrc.ec.europa.eu/our_

activities/public-health/risk_assessment_of_Biocides/doc/TNsG/TNsG_DATA_

REQUIREMENTS/TNsG-Data-Requirements.pdf. Accessed September 22, 2012.

18. Sattar SA. Hierarchy of susceptibility of viruses to environmental surface

disinfectants: a predictor of activity against new and emerging viral pathogens.

J AOAC Int 2007;90:1655-8.

19. Sattar SA. Promises and pitfalls of recent advances in chemical means of preventing the spread of nosocomial infections by environmental surfaces. Am J

Infect Control 2010;38:S34-40.

20. US Centers for Disease Control and Prevention. Biosafety in microbiological

and biomedical laboratories. 5th ed. CDC, Atlanta, GA. Available from: http://

www.cdc.gov/biosafety/publications/bmbl5/index.htm. Accessed September

22, 2012.

21. ASTM International. Standard quantitative disk carrier test method for determining the bactericidal, virucidal, fungicidal, mycobactericidal & sporicidal

activities of liquid chemicals. Document E-2197. West Conshohocken [PA]:

ASTM International; 2011.

22. Springthorpe VS, Sattar SA. Carrier tests to assess microbicidal activities of

chemical disinfectants for use on medical devices & environmental surfaces.

J AOAC International 2005;88:182-201.

23. Berendt AE, Turnbull L, Spady D, Rennie R, Forgie SE. Three swipes and you’re

out: how many swipes are needed to decontaminate plastic with disposable

wipes? Am J Infect Control 2011;39:442-3.

24. Sexton JD, Tanner BD, Maxwell SL, Gerba CP. Reduction in the microbial load on

high-touch surfaces in hospital rooms by treatment with a portable saturated

steam vapor disinfection system. Am J Infect Control 2011;39:655-62.

25. Page K, Wilson M, Parkin IP. Antimicrobial surfaces and their potential in

reducing the role of the inanimate environment in the incidence of hospitalacquired infections. J Mater Chem 2009;19:3819-31.

26. US Environmental Protection Agency 2001. Draft Interim guidance for nonresidual sanitization of hard inanimate food contact surfaces using pre-saturated

towelettes. Available from: http://www.epa.gov/oppad001/towelette.htm. Accessed September 25, 2012.

27. Carling PC, Bartley JM. Evaluating hygienic cleaning in health care settings: what

you do not know can harm your patients. Am J Infect Control 2010;38:S41-50.

28. Sabbah S, Springthorpe S, Sattar SA. Use of a mixture of surrogates for infectious bioagents in a standard approach to assessing disinfection of environmental surfaces. Appl Environ Microbiol 2010;76:6020-2.

29. Sattar SA, Springthorpe VS. Disinfection of environmental surfaces to interrupt

the spread of nosocomial pathogens: a critical look at use patterns & expectations. In: Rutala WA, editor. APIC preconference symposium on “Disinfection, Sterilization & Antisepsis: Principles, Practices, Current Issues & New

Research, ” Tampa, FL; 2007. p. 82e96.

S104

S.A. Sattar, J.-Y. Maillard / American Journal of Infection Control 41 (2013) S97-S104

30. Downey AS, Da Silva SM, Olson ND, Filliben JJ, Morrow JB. Impact of processing

method on recovery of bacteria from wipes used in biological surface sampling.

Appl Environ Microbiol 2012;78:5872-81.

31. Hernández A, Carrasco M, Ausina V. Mycobactericidal activity of chlorine

dioxide wipes in a modified prEN 14563 test. J Hosp Infect 2008;69:384-8.

32. Carter Y, Barry D. Tackling C difficile with environmental cleaning. Nursing

Time 2011;107:22-5.

33. Boyce JM, Havill NL, Lipka A, Havill H, Rizvani R. Practices. Infect Control Hosp

Epidemiol 2010;31:99-101.

34. Cheeseman KE, Denyer SP, Hosein IK, Williams GJ, Maillard J-Y. Evaluation of

the bactericidal efficacy of three different alcohol handrubs against 57 clinical

isolates of Staphylococcus aureus. J Hosp Infect 2009;72:319-25.

35. AOAC Official Method 961.02. Germicidal spray products as disinfectants.

Official method of analysis, 2009. Gaithersburg [MD]: AOAC International;

2009.

36. ASTM International. New test method for quantitative petri plate method

(QPM) for testing antimicrobial towelette products. Work item 32908. West

Conshohocken [PA]: ASTM International; 2012.

37. ASTM International. Standard practice for evaluation of pre-saturated or

impregnated towelettes for hard surface disinfection. Document E2362. West

Conshohocken [PA]: ASTM International; 2009.

38. CEN. Quantitative test method for the evaluation of bactericidal activity on

non-porous surfaces with mechanical action employing wipes or mops in the

medical area: test method and requirements (phase 2, step 2). CEN TC 216:

Draft 11e20118. Brussels [Belgium]: CEN; 2011.

39. US Environmental Protection Agency. Pre-saturated or impregnated towelettes confirmatory virucidal effectiveness; test using feline calicivirus as surrogate for norovirus. Available from: http://www.epa.gov/oppad001/pdf_files/

towelettes_confirmatory_virucidal.pdf. Accessed September 25, 2012.

40. US Environmental Protection Agency. 2012 Product performance test guidelines,

OCSPP 810.2200: Disinfectants for use on hard surfaces: efficacy data recommendations. Available from: http://www.regulations.gov/#!documentDetail;

D¼EPA-HQ-OPPT-2009-0150-0014. Accessed September 22, 2012.

41. Karageorgopoulos DE, Falagas ME. Current control and treatment of multidrugresistant Acinetobacter baumannii infections. Lancet Infect Dis 2008;8:7517-62.

42. Krishnan S, Manavathu EK, Chandrasekar PH. Aspergillus flavus: an emerging

non-fumigatus Aspergillus species of significance. Mycoses 2009;52:206-22.

43. Alexander S, John GT, Jesudason M, Jacob CK. Infections with atypical

mycobacteria in renal transplant recipients. Indian J Pathol Microbiol 2007;

50:482-4.

44. Sattar SA. Testing of chemicals as mycobactericidal agents. Chapter 6.3. In:

Fraise A, Maillard J-Y, Sattar SA, editors. Principles and practice of disinfection,

preservation and sterilization. 5th ed. Oxford [England]: Wiley-Blackwell; 2013.

45. US Environmental Protection Agency 2009. Guidance for the efficacy evaluation of products with sporicidal claims against Clostridium difficile. Available

from: http://www.epa.gov/oppad001/cdif-guidance.html. Accessed September

22, 2012.

46. Mattison K, Karthikeyan K, Abebe M, Malik N, Sattar SA, Farber JM, et al.

Survival of calicivirus in foods & on surfaces: experiments with feline calicivirus as a surrogate for norovirus. J Food Protect 2007;70:500-3.