(A) General Design Criteria for Limestone Contactors Installed in

advertisement

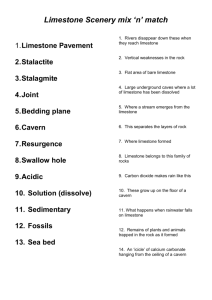

(A) General Design Criteria for Limestone Contactors Installed in Small Water Systems A designer of limestone contactor should be aware of the various factors affecting limestone dissolution before designing a contactor to ensure its optimal performance. In summary, the factors that can affect the dissolution of limestone include the quality of water to be stabilized and the physical and chemical characteristics of limestone to be used. Design Criteria Location in the Treatment Train U.S. Limestone contactors are typically placed after filtration, primary disinfection and chlorine contact. (Spencer, 2000). Germany South Africa Limestone contactors should be placed after disinfection (Stauder, 2002). Limestone contactors should be placed after clarification, filtration and chlorination (Mackintosh, De Souza and De Villiers, 2003a). In order to determine whether a limestone contactor is feasible to treat a water system, the following water quality parameters must be known (DVGW, 1998): The iron levels must be < 0.1 mg/L, aluminum levels < 0.15 mg/L and turbidity < 1 NTU (Mackintosh, De Souza and De Villiers, 2003a). There was also a pilot study conducted in British Columbia (Benjamin et al.,1992) that used a limestone contactor before flocculation to condition the water. Note: Besides the typical locations noted here, there have been suggestions that limestone contactors could also be used as a pretreatment unit to adjust pH for removal of iron, manganese and aluminum. Water Quality Characteristics The water to be treated with a limestone contactor must have low iron and turbidity content (Snoeyink et al., 1997). The USEPA (2003) prepared a flow diagram (Figure 1) to determine whether a limestone contactor would be a feasible option for a water system. The decision would be based on assessing the water quality parameters of the system. In summary, a water system should have a pH < 7.2, calcium < 60 mg/L and alkalinity < 100 mg/L. A special contactor design is required if the iron • Acid consumption, KS,4.3 The acid consumption, KS,4.3 is the acid consumption in meq/liter to achieve a pH of 4.3. This value multiplied by 61 approximately equals the concentration of hydrogen carbonate, HCO3- in ppm (Beforth, 2003). • Base consumption, KB,8.2 The base consumption, KB,8.2 is the amount of base consumed by water in meq/liter to content is more than 0.2 mg/L and manganese content is more than 0.05 mg/L. This is due to possibility of the iron and manganese coating the contactor, and slows the calcium carbonate dissolution (USEPA, 2003). The Spraystab I design has been used in South Africa for treatment of water that contains more than 0.2 mg/L of iron and 0.05 mg/L or manganese and treated with a limestone contactor. The water can first be aerated, then stabilized with limestone contactor and finally filtered through a sand filter. The values in Figure 1 are similar to those given by Spencer (2000) except that alkalinity was given as < 50 mg/L and hardness < 50 mg/L. In addition to the above, the designer must know the temperature range, total inorganic carbon levels (DIC) and total dissolved solids or conductivity. achieve a pH of 8.2 (Beforth, 2003). This value multiplied by 44 approximately equals the concentration of carbon dioxide, CO2 in ppm. • Calcium concentration • Saturation pH value, pHc after addition of calcite. According to Beforth (2003), since the reactivity of limestone is very low, one would find that KS,4.3 and KB,8.2 should be very low to achieve a pH in a range of 7.7 – 8.0. In addition, iron, manganese and aluminum levels must be less than the following concentrations to prevent formation of residue on the surface of the limestone media (DVGW, 1998): • Iron < 0.2 mg/L • Manganese < 0.05 mg/L • Aluminum < 0.05 mg/L If residues are formed, then iron, manganese, or aluminum removal may be required ahead of the limestone contactor (DVGW, 1998). Empty Bed Contact Time (EBCT) EBCT is in the range of 20 to 40 minutes if water is less than 5 oC, otherwise, EBCT in the range of 15 minutes to 1 hour have been used in successful contactor design. (Spencer, 2000). EBCT is the most important design criteria in Germany. EBCT usually varies between 20 and 45 minutes (0.33-0.75 h), depending on the CO2 and HCO3- contents in the raw water (Stauder, 2002). EBCT more than 20 minutes unless determined to be otherwise on-site. (Mackintosh, De Souza and De Villiers, 2003a). Loading Rate 2.4 m/hr or 1 gpm/ft2 (Spencer, 2000). The typical loading rates are in the range of 4 8 m/hr or 1.7 - 3.3 gpm/ft2 for common bed depth of 2 to 3 m. (Stauder, 2003). Less than 10 m/hr or 4.1 gpm/ft2 (Mackintosh, De Souza and De Villiers, 2003a). Ensure equal flow into all limestone contactors, and the flow should be less than the maximum design capacity. (Mackintosh, De Souza and De Villiers, 2003a). Flow Requirements Limestone contactors must be designed to The flow to the limestone contactor must not treat the maximum flow of the plant. exceed the maximum design capacity (Spencer, 2000). (DVGW, 1998). If dolomite is used as a media, the flow rate should not fall below the design flow rate by more than 30% (DVGW, 1998) to avoid the water from becoming oversaturated with respect to CaCO3 and precipitating in the contactor (Stauder, 2003). Limestone Bed Depth Limestone bed depth can be determined by calculation using computer programs such as DESCON and Limestone Bed Contactor: Corrosion Control and Treatment Analysis Program Version 1.02. (Please refer to the design aids). The limestone bed depth can be determined using the appropriate Figure 4 to 8 and the equations discussed in the design aids section. However, the typical limestone bed depth is in the range of 2 to 3 m (Stauder, 2003). If dolomite is used as a media, the total filter bed volume should be distributed across several filters to minimize pH fluctutations. Minimum limestone bed depth of 2 m is recommended (Mackintosh, De Souza and De Villiers, 2003a). Limestone Characteristics Limestone used should be that described in ASTM Standard C51-02 as “sedimentary rock consisting of mainly carbonate and containing no more than 0 to 5% magnesium carbonate” (Spencer, 2000). This standard is available from http://www.astm.org. There are several types of limestone media discussed by DVGW(1998) that can be used in a limestone contactor. These include dense calcium carbonate, porous calcium carbonate and dolomite. Dolomite is suitable to be used in a large contactor since it will provide a lower contact time (Stauder, 2002) although it also has some disadvantages (Please refer to the flow requirements section). The following shows the water quality characteristics that are applicable for each type of the limestone media (DVGW, 1998): Limestone used should consists of high calcium and low magnesium stone. Currently, limestone used to date in several installations in South Africa is the commercially available limestone pebbles from Bredasdorp, South Western Cape (De Souza et. al., 2000 and Mackintosh et. al., 2003a). It consists of 96% calcium, 1.7% silica, 1.3% magnesium and less than 0.1% iron and manganese by mass. The weighted sum of aluminum and iron in stone must not exceed 10 mg/g of stone (Letterman, 1995). Testing of constituents of stone must adhere to the ASTM Standard 25-99 (Chemical Analysis of Limestone, Quicklime and Hydrated Lime) (Spencer, 2000). The USEPA (2003) has expressed concern that the limestone should not contain significant amounts of materials such as heavy metals that would be a) Dense Calcium Carbonate i. Target pH=8 KS,4.3 + 2KB,8.2 < 1.5 mol/m3 [Ca] < 0.75 mol/m3 ii. Target pH=saturation pH KS,4.3 + 2KB,8.2 < 1.0 mol/m3 [Ca] < 0.75 mol/m3 b) Porous Calcium Carbonate KS,4.3 + 2KB,8.2 < 1.5 mol/m3 imparted to the water as the limestone dissolves. [Ca] < 0.75 mol/m3 c) Half-Burnt Dolomite KS,4.3 + 2KB,8.2 < 2.5 mol/m3 Depending on the type of limestone used (either calcium carbonate or half-burnt dolomite), it must comply with the requirements outlined in the following British Standards: • BS EN 1018:1998 (Chemicals used for treatment of water intended for human consumption – Calcium Carbonate). • BS EN 1017:1998 (Chemicals used for treatment of water intended for human consumption – Half Burnt Dolomite). These documents are available from http://www.techstreet.com/info/bsi.html Limestone Grain Sizes Repeated runs using DESCON revealed that 11 to 14 mm stone (0.4 to 0.55 inch) seems to be an optimal size. (Spencer, 2000). The following grain sizes are commercially available for calcium carbonate and half-burnt dolomite. • Dense Calcium Carbonate : 0.71-1.25 mm, 1.0-2.0 mm, 1.6-2.5 mm • Porous Calcium Carbonate : 1.0 – 3.0 mm • Half-Burnt Dolomite: 0.5-1.2 mm, 0.5-2.5 mm, 2.0-4.5 mm, 4.0-7.0mm ( Note: If undersized or oversize grains are present, they cannot be larger than 10% for the individual group.) However, size range of 1.0-2.0 mm is commonly used in Germany. Although, in some of the older large water treatment plants that are not able to properly backwash, larger media sizes are used. Based on experience, there is not a significant change in the Limestone used has a grading of +12mm – 15mm (De Souza et. al., 2000). The size of limestone that produced optimal results is 12 mm (Spencer, 2000). reactivity of the media for the size range between 0.7-3.0 mm (Stauder, 2003). Supporting Media Supporting media used is based on the AWWA Standards for Filtering and Support Media (Spencer, 2002). The size of the support media used should be larger than the limestone size (Spencer, 2002). Supporting media consists of 0.2 – 0.3 m in depth of inert materials (DVGW, 1998). Supporting media consists of 150 mm deep, 25 mm diameter granite aggregrate (Mackintosh, De Souza and De Villiers, 2003a). Design Aids DESCON model was developed by Letterman and Kothari (1995) to aid in the design of limestone contactors. This computer program has been used by Spencer (2002) to design the limestone contactor facility in Mars Hill, Maine. This program is also recommended for the design of a limestone contactor by USEPA (2003). A guideline for designing a limestone contactor is available (W 214/II: Entsaurung von Wasser Teil 2: Grundsatze fur Planung, Betrieb und Unterhaltung von Filteranlagen) from DVGW (1998). However, this guideline is based on empirical correlations. Therefore, Stauder (2003) suggests that for smaller plants, the limestone bed volume can be designed using the guideline and for larger plants, the limestone bed volume should be designed based on a pilot plant study. Stauder (2003) also suggests that it is very important (before designing) to obtain a reliable water analysis since any erroneous values can greatly affect the design. Computer software that can determine the calcium carbonate saturation of water is also very useful. CaCO3 saturation characteristics of water can be determined experimentally using the Marble Test. The Marble Test is an experiment based method to determine calcium carbonate saturation characteristics of water. DESCON calculates the depth of limestone required in a contactor based on the influent water chemistry, limestone particle size, superficial velocity and the desired effluent water chemistry (Letterman, 1995). Figure 2 shows an output from DESCON using USEPA (2003) data from a typical Western Water System as input to the program. In this system, surface water contributes 80% of the amount of water supplied. The limestone diameter was entered as 12 mm and limestone CaCO3 content as 98%. DESCON calculated the equilibrium pH to be 8.82 and it required user input for the target pH. Figure 4 to 8 are used to determine contact time using base and acid consumption of water at temperature of 10 oC for each of the following conditions. The contact time is then used to determine the minimum volume of media required in a contactor for several alternatives: (i) Dense calcium carbonate with grain size ranges between 1.0 – 2.0 mm and a target pH value of either 8 or pHc. Computer program such as STASOFT also used to determine the CaCO3 saturation and degree of stabilization of water using CaCO3. The target pH must be less than the equilibrium pH. Therefore, the target pH was set at 8.5. Based on the DESCON output, the depth of the limestone contactor to reach a target pH of 8.5 for this system was calculated as 3.1 ft. Another program used to design a limestone contactor was developed by Schott (2002) called Limestone Bed Contactor: Corrosion Control and Treatment Process Analysis Program Version 1.02. This program calculates the depth of the limestone bed, empty bed contact time and the limestone dissolved per volume of water treated from the initial to equilibrium condition. Other additional parameters that are calculated using this program include pH, total alkalinity, CO2 concentration, DIC, calcium content and copper content from the initial to equilibrium condition. Figure 3 shows example of the software output. (ii) Porous calcium carbonate with grain size ranges between 1.0 – 3.0 mm and a target pH value of either 8 or pHc. (iii)Half-burnt dolomite with grain size ranges between 0.5 – 2.5 mm and a target pH value of pHc. If the grain sizes used are not within the range specified in the figures, manufacturer’s recommendations should be used in designing a contactor. Figure 9 is used for temperature correction. Using Figure 4 to 8, the minimum volume of the limestone media required can be calculated as follows (DVGW, 1998): (i) Minimum volume of Limestone,VM: VM = Q x tf x f x 1/60 where: VM = minimum volume of media, m3 chosen using the appropriate Figure 4 to 8 (For dense CaCO3, VM may be lower than calculated if the target pH is less than 8.0 or pHc (Stauder, 2003). Currently in Germany, the enforceable pH for corrosion control is around 7.4 to 7.6. Therefore, the VM used can be about half of the calculated.) Q = flow rate, m3/hr tf = hypothetical contact time, min f = temperature correction factor (refer to Figure 9) Additional media, VB, is then added to the VM to account for media consumption during the period between two media fillings and backwashing (Stauder, 2003). Since VM is the minimum amount of media required in a contactor to achieve the desired pH, therefore VB must be added so that the volume of the media after consumption will never be less than VM. According to Stauder (2003), it requires experience to determine VB. It may depend on several factors besides media consumed due to the acidity of water or backwashing, such as the capacity of the truck used to transport the media, the size of the silo and the distance between the water treatment facility and the limestone supplier facility. However, VB can be estimated based on the following (Stauder, 2003): Estimation of VB: The amount of media consumed can be calculated based on the acidity of the water or the amount of CO2 present in the water (can be calculated from KB8.2). For example, for every mol of CO2 reacting with CaCO3 in water, 100 g of CaCO3 is consumed according to the following reaction: CO2 + CaCO3 + H2O = Ca2+ + 2HCO3If dolomite is used, for every mol of CO2 reacting with dolomite in water, 47 g of dolomite is consumed as determined empirically. Using the densities of CaCO3 and dolomite, the volume of media consumed can be calculated. In addition, 10% can be added to account for media losses during backwashing. The sum of VB and VM is the volume of the limestone bed, VF calculated as follows (DVGW, 1998): (ii) Filter Bed Volume, VF: VF = VM + VB where: VF = filter bed volume, m3 VB = consumption volume, m3 Click on this link to view an example on how to use Figure 4 to 10. Influent Distribution Systems Piping Requirements A bypass around the contactor and a drain within the contactor must be available to allow annual maintenance of a contactor (Spencer, 2000). Installation Requirements Contactor Configuration Both cylindrical and box-shaped contactors have been designed in the U.S. For small contactor facilities, there is no requirement on the influent distribution system as long as the contactors can be filled with water (Stauder, 2003). Special distribution system is only needed for large contactors. Use a false bottom feed systems instead of manifold/slotted pipe or other type systems (Mackintosh, De Souza and De Villiers, 2003a). Limestone contactors need to be equipped with devices for drainage of initial filtrate (DVGW, 1998). Piping to and from the units should be such that each individual contactor is able to operate independently, be filled independently, be flushed to waste in both upflow and downflow mode and handle excessive flow loading via an overflow pipe to waste (Mackintosh, De Souza and De Villiers, 2003a). The number of contactors that need to be installed depends on the site specification and plant throughput (Stauder, 2003). At least two contactors should be installed for each water system to allow uninterrupted operation while one of the contactors is under maintenance (Mackintosh, De Souza and De Villiers, 2003a). Most of the older water systems are rectangular open tanks and most of the newer water systems are cylindrical pressure tanks (Stauder, 2003). Cylindrical configuration, with ratio of height to diameter of at least 1:1. The structure should be completely enclosed, with access hatch on top for limestone addition. (Mackintosh, De Souza and De Villiers, 2003a). However, the configuration depends on the amount of water to treat and the benefit of keeping the pressure (Stauder, 2003). Rectangular configuration is also possible. However, the hydraulics of the system must be taken into consideration. The ratio of height to wall length must be at least 1:1 and the corners of the contactor must be benched/curved. The curved benching must be at least one quarter of the wall length. Construction Material Concrete is usually used for open contactors and stainless steel is typically used for closed contactors (Stauder, 2003). Cement-concrete or fiberglass (Mackintosh, De Souza and De Villiers, 2003a). Contactor Wall Protection For open contactors, the wall can be protected from corrosion using ceramic tiles while in the closed contactors, the wall can be protected with epoxy coating (Stauder, 2003). The internal contactor wall should be coated (for example with epoxy coating) to protect it from aggressive or abrasive reaction. (Mackintosh, De Souza and De Villiers, 2003a). Backwash Requirements Depending on the type of media, the limestone contactors should be backwashed at least once a week (DVGW, 1998). If the head loss increases above the allowed value, backwashing needs to be done more frequently. The limestone contactors must be able to down-flush fines to waste at least once a month until the site-specific frequency is determined (Mackintosh, De Souza and De Villers, 2003a). The following shows a successful backwash practice in Germany (DVGW, 1998): Backwash Duration Backwash Rate (m/hr) Step (minutes) Air Water 1 Air 3–5 60 None 10 – 12 2 Air/Water 5 – 10 60 3 Water None None 12 – 25 a Specified a The common duration is 10 – 15 minutes (Stauder, 2003). According to DVGW (1998), the dirty water from the backwash process contains solids (such as iron flocs, manganese flocs, aluminum flocs and undersized media) that may be basic. This is especially true for contactors using half-calcine dolomitic lime and if backwashing is carried out for the first time on a new media or after long idle periods. The backwash water does require proper disposal. Water Quality Monitoring Requirements Limestone contactors must be equipped with water quality monitoring taps before and after stabilization (DVGW, 1998). The most important parameter to measure is pH of the effluent from the contactor especially for a contactor using dolomitic limestone as a media. Limestone contactors should have visible indicator showing the level for media refilling Provide sample taps for water quality monitoring before and after stabilization. (Mackintosh, De Souza and De Villiers, 2003a). Provide two piezometers on each contactor to measure pressure loss across the limestone bed (Mackintosh, De (DVGW, 1998). The media refill level is determined from the filter bed volume and minimum volume. Media Refilling Facility Limestone contactors must be equipped with devices for measuring head loss (DVGW, 1998). The media can be refilled into the contactor either manually or hydraulically, but hydraulically is preferred (DVGW, 1998). Souza and De Villiers, 2003a). Pressure loss measurement is necessary to indicate that the limestone fines in the contactor need to be “down flushed”. The media can be refilled in a contactor manually or using a loading gantry facility (Mackintosh, De Souza and De Villiers, 2003). Usually, media refills are done manually if the limestone comes in lighter packages (i.e. 25 kg bags), but typically in the recent large units, a loading gantry facility is used since the limestone comes in heavier packages (1 ton bags). FIGURES Figure 1. Limestone Contactor Decision Tree (Spencer, 2003) Figure 2. DESCON Output Using the Typical Western Water System Data as Input Figure 3. Limestone Bed Contactor Corrosion Control and Treatment Analysis Program Version 1.02 (Schott, 2003) Figure 4. Contact Time as a function of Base Consumption (KB,8.2) and Acid Consumption (KS,4.3) for Dense Calcium Carbonate (Grain Size 1.02.0 mm). Temperature: 10oC, Processing Goal pH=8.0. (DVGW, 1998) Figure 5. Contact Time as a function of Base Consumption (KB,8.2) and Acid Consumption (KS,4.3) for Dense Calcium Carbonate (Grain Size 1.02.0 mm). Temperature: 10oC, Processing Goal pH=pHc. (DVGW, 1998) Figure 6. Contact Time as a function of Base Consumption (KB,8.2) and Acid Consumption (KS,4.3) for Porous Calcium Carbonate (Grain Size 1.03.0 mm). Temperature: 10oC, Processing Goal pH=8.0. (DVGW, 1998) Figure 7. Contact Time as a function of Base Consumption (KB,8.2) and Acid Consumption (KS,4.3) for Porous Calcium Carbonate (Grain Size 1.03.0 mm). Temperature: 10oC, Processing Goal pH=pHc. (DVGW, 1998) Figure 8. Contact Time as a function of Base Capacity (KB,8.2) and Acid Capacity (KS,4.3) for Half-Calcine Dolomitic Lime (Grain Size 0.5-2.5 mm). Temperature: 10oC, Processing Goal pH=pHc. (DVGW, 1998) Figure 9. Correction Factor as a Function of Water Temperature. (DVGW, 1998) SAMPLE PROBLEM Sample on how to use Figure 1 to 6 in W214/11 (DVGW, 1998): This example shows how to design a limestone contactor by using figure 1 to 6 in W214/11 (DVGW, 1998). Limestone contactor will be used to treat the following raw water: Raw Water* Treated by Mars Hill, Maine Water Treatment Plant (Spencer, 2000): Surface Water Source: Young’s Lake Lowest pH of influent to the limestone contactor = 7.18 Alkalinity in the raw water = 45 – 83 mg/L as CaCO3 Calcium in the raw water = 19 – 34 mg Ca/L *Note: These water quality parameters were obtained in 1996, before the limestone contactor was installed in the plant. Determination of KS,4.3 and KB,8.2: Use the worst case condition, pH = 7.18 and alkalinity of 45 mg/L as CaCO3 Most of the alkalinity source at pH = 7.18 is from HCO3-: KS,4.3 = [HCO3-] = 45 mg x 1 meq x 1 mmol HCO3- x 1 mol x 103 L = 0.9 mol 3 L 50mg 1 meq HCO3 10 mmol 1 m3 m3 Assume the lowest temperature, T = 5 oC, Therefore pKa1 = 6.52 at T = 5 oC (Snoeyink and Jenkins, 1980). Assume CO2 = H2CO3* and ignoring activity coefficients: KB,8.2 = [CO2] = [H2CO3*] [HCO3-][H+] = 10-pKa1 [H2CO3*] KB,8.2 = [CO2] = [H2CO3*] = (0.9 x 10-3)(10-7.18) mol x 103 L = 0.2 mol ( 10 -6.52 ) L m3 m3 Determination of Media Type: KS,4.3 + 2KB,8.2 = 0.9 + 2(0.2) = 1.3 mol/m3 [Ca] = 19 mg x mmol x mol x 103 L = 0.47 mol/m3 3 L 40.08 mg 10 mmol m3 Based on the total amount of KS,4.3 + 2KB,8.2, the calcium content and the requirement listed in Part 3.2 of W 214/11 (1998), the following media can be used: • Dense Calcium Carbonate, Target Goal pH=8. Figure 1 of W214/11 is applicable. • Porous Calcium Carbonate, Target Goal pH=8 or pH=pHc. Figure 3 of W214/11 is applicable. • Dolomite, Target Goal pH=pHc. Figure 5 of W214/11 is applicable. Applicability of Design Figures: Figure 1, 3 and 5 of W214/11 (or Figure 4,6 and 8 in this module) can be used to determine the contact time based on KS,4.3 and KB,8.2. Figure 6 of W214/11 (or Figure 9 in this module) is used for temperature correction. Design Method: Maximum flow rate, Q = 1600 m3/day (430,000 gallons/day) (Spencer, 2000) Loading Rate = 2.4 m/hr (1 gpm/ft2) (Spencer, 2000) Assume lowest temperature, T = 5 oC. (i) If using Dense Calcium Carbonate and the desired target pH=8: Assume size of media = 1.0 – 2.0 mm Target pH = 8 From Figure 1, tF = 25 min and from Figure 6, f = 1.5. Minimum bed volume, VM = tF x f x Q x 1/60 min = 25 min x 1.5 x 1600 m3/day x 1 day/24hr x 1 hr/60 min = 42 m3 Depth of limestone bed = tF x f x Loading Rate = 25 min x 1.5 x 2.4 m/hr x 1 hr/60 min = 1.5 m (5 ft) Surface area of the contactor = 1600 m3/day x 2.4 m/hr x 1 day/24 hr = 28 m2 Figure 1. Contact Time as a function of Base Consumption (KB,8.2) and Acid Consumption (KS,4.3) for Dense Calcium Carbonate (Grain Size 1.0-2.0 mm). Temperature: 10oC, Processing Goal pH=8.0. (DVGW, 1998) tF = 25 min Figure 6. Correction Factor as a Function of Water Temperature. (DVGW, 1998) f = 1.5 Determination Whether VB is Needed in the Design If the dissolution rate of the limestone is very slow, then a consumption volume, VB is not needed (Stauder, 2003). The need to include VB in the design of a limestone contactor is up to the designer. The choice depends much on the frequency of media refilling. Additional factors include the capacity of the limestone supplier truck and the capacity of the silo used to store the limestone (Stauder, 2003). If the capacity of the truck and the silo is small, it may limit the amount of limestone that can be refilled each time, therefore, the refill frequency must be chosen by taking these factors into account. The amount of CaCO3 dissolved for several options of media refills frequency is shown in this example. A run using MINTEQ reveals that at saturation, this water dissolves 0.008 g/L of Ca2+ (0.1988 mol/m3). The following calculations show the amount of CaCO3 dissolved daily, weekly, monthly and yearly based on the result obtained using MINTEQ. The daily consumption of CaCO3 = 1600 m3/day x 0.1988 mol/m3 x 100 g/mol x 10-3 kg/g = 32 kg/day Weekly consumption of CaCO3 = 31.8 kg/day x 7 days/week = 223 kg/week Monthly consumption of CaCO3 = 31.8 kg/day x 30 days/month = 954 kg/month Yearly consumption of CaCO3 = 31.8 kg/day x 365 days/yr = 11,607 kg/year Using the density of dense CaCO3 of 1500 kg/m³ (Table 1 in W214, DVGW 1998), the weight of CaCO3 can be calculated. Based on Figure 1 and 6, the minimum volume, VM of limestone needed to stabilize this water is 42 m³. This corresponds to 63,000 kg of CaCO3. The following table shows the percent of CaCO3 dissolved daily, weekly, monthly and yearly. No. 1 2 3 4 Frequency of Media Refilling Daily Weekly Monthly Yearly Amount of CaCO3 Dissolved 32 kg/day 223 kg/week 954 kg/month 11,607 kg/year Percent of CaCO3 Dissolved (%) 0.05 0.35 1.51 18.42 The above table shows that if the designer decides to refill the limestone either daily or weekly, the percent of CaCO3 dissolved between media refilling is very small (less than 1%). Since the amount dissolved is very small, the designer may exclude VB in the design if he/she decides to have the limestone refilled daily or weekly. Thus, the total contactor bed volume should only include the minimum volume of limestone required, VM. However, if a designer decides to have the limestone refilled monthly or yearly, then VB must be included in the design since a significant amount of limestone will be dissolved between media refilling. The amount of VB can be calculated based on the amount of CaCO3 dissolved as calculated above (954 kg for monthly refill and 11,607 kg for yearly refills) with the addition of 10% to account for losses of media due to backwashing. The following shows an example to calculate VB, the total contactor bed volume, VF and the total height of contactor for monthly media refills. VB = 954 kg / 1500 kg/m3 + 0.10 ( 42 m3 + 954 / 1500 kg/m3 ) = 5 m3 VF = 42 m3 + 5 m3 = 47 m3 Total Height of Contactor = 47 m3 / 28 m2 = 1.7 m (5.6 ft) (ii) If using Porous Calcium Carbonate and the desired target pH = 8: Assume size of media = 1.0 – 3.0 mm Target pH = 8 From Figure 3, tF = 11.5 min and from Figure 6, f = 1.5. Minimum bed volume, VM = tF x f x Q x 1/60 min = 11.5 min x 1.5 x 1600 m3/day x 1 day/24hr x 1 hr/60 min = 19.2 m3 Depth of limestone bed = tF x f x Loading Rate = 11.5 min x 1.5 x 2.4 m/hr x 1 hr/60 min = 0.7 m (2.2 ft) Surface area of the contactor = 1600 m3/day x 2.4 m/hr x 1 day/24 hr = 28 m2 Figure 3. Contact Time as a function of Base Consumption (KB,8.2) and Acid Consumption (KS,4.3) for Porous Calcium Carbonate (Grain Size 1.0-3.0 mm). Temperature: 10oC, Processing Goal pH=8.0. (DVGW, 1998) tF = 11.5 min (iii) If using Dolomite and the desired target pH = pHc Assume size of media = 0.5 – 2.5 mm Target pH = saturation pH = pHc From Figure 5, tF = 7.8 min and from Figure 6, f = 1.5. Minimum bed volume, VM = tF x f x Q x 1/60 min = 6.8 min x 1.5 x 1600 m3/day x 1 day/24hr x 1 hr/60 min = 11 m3 Depth of limestone bed = tF x f x Loading Rate = 6.8 min x 1.5 x 2.4 m/hr x 1 hr/60 min = 0.4 m (1.5 ft) Surface area of the contactor = 1600 m3/day x 2.4 m/hr x 1 day/24 hr = 28 m2 Figure 5. Contact Time as a function of Base Consumption (KB,8.2) and Acid Consumption (KS,4.3) for Porous Calcium Carbonate (Grain Size 1.0-3.0 mm). Temperature: 10oC, Processing Goal pH=pHc. (DVGW, 1998) tF = 6.8 min (B) Design Criteria Specifically for Small Groundwater Systems with Iron and Manganese Present Table 1 shows the treatment objectives and Table 2 shows the installation and operation requirements applicable for the Spraystab I unit used to stabilize water in small-scale groundwater systems containing iron and manganese in South Africa. Table 1. Treatment Objectives of Spraystab I Unit (Mackintosh, Engel and De Villiers 1997) No. Treatment Objectives 1. The unit should achieve an appreciable level of pH adjustment and stabilization. 2. The unit should be able to remove iron such that the iron level in the treated water is no more than 1 mg/L and preferably less than 0.3 mg/L. 3. The unit should be able to remove manganese such that the manganese level in the treated water is no more than 1 mg/L and preferably less than 0.1 mg/L. 4. The unit should be able to filter the water. 5. The unit should be able to treat between 25 and 50 m3/day. Table 2. Installation and Operation Requirements of Spraystab I Unit (Mackintosh, Engel and De Villiers, 1997) No. Installation and Operation Requirements 1. All components of the unit are easily handled by two people and easily transported. 2. The materials and equipment needed should result in a low cost and easy construction and repair. 3. The unit requires minimum operator attention and skills. 4. The unit utilizes minimum chemical dosing. If dosing is required, it should be selfregulating. 5. The unit should not require dosing pumps. 6. The unit should not require water pumps other than the well pump. 7. The unit must be robust and reliable. 8. The unit is independent of electrical control or operating systems. Table 3 shows the design criteria of the Spraystab I unit. Table 3. General Design Criteria of Spraystab I System (Mackintosh, De Souza and De Villiers, 2003b) No. 1. Components Access Lid 2. Spray Nozzles 3. Aeration Ducts 4. Vent Ducts 5. Limestone Media 6. Support Grid 7. Slotted Pipe Underdrain 8. Filtration Media Functions An access lid must be provided on a closed contactor to allow access for maintenance or cleaning work, prevent contamination from outside materials such as leaves and twigs, prevent the beds from algal/bacterial growth and minimize dissolution of carbon dioxide into the water. The 60o full cone spray nozzles are located at the center of the aeration ducts. The well pumps feeds directly to the spray nozzles. The nozzle height above the aeration duct is designed such that the air flowing into the aeration duct is at the maximum. The aeration ducts are located on the access lid and covered with coarse stainless steel wire mesh screens. The vent ducts are covered with coarse stainless steel wire mesh screens. The limestone contact unit consists of a bed of approximately 800 mm in depth of limestone with a grading of –15mm +12mm. The bed rests on top of the support grid. The support grid is located at the lower end of the limestone contactor unit of a Spraystab I unit. There is a 10 mm wire mesh screen placed on the support grid. Each compartment in the filtration unit of a Spraystab I unit is equipped with a slotted pipe underdrain. The slotted pipe feeds into a common manifold fitted with a raised outlet used to control the water level in the filtration unit. There are two media used in the filtration unit. The lower layer of the filtration unit consists of 0.3 to 0.5 mm graded filter sand to a depth of 300 mm above the underdrain. The upper layer of the filtration unit consists of 1.0 to 1.5 mm graded hydro-anthracite media. (C) General Design Criteria Specifically for Small Groundwater Systems without Iron and Manganese Present Table 4 shows the design criteria of the Spraystab II system used to stabilize water in small-scale groundwater systems without iron and manganese present. Table 4. General Design Criteria of Spraystab II System (Mackintosh, De Souza and De Villers, 2003b) No. Components 1. Access Lid 2. Spray Nozzles 3. Aeration Ducts 4. Vent Ducts 5. “Settling Tubes” 6. 7. Slotted Pipe Granite Layer 8. 9. Drain/Flush Valves Treated Water 10. Treated Water Outlet Pipe Loading Rate 11. Functions An access lid must be provided on a closed contactor to allow access for maintenance or cleaning work, prevent contamination from outside materials such as leaves and twigs, prevent the beds from algal/bacterial growth and minimize dissolution of carbon dioxide into the water. The type of material used for spray nozzles is important. The full cone HH stainless steel spray nozzles are more effective in aerating water and durable compared to PVC/plastic spray nozzles. In addition, PVC/plastic spray nozzles are also more prone to clogging resulting in poor performance in aeration. Each limestone contactor unit is required to have two aeration ducts (i.e. air inlets). Each duct have a diameter of 250 mm. The ducts must be covered with a stainless steel mesh to avoid leaves, twigs and other outside materials from building up on the surface of the limestone beds. Each limestone contactor unit is required to have two vent ducts, one on the access lid and the other on the roof of the tank. Each vent duct should have a diameter of 300 mm. Similar to the aeration ducts, the vent ducts mush also be covered with a stainless steel mesh. The “settling tubes” must be connected to the aeration ducts to allow the water from the aeration ducts to flow to the slotted pipe. The top of the “settling tubes” must be above the treated water level to vent the air between the aeration duct and the “setting tubes”. Slotted pipe manifold system results in uniform distribution of water in a small limestone contactor unit. A 150 mm deep later of 25 mm diameter granite aggregate is required between the limestone bed and the manifold system. The granite used must be appropriate for water treatment. At least two drain/flush valves are required for each limestone contactor unit, but four valves are preferred. The limestone contactor must be designed such that the treated water level is always less than the height of the “settling tubes” and is 200 mm above the limestone bed. A fully enclosed pipeline must be used to collect and transport the treated water to the storage tank to prevent contamination. The pipe must be positioned such that the treated water level is 200 mm above the limestone bed. Loading rate must be less than 10 m/hr. Higher loading rates will result in increased water turbidity.