Designs for High Current Applications

advertisement

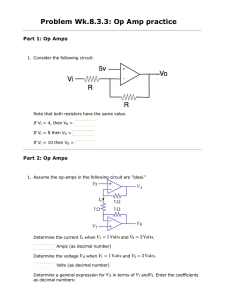

Designs for High Current Applications Donna Kepcia Technical Sales Manager Applications for High Current Inductors • • • • • • • Solar Power Conversion UPS systems Hybrid & Electric Vehicles Wind Power Conversion Transportation Three-phase chokes Large output chokes Products for High Current Applications POWDER CORES Kool Mµ® Toroids 62, 74, 102, 133 and 165 mm Kool Mµ® E and U cores 65 –160 mm Kool Mµ® and XFLUX ® Blocks – Create custom shapes XFLUX ® Toroids FERRITES New large geometries What is a “High Current” Inductor Application? 50 Amps 600 uH 150 Amps 84 uH 300 Amps 60 uH Design Goals: • • • • 35 kHz 400 Hz 6 kHz Target inductance achieved at maximum load Low temperature rise Lowest cost Smallest size Examine the constraints • • • • • • Frequency of operation Allowable Temperature Rise Cost Size and weight Geometry Conductor type Powder Core Material Comparison Table Material Characteristics High frequency Low Core cost Low Losses Readily available sizes Larger design Kool Mm XFlux Lower frequency Medium Core cost Higher Core Losses Lower Copper Losses Compact Design High Flux Smallest Design All frequencies Low Losses More variety of perms Higher cost Inductor design specifications Solar inverter DC current 50 Amps AC ripple 5 A p-p, RMS ripple 3.5 A Rated inductance 600 uH at 52.5 A Ambient temperature 25oC Acceptable operating temperature 110oC Temp rise 85oC allowed LI2= 1,500, Frequency 35 kHz Design Process High Flux Toroid • Calculate LI2 – Peak current (A) & inductance needed at that current (mH). • Use chart to select core with LI2 in range • Determine first cut turns • Determine mmf √ N= H= L * 106 AL NI le 50 A Design 0058337A2 Current Inductance 50 Amps 600 uH LI2 1,500 0058337A7 26 68 +/- 8% Al = 68 mH/1000 turns; +/- 8% 68 mH – 8% = 62.6 mH/1000 turns N= Ae = 0.678 cm2 le = 32.4 cm √ N = √(L in mH X 106 / Al) L * 106 AL N = √(0.6 mH X 106 / 62.6) = 96 turns H in Amp-Turns/cm = (N turns X I in Amps) / 9.84 cm H = ( 96 Turns X 50 A ) / 32.4 cm = 148 A-T/cm High Flux DC Bias Chart Determine inductance roll-off for High Flux using calculated mmf 148 Amp-Turns/cm About 79% Design Iterations – Recalculate roll off 96/ 0.79 = 122 H = (122 X 50A) / 32.4 cm = 188 A-T/cm Put the values back into the equation to make sure that the number of turns selected achieves target inductance under the peak DC bias condition. L in mH = (%H X N2 X AL ) / 106 0.670 mH = ( 0.72 X 1222 X 62.6 ) / 106 Meets requirements for Peak DC bias. Turns could be reduced. Software Kool Mu 0077165A7 300 Amps 60 uH 6 kHz UPS Output Inductor Block Inductor Design • Kool Mu • 150 Amps, 84 micro henries, 400 Hz – 3 Copper Air cores replaced with Kool Mu blocks – Total system losses were decreased by 900 watts from 3500 watts to 2600 watts for a 25% reduction in losses. – Cabinet size will be reduced saving material. Full load Inductance 80 uH Rated Current 150 Amps rms Inductance at low current 84 –0%/+5% uH Inductance (between 0 and 300 amps peak) Nominal 10%/+10% uH Inductance (between 300 and 450 amps peak) Nominal –25%/+10% uH Maximum 400 Hz current Rated rms +5% Amps rms Maximum 10 KHz current 18% of Rated rms Amps rms Maximum 20 KHz current 6.5% of Rated rms Amps rms Calculate the Number of Turns Required, N: N = (L*I pk*10)/(B max*Ac), N=26 N = (0.084*212A*10)/(0.375T*18), N=26 L = 84 uH , Target is 80 at peak I pk = 212 amps (nominal maximum peak current = 1.414 * 150 amps). B max = 0.375 Tesla (3750 Gauss). Chosen so that at absolute maximum peak current of 450 amps B max stays below 0.8 Tesla Inductance to drop no more than15% below initial at 300 A. Ac = 18 cm2 • Keep the windings away from the core by 0.125”; 3.175 mm to minimize losses. • Foil used to support 150 – 200 Amps was 0.019”; 0.482 mm. • Paper used was 0.003”; 0.076 mm thick. • A thickness of 0.007”; 0.178 mm was added to each wrap to compensate for inability to achieve 100% efficiency with the wraps. • Total area needed for winding: 26 X .029” + 0.125” = 0.754” = 19.1 mm. thick 3.75”; 95.25 mm wide Block Design for One Inductor Air gaps 16.0 cm 90 mm 30 mm 60 mm 105 mm 30 mm Air gaps 15 mm P core (mW/cm3) = F(KHz)1.60 * B(Kilogauss)2.0 Volume of core = 26 blocks * 27 cm3 /block = 702 cm3 This is the equation for the 26 permeability material. Assuming a flux density of 3.8 KG (0.38 Tesla) at 400 Hz 18% of this at 10 KHz, and 6.5% of this at 20 KHZ, we calculate: P core (mW/ cm3) = (0.4)1.6 * (3.8)2.0+ (10)1.6 * (3.8*0.18)2.0+ (20)1.6 * (3.8*0.065)2.0 = 3.33 + 18.63 + 7.36 = 29.3 P core loss = 29.3 mW/cm3 * 702 cm3 = 22 W Conclusions: ‣ Reduction in System Power Consumption by replacing 3 air cores by Kool Mu blocks—900 Watts. ‣ 700 was the combination of core losses and induction heating in the case from 1015 to 315 watts. ‣ Dimensions of the block inductors: 7.75”L x 4.6”W x 3.9”H ‣ Dimensions of the air core inductors: 6.75”L x 6.75”W x 9.5”H. ‣ Air core inductors require an additional 3” air perimeter away from metal ‣ Weight of block inductor is 15 lbs vs.16.5 lbs for air core. ‣ Cost of the new inductor is about 10% lower than the air core. ‣ Much higher cost savings are achieved because of lower power losses (easier to cool) and being able to make the overall unit smaller. Being smaller, lower cost, and 25% more energy efficient makes the unit more attractive to the end user. # Turns # Blocks of foil Block type Current Inductance 46 46 46 16 16 16 4741 26m 4741 26m 4741 26m 50 Amps 100 Amps 125 Amps 335 mh 250 mh 210 mh 46 46 46 46 30 30 30 30 4741 4741 4741 4741 26m 26m 26m 26m 50 Amps 75 Amps 100 Amps 150 Amps 550 mh 475 mh 413 mh 313 mh 100 50 25 12 12 12 8030 26m 8030 26m 8030 26m 50 Amps 100 Amps 200 Amps 800 mh 200 mh 49 mh AL Calculation adapted from MMPA geometrical guidelines 2 AL = 4πAeµ/ le Calculations Ae = C1/C2 cm2 Ie = C12/C2 cm AL Calculator for Block Structures A B C D E L A1 A2 A3 Millimeters 8 4741 backwall 150.0 one leg 47.5 thickness 41.0 D one core 20.0 Window width 95.0 Leg width 27.5 1127.50 1127.50 1127.50 2255.00 2255.00 2255.00 3382.50 1306.25 2612.50 3918.75 1050.00 3382.50 1127.50 2255.00 3382.50 1050.00 3382.50 1306.25 2612.50 3918.75 1050.00 A4 (C*L+C*(B-D))/2 1127.50 2255.00 3382.50 1216.88 2433.75 3650.63 1050.00 A5 (C*L+C*(B-D))/2 1127.50 2255.00 3382.50 1216.88 2433.75 3650.63 1050.00 40.00 190.00 40.00 43.20 43.20 40.00 190.00 40.00 43.20 43.20 40.00 190.00 40.00 43.20 43.20 41.0 190.0 41.0 69.51 69.51 41.0 190.0 41.0 69.51 69.51 41 100 190 160 41 100 69.5077 47.1239 69.5077 47.1239 0.3161 0.0003 0.1580 0.0001 0.1054 0.0000 0.3455 0.0003 0.1728 0.0001 0.1152 0.0000 l1 l2 l3 l4 l5 C*L C*(B-D) C*L 16 4741 24 4741 10 4741 20 4741 30 4741 6 8030 150.0 150.0 190.0 190.0 190.0 140.0 47.5 47.5 61.5 61.5 61.5 80 82.0 123.0 27.5 55.0 82.5 35.0 20.0 20.0 20.5 20.5 20.5 50 95.0 95.0 95.0 95.0 95.0 80.0 27.5 27.5 47.5 47.5 47.5 30 2*D 2*E 2*D p/4(L-(B-D)) p/4(L-(B-D)) C1 C2 # Blocks le Ae Ve Perm Al calc Al = 4pAeu/le 0.4326 0.0004 8 blocks 16 blocks 24 blocks 10 blocks 20 blocks 30 blocks 6 blocks 35.64 35.64 35.64 40.97 40.97 40.97 45.42 11.28 22.55 33.83 11.86 23.72 35.57 10.50 401.83 803.67 1205.50 485.83 971.67 1457.50 476.96 26 26 26 26 26 26 26 103.4 206.7 310.1 94.6 189.1 283.7 75.5 3800 3800 3800 3895 3895 3895 8000 mH/1000T Window area mm2 Block Series Sizes currently available: – 47 X 41 – 55 X 28 – 50 X 30 – 60 X 30 – 70 X 30 – 80 X 30 • New sizes can be tooled • Limits roughly 80 X 30 mm; 49 X 49 mm 20.0 mm 0.79” 50.5 mm 1.98” 30.3 mm 1.19” 15.0 mm 0.59” 00K5030B Recommended Adhesive and Dispensing system Bondmaster Elantas LOCTITE® ESP109 Air-powered Dispensers By using controlled air pressure and microprocessor-based timers – instead of operator guesswork – to regulate the amount of material applied to each part, Nordson EFD's air powered adhesive dispensing systems eliminate variability in benchtop dispensing processes. Kool Mu 100 AT/cm 200 AT/cm XFlux 100 AT/cm 200 AT/cm 40 mu 26 mu 55% 78% % initial 26% 50% perm 40 mu 26 mu 82% 92% % initial 47% 70% perm XFlux 00X4741B 00X5030B 00X6030B 00X8030B Kool Mm 26m, 40m 26m, 40m 26m, 40m 26m, 40m 00K4741B 26m & 60m 00K5030B 26m, 40m & 60m 00K5528B 26m, 40m & 60m 00K6030B 26m, 60m & 90m 00K8030B 14m, 26m, 8030BHT35 26m,40m, 60m Thank you for your time! Suggestions? Questions?