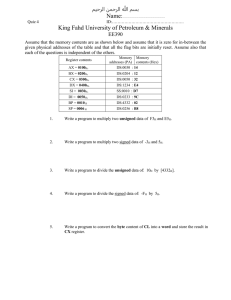

Wedge Bonding

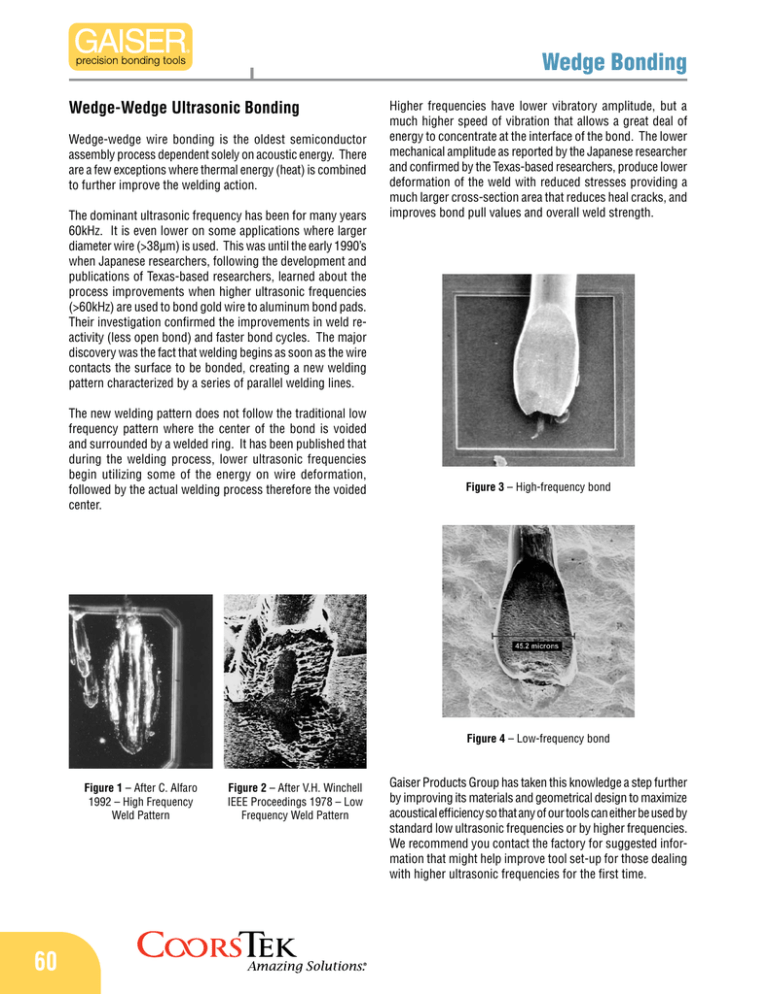

advertisement