Taber Rotary Abraser 5135

advertisement

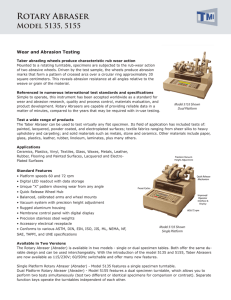

Taber®Rotary Abraser 5135/5155 Wear and Abrasion Testing Taber abrading wheels produce characteristic rub wear action. Mounted to a rotating turntable, specimens are subjected to the rub-wear action of two abrasive wheels. Driven by the test sample, the wheels produce abrasion marks that form a pattern of crossed arcs over a circular ring approximately 30 square centimeters. This reveals abrasion resistance at all angles relative to the weave or grain of the material. Referenced in numerous international test standards and specifications. Simple to operate, this instrument has been accepted worldwide as a standard for wear and abrasion research, quality and process control, materials evaluation, and product development. Taber Rotary Abrasers are capable of providing reliable data in a matter of minutes, compared to the years that may be required with in-use testing. Test a wide range of products. The Taber Abraser can be used to test virtually any flat specimen. Its field of application has included tests of: painted, lacquered, powder coated, and electroplated surfaces; textile fabrics ranging from sheer silks to heavy upholstery and carpeting; and solid materials such as metals, stone and ceramics. Other materials include paper, glass, plastics, leather, rubber, linoleum, laminates, plus many others. Model 5155 Shown Taber® Rotary Abraser 5135/5155 Wear and Abrasion Testing Available in Two Versions: Taber Rotary Abraser Includes: Model 5135 Single Platform Abraser Model 5155 Dual Platform Abraser 115/230V, 60/50Hz Auxiliary Weights 500g load & 1000g load Specimen Holder (E100-125) Hold Down Ring (E-100-101) Refacing Discs (S-11) Specimen Mounting Card Sample Package (S-36) Calibrade® Abrading Wheel Set (CS-10) Calibrade® Abrading Wheel Set (H-18) Vacuum Unit with Suction Hose & Round Brush Standard Features: Platform speeds 60 and 72 rpm Quick Release Wheel Hub Balanced, calibrated arms and wheel mounts Vacuum system with precision height adjustment Sealed aluminum housing Membrane control panel with digital display Precision stainless steel weights Accessory electrical receptacle Counter Weight Stud Abrading Wheel Precision Vacuum Pick-Up Height Adjustment Vacuum Pick-Up Nozzle Optional Accessories (sold separately): Calibration / Verification Kit Sample Cutter Wheel Refacer Quiet Cabinet Grit Feeder Scuffing Head Attachment Multi-Media Attachment Interchangeable Specimen Tables Arm Height Extension Kit Selection of Abrading Wheel Sets Test Accessories Auxiliary Weight Mount Precision Balanced Abrading Arm Quick Release Mechanism Specimen Holder Control Panel Send us your materials for a product demonstration LABOMAT ESSOR FRANCE 37 bd Anatole Francce 93287 SAINT DENIS Cedex FRANCE Model 5135 Shown LABOMAT ESSOR - FRANCE 37 boulevard Anatole France - F-93287 Saint-Denis Cedex Tél : +33 (0)1.48.09.66.11 Fax : +33 (0)1.48.09.98.65 Email : info@labomat.com Visit us at www.labomat.com LASS12/05 Are you getting the most out of your TABER® Abraser? Sample Cutter Quiet Cabinet Grit Feeder Prepare specimens for the Taber Rotary Abraser with the Model 5000 Sample Cutter. A heavy–duty blade cuts a 4.2-inch diameter specimen and the punch creates a precise ¼ inch center hole. Use for a variety of materials, including paper, cardboard, rubber, leather, vinyl, linoleum, carpet, textiles, thin metals, flexible plastics, plus many others. The Quiet Cabinet has been specially designed to reduce sound levels by approximately 20% and provide a convenient, dust-free workspace for your Taber Abraser. The upper cabinet features a hinged Plexiglas viewing window to monitor testing. The lower cabinet holds the abraser vacuum unit and includes a built-in exhaust system to provide the proper air circulation. The Grit Feeder is used to evaluate three body abrasion caused by the destructive action of fine hard particles. Originally designed to evaluate the resistance of floor surface coatings to abrasion, this instrument distributes a consistent flow of aluminum oxide grit onto a specimen surface before it passes under a pair of leather-clad wheels. The grit particles serve as the abradant and aids in the rolling action that contributes to the materials breakdown. Part No. Description Part No. Description 128372 Quiet Cabinet (115V/60Hz) 985000 Sample Cutter, Model 5000 129497 Quiet Cabinet (230V/50Hz) 128530 Replacement Blades Scuffing Head Wheel Refacer The Model 250 Diamond Wheel Refacer is a precision instrument that was specifically developed for dressing the contact surfaces ® of CALIBRADE wheels (H-10, H-18, H-22 and H-38). It is also suitable for ® CALIBRASE abrasive wheels that have become out-of-round (CS-10F, CS-10 and CS-17). Part No. Description 980250 Diamond Wheel Refacer, Model 250 128990 Single Point Diamond Tool 125608 Multiple Point Diamond Tool * Call for replacement tools for earlier models The Scuffing Head Attachment is used to evaluate the scuff-resistance of materials such as vinyl, painted surfaces, leather, car floor mats, etc. Mounted to the left hand abraser arm mount, a scuffing head and weight are used in place of the abrading wheels. As the table rotates, the scuffing head is dragged across the specimen surface. Three different profiles are offered. Part No. Description 980503-13 Scuffing Head Attachment Set (meets Ford FLTM BN 108-04) 98050313-1 Scuffing Head Attachment Set (meets General Motors GM9911P) 120918 Part No. Description 980503-1 Grit Feeder, Model 155 980503-2 Adjustable Grit Feeder, Model 255 121257 S-38 Standardization Plates 125529 S-39 Leather Wheel Set 121086 S-41 Aluminum Oxide Grit Multi-Media Attachment The Multi-Media Attachment can recreate contact surface wear caused by liquids, fluids and powders. Measure the abrasivity of materials including paints, pigments, adhesives, sealants, pastes, additives, etc. Part No. Description 985500 Multi-Media Abraser, Model 5500 Scuffing Head “A” 120920 Scuffing Head “B” 130352 Brass Pins 127524 Scuffing Head “C” 130353 Wear Discs For more informations on Taber® Industries products visit our web site www.labomat.com or call us +33 1 48 09 66 11 Test Accessories Specimen Holders Abrading Wheels Taber offers a selection of specimen plates to assist with the evaluation of coatings. Counterweights are available to expand the testing load. And, to test specimens that are greater than 12mm but less than 40mm, we offer the arm height extension kit. The Taber Abraser can be used for many different applications. Interchangeable specimen holders provide a suitable fixing device dependent on the material. Abrading Wheels are available in a range of ® abrasiveness. Calibrase wheels are a resilient composition, which are typically ® used to test rigid specimens. Calibrade wheels are a virtrified composition, often used to evaluate flexible specimens. Other wheels are available for specific applications and custom formulations can be developed upon request. Part No. Description 125563 S-16 Specimen Plates (steel) 132088-1 S-17 Specimen Placques (wood) 132086 S-18 Specimen Plates (aluminum) 125561 125562 121257 S-31 NEMA Standardization Plates (glass) S-34 NEMA Standardization Plates (zinc) S-38 Standardization Plates (Plexiglas) 126108 Counterweights, 125g 131376 Counterweights, 175g 132690 Arm Height Extension Kit (for Model 5130/5131) 132705 Arm Height Extension Kit (for Model 5150/5151) Specimen Mounting Mounting cards provide a unique way to mount flexible specimens, and include a test report to capture critical data. Mounting sheets allow you to affix specimens directly to a specimen table. E100-125 – Standard; provided with all instruments, used to test most rigid or flexible specimens (includes E100-101). E100-10 – Transparent; enables textile specimens to be viewed against a light. E140-14 – Ring Clamp; eight screws spaced evenly on a clamp plate to test slightly warped specimens. E140-15 – Textile, Tensioning; incorporates a raised wear track to provide extra tensioning to the material. E140-18 – Textile, Rimmed; provides an initial stretch to woven fabrics, minimizing the tendency to wrinkle if tested wet. E140-19 – Drive-Pin Type; used for rigid, square specimens without the need for a center hole. E140-21 – NEMA Threaded Ring; incorporates a clamp plate and flanged clamp ring to test slightly warped specimens, ring is threaded to the body of the holder. E140-75 – Rimmed; a raised rim retains liquids allowing you to determine the effect of absorbed or surface moisture on abrasion resistance. E-3945 – Multiple; holder permits simultaneous testing of lightweight, flexible specimens. S-21 – Extension Nut; use when sample thickness is ¼” to ½”. Part No. Part No. Description 125560 S-36 Specimen Mounting Cards (4 ¼” square) 129270 125558 129271 S-36-1 Specimen Mounting Cards (4 ¼” round) S-37 Specimen Mounting Sheets (4 ¼” square) S-37-1 Specimen Mounting Sheets (4 ¼” round) Description 120990 E100-125 Standard Holder 125795 E100-101 Hold-Down Ring (4-17/64” diameter) 125796 E100-102 Hold-Down Ring (4-21/64” diameter) 121205 E100-10 Transparent 121155 E140-14 Ring Clamp Part No. Description Call Taber Custom Wheel Formulations 125344 CS-0 or S-32 (rubber) 125319 CS-5 (felt) 125321 CS-10F (light abrasion) 125320 CS-10 (medium abrasion) 132684 CS-10P (engineered for paper) 130950 CS-10W (CS-10 with no color) 125322 CS-17 (coarse abrasion) 125323 H-10 (light abrasion) 125324 H-18 (medium abrasion) 125325 H-22 (medium abrasion) 125326 H-38 (light abrasion) 125345 S-35 (tungsten carbide) 125529 S-39 (leather-clad) 121124 S-33 Sandpaper Strips 125564 S-42 Sandpaper Strips 121102 S-11 Refacing Discs 125777 ST-11 Refacing Stone Calibration Verification Kit To generate useful data, it is critical that the Taber Abraser is within established calibration tolerances. The Calibration Verification Kit provides a fast, reliable system check to verify if a Taber Rotary Platform Abraser is within calibration. When properly used, this cost effective method enables users to determine if an instrument should be returned to the factory for recalibration or repair prior to it’s scheduled calibration. 121148 E140-15 Textile, Tensioning 121208 E140-18 Textile, Rimmed 121207 E140-19 Drive-Pin Type Part No. Description E140-21 NEMA Threaded Ring 132030 Rotary Abraser Calibration Verification Kit 132150-1 S-45 Wheel Tracking Cards 121206 125604 E140-75 Rimmed 121241 E-3945 Multiple 121224 S-21 Extension Nut For more informations on Taber® Industries products visit our web site www.labomat.com or call us +33 1 48 09 66 11