Lighting Handbook (DN81) - Digi-Key

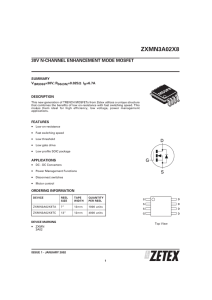

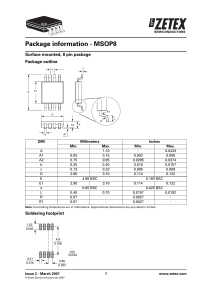

advertisement