xxxxx_Captive_2014_Text WORKING

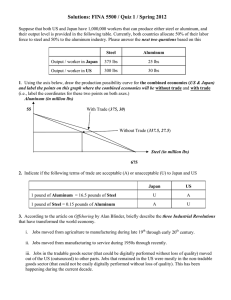

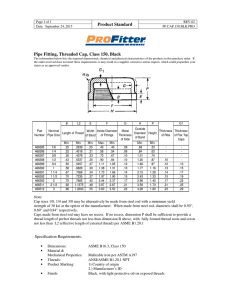

advertisement