BACK COVER

FRONT COVER

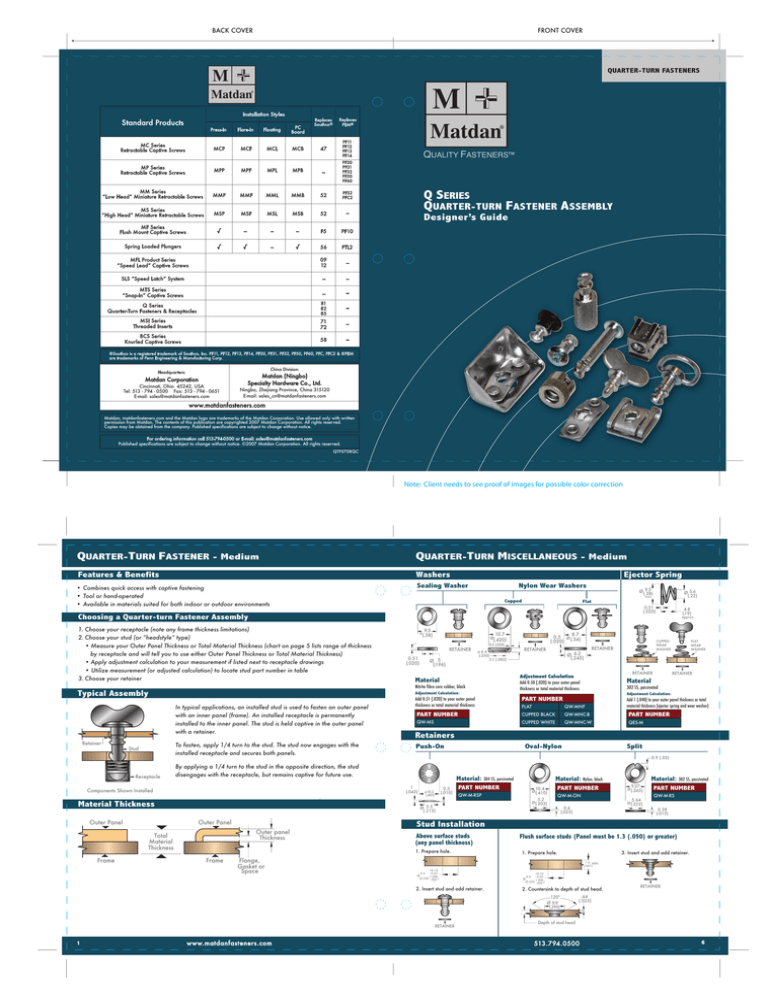

QUARTER-TURN FASTENERS

Installation Styles

Standard Products

MC Series

Retractable Captive Screws

Press-In

Flare-In

Floating

PC

Board

MCP

MCF

MCL

MCB

Replaces

Southco®

Replaces

PEM®

47

PF11

PF12

PF13

PF14

MP Series

Retractable Captive Screws

MPP

MPF

MPL

MPB

_

PF30

PF31

PF32

PF50

PF60

MM Series

“Low Head” Miniature Retractable Screws

MMP

MMF

MML

MMB

52

PFS2

PFC2

MS Series

“High Head” Miniature Retractable Screws

MSP

MSF

MSL

MSB

52

MF Series

Flush Mount Captive Screws

√

Spring Loaded Plungers

√

√

√

Q SERIES

QUARTER-TURN FASTENER ASSEMBLY

Designer’s Guide

F5

PF10

56

PTL2

09

12

MFL Product Series

“Speed Lead” Captive Screws

SLS “Speed Latch” System

MTS Series

“Snap-In” Captive Screws

Q Series

Quarter-Turn Fasteners & Receptacles

81

82

85

MSI Series

Threaded Inserts

71

72

BCS Series

Knurled Captive Screws

58

®Southco is a registered trademark of Southco, Inc. PF11, PF12, PF13, PF14, PF30, PF31, PF32, PF50, PF60, PFC, PFC2 & ®PEM

are trademarks of Penn Engineering & Manufacturing Corp.

China Division:

Headquarters:

Matdan Corporation

Cincinnati, Ohio 45242, USA

Tel: 513 - 794 - 0500 Fax: 513 - 794 - 0651

E-mail: sales@matdanfasteners.com

Matdan (Ningbo)

Specialty Hardware Co., Ltd.

Ningbo, Zhejiang Province, China 315120

E-mail: sales_cn@matdanfasteners.com

www.matdanfasteners.com

Matdan, matdanfasteners.com and the Matdan logo are trademarks of the Matdan Corporation. Use allowed only with written

permission from Matdan. The contents of this publication are copyrighted 2007 Matdan Corporation. All rights reserved.

Copies may be obtained from the company. Published specifications are subject to change without notice.

For ordering information call 513-794-0500 or E-mail: sales@matdanfasteners.com

Published specifications are subject to change without notice. ©2007 Matdan Corporation. All rights reserved.

QTF0708QC

Note: Client needs to see proof of images for possible color correction

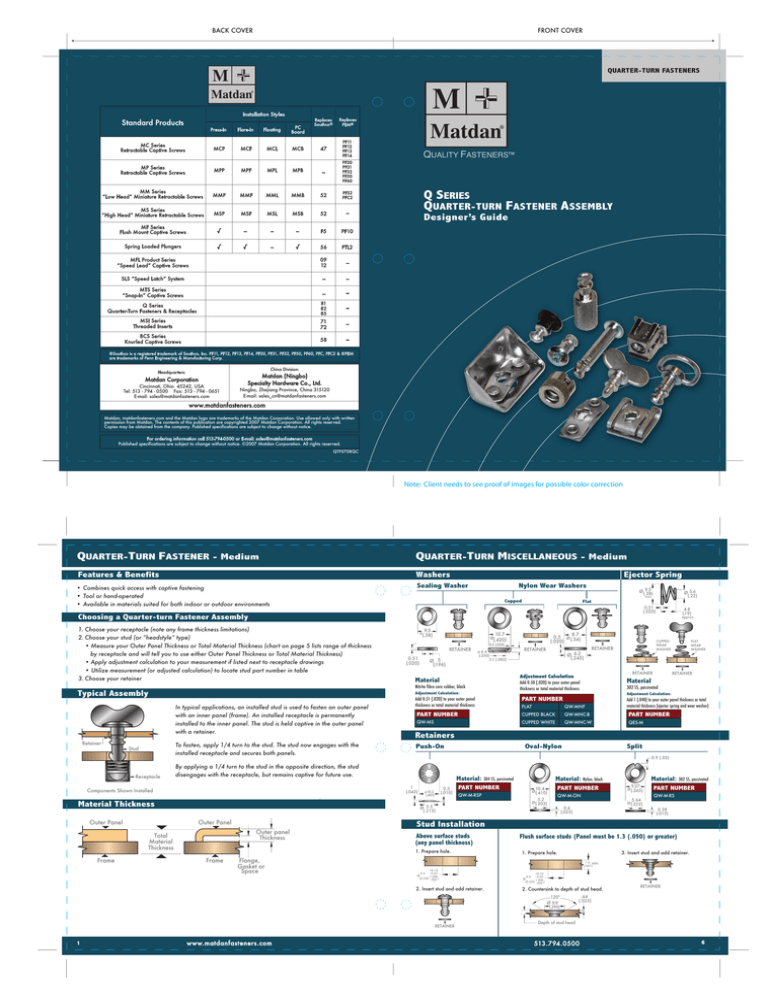

QUARTER-TURN FASTENER - Medium

QUARTER-TURN MISCELLANEOUS - Medium

Features & Benefits

Washers

• Combines quick access with captive fastening

• Tool or hand-operated

• Available in materials suited for both indoor or outdoor environments

Sealing Washer

Ejector Spring

Nylon Wear Washers

Ø 9.5

(.38)

Cupped

Flat

0.51

(.020)

Choosing a Quarter-turn Fastener Assembly

To fasten, apply 1/4 turn to the stud. The stud now engages with the

installed receptacle and secures both panels.

RETAINER

0.51

(.020)

0.5 (.020)

Ø 6.4

Ø 5

(.196)

Add 0.51 (.020) to your outer panel

thickness or total material thickness

Outer panel

Thickness

Total

Material

Thickness

Flange,

Gasket or

Space

Ø 6.2

(.245)

RETAINER

302 SS, passivated

Adjustment Calculation:

PART NUMBER

Add 1 (.040) to your outer panel thickness or total

material thickness (ejector spring and wear washer)

CUPPED BLACK

QW-MNC-B

PART NUMBER

QW-MS

CUPPED WHITE

QW-MNC-W

QES-M

Retainers

Push-On

Oval-Nylon

Split

0.9 (.03)

Material: 304 SS, passivated

0.3

(.010)

Ø 10.2

(.400)

PART NUMBER

QW-M-RSP

Material: 302 SS, passivated

Material: Nylon, black

10.4

Ø (.410)

5.2

Ø (.203)

PART NUMBER

QW-M-ON

9.27

Ø (.365)

5.64

Ø (.222)

0.6

(.025)

PART NUMBER

QW-M-RS

0.38

(.015)

Stud Installation

Above surface studs

(any panel thickness)

Flush surface studs (Panel must be 1.3 (.050) or greater)

3. Insert stud and add retainer.

1. Prepare hole.

1.3 MIN.

(.051)

+0.13

6.4

-.0.05

Ø

+.005

(0.250 -.002 )

+0.13

6.4

-.0.05

Ø

+.005

(0.250 -.002 )

2. Countersink to depth of stud head.

120°

Ø 9.9

(.390)

RETAINER

www.matdanfasteners.com

FLAT

WEAR

WASHER

Material

PART NUMBER

2. Insert stud and add retainer.

1

RETAINER

Adjustment Calculation

Add 0.50 (.020) to your outer panel

thickness or total material thickness

QW-MNF

1. Prepare hole.

Frame

RETAINER

CUPPED

WEAR

WASHER

RETAINER

FLAT

Ø 5.5

(.215)

Outer Panel

8.7

0.5 Ø

(.020) (.34)

(.250)

2.1 (.082)

Material

1

(.043)

Material Thickness

Frame

10.7

Ø(.420)

By applying a 1/4 turn to the stud in the opposite direction, the stud

disengages with the receptacle, but remains captive for future use.

Components Shown Installed

Outer Panel

9.5

(.38)

Adjustment Calculation:

In typical applications, an installed stud is used to fasten an outer panel

with an inner panel (frame). An installed receptacle is permanently

installed to the inner panel. The stud is held captive in the outer panel

with a retainer.

Receptacle

Ø

Nitrite fibre core rubber, black

Typical Assembly

Stud

4.8

(.19)

approx.

1. Choose your receptacle (note any frame thickness limitations)

2. Choose your stud (or ”headstyle” type)

• Measure your Outer Panel Thickness or Total Material Thickness (chart on page 5 lists range of thickness

by receptacle and will tell you to use either Outer Panel Thickness or Total Material Thickness)

• Apply adjustment calculation to your measurement if listed next to receptacle drawings

• Utilize measurement (or adjusted calculation) to locate stud part number in table

3. Choose your retainer

Retainer

Ø 5.6

(.22)

MAX.

RETAINER

.64

(.025)

Depth of stud head

513.794.0500

6

BACK COVER

FRONT COVER

QUARTER-TURN FASTENERS

Installation Styles

Standard Products

MC Series

Retractable Captive Screws

Press-In

Flare-In

Floating

PC

Board

MCP

MCF

MCL

MCB

Replaces

Southco®

Replaces

PEM®

47

PF11

PF12

PF13

PF14

MP Series

Retractable Captive Screws

MPP

MPF

MPL

MPB

_

PF30

PF31

PF32

PF50

PF60

MM Series

“Low Head” Miniature Retractable Screws

MMP

MMF

MML

MMB

52

PFS2

PFC2

MS Series

“High Head” Miniature Retractable Screws

MSP

MSF

MSL

MSB

52

MF Series

Flush Mount Captive Screws

√

Spring Loaded Plungers

√

√

√

Q SERIES

QUARTER-TURN FASTENER ASSEMBLY

Designer’s Guide

F5

PF10

56

PTL2

09

12

MFL Product Series

“Speed Lead” Captive Screws

SLS “Speed Latch” System

MTS Series

“Snap-In” Captive Screws

Q Series

Quarter-Turn Fasteners & Receptacles

81

82

85

MSI Series

Threaded Inserts

71

72

BCS Series

Knurled Captive Screws

58

®Southco is a registered trademark of Southco, Inc. PF11, PF12, PF13, PF14, PF30, PF31, PF32, PF50, PF60, PFC, PFC2 & ®PEM

are trademarks of Penn Engineering & Manufacturing Corp.

China Division:

Headquarters:

Matdan Corporation

Cincinnati, Ohio 45242, USA

Tel: 513 - 794 - 0500 Fax: 513 - 794 - 0651

E-mail: sales@matdanfasteners.com

Matdan (Ningbo)

Specialty Hardware Co., Ltd.

Ningbo, Zhejiang Province, China 315120

E-mail: sales_cn@matdanfasteners.com

www.matdanfasteners.com

Matdan, matdanfasteners.com and the Matdan logo are trademarks of the Matdan Corporation. Use allowed only with written

permission from Matdan. The contents of this publication are copyrighted 2007 Matdan Corporation. All rights reserved.

Copies may be obtained from the company. Published specifications are subject to change without notice.

For ordering information call 513-794-0500 or E-mail: sales@matdanfasteners.com

Published specifications are subject to change without notice. ©2007 Matdan Corporation. All rights reserved.

QTF0708QC

Note: Client needs to see proof of images for possible color correction

QUARTER-TURN FASTENER - Medium

QUARTER-TURN MISCELLANEOUS - Medium

Features & Benefits

Washers

• Combines quick access with captive fastening

• Tool or hand-operated

• Available in materials suited for both indoor or outdoor environments

Sealing Washer

Ejector Spring

Nylon Wear Washers

Ø 9.5

(.38)

Cupped

Flat

0.51

(.020)

Choosing a Quarter-turn Fastener Assembly

To fasten, apply 1/4 turn to the stud. The stud now engages with the

installed receptacle and secures both panels.

RETAINER

0.51

(.020)

0.5 (.020)

Ø 6.4

Ø 5

(.196)

Add 0.51 (.020) to your outer panel

thickness or total material thickness

Outer panel

Thickness

Total

Material

Thickness

Flange,

Gasket or

Space

Ø 6.2

(.245)

RETAINER

302 SS, passivated

Adjustment Calculation:

PART NUMBER

Add 1 (.040) to your outer panel thickness or total

material thickness (ejector spring and wear washer)

CUPPED BLACK

QW-MNC-B

PART NUMBER

QW-MS

CUPPED WHITE

QW-MNC-W

QES-M

Retainers

Push-On

Oval-Nylon

Split

0.9 (.03)

Material: 304 SS, passivated

0.3

(.010)

Ø 10.2

(.400)

PART NUMBER

QW-M-RSP

Material: 302 SS, passivated

Material: Nylon, black

10.4

Ø (.410)

5.2

Ø (.203)

PART NUMBER

QW-M-ON

9.27

Ø (.365)

5.64

Ø (.222)

0.6

(.025)

PART NUMBER

QW-M-RS

0.38

(.015)

Stud Installation

Above surface studs

(any panel thickness)

Flush surface studs (Panel must be 1.3 (.050) or greater)

3. Insert stud and add retainer.

1. Prepare hole.

1.3 MIN.

(.051)

+0.13

6.4

-.0.05

Ø

+.005

(0.250 -.002 )

+0.13

6.4

-.0.05

Ø

+.005

(0.250 -.002 )

2. Countersink to depth of stud head.

120°

Ø 9.9

(.390)

RETAINER

www.matdanfasteners.com

FLAT

WEAR

WASHER

Material

PART NUMBER

2. Insert stud and add retainer.

1

RETAINER

Adjustment Calculation

Add 0.50 (.020) to your outer panel

thickness or total material thickness

QW-MNF

1. Prepare hole.

Frame

RETAINER

CUPPED

WEAR

WASHER

RETAINER

FLAT

Ø 5.5

(.215)

Outer Panel

8.7

0.5 Ø

(.020) (.34)

(.250)

2.1 (.082)

Material

1

(.043)

Material Thickness

Frame

10.7

Ø(.420)

By applying a 1/4 turn to the stud in the opposite direction, the stud

disengages with the receptacle, but remains captive for future use.

Components Shown Installed

Outer Panel

9.5

(.38)

Adjustment Calculation:

In typical applications, an installed stud is used to fasten an outer panel

with an inner panel (frame). An installed receptacle is permanently

installed to the inner panel. The stud is held captive in the outer panel

with a retainer.

Receptacle

Ø

Nitrite fibre core rubber, black

Typical Assembly

Stud

4.8

(.19)

approx.

1. Choose your receptacle (note any frame thickness limitations)

2. Choose your stud (or ”headstyle” type)

• Measure your Outer Panel Thickness or Total Material Thickness (chart on page 5 lists range of thickness

by receptacle and will tell you to use either Outer Panel Thickness or Total Material Thickness)

• Apply adjustment calculation to your measurement if listed next to receptacle drawings

• Utilize measurement (or adjusted calculation) to locate stud part number in table

3. Choose your retainer

Retainer

Ø 5.6

(.22)

MAX.

RETAINER

.64

(.025)

Depth of stud head

513.794.0500

6

QUARTER-TURN STUDS - Medium

Oval Slotted

Hex

Combo

Slot

1.2 (.05) wide

1.2 (.05) deep

2.3

(.090)

QUARTER-TURN RECEPTACLES - Medium

L

Ø 9.53

(.375)

Ultrasonic (Installation into thermoplastics)

1. Prepare hole as shown

15.1

(.59)

No. 2 Phillips

Recess

11.2

(.44)

2.5 ± 0.1

Zinc Plate, Chromate plus sealer

Optional: 300 Stainless Steel, Passivated

OUTER PANEL THICKNESS*

TOTAL MATERIAL THICKNESS*

MAX.

------0.5 (.019)

1 (.039)

1.5 (.059)

2 (.079)

2.5 (.099)

3 (.119)

3.5 (.139)

4.1 (.159)

4.6 (.179)

5.1 (.199)

5.6 (.219)

6.1 (.239)

6.6 (.259)

7.1 (.279)

7.6 (.299)

8.1 (.319)

8.6 (.339)

9.1 (.359)

9.6 (.379)

10.1 (.399)

10.7 (.419)

11.2 (.439)

MIN.

------1.3 (.050)

1.8 (.070)

2.3 (.090)

2.8 (.110)

3.3 (.130)

3.8 (.150)

4.3 (.170)

4.8 (.190)

5.3 (.210)

5.8 (.230)

6.4 (.250)

6.9 (.270)

7.4 (.290)

7.9 (.310)

8.4 (.330)

8.9 (.350)

9.4 (.370)

9.9 (.390)

10.4 (.410)

10.9 (.430)

11.4 (.450)

11.9 (.470)

1.7

(.068)

No. 2 Phillips recess

1. For stainless steel studs,

replace last 2 digits of part

number with SS.

2. For black oxide finish –

change last digit to B

Standard: Carbon Steel, Case Hardened,

FOR ALL OTHER RECEPTACLES:

QR-MC-C / QR-MC-S

QR-MLO-C /QR-MLO-S

QR-MLW-C QR-MLB-C

QR-MN-C

QR-LS-C

TOTAL MATERIAL THICKNESS*

MAX.

------1.8 (.069)

2.3 (.089)

2.8 (.109)

3.3 (.129)

3.8 (.149)

4.3 (.169)

4.8 (.189)

5.3 (.209)

5.8 (.229)

6.3 (.249)

6.9 (.269)

7.4 (.289)

7.9 (.309)

8.4 (.329)

8.9 (.349)

9.4 (.369)

9.9 (.389)

10.4 (.409)

10.9 (.429)

11.4 (.449)

11.9 (.469)

12.4 (.489)

MIN.

2.3 (.090)

2.8 (.110)

3.3 (.130)

3.8 (.150)

4.3 (.170)

4.8 (.190)

5.3 (.210)

5.8 (.230)

6.4 (.250)

6.9 (.270)

7.4 (.290)

7.9 (.310)

8.4 (.330)

8.9 (.350)

9.4 (.370)

9.9 (.390)

10.4 (.410)

10.9 (.430)

11.4 (.450)

11.9 (.470)

12.5 (.490)

13 (.510)

13.5 (.530)

14 (.550)

14.5 (.570)

MAX.

2.8 (.109)

3.3 (.129)

3.8 (.149)

4.3 (.169)

4.8 (.189)

5.3 (.209)

5.8 (.229)

6.3 (.249)

6.9 (.269)

7.4 (.289)

7.9 (.309)

8.4 (.329)

8.9 (.349)

9.4 (.369)

9.9 (.389)

10.4 (.409)

10.9 (.429)

11.4 (.449)

11.9 (.469)

12.4 (.489)

12.9 (.509)

13.5 (.529)

14 (.549)

14.5 (.569)

15 (.589)

.51

(.020)

*Horn design may vary

with material and application.

Material and Finish

MATERIAL AND FINISH

FOR PRESS-IN

RECEPTACLE:

QR-MPS

HORN*

Ø 13.4

(.53)

over

knurl

°30

ORDERING NOTES:

FOR PRESS-IN

RECEPTACLES:

QR-MU-C

QR-MPB1-C

QR-MPB2-C

RETAINER

10.29

(.405)

Flush Phillips Recess

TO ORDER:

Change first 3 digits of part

number to: QSS

Outer panel thickness:

1.5 (.060) Min. 3.2 (.125) Max

Minimum stud grip range:

4.5 (.180)

(.14 ± .01)

Flush

For use when

receptacle is horizontal.

Receptacle: 1010 Steel, case

hardened, zinc plate, chromate

plus sealer

Shell: Low carbon steel, zinc

plate, chromate plus sealer

Spring: 302 SS, zinc immersion

coating

RETAINER

HORN*

PART NUMBER

QR-MU-C

*Horn design may vary

with material and application.

Clip-On

TO COMPLETE PART

NUMBER IN ( ) BELOW,

SELECT HEAD STYLE

U

L

F

QS-M (Drive) -395-CZ

QS-M (Drive) -415-CZ

QS-M (Drive) -435-CZ

QS-M (Drive) -455-CZ

QS-M (Drive) -475-CZ

QS-M (Drive) -495-CZ

QS-M (Drive) -515-CZ

QS-M (Drive) -535-CZ

QS-M (Drive) -555-CZ

QS-M (Drive) -575-CZ

QS-M (Drive) -595-CZ

QS-M (Drive) -615-CZ

QS-M (Drive) -635-CZ

QS-M (Drive) -655-CZ

QS-M (Drive) -675-CZ

QS-M (Drive) -695-CZ

QS-M (Drive) -715-CZ

QS-M (Drive) -735-CZ

QS-M (Drive) -755-CZ

QS-M (Drive) -775-CZ

QS-M (Drive) -795-CZ

QS-M (Drive) -815-CZ

QS-M (Drive) -835-CZ

QS-M (Drive) -855-CZ

QS-M (Drive) -875-CZ

3.2 (.127)

3.7 (.147)

4.2 (.167)

4.8 (.187)

5.3 (.207)

5.8 (.227)

6.3 (.247)

6.8 (.267)

7.3 (.287)

7.8 (.307)

8.3 (.327)

8.8 (.347)

9.3 (.367)

9.8 (.387)

10.3 (.407)

10.9 (.427)

11.4 (.447)

11.9 (.467)

12.4 (.487)

12.9 (.507)

13.4 (.527)

13.9 (.547)

14.4 (.567)

14.9 (.587)

15.4 (.607)

6.2 (.245)

6.7 (.265)

7.2 (.285)

7.8 (.305)

8.3 (.325)

8.8 (.345)

9.3 (.365)

9.8 (.385)

10.3 (.405)

10.8 (.425)

11.3 (.445)

11.8 (.465)

12.3 (.485)

12.8 (.505)

13.3 (.525)

13.8 (.545)

14.4 (.565)

14.9 (.585)

15.4 (.605)

15.9 (.625)

16.4 (.645)

16.9 (.665)

17.4 (.685)

17.9 (.705)

18.4 (.725)

10 (.395)

10.5 (.415)

11.1 (.435)

11.6 (.455)

12.1 (.475)

12.6 (.495)

13.1 (.515)

13.6 (.535)

14.1 (.555)

14.6 (.575)

15.1 (.595)

15.6 (.615)

16.1 (.635)

16.6 (.655)

17.2 (.675)

17.7 (.695)

18.2 (.715)

18.7 (.735)

19.2 (.755)

19.7 (.775)

20.2 (.795)

20.7 (.815)

21.2 (.835)

21.7 (.855)

22.2 (.875)

Adjustment Calculation:

To determine your total material thickness for stud selection use:

18

(.71)

Figure 1

Figure 2

7.1

(.28)

A

A

7.9

(.31)

15.9

(.63)

7.5 (.296) MIN.

C

0.64

(.025)

C

B

B

A + B + 1. 40 (.055) (constant)

when C is 0.64 (.025) .

7.5 (.296) MAX.

Frame thickness

.51 to 5

(.020) (.195)

A + B + C + 0.76 (.030) (constant)

when C is 0.65 (.026) or greater.

Material and Finish

1064 Steel, zinc immersion coating

or 17-7 SS, passivated

Ø 7.9 (.312) MIN.

PART NUMBER

STEEL

QR-MC-C

STAINLESS QR-MC-S

* Please see corresponding pages for potential adjustment calculation required on ejector spring, washers and on some receptacles and retainers. Additional sizes, and finishes available. Contact Matdan for assistance.

www.matdanfasteners.com

5

Outer panel will standoff

by the thickness of the retainer.

3. Method B - Flush with surface

DIMENSIONS

STUD PART NUMBERS

+0.09

11.9 -.0.00

Ø

+.003

(.469 -.000 )

3.6 ± 0.3

2. Choose one of the methods below:

Method A - Recessed to 0.5 (.020) depth

11.1

(.44)

OPTIONAL SNAP-IN ASSEMBLY

4.8

MIN.

(.19)

MIN.

(.100 ±.005)

Ø11.81

(.465)

Slot

1.2 (.05) wide

,

1.2 (.05) deep

22.2

(.88)

.30

(.012)

17.5

(.69)

Bail Horizontal

Wing

Six-lobe

+0.09

11.9 -.0.00

Ø

+.003

(.469 -.000 )

Optional alignment lug

For use when

receptacle is vertical.

Oval Phillips

MIN.

------0 (.000)

0.5 (.020)

1 (.040)

1.5 (.060)

2 (.080)

2.5 (.100)

3 (.120)

3.6 (.140)

4.1 (.160)

4.6 (.180)

5.1 (.200)

5.6 (.220)

6.1 (.240)

6.6 (.260)

7.1 (.280)

7.6 (.300)

8.1 (.320)

8.6 (.340)

9.1 (.360)

9.6 (.380)

10.2 (.400)

10.7 (.420)

Installation

LOCKING STOPS

4.5

(.175)

Ø 4

(.156)

Ø 6.1

(.240)

18.3

(.72)

Knurled Head

Ø 9.9

(.39)

2.8

(.110)

Ø 5

(.198)

F

Knurled

3 mm hex

socket

Ø 9.5

(.375)

U

Bail Vertical

513.794.0500

Job: Q Series Bro

Design3

Die: 8.5"x11" final

3039 Irvella Place

Cincinnati, Ohio 45238

513.662.0067

2

Date: 7/2008

Application: Illustrator CS2

cyan

magenta yellow

black

7477 CV

Process

4 Color Process

Client’s stamp of approval Design3 Inc. makes every effort to ensure artwork is 100% correct. Your review and signature of approval indicates

this art is correct as indicated here, and requires no further modifications from Design3. Thank you for your business.

QUARTER-TURN RECEPTACLES - Medium

QUARTER-TURN RECEPTACLES - Medium

Press-in (Shielded Type)

Leaf Spring

0.9±0.1

(.036±.005)

Receptacle: 1010 Steel, hardened, zinc plate,

chromate plus sealer

Shell: Low carbon steel, hardened, zinc

plate, chromate plus sealer

Spring: 302 SS, zinc immersion coating

Cap: Aluminum, natural

+0.0

11 -0.4

(.435

Riveting Type - with base

Material and Finish

13.7 ±0.3

(.540±.010)

12.7 ± 0.3

(.500 ±.010)

+.001

-.004 )

RETAINING CAP

RECEPTACLE PLATE

RECEPTACLE

HOUSING

PART NUMBER

Two orientation marks. Wing or

slot of stud will be 90° from these

marks when fastened.

NOTE: To be used in low carbon steels,

aluminum and stainless steels in an annealed

condition RB85 or softer.

Installation

NOTE: For inner panels less than 1.3 (.051) thick,

the retainer will create a small gap. To select the

proper stud, assume the inner panel thickness as

1.3 (.051).

2. Press receptacle into hole until shoulder

meets panel surface.

ADJUSTMENT CALCULATION

To determine your total material

thickness, substitute 1.3 (.051) for

frame thickness if frame thickness

is less than 1.3 (.051).

3. To select proper stud grip, determine

total panel thickness and select stud

from corresponding stud selection table.

Swell rivet shank to

Swell rivet shank to

Ø 2.7 -0.00 (.107 -.000)

+.010

Ø 2.7 -0.00 (.107 -.000)

+0.25

26.6 (1.05)

5.7

(.22)

REF.

+.010

26.2 (1.03)

RETAINER

9.5 (.38)

Ø 2.6

(.102)

Ø 2.6 (.102+.004

-.001)

Material and Finish

PART NUMBER

Spring: 1065 Steel, zinc immersion

coating

Base: 1010 Steel, zinc immersion

coating

Ø 5.2 (.205)

Ø 7.9 (.31)

QR-MLB-C

NOTE: Spring must float freely

before riveting.

Welding Type

This hole must stay

sharp. Do not

chamfer

+0.1

11.1 -0.0

Ø

+.003

(.437 -.000 )

11.2 (.44)

STUD

12

(.465)

0.9 MIN.*

(.035)

Material and Finish

PART NUMBER

Spring: 1065 Steel, zinc immersion

STEEL

coating or 17-7 SS, passivated

Eyelet: Steel, zinc immersion coating

or 300 SS, passivated

Total Panel

Thickness

32 (1.26)

16

(.63)

3.2

(.125)

NOTE: Spring must float freely

before riveting.

D

19 (.750)

26.6 (1.05)

9.5

(.375)

FRAME

9.5 (.38)

Receptacle: 1010 Steel,

LOCKING

STOPS

11.8

(.465)

hardened, zinc plate, chromate plus sealer

Shell: Low carbon Steel,

hardened, zinc plate, chromate plus sealer

Retainer & Spring: 302 SS, zinc immersion

10.3

(.405)

Installation

OUTER PANEL

OUTER PANEL

Material and Finish

WITH 90° LOCKING STOPS

QR-MPBI-C

W/O 90° LOCKING STOPS

QR-MPB2-C

PART NUMBER

Spring: 1065 Steel, zinc immersion coating

QR-MLW-C

Base: 1010 Steel, zinc immersion

coating

PART NUMBER

DOOR OR

PANEL

Welding studs: Steel, copper plate

NOTE: Spring must float freely

before riveting.

19(.750)

Ø

(.469 +.003 )

-.000

Material and Finish

Housing: 301 SS, natural

Receptacle: 1010 Steel, case hardened

11.1

MIN.

(.44)

zinc plate, chromate plus sealer

Spring: 302 SS, passivated

Retainer: 301 SS, natural

+0.09

0.5 (.020)

0.5 (.020)

14.3

(.56)

PART NUMBER

2

MIN.

(.080)

11.9 ± 0.1

(.469 ± .005)

14.3

(.56)

3

1.6

(.06)

Snap-in

RETAINER

11.9 -0.00

Ø

)

(.469 +.003

-.000

17

(.67)

Adjustment Calculation

To determine your total material

thickness calculate: D + 1.5 (.060).

Please use total material

Material and Finish

Spring: 1065 Steel, zinc immersion coating thickness column.

Angle Bracket: 1010 Steel, zinc plate,

PART NUMBER

Chromate plus sealer

QR-LS-C

Eyelet: Steel, zinc immersion coating

RETAINER

+0.09

0.4(.015)MIN.

for RETAINER

2 mounting holes,

Ø 3.3 (.130)

11.9 ± 0.1

(.469 ± .005)

11.9 -0.00

8.3

(.33)

6.4

Ø

(.250)

8.3

(.33) 17.1

(.67)

Press-in (Blind Applications & Solid Materials)

Ø

QR-MLO-C

STAINLESS QR-MLO-S

Side Mount Type

5.4

(.21)

Material and Finish

5.7

(.22)

REF.

9.5 (.38)

OUTER PANEL

Inner Panel

3.2

(.125)

11.9 (.47)

Hole size, Ø .098 in. for

3⁄32 rivet Ø 2.6 mm for

2.5 mm rivet

Hole size, Ø .098 in. for

3⁄32 rivet Ø 2.6 mm for

2.5 mm rivet

+0.25

19 (.750)

Countersink

or dimple

3.2

(.125)

11.2 (.44)

QR-MPS

SPRING

1. Drill or punch hole in panel as shown.

19 (.750)

Countersink

or dimple

Riveting Type - without base

www.matdanfasteners.com

11.4

(.45)

2.5 (.100) MAX.

frame thickness

513.794.0500

QR-MN-C

ADJUSTMENT CALCULATION

To determine your total material

thickness calculate: outer panel

thickness + 5.08 (.200) - please

use total material thickness column.

4

QUARTER-TURN STUDS - Medium

Oval Slotted

Hex

Combo

Slot

1.2 (.05) wide

1.2 (.05) deep

2.3

(.090)

QUARTER-TURN RECEPTACLES - Medium

L

Ø 9.53

(.375)

Ultrasonic (Installation into thermoplastics)

1. Prepare hole as shown

15.1

(.59)

No. 2 Phillips

Recess

11.2

(.44)

2.5 ± 0.1

Zinc Plate, Chromate plus sealer

Optional: 300 Stainless Steel, Passivated

OUTER PANEL THICKNESS*

TOTAL MATERIAL THICKNESS*

MAX.

------0.5 (.019)

1 (.039)

1.5 (.059)

2 (.079)

2.5 (.099)

3 (.119)

3.5 (.139)

4.1 (.159)

4.6 (.179)

5.1 (.199)

5.6 (.219)

6.1 (.239)

6.6 (.259)

7.1 (.279)

7.6 (.299)

8.1 (.319)

8.6 (.339)

9.1 (.359)

9.6 (.379)

10.1 (.399)

10.7 (.419)

11.2 (.439)

MIN.

------1.3 (.050)

1.8 (.070)

2.3 (.090)

2.8 (.110)

3.3 (.130)

3.8 (.150)

4.3 (.170)

4.8 (.190)

5.3 (.210)

5.8 (.230)

6.4 (.250)

6.9 (.270)

7.4 (.290)

7.9 (.310)

8.4 (.330)

8.9 (.350)

9.4 (.370)

9.9 (.390)

10.4 (.410)

10.9 (.430)

11.4 (.450)

11.9 (.470)

1.7

(.068)

No. 2 Phillips recess

1. For stainless steel studs,

replace last 2 digits of part

number with SS.

2. For black oxide finish –

change last digit to B

Standard: Carbon Steel, Case Hardened,

FOR ALL OTHER RECEPTACLES:

QR-MC-C / QR-MC-S

QR-MLO-C /QR-MLO-S

QR-MLW-C QR-MLB-C

QR-MN-C

QR-LS-C

TOTAL MATERIAL THICKNESS*

MAX.

------1.8 (.069)

2.3 (.089)

2.8 (.109)

3.3 (.129)

3.8 (.149)

4.3 (.169)

4.8 (.189)

5.3 (.209)

5.8 (.229)

6.3 (.249)

6.9 (.269)

7.4 (.289)

7.9 (.309)

8.4 (.329)

8.9 (.349)

9.4 (.369)

9.9 (.389)

10.4 (.409)

10.9 (.429)

11.4 (.449)

11.9 (.469)

12.4 (.489)

MIN.

2.3 (.090)

2.8 (.110)

3.3 (.130)

3.8 (.150)

4.3 (.170)

4.8 (.190)

5.3 (.210)

5.8 (.230)

6.4 (.250)

6.9 (.270)

7.4 (.290)

7.9 (.310)

8.4 (.330)

8.9 (.350)

9.4 (.370)

9.9 (.390)

10.4 (.410)

10.9 (.430)

11.4 (.450)

11.9 (.470)

12.5 (.490)

13 (.510)

13.5 (.530)

14 (.550)

14.5 (.570)

MAX.

2.8 (.109)

3.3 (.129)

3.8 (.149)

4.3 (.169)

4.8 (.189)

5.3 (.209)

5.8 (.229)

6.3 (.249)

6.9 (.269)

7.4 (.289)

7.9 (.309)

8.4 (.329)

8.9 (.349)

9.4 (.369)

9.9 (.389)

10.4 (.409)

10.9 (.429)

11.4 (.449)

11.9 (.469)

12.4 (.489)

12.9 (.509)

13.5 (.529)

14 (.549)

14.5 (.569)

15 (.589)

.51

(.020)

*Horn design may vary

with material and application.

Material and Finish

MATERIAL AND FINISH

FOR PRESS-IN

RECEPTACLE:

QR-MPS

HORN*

Ø 13.4

(.53)

over

knurl

°30

ORDERING NOTES:

FOR PRESS-IN

RECEPTACLES:

QR-MU-C

QR-MPB1-C

QR-MPB2-C

RETAINER

10.29

(.405)

Flush Phillips Recess

TO ORDER:

Change first 3 digits of part

number to: QSS

Outer panel thickness:

1.5 (.060) Min. 3.2 (.125) Max

Minimum stud grip range:

4.5 (.180)

(.14 ± .01)

Flush

For use when

receptacle is horizontal.

Receptacle: 1010 Steel, case

hardened, zinc plate, chromate

plus sealer

Shell: Low carbon steel, zinc

plate, chromate plus sealer

Spring: 302 SS, zinc immersion

coating

RETAINER

HORN*

PART NUMBER

QR-MU-C

*Horn design may vary

with material and application.

Clip-On

TO COMPLETE PART

NUMBER IN ( ) BELOW,

SELECT HEAD STYLE

U

L

F

QS-M (Drive) -395-CZ

QS-M (Drive) -415-CZ

QS-M (Drive) -435-CZ

QS-M (Drive) -455-CZ

QS-M (Drive) -475-CZ

QS-M (Drive) -495-CZ

QS-M (Drive) -515-CZ

QS-M (Drive) -535-CZ

QS-M (Drive) -555-CZ

QS-M (Drive) -575-CZ

QS-M (Drive) -595-CZ

QS-M (Drive) -615-CZ

QS-M (Drive) -635-CZ

QS-M (Drive) -655-CZ

QS-M (Drive) -675-CZ

QS-M (Drive) -695-CZ

QS-M (Drive) -715-CZ

QS-M (Drive) -735-CZ

QS-M (Drive) -755-CZ

QS-M (Drive) -775-CZ

QS-M (Drive) -795-CZ

QS-M (Drive) -815-CZ

QS-M (Drive) -835-CZ

QS-M (Drive) -855-CZ

QS-M (Drive) -875-CZ

3.2 (.127)

3.7 (.147)

4.2 (.167)

4.8 (.187)

5.3 (.207)

5.8 (.227)

6.3 (.247)

6.8 (.267)

7.3 (.287)

7.8 (.307)

8.3 (.327)

8.8 (.347)

9.3 (.367)

9.8 (.387)

10.3 (.407)

10.9 (.427)

11.4 (.447)

11.9 (.467)

12.4 (.487)

12.9 (.507)

13.4 (.527)

13.9 (.547)

14.4 (.567)

14.9 (.587)

15.4 (.607)

6.2 (.245)

6.7 (.265)

7.2 (.285)

7.8 (.305)

8.3 (.325)

8.8 (.345)

9.3 (.365)

9.8 (.385)

10.3 (.405)

10.8 (.425)

11.3 (.445)

11.8 (.465)

12.3 (.485)

12.8 (.505)

13.3 (.525)

13.8 (.545)

14.4 (.565)

14.9 (.585)

15.4 (.605)

15.9 (.625)

16.4 (.645)

16.9 (.665)

17.4 (.685)

17.9 (.705)

18.4 (.725)

10 (.395)

10.5 (.415)

11.1 (.435)

11.6 (.455)

12.1 (.475)

12.6 (.495)

13.1 (.515)

13.6 (.535)

14.1 (.555)

14.6 (.575)

15.1 (.595)

15.6 (.615)

16.1 (.635)

16.6 (.655)

17.2 (.675)

17.7 (.695)

18.2 (.715)

18.7 (.735)

19.2 (.755)

19.7 (.775)

20.2 (.795)

20.7 (.815)

21.2 (.835)

21.7 (.855)

22.2 (.875)

Adjustment Calculation:

To determine your total material thickness for stud selection use:

18

(.71)

Figure 1

Figure 2

7.1

(.28)

A

A

7.9

(.31)

15.9

(.63)

7.5 (.296) MIN.

C

0.64

(.025)

C

B

B

A + B + 1. 40 (.055) (constant)

when C is 0.64 (.025) .

7.5 (.296) MAX.

Frame thickness

.51 to 5

(.020) (.195)

A + B + C + 0.76 (.030) (constant)

when C is 0.65 (.026) or greater.

Material and Finish

1064 Steel, zinc immersion coating

or 17-7 SS, passivated

Ø 7.9 (.312) MIN.

PART NUMBER

STEEL

QR-MC-C

STAINLESS QR-MC-S

* Please see corresponding pages for potential adjustment calculation required on ejector spring, washers and on some receptacles and retainers. Additional sizes, and finishes available. Contact Matdan for assistance.

www.matdanfasteners.com

5

Outer panel will standoff

by the thickness of the retainer.

3. Method B - Flush with surface

DIMENSIONS

STUD PART NUMBERS

+0.09

11.9 -.0.00

Ø

+.003

(.469 -.000 )

3.6 ± 0.3

2. Choose one of the methods below:

Method A - Recessed to 0.5 (.020) depth

11.1

(.44)

OPTIONAL SNAP-IN ASSEMBLY

4.8

MIN.

(.19)

MIN.

(.100 ±.005)

Ø11.81

(.465)

Slot

1.2 (.05) wide

,

1.2 (.05) deep

22.2

(.88)

.30

(.012)

17.5

(.69)

Bail Horizontal

Wing

Six-lobe

+0.09

11.9 -.0.00

Ø

+.003

(.469 -.000 )

Optional alignment lug

For use when

receptacle is vertical.

Oval Phillips

MIN.

------0 (.000)

0.5 (.020)

1 (.040)

1.5 (.060)

2 (.080)

2.5 (.100)

3 (.120)

3.6 (.140)

4.1 (.160)

4.6 (.180)

5.1 (.200)

5.6 (.220)

6.1 (.240)

6.6 (.260)

7.1 (.280)

7.6 (.300)

8.1 (.320)

8.6 (.340)

9.1 (.360)

9.6 (.380)

10.2 (.400)

10.7 (.420)

Installation

LOCKING STOPS

4.5

(.175)

Ø 4

(.156)

Ø 6.1

(.240)

18.3

(.72)

Knurled Head

Ø 9.9

(.39)

2.8

(.110)

Ø 5

(.198)

F

Knurled

3 mm hex

socket

Ø 9.5

(.375)

U

Bail Vertical

513.794.0500

Job: Q Series Bro

Design3

Die: 8.5"x11" final

3039 Irvella Place

Cincinnati, Ohio 45238

513.662.0067

2

Date: 7/2008

Application: Illustrator CS2

cyan

magenta yellow

black

7477 CV

Process

4 Color Process

Client’s stamp of approval Design3 Inc. makes every effort to ensure artwork is 100% correct. Your review and signature of approval indicates

this art is correct as indicated here, and requires no further modifications from Design3. Thank you for your business.

QUARTER-TURN RECEPTACLES - Medium

QUARTER-TURN RECEPTACLES - Medium

Press-in (Shielded Type)

Leaf Spring

0.9±0.1

(.036±.005)

Receptacle: 1010 Steel, hardened, zinc plate,

chromate plus sealer

Shell: Low carbon steel, hardened, zinc

plate, chromate plus sealer

Spring: 302 SS, zinc immersion coating

Cap: Aluminum, natural

+0.0

11 -0.4

(.435

Riveting Type - with base

Material and Finish

13.7 ±0.3

(.540±.010)

12.7 ± 0.3

(.500 ±.010)

+.001

-.004 )

RETAINING CAP

RECEPTACLE PLATE

RECEPTACLE

HOUSING

PART NUMBER

Two orientation marks. Wing or

slot of stud will be 90° from these

marks when fastened.

NOTE: To be used in low carbon steels,

aluminum and stainless steels in an annealed

condition RB85 or softer.

Installation

NOTE: For inner panels less than 1.3 (.051) thick,

the retainer will create a small gap. To select the

proper stud, assume the inner panel thickness as

1.3 (.051).

2. Press receptacle into hole until shoulder

meets panel surface.

ADJUSTMENT CALCULATION

To determine your total material

thickness, substitute 1.3 (.051) for

frame thickness if frame thickness

is less than 1.3 (.051).

3. To select proper stud grip, determine

total panel thickness and select stud

from corresponding stud selection table.

Swell rivet shank to

Swell rivet shank to

Ø 2.7 -0.00 (.107 -.000)

+.010

Ø 2.7 -0.00 (.107 -.000)

+0.25

26.6 (1.05)

5.7

(.22)

REF.

+.010

26.2 (1.03)

RETAINER

9.5 (.38)

Ø 2.6

(.102)

Ø 2.6 (.102+.004

-.001)

Material and Finish

PART NUMBER

Spring: 1065 Steel, zinc immersion

coating

Base: 1010 Steel, zinc immersion

coating

Ø 5.2 (.205)

Ø 7.9 (.31)

QR-MLB-C

NOTE: Spring must float freely

before riveting.

Welding Type

This hole must stay

sharp. Do not

chamfer

+0.1

11.1 -0.0

Ø

+.003

(.437 -.000 )

11.2 (.44)

STUD

12

(.465)

0.9 MIN.*

(.035)

Material and Finish

PART NUMBER

Spring: 1065 Steel, zinc immersion

STEEL

coating or 17-7 SS, passivated

Eyelet: Steel, zinc immersion coating

or 300 SS, passivated

Total Panel

Thickness

32 (1.26)

16

(.63)

3.2

(.125)

NOTE: Spring must float freely

before riveting.

D

19 (.750)

26.6 (1.05)

9.5

(.375)

FRAME

9.5 (.38)

Receptacle: 1010 Steel,

LOCKING

STOPS

11.8

(.465)

hardened, zinc plate, chromate plus sealer

Shell: Low carbon Steel,

hardened, zinc plate, chromate plus sealer

Retainer & Spring: 302 SS, zinc immersion

10.3

(.405)

Installation

OUTER PANEL

OUTER PANEL

Material and Finish

WITH 90° LOCKING STOPS

QR-MPBI-C

W/O 90° LOCKING STOPS

QR-MPB2-C

PART NUMBER

Spring: 1065 Steel, zinc immersion coating

QR-MLW-C

Base: 1010 Steel, zinc immersion

coating

PART NUMBER

DOOR OR

PANEL

Welding studs: Steel, copper plate

NOTE: Spring must float freely

before riveting.

19(.750)

Ø

(.469 +.003 )

-.000

Material and Finish

Housing: 301 SS, natural

Receptacle: 1010 Steel, case hardened

11.1

MIN.

(.44)

zinc plate, chromate plus sealer

Spring: 302 SS, passivated

Retainer: 301 SS, natural

+0.09

0.5 (.020)

0.5 (.020)

14.3

(.56)

PART NUMBER

2

MIN.

(.080)

11.9 ± 0.1

(.469 ± .005)

14.3

(.56)

3

1.6

(.06)

Snap-in

RETAINER

11.9 -0.00

Ø

)

(.469 +.003

-.000

17

(.67)

Adjustment Calculation

To determine your total material

thickness calculate: D + 1.5 (.060).

Please use total material

Material and Finish

Spring: 1065 Steel, zinc immersion coating thickness column.

Angle Bracket: 1010 Steel, zinc plate,

PART NUMBER

Chromate plus sealer

QR-LS-C

Eyelet: Steel, zinc immersion coating

RETAINER

+0.09

0.4(.015)MIN.

for RETAINER

2 mounting holes,

Ø 3.3 (.130)

11.9 ± 0.1

(.469 ± .005)

11.9 -0.00

8.3

(.33)

6.4

Ø

(.250)

8.3

(.33) 17.1

(.67)

Press-in (Blind Applications & Solid Materials)

Ø

QR-MLO-C

STAINLESS QR-MLO-S

Side Mount Type

5.4

(.21)

Material and Finish

5.7

(.22)

REF.

9.5 (.38)

OUTER PANEL

Inner Panel

3.2

(.125)

11.9 (.47)

Hole size, Ø .098 in. for

3⁄32 rivet Ø 2.6 mm for

2.5 mm rivet

Hole size, Ø .098 in. for

3⁄32 rivet Ø 2.6 mm for

2.5 mm rivet

+0.25

19 (.750)

Countersink

or dimple

3.2

(.125)

11.2 (.44)

QR-MPS

SPRING

1. Drill or punch hole in panel as shown.

19 (.750)

Countersink

or dimple

Riveting Type - without base

www.matdanfasteners.com

11.4

(.45)

2.5 (.100) MAX.

frame thickness

513.794.0500

QR-MN-C

ADJUSTMENT CALCULATION

To determine your total material

thickness calculate: outer panel

thickness + 5.08 (.200) - please

use total material thickness column.

4

QUARTER-TURN STUDS - Medium

Oval Slotted

Hex

Combo

Slot

1.2 (.05) wide

1.2 (.05) deep

2.3

(.090)

QUARTER-TURN RECEPTACLES - Medium

L

Ø 9.53

(.375)

Ultrasonic (Installation into thermoplastics)

1. Prepare hole as shown

15.1

(.59)

No. 2 Phillips

Recess

11.2

(.44)

2.5 ± 0.1

Zinc Plate, Chromate plus sealer

Optional: 300 Stainless Steel, Passivated

OUTER PANEL THICKNESS*

TOTAL MATERIAL THICKNESS*

MAX.

------0.5 (.019)

1 (.039)

1.5 (.059)

2 (.079)

2.5 (.099)

3 (.119)

3.5 (.139)

4.1 (.159)

4.6 (.179)

5.1 (.199)

5.6 (.219)

6.1 (.239)

6.6 (.259)

7.1 (.279)

7.6 (.299)

8.1 (.319)

8.6 (.339)

9.1 (.359)

9.6 (.379)

10.1 (.399)

10.7 (.419)

11.2 (.439)

MIN.

------1.3 (.050)

1.8 (.070)

2.3 (.090)

2.8 (.110)

3.3 (.130)

3.8 (.150)

4.3 (.170)

4.8 (.190)

5.3 (.210)

5.8 (.230)

6.4 (.250)

6.9 (.270)

7.4 (.290)

7.9 (.310)

8.4 (.330)

8.9 (.350)

9.4 (.370)

9.9 (.390)

10.4 (.410)

10.9 (.430)

11.4 (.450)

11.9 (.470)

1.7

(.068)

No. 2 Phillips recess

1. For stainless steel studs,

replace last 2 digits of part

number with SS.

2. For black oxide finish –

change last digit to B

Standard: Carbon Steel, Case Hardened,

FOR ALL OTHER RECEPTACLES:

QR-MC-C / QR-MC-S

QR-MLO-C /QR-MLO-S

QR-MLW-C QR-MLB-C

QR-MN-C

QR-LS-C

TOTAL MATERIAL THICKNESS*

MAX.

------1.8 (.069)

2.3 (.089)

2.8 (.109)

3.3 (.129)

3.8 (.149)

4.3 (.169)

4.8 (.189)

5.3 (.209)

5.8 (.229)

6.3 (.249)

6.9 (.269)

7.4 (.289)

7.9 (.309)

8.4 (.329)

8.9 (.349)

9.4 (.369)

9.9 (.389)

10.4 (.409)

10.9 (.429)

11.4 (.449)

11.9 (.469)

12.4 (.489)

MIN.

2.3 (.090)

2.8 (.110)

3.3 (.130)

3.8 (.150)

4.3 (.170)

4.8 (.190)

5.3 (.210)

5.8 (.230)

6.4 (.250)

6.9 (.270)

7.4 (.290)

7.9 (.310)

8.4 (.330)

8.9 (.350)

9.4 (.370)

9.9 (.390)

10.4 (.410)

10.9 (.430)

11.4 (.450)

11.9 (.470)

12.5 (.490)

13 (.510)

13.5 (.530)

14 (.550)

14.5 (.570)

MAX.

2.8 (.109)

3.3 (.129)

3.8 (.149)

4.3 (.169)

4.8 (.189)

5.3 (.209)

5.8 (.229)

6.3 (.249)

6.9 (.269)

7.4 (.289)

7.9 (.309)

8.4 (.329)

8.9 (.349)

9.4 (.369)

9.9 (.389)

10.4 (.409)

10.9 (.429)

11.4 (.449)

11.9 (.469)

12.4 (.489)

12.9 (.509)

13.5 (.529)

14 (.549)

14.5 (.569)

15 (.589)

.51

(.020)

*Horn design may vary

with material and application.

Material and Finish

MATERIAL AND FINISH

FOR PRESS-IN

RECEPTACLE:

QR-MPS

HORN*

Ø 13.4

(.53)

over

knurl

°30

ORDERING NOTES:

FOR PRESS-IN

RECEPTACLES:

QR-MU-C

QR-MPB1-C

QR-MPB2-C

RETAINER

10.29

(.405)

Flush Phillips Recess

TO ORDER:

Change first 3 digits of part

number to: QSS

Outer panel thickness:

1.5 (.060) Min. 3.2 (.125) Max

Minimum stud grip range:

4.5 (.180)

(.14 ± .01)

Flush

For use when

receptacle is horizontal.

Receptacle: 1010 Steel, case

hardened, zinc plate, chromate

plus sealer

Shell: Low carbon steel, zinc

plate, chromate plus sealer

Spring: 302 SS, zinc immersion

coating

RETAINER

HORN*

PART NUMBER

QR-MU-C

*Horn design may vary

with material and application.

Clip-On

TO COMPLETE PART

NUMBER IN ( ) BELOW,

SELECT HEAD STYLE

U

L

F

QS-M (Drive) -395-CZ

QS-M (Drive) -415-CZ

QS-M (Drive) -435-CZ

QS-M (Drive) -455-CZ

QS-M (Drive) -475-CZ

QS-M (Drive) -495-CZ

QS-M (Drive) -515-CZ

QS-M (Drive) -535-CZ

QS-M (Drive) -555-CZ

QS-M (Drive) -575-CZ

QS-M (Drive) -595-CZ

QS-M (Drive) -615-CZ

QS-M (Drive) -635-CZ

QS-M (Drive) -655-CZ

QS-M (Drive) -675-CZ

QS-M (Drive) -695-CZ

QS-M (Drive) -715-CZ

QS-M (Drive) -735-CZ

QS-M (Drive) -755-CZ

QS-M (Drive) -775-CZ

QS-M (Drive) -795-CZ

QS-M (Drive) -815-CZ

QS-M (Drive) -835-CZ

QS-M (Drive) -855-CZ

QS-M (Drive) -875-CZ

3.2 (.127)

3.7 (.147)

4.2 (.167)

4.8 (.187)

5.3 (.207)

5.8 (.227)

6.3 (.247)

6.8 (.267)

7.3 (.287)

7.8 (.307)

8.3 (.327)

8.8 (.347)

9.3 (.367)

9.8 (.387)

10.3 (.407)

10.9 (.427)

11.4 (.447)

11.9 (.467)

12.4 (.487)

12.9 (.507)

13.4 (.527)

13.9 (.547)

14.4 (.567)

14.9 (.587)

15.4 (.607)

6.2 (.245)

6.7 (.265)

7.2 (.285)

7.8 (.305)

8.3 (.325)

8.8 (.345)

9.3 (.365)

9.8 (.385)

10.3 (.405)

10.8 (.425)

11.3 (.445)

11.8 (.465)

12.3 (.485)

12.8 (.505)

13.3 (.525)

13.8 (.545)

14.4 (.565)

14.9 (.585)

15.4 (.605)

15.9 (.625)

16.4 (.645)

16.9 (.665)

17.4 (.685)

17.9 (.705)

18.4 (.725)

10 (.395)

10.5 (.415)

11.1 (.435)

11.6 (.455)

12.1 (.475)

12.6 (.495)

13.1 (.515)

13.6 (.535)

14.1 (.555)

14.6 (.575)

15.1 (.595)

15.6 (.615)

16.1 (.635)

16.6 (.655)

17.2 (.675)

17.7 (.695)

18.2 (.715)

18.7 (.735)

19.2 (.755)

19.7 (.775)

20.2 (.795)

20.7 (.815)

21.2 (.835)

21.7 (.855)

22.2 (.875)

Adjustment Calculation:

To determine your total material thickness for stud selection use:

18

(.71)

Figure 1

Figure 2

7.1

(.28)

A

A

7.9

(.31)

15.9

(.63)

7.5 (.296) MIN.

C

0.64

(.025)

C

B

B

A + B + 1. 40 (.055) (constant)

when C is 0.64 (.025) .

7.5 (.296) MAX.

Frame thickness

.51 to 5

(.020) (.195)

A + B + C + 0.76 (.030) (constant)

when C is 0.65 (.026) or greater.

Material and Finish

1064 Steel, zinc immersion coating

or 17-7 SS, passivated

Ø 7.9 (.312) MIN.

PART NUMBER

STEEL

QR-MC-C

STAINLESS QR-MC-S

* Please see corresponding pages for potential adjustment calculation required on ejector spring, washers and on some receptacles and retainers. Additional sizes, and finishes available. Contact Matdan for assistance.

www.matdanfasteners.com

5

Outer panel will standoff

by the thickness of the retainer.

3. Method B - Flush with surface

DIMENSIONS

STUD PART NUMBERS

+0.09

11.9 -.0.00

Ø

+.003

(.469 -.000 )

3.6 ± 0.3

2. Choose one of the methods below:

Method A - Recessed to 0.5 (.020) depth

11.1

(.44)

OPTIONAL SNAP-IN ASSEMBLY

4.8

MIN.

(.19)

MIN.

(.100 ±.005)

Ø11.81

(.465)

Slot

1.2 (.05) wide

,

1.2 (.05) deep

22.2

(.88)

.30

(.012)

17.5

(.69)

Bail Horizontal

Wing

Six-lobe

+0.09

11.9 -.0.00

Ø

+.003

(.469 -.000 )

Optional alignment lug

For use when

receptacle is vertical.

Oval Phillips

MIN.

------0 (.000)

0.5 (.020)

1 (.040)

1.5 (.060)

2 (.080)

2.5 (.100)

3 (.120)

3.6 (.140)

4.1 (.160)

4.6 (.180)

5.1 (.200)

5.6 (.220)

6.1 (.240)

6.6 (.260)

7.1 (.280)

7.6 (.300)

8.1 (.320)

8.6 (.340)

9.1 (.360)

9.6 (.380)

10.2 (.400)

10.7 (.420)

Installation

LOCKING STOPS

4.5

(.175)

Ø 4

(.156)

Ø 6.1

(.240)

18.3

(.72)

Knurled Head

Ø 9.9

(.39)

2.8

(.110)

Ø 5

(.198)

F

Knurled

3 mm hex

socket

Ø 9.5

(.375)

U

Bail Vertical

513.794.0500

Job: Q Series Bro

Design3

Die: 8.5"x11" final

3039 Irvella Place

Cincinnati, Ohio 45238

513.662.0067

2

Date: 7/2008

Application: Illustrator CS2

cyan

magenta yellow

black

7477 CV

Process

4 Color Process

Client’s stamp of approval Design3 Inc. makes every effort to ensure artwork is 100% correct. Your review and signature of approval indicates

this art is correct as indicated here, and requires no further modifications from Design3. Thank you for your business.

QUARTER-TURN RECEPTACLES - Medium

QUARTER-TURN RECEPTACLES - Medium

Press-in (Shielded Type)

Leaf Spring

0.9±0.1

(.036±.005)

Receptacle: 1010 Steel, hardened, zinc plate,

chromate plus sealer

Shell: Low carbon steel, hardened, zinc

plate, chromate plus sealer

Spring: 302 SS, zinc immersion coating

Cap: Aluminum, natural

+0.0

11 -0.4

(.435

Riveting Type - with base

Material and Finish

13.7 ±0.3

(.540±.010)

12.7 ± 0.3

(.500 ±.010)

+.001

-.004 )

RETAINING CAP

RECEPTACLE PLATE

RECEPTACLE

HOUSING

PART NUMBER

Two orientation marks. Wing or

slot of stud will be 90° from these

marks when fastened.

NOTE: To be used in low carbon steels,

aluminum and stainless steels in an annealed

condition RB85 or softer.

Installation

NOTE: For inner panels less than 1.3 (.051) thick,

the retainer will create a small gap. To select the

proper stud, assume the inner panel thickness as

1.3 (.051).

2. Press receptacle into hole until shoulder

meets panel surface.

ADJUSTMENT CALCULATION

To determine your total material

thickness, substitute 1.3 (.051) for

frame thickness if frame thickness

is less than 1.3 (.051).

3. To select proper stud grip, determine

total panel thickness and select stud

from corresponding stud selection table.

Swell rivet shank to

Swell rivet shank to

Ø 2.7 -0.00 (.107 -.000)

+.010

Ø 2.7 -0.00 (.107 -.000)

+0.25

26.6 (1.05)

5.7

(.22)

REF.

+.010

26.2 (1.03)

RETAINER

9.5 (.38)

Ø 2.6

(.102)

Ø 2.6 (.102+.004

-.001)

Material and Finish

PART NUMBER

Spring: 1065 Steel, zinc immersion

coating

Base: 1010 Steel, zinc immersion

coating

Ø 5.2 (.205)

Ø 7.9 (.31)

QR-MLB-C

NOTE: Spring must float freely

before riveting.

Welding Type

This hole must stay

sharp. Do not

chamfer

+0.1

11.1 -0.0

Ø

+.003

(.437 -.000 )

11.2 (.44)

STUD

12

(.465)

0.9 MIN.*

(.035)

Material and Finish

PART NUMBER

Spring: 1065 Steel, zinc immersion

STEEL

coating or 17-7 SS, passivated

Eyelet: Steel, zinc immersion coating

or 300 SS, passivated

Total Panel

Thickness

32 (1.26)

16

(.63)

3.2

(.125)

NOTE: Spring must float freely

before riveting.

D

19 (.750)

26.6 (1.05)

9.5

(.375)

FRAME

9.5 (.38)

Receptacle: 1010 Steel,

LOCKING

STOPS

11.8

(.465)

hardened, zinc plate, chromate plus sealer

Shell: Low carbon Steel,

hardened, zinc plate, chromate plus sealer

Retainer & Spring: 302 SS, zinc immersion

10.3

(.405)

Installation

OUTER PANEL

OUTER PANEL

Material and Finish

WITH 90° LOCKING STOPS

QR-MPBI-C

W/O 90° LOCKING STOPS

QR-MPB2-C

PART NUMBER

Spring: 1065 Steel, zinc immersion coating

QR-MLW-C

Base: 1010 Steel, zinc immersion

coating

PART NUMBER

DOOR OR

PANEL

Welding studs: Steel, copper plate

NOTE: Spring must float freely

before riveting.

19(.750)

Ø

(.469 +.003 )

-.000

Material and Finish

Housing: 301 SS, natural

Receptacle: 1010 Steel, case hardened

11.1

MIN.

(.44)

zinc plate, chromate plus sealer

Spring: 302 SS, passivated

Retainer: 301 SS, natural

+0.09

0.5 (.020)

0.5 (.020)

14.3

(.56)

PART NUMBER

2

MIN.

(.080)

11.9 ± 0.1

(.469 ± .005)

14.3

(.56)

3

1.6

(.06)

Snap-in

RETAINER

11.9 -0.00

Ø

)

(.469 +.003

-.000

17

(.67)

Adjustment Calculation

To determine your total material

thickness calculate: D + 1.5 (.060).

Please use total material

Material and Finish

Spring: 1065 Steel, zinc immersion coating thickness column.

Angle Bracket: 1010 Steel, zinc plate,

PART NUMBER

Chromate plus sealer

QR-LS-C

Eyelet: Steel, zinc immersion coating

RETAINER

+0.09

0.4(.015)MIN.

for RETAINER

2 mounting holes,

Ø 3.3 (.130)

11.9 ± 0.1

(.469 ± .005)

11.9 -0.00

8.3

(.33)

6.4

Ø

(.250)

8.3

(.33) 17.1

(.67)

Press-in (Blind Applications & Solid Materials)

Ø

QR-MLO-C

STAINLESS QR-MLO-S

Side Mount Type

5.4

(.21)

Material and Finish

5.7

(.22)

REF.

9.5 (.38)

OUTER PANEL

Inner Panel

3.2

(.125)

11.9 (.47)

Hole size, Ø .098 in. for

3⁄32 rivet Ø 2.6 mm for

2.5 mm rivet

Hole size, Ø .098 in. for

3⁄32 rivet Ø 2.6 mm for

2.5 mm rivet

+0.25

19 (.750)

Countersink

or dimple

3.2

(.125)

11.2 (.44)

QR-MPS

SPRING

1. Drill or punch hole in panel as shown.

19 (.750)

Countersink

or dimple

Riveting Type - without base

www.matdanfasteners.com

11.4

(.45)

2.5 (.100) MAX.

frame thickness

513.794.0500

QR-MN-C

ADJUSTMENT CALCULATION

To determine your total material

thickness calculate: outer panel

thickness + 5.08 (.200) - please

use total material thickness column.

4

QUARTER-TURN STUDS - Medium

Oval Slotted

Hex

Combo

Slot

1.2 (.05) wide

1.2 (.05) deep

2.3

(.090)

QUARTER-TURN RECEPTACLES - Medium

L

Ø 9.53

(.375)

Ultrasonic (Installation into thermoplastics)

1. Prepare hole as shown

15.1

(.59)

No. 2 Phillips

Recess

11.2

(.44)

2.5 ± 0.1

Zinc Plate, Chromate plus sealer

Optional: 300 Stainless Steel, Passivated

OUTER PANEL THICKNESS*

TOTAL MATERIAL THICKNESS*

MAX.

------0.5 (.019)

1 (.039)

1.5 (.059)

2 (.079)

2.5 (.099)

3 (.119)

3.5 (.139)

4.1 (.159)

4.6 (.179)

5.1 (.199)

5.6 (.219)

6.1 (.239)

6.6 (.259)

7.1 (.279)

7.6 (.299)

8.1 (.319)

8.6 (.339)

9.1 (.359)

9.6 (.379)

10.1 (.399)

10.7 (.419)

11.2 (.439)

MIN.

------1.3 (.050)

1.8 (.070)

2.3 (.090)

2.8 (.110)

3.3 (.130)

3.8 (.150)

4.3 (.170)

4.8 (.190)

5.3 (.210)

5.8 (.230)

6.4 (.250)

6.9 (.270)

7.4 (.290)

7.9 (.310)

8.4 (.330)

8.9 (.350)

9.4 (.370)

9.9 (.390)

10.4 (.410)

10.9 (.430)

11.4 (.450)

11.9 (.470)

1.7

(.068)

No. 2 Phillips recess

1. For stainless steel studs,

replace last 2 digits of part

number with SS.

2. For black oxide finish –

change last digit to B

Standard: Carbon Steel, Case Hardened,

FOR ALL OTHER RECEPTACLES:

QR-MC-C / QR-MC-S

QR-MLO-C /QR-MLO-S

QR-MLW-C QR-MLB-C

QR-MN-C

QR-LS-C

TOTAL MATERIAL THICKNESS*

MAX.

------1.8 (.069)

2.3 (.089)

2.8 (.109)

3.3 (.129)

3.8 (.149)

4.3 (.169)

4.8 (.189)

5.3 (.209)

5.8 (.229)

6.3 (.249)

6.9 (.269)

7.4 (.289)

7.9 (.309)

8.4 (.329)

8.9 (.349)

9.4 (.369)

9.9 (.389)

10.4 (.409)

10.9 (.429)

11.4 (.449)

11.9 (.469)

12.4 (.489)

MIN.

2.3 (.090)

2.8 (.110)

3.3 (.130)

3.8 (.150)

4.3 (.170)

4.8 (.190)

5.3 (.210)

5.8 (.230)

6.4 (.250)

6.9 (.270)

7.4 (.290)

7.9 (.310)

8.4 (.330)

8.9 (.350)

9.4 (.370)

9.9 (.390)

10.4 (.410)

10.9 (.430)

11.4 (.450)

11.9 (.470)

12.5 (.490)

13 (.510)

13.5 (.530)

14 (.550)

14.5 (.570)

MAX.

2.8 (.109)

3.3 (.129)

3.8 (.149)

4.3 (.169)

4.8 (.189)

5.3 (.209)

5.8 (.229)

6.3 (.249)

6.9 (.269)

7.4 (.289)

7.9 (.309)

8.4 (.329)

8.9 (.349)

9.4 (.369)

9.9 (.389)

10.4 (.409)

10.9 (.429)

11.4 (.449)

11.9 (.469)

12.4 (.489)

12.9 (.509)

13.5 (.529)

14 (.549)

14.5 (.569)

15 (.589)

.51

(.020)

*Horn design may vary

with material and application.

Material and Finish

MATERIAL AND FINISH

FOR PRESS-IN

RECEPTACLE:

QR-MPS

HORN*

Ø 13.4

(.53)

over

knurl

°30

ORDERING NOTES:

FOR PRESS-IN

RECEPTACLES:

QR-MU-C

QR-MPB1-C

QR-MPB2-C

RETAINER

10.29

(.405)

Flush Phillips Recess

TO ORDER:

Change first 3 digits of part

number to: QSS

Outer panel thickness:

1.5 (.060) Min. 3.2 (.125) Max

Minimum stud grip range:

4.5 (.180)

(.14 ± .01)

Flush

For use when

receptacle is horizontal.

Receptacle: 1010 Steel, case

hardened, zinc plate, chromate

plus sealer

Shell: Low carbon steel, zinc

plate, chromate plus sealer

Spring: 302 SS, zinc immersion

coating

RETAINER

HORN*

PART NUMBER

QR-MU-C

*Horn design may vary

with material and application.

Clip-On

TO COMPLETE PART

NUMBER IN ( ) BELOW,

SELECT HEAD STYLE

U

L

F

QS-M (Drive) -395-CZ

QS-M (Drive) -415-CZ

QS-M (Drive) -435-CZ

QS-M (Drive) -455-CZ

QS-M (Drive) -475-CZ

QS-M (Drive) -495-CZ

QS-M (Drive) -515-CZ

QS-M (Drive) -535-CZ

QS-M (Drive) -555-CZ

QS-M (Drive) -575-CZ

QS-M (Drive) -595-CZ

QS-M (Drive) -615-CZ

QS-M (Drive) -635-CZ

QS-M (Drive) -655-CZ

QS-M (Drive) -675-CZ

QS-M (Drive) -695-CZ

QS-M (Drive) -715-CZ

QS-M (Drive) -735-CZ

QS-M (Drive) -755-CZ

QS-M (Drive) -775-CZ

QS-M (Drive) -795-CZ

QS-M (Drive) -815-CZ

QS-M (Drive) -835-CZ

QS-M (Drive) -855-CZ

QS-M (Drive) -875-CZ

3.2 (.127)

3.7 (.147)

4.2 (.167)

4.8 (.187)

5.3 (.207)

5.8 (.227)

6.3 (.247)

6.8 (.267)

7.3 (.287)

7.8 (.307)

8.3 (.327)

8.8 (.347)

9.3 (.367)

9.8 (.387)

10.3 (.407)

10.9 (.427)

11.4 (.447)

11.9 (.467)

12.4 (.487)

12.9 (.507)

13.4 (.527)

13.9 (.547)

14.4 (.567)

14.9 (.587)

15.4 (.607)

6.2 (.245)

6.7 (.265)

7.2 (.285)

7.8 (.305)

8.3 (.325)

8.8 (.345)

9.3 (.365)

9.8 (.385)

10.3 (.405)

10.8 (.425)

11.3 (.445)

11.8 (.465)

12.3 (.485)

12.8 (.505)

13.3 (.525)

13.8 (.545)

14.4 (.565)

14.9 (.585)

15.4 (.605)

15.9 (.625)

16.4 (.645)

16.9 (.665)

17.4 (.685)

17.9 (.705)

18.4 (.725)

10 (.395)

10.5 (.415)

11.1 (.435)

11.6 (.455)

12.1 (.475)

12.6 (.495)

13.1 (.515)

13.6 (.535)

14.1 (.555)

14.6 (.575)

15.1 (.595)

15.6 (.615)

16.1 (.635)

16.6 (.655)

17.2 (.675)

17.7 (.695)

18.2 (.715)

18.7 (.735)

19.2 (.755)

19.7 (.775)

20.2 (.795)

20.7 (.815)

21.2 (.835)

21.7 (.855)

22.2 (.875)

Adjustment Calculation:

To determine your total material thickness for stud selection use:

18

(.71)

Figure 1

Figure 2

7.1

(.28)

A

A

7.9

(.31)

15.9

(.63)

7.5 (.296) MIN.

C

0.64

(.025)

C

B

B

A + B + 1. 40 (.055) (constant)

when C is 0.64 (.025) .

7.5 (.296) MAX.

Frame thickness

.51 to 5

(.020) (.195)

A + B + C + 0.76 (.030) (constant)

when C is 0.65 (.026) or greater.

Material and Finish

1064 Steel, zinc immersion coating

or 17-7 SS, passivated

Ø 7.9 (.312) MIN.

PART NUMBER

STEEL

QR-MC-C

STAINLESS QR-MC-S

* Please see corresponding pages for potential adjustment calculation required on ejector spring, washers and on some receptacles and retainers. Additional sizes, and finishes available. Contact Matdan for assistance.

www.matdanfasteners.com

5

Outer panel will standoff

by the thickness of the retainer.

3. Method B - Flush with surface

DIMENSIONS

STUD PART NUMBERS

+0.09

11.9 -.0.00

Ø

+.003

(.469 -.000 )

3.6 ± 0.3

2. Choose one of the methods below:

Method A - Recessed to 0.5 (.020) depth

11.1

(.44)

OPTIONAL SNAP-IN ASSEMBLY

4.8

MIN.

(.19)

MIN.

(.100 ±.005)

Ø11.81

(.465)

Slot

1.2 (.05) wide

,

1.2 (.05) deep

22.2

(.88)

.30

(.012)

17.5

(.69)

Bail Horizontal

Wing

Six-lobe

+0.09

11.9 -.0.00

Ø

+.003

(.469 -.000 )

Optional alignment lug

For use when

receptacle is vertical.

Oval Phillips

MIN.

------0 (.000)

0.5 (.020)

1 (.040)

1.5 (.060)

2 (.080)

2.5 (.100)

3 (.120)

3.6 (.140)

4.1 (.160)

4.6 (.180)

5.1 (.200)

5.6 (.220)

6.1 (.240)

6.6 (.260)

7.1 (.280)

7.6 (.300)

8.1 (.320)

8.6 (.340)

9.1 (.360)

9.6 (.380)

10.2 (.400)

10.7 (.420)

Installation

LOCKING STOPS

4.5

(.175)

Ø 4

(.156)

Ø 6.1

(.240)

18.3

(.72)

Knurled Head

Ø 9.9

(.39)

2.8

(.110)

Ø 5

(.198)

F

Knurled

3 mm hex

socket

Ø 9.5

(.375)

U

Bail Vertical

513.794.0500

Job: Q Series Bro

Design3

Die: 8.5"x11" final

3039 Irvella Place

Cincinnati, Ohio 45238

513.662.0067

2

Date: 7/2008

Application: Illustrator CS2

cyan

magenta yellow

black

7477 CV

Process

4 Color Process

Client’s stamp of approval Design3 Inc. makes every effort to ensure artwork is 100% correct. Your review and signature of approval indicates

this art is correct as indicated here, and requires no further modifications from Design3. Thank you for your business.

QUARTER-TURN RECEPTACLES - Medium

QUARTER-TURN RECEPTACLES - Medium

Press-in (Shielded Type)

Leaf Spring

0.9±0.1

(.036±.005)

Receptacle: 1010 Steel, hardened, zinc plate,

chromate plus sealer

Shell: Low carbon steel, hardened, zinc

plate, chromate plus sealer

Spring: 302 SS, zinc immersion coating

Cap: Aluminum, natural

+0.0

11 -0.4

(.435

Riveting Type - with base

Material and Finish

13.7 ±0.3

(.540±.010)

12.7 ± 0.3

(.500 ±.010)

+.001

-.004 )

RETAINING CAP

RECEPTACLE PLATE

RECEPTACLE

HOUSING

PART NUMBER

Two orientation marks. Wing or

slot of stud will be 90° from these

marks when fastened.

NOTE: To be used in low carbon steels,

aluminum and stainless steels in an annealed

condition RB85 or softer.

Installation

NOTE: For inner panels less than 1.3 (.051) thick,

the retainer will create a small gap. To select the

proper stud, assume the inner panel thickness as

1.3 (.051).

2. Press receptacle into hole until shoulder

meets panel surface.

ADJUSTMENT CALCULATION

To determine your total material

thickness, substitute 1.3 (.051) for

frame thickness if frame thickness

is less than 1.3 (.051).

3. To select proper stud grip, determine

total panel thickness and select stud

from corresponding stud selection table.

Swell rivet shank to

Swell rivet shank to

Ø 2.7 -0.00 (.107 -.000)

+.010

Ø 2.7 -0.00 (.107 -.000)

+0.25

26.6 (1.05)

5.7

(.22)

REF.

+.010

26.2 (1.03)

RETAINER

9.5 (.38)

Ø 2.6

(.102)

Ø 2.6 (.102+.004

-.001)

Material and Finish

PART NUMBER

Spring: 1065 Steel, zinc immersion

coating

Base: 1010 Steel, zinc immersion

coating

Ø 5.2 (.205)

Ø 7.9 (.31)

QR-MLB-C

NOTE: Spring must float freely

before riveting.

Welding Type

This hole must stay

sharp. Do not

chamfer

+0.1

11.1 -0.0

Ø

+.003

(.437 -.000 )

11.2 (.44)

STUD

12

(.465)

0.9 MIN.*

(.035)

Material and Finish

PART NUMBER

Spring: 1065 Steel, zinc immersion

STEEL

coating or 17-7 SS, passivated

Eyelet: Steel, zinc immersion coating

or 300 SS, passivated

Total Panel

Thickness

32 (1.26)

16

(.63)

3.2

(.125)

NOTE: Spring must float freely

before riveting.

D

19 (.750)

26.6 (1.05)

9.5

(.375)

FRAME

9.5 (.38)

Receptacle: 1010 Steel,

LOCKING

STOPS

11.8

(.465)

hardened, zinc plate, chromate plus sealer

Shell: Low carbon Steel,

hardened, zinc plate, chromate plus sealer

Retainer & Spring: 302 SS, zinc immersion

10.3

(.405)

Installation

OUTER PANEL

OUTER PANEL

Material and Finish

WITH 90° LOCKING STOPS

QR-MPBI-C

W/O 90° LOCKING STOPS

QR-MPB2-C

PART NUMBER

Spring: 1065 Steel, zinc immersion coating

QR-MLW-C

Base: 1010 Steel, zinc immersion

coating

PART NUMBER

DOOR OR

PANEL

Welding studs: Steel, copper plate

NOTE: Spring must float freely

before riveting.

19(.750)

Ø

(.469 +.003 )

-.000

Material and Finish

Housing: 301 SS, natural

Receptacle: 1010 Steel, case hardened

11.1

MIN.

(.44)

zinc plate, chromate plus sealer

Spring: 302 SS, passivated

Retainer: 301 SS, natural

+0.09

0.5 (.020)

0.5 (.020)

14.3

(.56)

PART NUMBER

2

MIN.

(.080)

11.9 ± 0.1

(.469 ± .005)

14.3

(.56)

3

1.6

(.06)

Snap-in

RETAINER

11.9 -0.00

Ø

)

(.469 +.003

-.000

17

(.67)

Adjustment Calculation

To determine your total material

thickness calculate: D + 1.5 (.060).

Please use total material

Material and Finish

Spring: 1065 Steel, zinc immersion coating thickness column.

Angle Bracket: 1010 Steel, zinc plate,

PART NUMBER

Chromate plus sealer

QR-LS-C

Eyelet: Steel, zinc immersion coating

RETAINER

+0.09

0.4(.015)MIN.

for RETAINER

2 mounting holes,

Ø 3.3 (.130)

11.9 ± 0.1

(.469 ± .005)

11.9 -0.00

8.3

(.33)

6.4

Ø

(.250)

8.3

(.33) 17.1

(.67)

Press-in (Blind Applications & Solid Materials)

Ø

QR-MLO-C

STAINLESS QR-MLO-S

Side Mount Type

5.4

(.21)

Material and Finish

5.7

(.22)

REF.

9.5 (.38)

OUTER PANEL

Inner Panel

3.2

(.125)

11.9 (.47)

Hole size, Ø .098 in. for

3⁄32 rivet Ø 2.6 mm for

2.5 mm rivet

Hole size, Ø .098 in. for

3⁄32 rivet Ø 2.6 mm for

2.5 mm rivet

+0.25

19 (.750)

Countersink

or dimple

3.2

(.125)

11.2 (.44)

QR-MPS

SPRING

1. Drill or punch hole in panel as shown.

19 (.750)

Countersink

or dimple

Riveting Type - without base

www.matdanfasteners.com

11.4

(.45)

2.5 (.100) MAX.

frame thickness

513.794.0500

QR-MN-C

ADJUSTMENT CALCULATION

To determine your total material

thickness calculate: outer panel

thickness + 5.08 (.200) - please

use total material thickness column.

4

BACK COVER

FRONT COVER

QUARTER-TURN FASTENERS

Installation Styles

Standard Products

MC Series

Retractable Captive Screws

Press-In

Flare-In

Floating

PC

Board

MCP

MCF

MCL

MCB

Replaces

Southco®

Replaces

PEM®

47

PF11

PF12

PF13

PF14

MP Series

Retractable Captive Screws

MPP

MPF

MPL

MPB

_

PF30

PF31

PF32

PF50

PF60

MM Series

“Low Head” Miniature Retractable Screws

MMP

MMF

MML

MMB

52

PFS2

PFC2

MS Series

“High Head” Miniature Retractable Screws

MSP

MSF

MSL

MSB

52

MF Series

Flush Mount Captive Screws

√

Spring Loaded Plungers

√

√

√

Q SERIES

QUARTER-TURN FASTENERS ASSEMBLY

Designer’s Guide

F5

PF10

56

PTL2

09

12

MFL Product Series

“Speed Lead” Captive Screws

SLS “Speed Latch” System

MTS Series

“Snap-In” Captive Screws

Q Series

Quarter-Turn Fasteners & Receptacles

81

82

85

MSI Series

Threaded Inserts

71

72

BCS Series

Knurled Captive Screws

58

®Southco is a registered trademark of Southco, Inc. PF11, PF12, PF13, PF14, PF30, PF31, PF32, PF50, PF60, PFC, PFC2 & ®PEM

are trademarks of Penn Engineering & Manufacturing Corp.

China Division:

Headquarters:

Matdan (Ningbo)

Specialty Hardware Co., Ltd.

Matdan Corporation

Cincinnati, Ohio 45242, USA

Tel: 513 - 794 - 0500 Fax: 513 - 794 - 0651

E-mail: sales@matdanfasteners.com

Ningbo, Zhejiang Province, China 315120

E-mail: sales_cn@matdanfasteners.com

www.matdanfasteners.com

Matdan, matdanfasteners.com and the Matdan logo are trademarks of the Matdan Corporation. Use allowed only with written

permission from Matdan. The contents of this publication are copyrighted 2007 Matdan Corporation. All rights reserved.

Copies may be obtained from the company. Published specifications are subject to change without notice.

For ordering information call 513-794-0500 or E-mail: sales@matdanfasteners.com

Published specifications are subject to change without notice. ©2007 Matdan Corporation. All rights reserved.

QTF0708QC

Note: Client needs to see proof of images for possible color correction

QUARTER-TURN FASTENER - Medium

QUARTER-TURN MISCELLANEOUS - Medium

Features & Benefits

Washers

• Combines quick access with captive fastening

• Tool or hand-operated

• Available in materials suited for both indoor or outdoor environments

Sealing Washer

Ejector Spring

Nylon Wear Washers

Ø 9.5

(.38)

Cupped

Flat

0.51

(.020)

Choosing a Quarter-turn Fastener Assembly

1. Choose your receptacle (note any frame thickness limitations)

2. Choose your stud (or ”headstyle” type)

• Measure your Outer Panel Thickness or Total Material Thickness (chart on page 5 lists range of thickness

by receptacle and will tell you to use either Outer Panel Thickness or Total Material Thickness)

• Apply adjustment calculation to your measurement if listed next to receptacle drawings

• Utilize measurement (or adjusted calculation) to locate stud part number in table

3. Choose your retainer

Retainer

Stud

Receptacle

To fasten, apply 1/4 turn to the stud. The stud now engages with the