CommScope

Instruction Sheet

631-460-136-7

Issue 3, February 2004

Material ID 848 136 503

249-A Frame Mounting Kit

Installation Instructions

General

This instruction sheet provides a procedure for installing the 249-A Frame Mounting Kit onto the 489-Type

Building Entrance Protector (BEP) and the 589-Type Building Entrance Terminal (BET).

How to Contact Us

•

To find out more about Carrier Apparatus products, visit us on the web at:

http://cw.commscope.com/

•

For technical assistance regarding Carrier Apparatus products: contact your local CommScope account

representative or Commscope technical support at 1-800-344-0223.

•

Report any missing or damaged parts to CommScope customer service in Omaha, Nebraska, at

1-866-539-2795.

Ordering Information

Product Name

Apparatus Code

Material ID

249-A Frame Mounting Kit

249-A

108 231 416

Description

489 / 589 Mounting Bracket

Parts Included

Item

Number of Items

Part Name

Description

1

2

Bracket, Adjustable

Long adjustable piece of mounting bracket

2

2

Bracket, Fixed

Short fixed piece of mounting bracket

3

6

Screws, Thread-cutting

Screws to attach sheet metal bracket to plastic enclosure

1

Instruction Sheet

Mounting procedure

Tools Required

•

Driver for screws above

•

•

Four 12-24 x ½" screws, or 15mm M6 screws, or M6 cage-nuts

Flat-head screwdriver

Mounting the Bracket to the Unit

NOTE: Use this procedure in conjunction with either the 489-BEP or 589-BET installation and

cabling instruction sheets, as appropriate.

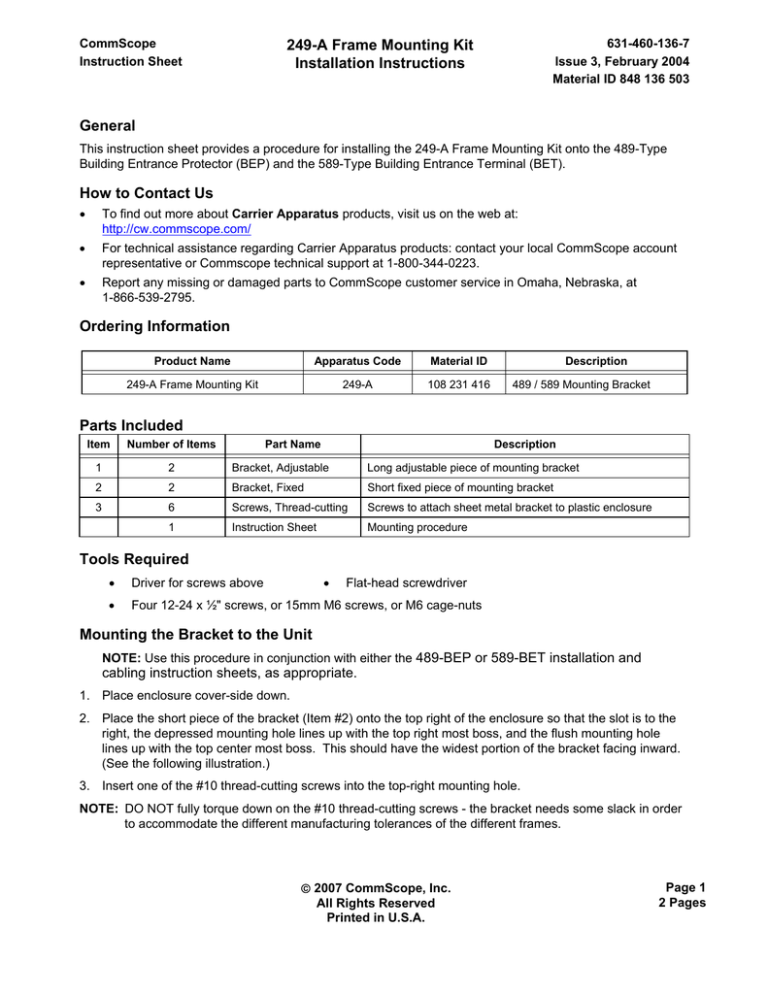

1. Place enclosure cover-side down.

2. Place the short piece of the bracket (Item #2) onto the top right of the enclosure so that the slot is to the

right, the depressed mounting hole lines up with the top right most boss, and the flush mounting hole

lines up with the top center most boss. This should have the widest portion of the bracket facing inward.

(See the following illustration.)

3. Insert one of the #10 thread-cutting screws into the top-right mounting hole.

NOTE: DO NOT fully torque down on the #10 thread-cutting screws - the bracket needs some slack in order

to accommodate the different manufacturing tolerances of the different frames.

© 2007 CommScope, Inc.

All Rights Reserved

Printed in U.S.A.

Page 1

2 Pages

Material ID 848 136 503

Instruction Sheet

SLOT

PLACE THE SHORT PIECE

OF MOUNTING BRACKET

ON THE TOP RIGHT OF ENCLOSURE

2

DEPRESSED

MOUNT

HOLE

SLOT

PLACE THE LONG PIECE

OF MOUNTING BRACKET

ON TOP LEFT OF ENCLOSURE

PLACE THE 2nd LONG PIECE

OF THE MOUNTING BRACKET

ON BOTTOM LEFT OF ENCLOSURE

4

5

3

INSERT

#10 THREADCUTTING

SCREW

5

6

SLOT

SLOT

7

PLACE THE 2nd SHORT PIECE

OF THE MOUNTING BRACKET

ON THE TOP RIGHT OF ENCLOSURE

9

8

9

4. Place the long piece of the bracket (Item #1) onto the top left of the enclosure so that the slot is to the left,

the raised mounting hole lines up with the top left most boss, and the flush mounting hole lines up with

the top center most boss. This position places the widest portion of the bracket facing inward.

With the slot to the left and the holes to the top of the centerline of the bracket, Item #1 has 3 raised holes

and 3 flush holes. The right most raised and flush holes are for mounting to a 23-inch frame, the center

raised and flush holes are for mounting to an ETSI frame, and the left raised and flush holes are for

mounting to a 19-inch frame. Use the holes that are appropriate for sizing the bracket to your frame.

5. Insert two more of the #10 thread-cutting screws into the top-center and top-left mounting holes. DO

NOT fully torque down on the screw.

6. Place the second long piece (Item #1) onto the bottom left of the enclosure so that the slot is again to the

left, the depressed mounting hole lines up with the bottom left most boss, and the flush mounting hole

lines up with the bottom center most boss. The widest portion of the bracket faces inward.

7. Insert one of the #10 thread-cutting screws into the bottom-left mounting hole. DO NOT fully torque down

on the screw.

8. Place the second short piece (Item #2) onto the bottom right of the enclosure so that the slot is to the

right, the raised mounting hole lines up with the bottom right most boss, and the flush mounting hole lines

up with the bottom center most boss. The widest portion of the bracket faces inward.

9. Insert the last two of the #10 thread-cutting screws into the bottom-center and bottom-right mounting

hole. DO NOT fully torque down on the screw.

Mounting the Unit to a Bay

1. For a more flush mounting arrangement, place the unit in from the back of frame. For a higher density or

one-sided mounting arrangement, place the unit in from the front of frame.

2. Align the slots of the bracket with the mounting holes in the bay.

3. Use 12-24 screws, M6 screws, or M6 cage nuts to fasten the unit to the bay.

4. Repeat as needed.

Page 2

2 Pages