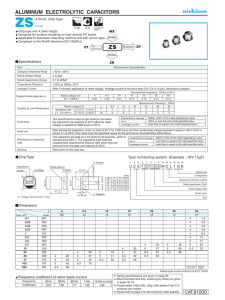

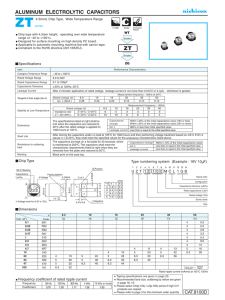

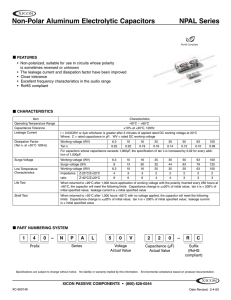

ALUMINUM ELECTROLYTIC CAPACITORS

advertisement