150 CLZ Aluminum Capacitors SMD (Chip), High Temperature

advertisement

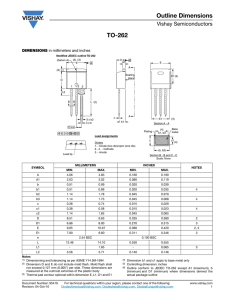

Not Recommended for New Designs, Use 150 CRZ 150 CLZ www.vishay.com Vishay BCcomponents Aluminum Capacitors SMD (Chip), High Temperature FEATURES • Polarized aluminum electrolytic non-solid electrolyte, self healing capacitors, • SMD-version with base plate, reflow solderable • Very low impedance, very high ripple current • Very long useful life: 3000 h at 105 °C • Charge and discharge proof, no peak current limitation • ATTENTION: for maximum safe soldering conditions refer to Fig. 4 140 CLH 125 °C APPLICATIONS high temperature • SMD technology, for high mounting density 153 CLV 153 CRV low Z 150 CLZ Lead (Pb)-free • Industrial and professional applications • Automotive, general industrial Fig. 1 • Smoothing, filtering, buffering QUICK REFERENCE DATA DESCRIPTION Nominal case sizes (L x W x H in mm) Rated capacitance range, CR Tolerance on CR Rated voltage range, UR Category temperature range Endurance test at 105 °C Useful life at 105 °C: case size 10 x 10 x 10 case size 10 x 10 x 14 Useful life at 40 °C; 1.8 x lR applied: case size 10 x 10 x 10 case size 10 x 10 x 14 Shelf life at 0 V, 105 °C Based on sectional specification Climatic category IEC 60068 MARKING VALUE 8 x 8 x 10 to 10 x 10 x 14 33 μF to 1000 μF ± 20 % 6.3 V to 63 V -55 °C to +105 °C 2000 h • Rated capacitance (in μF) • Rated voltage (in V) • Date code, in accordance with IEC 60062 • Black mark or “-” sign indicating the cathode (the anode is identified by bevelled edges) • Code indicating group number (Z) 2500 h 3000 h PACKAGING Supplied in blister tape on reel. 125 000 h 150 000 h 1000 h IEC 60384-18 / CECC32300 55/105/56 SELECTION CHART FOR CR, UR, AND RELEVANT NOMINAL CASE SIZES (L x W x H in mm) CR (μF) 33 47 68 100 150 220 330 470 680 1000 Revision: 19-Jan-15 6.3 8 x 8 x 10 10 x 10 x 10 10 8 x 8 x 10 8 x 8 x 10 10 x 10 x 10 10 x 10 x 14 16 8 x 8 x 10 8 x 8 x 10 10 x 10 x 10 10 x 10 x 14 - UR (V) 25 8 x 8 x 10 8 x 8 x 10 10 x 10 x 10 10 x 10 x 14 - 35 8 x 8 x 10 10 x 10 x 10 10 x 10 x 14 - 50 8 x 8 x 10 10 x 10 x 10 10 x 10 x 14 - 63 8 x 8 x 10 8 x 8 x 10 10 x 10 x 10 10 x 10 x 10 10 x 10 x 14 - Document Number: 28304 1 For technical questions, contact: aluminumcaps1@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 Not Recommended for New Designs, Use 150 CRZ 150 CLZ www.vishay.com Vishay BCcomponents Table 1 DIMENSIONS in millimeters AND MASS NOMINAL CASE SIZE LxWxH 8 x 8 x 10 10 x 10 x 10 10 x 10 x 14 CASE CODE 0810 1010 1014 Lmax. Wmax. Hmax. ØD Bmax. S L1 max. 8.5 10.5 10.5 8.5 10.5 10.5 10.5 10.5 14.3 8.0 10.0 10.0 1.0 1.0 1.0 3.1 4.5 4.5 9.9 11.8 11.8 MASS (g) 1.0 1.3 1.5 L 0.4 ± 0.2 WB C S C 0.3 max. Fig. 2 - Dimensional outline Table 2 TAPE AND REEL DIMENSIONS in millimeters, PACKAGING QUANTITIES NOMINAL CASE SIZE LxWxH 8 x 8 x 10 10 x 10 x 10 10 x 10 x 14 CASE CODE 0810 1010 1014 PITCH P1 16 16 16 TAPE WIDTH W 24 24 24 TAPE THICKNESS T2 11.3 11.3 14.8 PACKAGING QUANTITY PER REEL 500 500 250 REEL DIA. 380 380 330 Note • Detailed tape dimensions see section “PACKAGING”. MOUNTING The capacitors are designed for automatic placement on to printed-circuit boards. Optimum dimensions of soldering pads depend amongst others on soldering method, mounting accuracy, print layout and / or adjacent components. For recommended soldering pad dimensions, refer to Fig. 3 and Table 3. b a c a Fig. 3 - Recommended solder pad dimensions SOLDERING Soldering conditions are defined by the curve, temperature versus time, where the temperature is that measured on the soldering pad during processing. For maximum conditions refer to Fig. 4. Any temperature versus time curve which does not exceed the specified maximum curves may be applied. Table 3 AS A GENERAL PRINCIPLE, TEMPERATURE AND DURATION SHALL BE THE MINIMUM NECESSARY REQUIRED TO ENSURE GOOD SOLDERING CONNECTIONS. HOWEVER, THE SPECIFIED MAXIMUM CURVES SHOULD NEVER BE EXCEEDED. TPAD 280 (°C) 260 240 RECOMMENDED SOLDERING PAD DIMENSIONS in millimeters 220 200 180 CASE CODE a b c 0810 3.5 2.5 3.0 1010 4.3 2.5 4.0 120 1014 4.3 2.5 4.0 100 160 140 80 0 50 100 150 200 t (s) 250 Fig. 4 - Maximum temperature load during infrared reflow soldering measured on the soldering pad Revision: 19-Jan-15 Document Number: 28304 2 For technical questions, contact: aluminumcaps1@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 Not Recommended for New Designs, Use 150 CRZ 150 CLZ www.vishay.com Vishay BCcomponents ORDERING EXAMPLE ELECTRICAL DATA Electrolytic capacitor 150 CLZ series SYMBOL DESCRIPTION CR Rated capacitance at 100 Hz, tolerance ± 20 % 220 μF/50 V; ± 20 % IR Rated RMS ripple current at 100 kHz, 105 °C Nominal case size: 10 mm x 10 mm x 14 mm; taped on reel Max. leakage current after 2 min at UR Ordering code: MAL215095102E3 Former 12NC: 2222 150 95102 IL2 tan Z Max. dissipation factor at 100 Hz Max. impedance at 100 kHz Note • Unless otherwise specified, all electrical values in Table 4 apply at Tamb = 20 °C, P = 86 kPa to 106 kPa, RH = 45 % to 75 %. Table 4 ELECTRICAL DATA AND ORDERING INFORMATION UR (V) 6.3 10 16 25 35 50 63 CR (μF) NOMINAL CASE SIZE LxWxH (mm) 470 1000 330 470 680 1000 220 330 470 680 150 220 330 470 100 220 330 68 100 220 33 47 47 68 100 8x8 x10 10 x10 x10 8 x8 x10 8 x8 x10 10 x 10 x10 10 x 10 x 14 8 x8 x10 8 x8 x10 10 x10 x10 10 x10 x14 8 x8 x10 8 x8 x10 10 x 10 x 10 10 x10 x14 8 x8 x10 10 x 10 x10 10 x 10 x 14 8 x8 x10 10 x10 x10 10 x 10 x 14 8 x8 x10 8 x8 x10 10 x10 x10 10 x 10 x 10 10 x10 x14 IR 105 °C 100 kHz (mA) 435 670 435 435 670 850 435 435 670 850 420 420 640 820 405 630 790 333 490 620 270 270 390 390 507 IL2 2 min. (mA) tan 100 Hz Z 100 kHz () ORDERING CODE MAL2150....... 30 63 33 47 68 100 35 53 75 109 38 55 83 118 35 77 116 34 50 110 21 30 30 43 63 0.24 0.24 0.20 0.20 0.20 0.20 0.16 0.16 0.16 0.16 0.14 0.14 0.14 0.14 0.12 0.12 0.12 0.12 0.12 0.12 0.10 0.10 0.10 0.10 0.10 0.25 0.13 0.25 0.25 0.13 0.10 0.25 0.25 0.13 0.10 0.28 0.28 0.14 0.11 0.30 0.15 0.12 0.48 0.24 0.19 0.65 0.65 0.38 0.38 0.29 95311E3 95301E3 95411E3 95412E3 95401E3 95402E3 95511E3 95512E3 95501E3 95502E3 95611E3 95612E3 95601E3 95602E3 95011E3 95001E3 95002E3 95111E3 95101E3 95102E3 95812E3 95811E3 95801E3 95802E3 95803E3 ADDITIONAL ELECTRICAL DATA PARAMETER Voltage Surge voltage for short periods Reverse voltage for short periods Current Leakage current Inductance Equivalent series inductance (ESL) Resistance Equivalent series resistance (ESR) at 100 Hz Revision: 19-Jan-15 CONDITIONS VALUE IEC 60384-18, subclause 4.14 IEC 60384-18, subclause 4.16 Us 1.15 x UR Urev. 1 V After 2 min at UR IL2 0.01 x CR x UR Typ. 16 nH Calculated from tan max. and CR (see Table 4) ESR = tan /2 f CR Document Number: 28304 3 For technical questions, contact: aluminumcaps1@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 Not Recommended for New Designs, Use 150 CRZ 150 CLZ www.vishay.com Vishay BCcomponents DISSIPATION FACTOR (tan ) CAPACITANCE (C) 1.2 100 C C0 Curve 1: 10 V Curve 2: 63 V tan tan δ 1 1.0 1 2 10 2 1.0 2 1 2 1 0.9 Curve 1: 10 V Curve 2: 63 V 1 0.8 0.1 -60 -40 -20 0 20 40 60 80 100 Tamb (°C) C0 = capacitance at 20 °C, 100 Hz -60 120 -40 -20 0 20 40 60 80 tan δ0 = typical tan δ at 20 °C, 100 Hz 100 12 Tamb (°C) Fig. 6 - Typical multiplier of dissipation factor (tan ) as a function of ambient temperatures Fig. 5 - Typical multiplier of capacitance as a function of ambient temperatures EQUIVALENT SERIES RESISTANCE (ESR) IMPEDANCE (Z) 10 1000 ESR ESR0 Curve 1: 10 V Curve 2: 63 V 2 UR = 10 V Curve 1: case code 0810, 470 µF Curve 2: case code 1010, 680 µF Curve 3: case code 1014, 1000 µF Z (Ω) 100 1 1 10 1 1 2 2 3 1 0.1 0.1 10 1 10 2 10 3 10 4 10 1 10 5 f (Hz) 10 2 10 3 10 4 10 5 f (Hz) Tamb = 20 °C ESR0 = typical at 20 °C, 100 Hz Fig. 7 - Typical multiplier of ESR as a function of frequency 102 Fig. 8 - Typical impedance as a function of frequency 102 Z (Ω) Z (Ω) 10 10 1 1 0.1 1 2 3 1 2 3 UR = 35 V Curve 1: case code 0810, 100 µF Curve 2: case code 1010, 220 µF Curve 3: case code 1014, 330 µF UR = 63 V Curve 1: case code 0810, 47 µF Curve 2: case code 1010, 68 µF Curve 3: case code 1014, 100 µF 0.1 0.01 0.01 10 1 10 2 10 3 10 4 f (Hz) 10 5 Tamb (20 °C) Fig. 9 - Typical impedance as a function of frequency Revision: 19-Jan-15 10 1 10 2 10 3 10 4 f (Hz) 10 5 Tamb (20 °C) Fig. 10 - Typical impedance as a function of frequency Document Number: 28304 4 For technical questions, contact: aluminumcaps1@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 Not Recommended for New Designs, Use 150 CRZ 150 CLZ www.vishay.com Vishay BCcomponents RIPPLE CURRENT AND USEFUL LIFE CCC206 3.8 3.7 IA IR 3.6 3.5 3.4 3.3 3.2 3.1 3.0 2.8 Lifetime multiplier 2.6 1.0 2.4 1.5 2.0 2.2 3.0 4.0 2.0 6.0 8.0 2 1 1.8 1.6 20 30 1.4 1.2 1.0 0.8 0.5 0.0 60 0 10 0 15 0 20 IA = actual ripple current at 100 kHz IR = rated ripple current at 100 kHz, 105 °C (1) Useful life at 105 °C and IR applied: case code ≤ 1010: 2500 h case code = 1014: 3000 h 40 50 (1) 60 70 80 90 100 110 Tamb (°C) Fig. 11 - Multiplier of useful life as a function of ambient temperature and ripple current load MULTIPLIER OF RIPPLE CURRENT (IR) AS A FUNCTION OF FREQUENCY FREQUENCY (Hz) IR MULTIPLIER UR = 6.3 V TO 25 V UR = 35 V UR = 50 V TO 63 V 100 0.70 0.65 0.60 300 0.80 0.80 0.75 1000 0.85 0.85 0.85 3000 0.93 0.93 0.93 10 000 0.95 0.95 0.95 30 000 0.97 0.97 0.97 100 000 1.00 1.00 1.00 Revision: 19-Jan-15 Document Number: 28304 5 For technical questions, contact: aluminumcaps1@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 Not Recommended for New Designs, Use 150 CRZ 150 CLZ www.vishay.com Vishay BCcomponents TEST PROCEDURES AND REQUIREMENTS TEST PROCEDURE (quick reference) REQUIREMENTS NAME OF TEST REFERENCE Mounting IEC 60 384-18, subclause 4.3 Shall be performed prior to tests mentioned below; reflow soldering; for maximum temperature load refer to chapter “Mounting” Endurance IEC 60 384-18 / CECC 32300, subclause 4.15 Tamb = 105 °C; UR applied; 2000 h Useful life CECC 30301, subclause 1.8.1 Tamb = 105 C; UR and IR applied; case size 10 x 10 x 10: 2500 h case size = 10 x 10 x 14: 3000 h C/C:50 % tan 3 x spec. limit IL2 spec. limit no short or open circuit total failure percentage: 1 % Shelf life (storage at high temperature) IEC 60 384-18/ CECC 32 300, subclause 4.17 Tamb = 105 °C; no voltage applied; 1000 h after test: UR to be applied for 30 min, 24 h to 48 h before measurement For requirements see “Endurance test” above Revision: 19-Jan-15 C/C:± 5 % tan spec. limit IL2 spec. limit UR = 6.3 V; C/C: ± 25 % UR 10 V; C/C: ± 20 % tan 2 x spec. limit IL2 spec. limit Document Number: 28304 6 For technical questions, contact: aluminumcaps1@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 Legal Disclaimer Notice www.vishay.com Vishay Disclaimer ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE. Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other disclosure relating to any product. Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special, consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular purpose, non-infringement and merchantability. Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular product with the properties described in the product specification is suitable for use in a particular application. Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed therein. Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining applications or for any other application in which the failure of the Vishay product could result in personal injury or death. Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners. Revision: 13-Jun-16 1 Document Number: 91000