Faults and Events Recorder RZ-40

advertisement

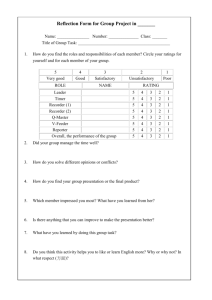

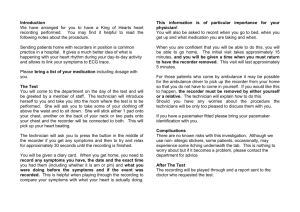

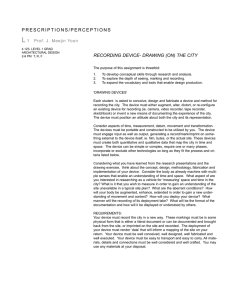

Approved by PSE Faults & Events Recorder RZ-40 Faults Recording and Evaluation System ET-Expert The essence of the problem When operating electrical power engineering equipment a correct decision-making process in fault and emergency conditions and their later analysis is an essential factor. The realization of these essential functions requires an application of recorders and IT systems supporting the operators' and experts' work. While it is true that modern microprocessor equipment has its own faults and events recorders, however, their functionality is limited with regard to individual software, transmission protocols, time synchronization etc. Moreover, the recorders integrated with electrical power engineering automatics equipment fulfil only a supplementary function what limits their functionality by design. Therefore on the objects where it is essential to make fast and correct running decisions it is necessary to use independent, dedicated recording equipment connected in a coherent recording system. The dedicated records increase reliability of the data, have an optimally selected list of recorded signals, better parameters and, what is very important, make these signals and runs that are most interesting at a given moment accessible in a fast and unified manner. The recording system provides the integrity of the data from various sources, their arrangement and developed tools enabling a complete analysis of this information on a joint time axis. We are glad to inform you that the faults and events recorder RZ-40 have undergone successfully PSE approval tests as one of not numerous and has been classified in the "A" class what means that it can be used on all the power stations Faults and Events Recorder RZ-40 Fig.1 In-Out Faults Recorder Diagram Fault recorder RZ-40 The faults recorder RZ-40 is a modern multiprocessor electronic device. It can fulfil two basic roles as · · Object signals a faults recorder which collects the data and makes them accessible for the needs of electrical power engineering analysis during fault and emergency conditions, an independent system verifying the operation of protective devices. Binary inputs 3 signals relays Voltage inputs ETHERNET 10/100-BASE/T Current inputs RS-485 Power supply RS 232 Signalling IT Network - GPS receiver - SCADA - Events printer - Modem (RS 232 only) Operator’s panel Local operation RS 232 Local PC New features of RZ-40 Fig. 2 Continuous recording idea from RAM memory to Compact Flash Continous recording A modified algorithm of access to the data is a unique feature of RZ-40. The faults recorder is able to move the data from the RAM buffer to the Compact Flash memory continuously during faults recording at the same time. Since the RAM size is no longer a recording limitation therefore it is possible to achieve recording times amounting to tens-of-seconds (60 sec. in standard). Such a long recordings could be achieved even if recordings concern 16 analogue inputs, 48 digital inputs with sampling frequency of 8kHz. RAM Compact Flash Trends recorder A built-in trends (network parameters) recorder is another new feature. In this case the sampling frequency is significantly less. A break between a record of individual samples can amount from 5ms to 30s and recording times can amount to several hours. The trends recorder enables an analysis of phenomena which are developing in a longer time period. Internal logic states recording In case of the events recorder beside recording the changes of internal states of binary signals it is possible to record internal logic states (e.g. initiation of analogue triggers). It facilitates a fast determination of the reason of triggering the faults recorder from the events list level. Criterion values recording It is possible to record virtual channels in which the values are estimated on the basis of recorded analogue parameters and predefined mathematic formulas (e.g. power, impedance, frequency). Therefore an analysis of protective automatics operation becomes much easier. Test mode In this mode all the recorded data are stored and saved in a separate directory (folder) what distinguishes them from the signals saved during a “normal” operation of the recorder. The test mode enables a fast and safe removal of the data gathered during trial runs. Record locking This function allows to lock the record of signals in situations that do not require to be recorded, keeping all the other functions of the device, such as e.g. current measures or, input signals monitoring). Software A basic software (ET-Manager) is furnished together with the faults recorder; this software allows the user to: · connect with many other faults recorders,, · view, enter and edit setpoints of the faults recorders, · present a current recorder status, input values as well as estimated values, · load and save the recorded data on the disk, · perform ( zoom, trim) a graphic presentation and analysis of recorded runs, · form virtual channels being functions of recorded real channels, · print, export the data to a text file. Advantages Main technical data Recording: Analogue runs Events Trends Virtual values Measuring inputs: Modular structure 16 analogue and 36 digital channels in standard Up to 18 analogue channels Up to 120 digital channels Triggering: Up-slope of binary signal Down-slope of binary signal Exceedance of set instantaneous value Change of effective value of analogue signal Change of value of criterion signal Triggering of other faults recorders Remote triggering Accuracy of the measurement: Sampling frequency 2/4/8/16 kHz (fast) Sampling frequency 1ms...30s (slow) Parallel sampling in each channel Resolution of the data record: 16 bit Accuracy of the measurement 0,5% Time synchronization: external pulses, GPS or time server NTP Measuring range 40A/200A DC 30A/150A AC Data storage and communication: Internal RAM 2MB Memory (disk Compact Flash) up to 2GB Record for files in COMTRADE format Communication ports: RS232, RS485, ETHERNET Access to the data through FTP, Communication protocols: MODBUS RTU, Ethernet (EGD, TCP/IP) · wide selection of triggering criteria, · possibility to enter setpoints and visualization from the operational panel · low power consumption (low load for guaranteed power supply), · advanced, clear and easy-to-operate software, · galvanic separation of input signals, · constant component handling, wide measuring range, · adaptation of inputs to the level of object signals. Faults Recording and Evaluation System ET-Expert based on the faults recorder RZ-40 was awarded during the International Power Industry Fair ENERGETAB 2008! www.energotest.com.pl Faults Recording and Evaluation System ET-Expert The Faults Recording and Evaluation System ET-Expert is a culmination of long-term research and development works performed by Energotest within the issues connected with recording and analysing fault and emergency phenomena in electrical systems. ET-Expert is a combination of: · modern faults and events recorder RZ-40 · unique software packet, the only one on the Polish market, consisting of two modules ET-Analog and ET-History Thanks to this combination a fast and precise record and analysis of fault conditions in electrical power engineering objects is possible. It is a key value of the recording system ETExpert that at the moment of failure or fault condition of electrical power engineering system the operator achieves precisely this information that is needed in a fast and convenient way. The implementation of the system ET-Expert on a concrete electrical power engineering object requires naturally the execution of determined engineering tasks. The first important task includes the preparation of project, in particular, the selection of analogue and binary parameters and values which need to be estimated and recorded. The record triggering criteria and start-up of the whole system connected with entering corrections ensuring an optimal operation of recording system, faults and event analysis in the devices and electrical power engineering network of the object. A schematic and functional structure of the system is illustrated in the figure below. ET-Expert - The complex system idea. System rejestracji i analiz ET-Expert Object Optimal selection of recorded values Appropriate selection of record triggering Software layer Physical layer Modern faults recorders RZ-40 Possibility to achive the data from other sourcers Technical support communication and record transfer time synchronization at the level 50 m s Projects Thanks to the software the system enables to download the records from many independent devices to one central records database and their collective analysis. All the records, overlapped in time, are located in a joint chart, regardless of the fact from which device they come. The records are downloaded from the devices and saved in the records base automatically. On the basis of the records, also automatically, a base of all input signals in the system is formed. It is possible to group the signals according to the affiliation to the selected objects and to search out in the records only these runs that come from an indicated object. References: · Kêdzierzyn-Azoty 220kV Substation – PSE Po³udnie S.A., · Boguchwa³a 220kV Substation – PSE Wschód S.A., · Lubocza 220kV Substation – PSE Po³udnie S.A., · Z¹bkowice 220kV Substation – PSE Zachód S.A., · Siersza 220kV Substation – PSE Po³udnie S.A., · Namys³ów 110kV Substation – TAURON Dystrybucja S.A., · Krapkowice 110kV Substation – TAURON Dystrybucja S.A., · Umuahia 132kV/332kV Substation – Nigeria, · 110kV/6kV GST3, GST6, GST7 Substations in Arcelor Mittal Steelworks Kraków, · Opole Power Plant – power output of the units Nos. 1, 2, 3 and 4, · £agisza Power Plant – power output, · ¯erañ Heat and Power Plant – 110kV substation, power output, · Siersza Power Plant – 110kV substation and power output of all units Energotest Ltd. Chorzowska 44B, 44-100 Gliwice tel.: +48 32 270 45 18 ; fax: +48 32 270 45 17 sekretariat@energotest.com.pl www.energotest.com.pl Operator Central record base Implementation on the object Multi-access to the data Advanced tools for faults processing: ET-Analog ET-History Start-up Basic features of the system ET-Expert: · all records are stored in one joint, refunded database, · possibility to make the data accessible to many users at the same time, · possibility to get the records from the faults recorder RZ-40 as well as from the other sources (other faults recorders, protective devices), · information selection from the point of view of the analysed phenomenon and not recorder location, · synchronization of recorded runs at the level of 50µs, · advanced options of information filtering, · advanced options of information integration and processing Realization of turn-key system includes: · technical support, · project development, · delivery of devices, · assembly supervision, · Start-up, · personnel trainings, · guarantee and post-guarantee service. System is dedicated for: · transmission and distribution lines of the National Power System, · power plants, heat and power plants · industrial plants