Anechoic Chambers

advertisement

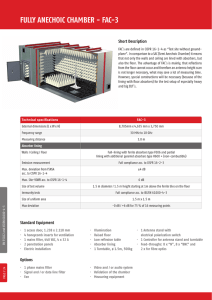

Anechoic Chambers Frankonia Turnkey Solutions Anechoic chambers for EMI/EMS tests according to IEC/EN/ISO/MIL and CISPR standards FRANKONIA The pole position. FRANKONIA Frankonia Group The FRANKONIA GROUP was founded in 1987 as a solution provider for EMC laboratories to meet the increasing demand for highly specialized testing environments for the electronic and automotive industry. With more than 25 years of experience to date, FRANKONIA maintains its leading position in EMC solutions worldwide. Without limitations in capabilities and resources, FRANKONIA develops future-oriented concepts for EMC laboratories, which guarantees an optimal use of resources as well as the best possible customized solutions. tFRANKONIA demonstrates a global presence in cooperation, with a well-structured network of productions, representations and service units. tFRANKONIA strives to be the preferred partner for customized and state-of-the-art solutions. tFRANKONIA provides fundamental knowledge to operate as a complete solution provider. tFRANKONIA implements innovative technologies to enhance the efficiency and improve the outcomes and quality along with customers’ needs. We are proud of our highly specialized team that is putting our customers’ demands into practice. It is our philosophy to improve the products, to realize new ideas, and to complete our product range within our broad scope of business. The fact that FRANKONIA is able to offer complete solutions from the first sketch to the final handover makes FRANKONIA a unique and trustworthy partner worldwide. Frankonia’s authenticity FRANKONIA stands for latest technologies, highest quality, innovative concepts and materials, and reliable solutions. Due to its easy and efficient usability along with its time-saving configuration, Frankonia’s Anechoic Chambers set new standards for innovative and complete EMC testing solutions and offer a real added value to our customers. PAGE 4 Frankonia solutions FRANKONIA as a turnkey solution provider and manufacturer offers a complete range of anechoic chambers, test equipment, instruments, software and accessories. Additionally, our broad range of doors, gates, turntables, monitoring equipment, and positioning devices can be easily integrated to meet our customers’ needs. Frankonia Product Details RF-Shielding Doors and Gates Ventilation, Feed-through and Wave-guide Components Chamber Interior and Electrical Integration Positioning Devices and Accessories Frankosorb® Absorber Technology Chamber Details 6 7 8 9 10 11 12 Frankonia Anechoic Chambers 14 15 16 17 18 20 21 22 24 26 28 PAGE 5 Ultra Compact Chamber - UCC Compact Hybrid Chamber - CHC MIL-Compact Hybrid Chamber - MIL-CHC Automotive Components Testing Chamber - ACTC E-Drive Testing Chamber - EDTC Automotive Vehicle Testing Chamber - AVTC Fully Anechoic Chamber - FAC-3 Semi Anechoic Chamber - SAC-3 Plus Semi Anechoic Chamber - SAC-10 Plus Semi Anechoic Chamber - SAC-10 Impressions RF-ShIelDING RF-Shielding The RF-shielding is Frankonia’s basic system and follows the principles of the Faraday cage. The modular and prefabricated high-quality RFshielding is typically a pan-type shielding made of 2.0 mm galvanized steel that is manufactured to perfection. Frankonia’s shielding is used for all kinds of chambers and shielded rooms, such as control room, amplifier room, or any other room that requires a shielded standard. Standardization matters to ensure the highest shielding quality and to ensure a maximum of functionality and flexibility that adapts to all special conditions. The complete shielding system is designed to match current or even future modifications and requirements in length, width and height. Thanks to the modular and prefabricated system, modifications can be realized in a very short time at lowest costs, minimizing dirt, dust and noise. Frankonia’s contribution to an overall modular system allows for a complete transfer of all kinds of chamber and is therefore a future-proofed solution. Each pan-type shielding module offers an all-side reverse bending in order to achieve a self-supporting static structure, and to bolt the modules correctly. Besides this, it allows for an internal installation of accessories without penetrating the shielding. Frankonia’s shielding is prepared for internal bolting that allows an installation very close to the building surface. In special cases, the shielding can be bolted in reverse from outside. The corners are welded completely in-house and so are assured a perfect connection to the surrounding modules. Frankonia’s shielding is a complete self-supporting construction system with a module standard of 3.0 x 1.2 m that is bolted every 75.0 mm. In between all modules a highly conductive mesh gasket is integrated that ensures a long-lasting shielding quality. Within this system, all Frankonia components, e.g., honeycombs, doors and gates, feed-throughs or filters, offers the same RF quality level. Shielding Attenuation Frequency Shielding Attenuation Field 10 kHz >80 dB Magnetic 100 kHz >100 dB Magnetic 1 MHz >100 dB Magnetic 100 MHz >110 dB Plane wave 400 MHz >110 dB Plane wave 1 GHz >110 dB Plane wave 18 GHz >100 dB Microwave 40 GHz >90 dB Microwave The standard shielding is made of German steel that offers a minimum of 20.0 µm galvanic coating in accordance with DIN 17162/EN 10142 with quality index DX 52 D+Z. The acceptable tolerance is in accordance with DIN/EN 10143 limited and is a minimum 275 g/m2. Steel structure PAGE 6 For static purposes, larger chambers require an additional steel structure support that perfectly meets the shielding fixation, considers a variable static design for different chamber sizes and configurations, and adapts to any specific building characteristics and conditioning layouts. Frankonia’s steel structure is a totally self-supporting system and does not require a connection to the existing building. Furthermore, the steel structure is painted for corrosion prevention with a guarantee of 10 years. Moreover, Frankonia’s steel structure considers country-specific seismic conditions as well as low point loading to the buildings’ concrete slab. Features t Prefabricated and modular shielding modules; incl. steel structure that meets specific static purposes t High-class and identical shielding attenuation for modules, doors, gates and all accessories t Various doors and gates, as well as ramps and platforms t Broad range of ventilation, feed-through, and wave-guide components t Complete interior and electrical integration DOORS AND GATeS Doors and gates The doors and gates by Frankonia are designed according to industrial standards in respect of durability, flexibility and all kinds of safety issues related to the EC machinery directive. General characteristics t Very strong construction for long-lasting stability t RF-shielding realized with an innovative triple row of highly conductive copper beryllium contact springs t The complete triple-row knife-edge system is easily exchangeable t Threshold protection considered to avoid damage t Materials are hot-galvanized for corrosion prevention t All materials used are equal to the shielding to ensure continuous quality t Clever and easy to maintain t MTBF: tested for more than 20,000 opening/closing cycles t Door frame and leaf finish color in RAL 9002, or individual color The triple-row knife-edge system achieves by its innovative design the same shielding effectiveness as the standard shielding modules, and therefore offers continuous quality. This special development allows for complex double-pivoted hinges that stabilize the construction and greatly extend the lifespan of the highly conductive contact springs. Furthermore, this system reduces the maintenance intervals to a minimum, ensuring a stable shielding performance. Gates All gates are available in a fully automatic version without limitation in size, which meets all kinds of EUT and customer-specific requirements. Any version of the sliding gate is perfectly integrated to the shielding and respects the in-plane lining of the wall absorbers. A great advantage of Frankonia’s sliding doors and gates is the fact that all types of pyramid and hybrid absorbers, up to a length of 2.4 m, can be directly installed on the door leaf. Considering the EC machinery directive for safety issues to ensure a user-friendly and safe movement, audio and visible signals automatically turn on while moving. Ramps and platforms Features t Integrated door stopper to limit the door movement t Integrated locking system, interlock and sluice function, prepared for badge or code locking t Triple-row knife-edge system of highly conductive contact springs t Variety of doors and gate, as well as ramps and lifting platforms t Manual, electric or pneumatic latching t Fully automatized movement t Direct absorber lining in-plane with wall absorbers t Designed and built for long-lasting performance and stability t User-friendly and safe use according to EC machinery directive PAGE 7 In addition to all kind of doors and gates, ramps and lifting platforms are available either for manual or automatic movements. A sliding platform completes Frankonia’s range of EUT and personal access solutions for the chambers. As a specialist in customer-specific requirements, there are no limitations in weight and size. VeNTIlATION, FeeD-ThROuGh AND WAVe-GuIDe COmPONeNTS Frankonia as a specialist in RF-shielding and EMC testing chambers provides complementary, standardized and customized products to maintain its position as a turnkey provider. This includes, for instance, connection panel (CP) located in the floor, penetration panels (PP) incl. connectors located on the wall, wave-guide components for liquids, air or gases, fiberglass feed-through components, special cable feed-through via RFI trap, and all kinds of ventilation and air conditioning. Ventilation The ventilation in chambers and shielded rooms is a very important aspect for the comfort of users, but is mainly necessary to ensure a stable temperature during the test procedure, a cooling of the equipment under test (EUT), and is furthermore required in order to reproduce testing conditions. The shielded ventilation can be realized via special filters called honeycomb with a frequency range from 10 kHz up to 18 GHz (40 GHz as option), and can be located individually on the shielding modules that meet any applications, e.g., for air balancing, gas exhaustion, or with a tube adapter. Frankonia’s honeycombs are designed in such a way that local air ducts can be easily mounted. In the scope of Frankonia’s turnkey capabilities, a complete air conditioning unit is available for any kind of chamber size and application. Gas evacuating and protection systems as well as extinguishing systems are available too. Features t Honeycombs up to 18 GHz (40 GHz as option) t Complete AC unit for specific applications and chamber sizes t Additional gas evacuating and protection systems and extinguishing systems available t Turnkey solution Feed-through and wave-guide components Feed-through components of any kind are required to meet RF standards without minimizing the shielding attenuation. Frankonia’s broad range of feed-through components meet all requirements at the highest standards, covering the whole frequency range. All feed-through components are located on penetration panels in order to easily modify the configuration due to future tasks. Replacing a complete penetration panel or even just a connector or feed-through component is very simple. Our standard range of feed-through components includes fiber optics and wave-guide components for compressed air, liquids or gases. Features t Individual penetration panels (PP) t Broad range of feed-through components, e.g., fiber optics t Broad range of wave-guide components, e.g., compressed air, liquids or gases RFI trap PAGE 8 In the case of feeding through a special or non-standardized cable, the RFI trap offers the right characteristics. It is designed as a drain siphon mountable on a penetration panel. Frankonia’s RFI trap is filled with copper granulates that ensures the right conductivity, and allows a continuous cable installation without an interface, e.g., connector. Features t Non-standardized cable feed-through t High conductivity ChAmbeR INTeRIOR AND eleCTRICAl INTeGRATION Chamber interior Frankonia’s shielded rooms and chambers of every kind provide an appealing internal finish. This includes an adapted inner lining for walls and ceilings that can be made with almost every material our customers desire, for instance, glass, plasterboard, PVC or stainless steel. The floor is designed as a false floor that is adjustable in height in order to ensure a minimum space for all necessary ducting. The standard version allows a load of 500 kg/m2, but is almost without limitation according to customers’ requirements. In the case of a semi-anechoic chamber, a ground plane of 2.0 mm made of hot-galvanized steel is installed on the false floor that is perfectly connected to the shielding modules on the walls. In order to support any kind of EUT weights, Frankonia has special solutions to support heavyweight EUT’s, even taking into account more than 80.0 tons. Inside a fully anechoic chamber the requirement is different, and a lifted floor made of wood or plastic is necessary. In this case, the lifted floor can be realized for the whole surface, as a catwalk in certain parts of the chamber, or as free walkway around the front of the absorbers. Features t Internal cladding with various materials possible t False floors and heavyweight floors without limitations in weight t Ground plane for SAC or low-reflective lifted floors for FAC available electrical integration The complete electrical integration for each chamber is designed according to EU safety standards and is prepared as an upgradable solution that allows future modifications. In its standard configuration, an electrical distribution box with MCBs and RCDs, illumination with halogen or LED lights, connection panels for the false floor, and an emergency panic button incl. a battery buffered emergency light are considered. Depending on which absorber lining is selected, Frankonia’s electrical distribution box is accessible from inside or outside, and ensures at all times a user-friendly control. All our lights are optionally available with a lamp lifter in order to change the lighting situation or to change bulbs. Along with our white-colored absorbers and their ability to reduce possible reflections, the quantity of lights can be configured to a minimum and offer optimum lighting conditions. In order to provide the necessary power and data line connections for the EMC testing procedures, Frankonia’s connection panels can be placed in the false floor and individually configured with power outlets and connectors. Additional to the connection panels in the floor are the penetration panels located at the walls. Furthermore, a complete range of power line, data line, and signal line filters are available, too. Frankonia’s specially designed ducting and electrical engineering ensures the shortest cable length and highest flexibility for future modifications, as well as a cost-effective and state-of-the-art integration. PAGE 9 Features t Complete and integrative electrical installation t Upgradable for future tasks t Optimum lighting conditions with halogen or LED lights; lamp lifter as option t Connection panel (CP) for the false floor with individual configurations t Penetration panels (PP) for the walls with individual configurations t Complete range of power line, data line, and signal line filters t Turnkey solution POSITIONING DeVICeS AND ACCeSSORIeS To complete our product range for EMC testing chambers, Frankonia offers a variety of innovative positioning devices and accessories required in modern testing facilities. Positioning devices t Turntables (FTM) and dynamometer from our partners t Automotive powertrain test components t Antenna stand for manual use (FSM) with polarization switch (FPD) t Antenna mast for automatic use (FAM) t Positioning controller (FC) t Frankonia’s customizable software Accessories t Low reflective testing table in accordance with CISPR 22 (FTT) t Grounded testing table in accordance with CISPR 25 (FGT) t Shielded audio system (FAS) t Shielded camera system (FMC) t Recorder for audio and video signals t Optical transmitters t Feed-through components t Wave-guide components More details are available in the separate brochure ‘Accessories for Anechoic Chambers’. PAGE 10 Furthermore, the turnkey capabilities of Frankonia also encompass testing equipment for emissions and immunity tests. This includes a broad range of antennas, pre-amplifiers, broadband RF power amplifiers, software, GTEM cells, striplines, open/closed TEM cells, and receivers. With our own range and that of our partners, Frankonia can serve all demands in EMC test equipment. FRANKOSORb® AbSORbeR TeChNOlOGy Frankosorb® unique absorber technology The Frankonia’s Frankosorb® absorber technology combines a variety of high-performance standards in a single solution. Due to its unique method, Frankosorb® technology is available either as a hybrid solution in combination with ferrite absorbers, or as a standalone pyramid solution with a length up to 2.4 m. The most important advantage of the Frankosorb® long pyramid absorbers is the covering of the whole frequency range so that additional ferrite absorbers are unnecessary. Key facts t Long-lasting absorber performance and stability t Non-combustible according to DIN 4102 Class A2, or t Non-inflammable according to DIN 4102 Class B1 and B2 t High power handling absorbers A2 absorbers: 2 kW/m2 or 850 V/m (continuous duty); 3.5 kW/m2 or 1,150 V/m (intermediate power) B1/B2 absorbers: 1 kW/m2 or 600 V/m (continuous duty); 2.6 kW/m2 or 1,000 V/m (intermediate power) t High absorption capability t Humidity-proof t Proven performance characteristics ensure reproducible results t Guaranteed performance for a minimum of 10 years t Damage-proof t No dirt, carbon smell or dust t Easy to clean and washable t Clean room classification according to ISO 14644-1 Class 5 t No aging or drooping t Space-saving and stackable floor absorbers t Easy installation without using glue or other harmful substances t White coloring that improves the illumination level t Easily removable, fixation either by screw or hanging type Due to the stable performance characteristics and its unique non-combustible character, a safe environment and EUT protection can been assured, which also leads to a constant and long-lasting testing quality. Aligned with customers’ requirements, the Frankosorb® absorbers are available in several configurations that achieve a cost-effective and high-performance solution. Thus, Frankonia’s chambers together with the Frankosorb® absorber technology offer the best choice for long-term investments. PAGE 11 Frankosorb® absorber types Pxxx Pyramid absorbers in thin-film technology, available in 450, 600, 900, 2,000, 2,200 and 2,400 mm length PFxx Pyramid foam absorbers Hxxx Hybrid absorbers in thin-film technology, available in 450, 600 and 1,000 mm length HFxx Hybrid foam absorbers F006 Ferrite absorbers ChAmbeR DeTAIlS Honeycomb Honeycomb with fan Steel structure RF-shielding Hybrid absorbers up to 40 GHz Ferrite absorbers 30 MHz to 1 GHz LED Illumination Video system Power-, data-, and signal line filters PAGE 12 Electric distribution box RF-shielded door Ramp Penetration panel (PP) Raised floor Turntable Ground plane Connection panel (CP) Antenna mast PAGE 13 Cable duct ulTRA COmPACT ChAmbeR - uCC Frankonia’s ultra compact chamber solution at 1.0 m measuring distance The UCC is Frankonia’s alternative solution to the GTEM cell for pre-compliance testing as well as for research and science purposes. The most important advantages of the UCC is that the test engineer is able to enter the chamber, which allows for an easier, better and even larger EUT setup. The ultra compact chamber solution is designed for pre-compliance radiated emission and immunity tests, conducted tests, and pre-compliance tests for automotive components by the CISPR 25 method. uCC Technical specification External dimension (L x W x H) 4.280 m x 3.080 m x 2.550 m Frequency range 150 kHz to 18 GHz (option 40 GHz) Absorber lining Walls and ceiling Full lining with ferrite absorbers; partial lining with Frankosorb® hybrid absorbers HF300 Floor Movable ferrite absorbers between antenna and EUT PAGE 14 uCC - Performance Emission test (EMI) Pre-compliance by the CISPR 25 method Measuring distance 1.0 m Immunity test (EMS) Pre-compliance by the method IEC/EN 61000-4-3 and DIN/ISO 11452-2 Uniform area 0.5 m x 0.5 m Measuring distance 1.0 m Deviation FU (80 MHz to 18 GHz) 0 dB/+6 dB at 100 % of 4 measuring points Features t Alternative to GTEM cell t Radiated emissions (EMI): Pre-compliance by the CISPR 25 method t Radiated immunity (EMS): Pre-compliance by the IEC/EN 61000-4-3 and DIN/ISO 11452-2 method t Compact chamber design and adapted hybrid absorber lining with Frankosorb® t Turnkey solution COmPACT hybRID ChAmbeR - ChC Frankonia’s compact hybrid chamber solution at 3.0 m measuring distance The CHC is Frankonia’s optimal solution for both pre-compliance emission tests and full compliance immunity tests at 3.0 m measuring distance. The most important advantage of the CHC is the upgradability from semi-anechoic chamber with ground plane to fully anechoic chamber with absorbers on the ground. ChC Technical specification External dimension (L x W x H) 7.355 m x 3.755 m x 3.300 m Frequency range 30 MHz to 18 GHz (option 40 GHz) Absorber lining Walls and ceiling Full lining with ferrite absorbers; partial lining with Frankosorb® hybrid absorbers H450 Floor Movable hybrid absorbers between antenna and EUT; optional configuration for fully anechoic chamber Emission test (EMI) Pre-compliance by the method CISPR 11, CISPR 14-1, CISPR 16-2-3, CISPR 22, CISPR 32 (semi-configuration) Measuring distance 3.0 m Chamber validation According to CISPR 16-1-4 Quiet zone (semi configuration) ø 1.2 m; height 2.0 m Quiet zone (fully configuration) ø 1.2 m; height 1.0 m Immunity test (EMS) Full compliance according to IEC/EN 61000-4-3 Uniform area 1.5 m x 1.5 m Measuring distance 3.0 m Chamber validation According to IEC/EN 61000-4-3 Deviation FU (80 MHz to 18 GHz) 0 dB /+6 dB at 75 % of 16 measuring points Features t Radiated emissions (EMI): Pre-compliance by the methods of CISPR 11, CISPR 14-1, CISPR 16-2-3, CISPR 22, and CISPR 32 (semi configuration) t Radiated immunity (EMS): Compliance according to IEC/EN 61000-4-3 t Compact chamber design and adapted hybrid absorber lining with Frankosorb® t Upgradability to a fully anechoic chamber t Turnkey solution PAGE 15 ChC - Performance mIl COmPACT hybRID ChAmbeR - mIl-ChC Frankonia’s compact hybrid chamber solution at 1.0 m measuring distance according to MIL-STD 461F The MIL-CHC is Frankonia’s solution for radiated emission and immunity tests at 1.0 m measuring distance. The compact hybrid chamber solution is designed according to MILSTD 461F and includes a test table up to 3.0 m width. mIl-ChC Technical specification External dimension (L x W x H) 4.880 m x 4.880 m x 3.000 m Frequency range 30 MHz to 18 GHz (option 40 GHz) Absorber lining Walls and ceiling Optimized lining with ferrite absorbers; partial lining with Frankosorb® hybrid absorbers H450 Floor Movable absorbers as option Frankonia’s expertise in turnkey projects and the ability to provide solutions fully adapted to customers’ demands allows especially for military testing of heavyweight and large EUT’s. Please ask for more details. mIl-ChC - Performance Emission test (EMI) Compliance according to MIL-STD 461F Immunity test (EMS) Compliance according to MIL-STD 461F Measuring distance 1.0 m PAGE 16 Absorption at normal incidence 80 MHz to 200 MHz ≥6 dB above 200 MHz ≥10 dB Features t Radiated emissions (EMI): Compliance according to MIL-STD 461F t Radiated immunity (EMS): Compliance according to MIL-STD 461F t Compact chamber design and adapted hybrid absorber lining with Frankosorb® t Turnkey solution AuTOmOTIVe COmPONeNTS TeSTING ChAmbeR - ACTC Frankonia’s automotive component testing chamber solution at 1.0 m measuring distance The ACTC is Frankonia’s solution for compliant radiation tests of automotive components according to DIN/ISO 11452-2 and CISPR 25. The standard version of the ACTC is equipped for measurements from 150 kHz to 18 GHz (40 GHz as option) at 1.0 m measuring distance. A permanent plug-in contact strip is installed between the absorbers to ensure the electrical connection of the test table to the shielding, and includes the test table as required according to CISPR 25. The most important advantage of the ACTC is the compact chamber size and its optimum functionality which fulfills compliance requirements. ACTC Technical specification External dimension (L x W x H) 6.380 m x 5.480 m x 3.750 m Frequency range 150 kHz to 18 GHz (option 40 GHz) Measuring distance 1.0 m Absorber lining Walls and ceiling Optimized lining with ferrite absorbers; partial lining with Frankosorb® hybrid absorbers H450 Floor Movable absorbers as option; ground plane as option Emission test (EMI) Full compliance according to CISPR 25 (ALSE requirements) Immunity test (EMS) Full compliance according to DIN/ISO 11452-2 (ALSE requirements) Features t Radiated emissions (EMI): Compliance according to CISPR 25 t Radiated immunity (EMS): Compliance according to DIN/ISO 11452-2 t Compact chamber design and adapted hybrid absorber lining with Frankosorb® t Broad range of accessories t Turnkey solution PAGE 17 ACTC - Performance e-DRIVe TeSTING ChAmbeR - eDTC Frankonia’s e-drive testing chamber solution for powertrain components and systems related to hybrid, electric, fuel cell and battery drive systems The EDTC is Frankonia’s fully compliant e-drive and powertrain testing chamber solution that is designed for EMC components and system testing for all types of hybrid, electric, fuel cell and battery drive systems. The term powertrain describes the main components that generate power and deliver it to the road, water or air. With its innovative concept and its optimized layout that is based on the ACTC (automotive components testing chamber), the EDTC offers superior conditions for radiation testing according to CISPR 25 and DIN/ISO 11452-2, and remarkable minimized reflections. The chamber is lined with ferrite absorbers and partially lined with Frankosorb® hybrid absorbers to cover a frequency range from 150 kHz to 18 GHz (40 GHz as option) that offers outstanding performance. eDTC - Powertrain testing chamber Technical specification External dimension (L x W x H) 7.880 m x 5.330 m x 4.050 m (exemplary) Frequency range 150 kHz to 18 GHz (option 40 GHz) Measuring distance 1.0 m Basement Vibration-free and non-interacting solid basement (floating slab) Absorber lining Walls and ceiling Optimized lining with ferrite absorbers and Frankosorb® hybrid absorbers Floor Highly conductive floor finish and protection EUT test table According to CISPR 25, incl. drive unit bench and fixation set, and optional mobile absorbers exemplary concept for eDTC 250 kW version 2 7 2 8 1 26 2 9 2 3 2 4 PAGE 18 2 5 Explanation: 1) Dyno 2) Test bench 3) CISPR25 table and setup 4) EMI/EMS test system 5) EDTC chamber and outline slab 6) Control center 7) Automation system and conditioning unit 8) Air conditioning 9) Free space for, e.g., battery load system eDTC - Performance Emission test (EMI) Full compliance according to CISPR 25 Ed. 4 (performance absorption material min. ≥6 dB) Immunity test (EMS) Full compliance according to DIN/ISO 11452-2 (reduction of reflection in the test area min. -10 dB) EDTC - Powertrain component and system configurations Technical specification Version* EDTC-250 EDTC-500 EDTC-800 Power range 250 kW 500 kW 800 kW Torque 550 Nm 1,100 Nm 5,100 Nm Revolution speed up to 8,500 RPM Energy system Dynamic DC-source/DC-sink; up to 1,000 VDC and up to 500 A; common DC-bus with dynamometer drive Conditioning unit Liquid or air cooling and simulation for dynamometer drive and battery simulation from -20 °C up to +100 °C; Liquid cooling and simulation for e-motor (EUT) under test from -20 °C up to +100 °C Test solution Powertrain components and system tests related to hybrid, electric, fuel cell and battery drive systems up to 3,500 RPM Features t Radiated emissions (EMI): Full compliance according to CISPR 25 t Radiated immunity (EMS): Full compliance according to ISO 11452-2 t Complete range of powertrain components and complete systems in one chamber t Cutting-edge test equipment for powertrain components and complete systems t Automatized and customizable software solutions t Reproducible test conditions t Common DC-bus with battery simulation (reduces conversion loss) t Highest quality and performance level up to 1,000 kW at 8,500 RPM t Battery simulator up to 1,000 VDC and up to 500 A t Conditioning unit for permanent temperature control and simulation from -20 °C up to +100 °C t Highest European safety standards t Can be used for non-EMC testing procedures t Modification kit for existing chambers t Compact chamber solution; upgradable for future tasks t Optimized absorber lining with Frankosorb® long-lasting absorbers (Frankonia technology) t EMC knowledge-exchange base and worldwide service t Turnkey solution PAGE 19 *Other configurations available on request AuTOmOTIVe VehICle TeSTING ChAmbeR - AVTC Frankonia’s anechoic chamber solution at 3.0 m measuring distance for vehicle testing The AVTC is Frankonia’s solution for radiated emissions and immunity tests on vehicle and components according to CISPR12 and CISPR25, as well as for ISO 11451-2 and ISO 11452-2. The semi-anechoic chamber is designed to allow vehicle testing up to 5.0 m length (on turntable ø 5.0 m) for measuring distances of 3.0 meters. Moreover, it is easily possible to upgrade the chamber for emission tests according to CISPR11, CISPR14-1, CISPR 16-1-4, CISPR22 and CISPR32, as well as for immunity test according to IEC/EN 61000-4-3. The perfect balance of a compact chamber layout and an optimized absorber configuration, moreover, leads to minimized reflections and offers great performance and flexibility. The frequency range of Frankonia’s automotive vehicle testing chamber is from 26 MHz to 18 GHz (40 GHz as option). Along with our turnkey solution capabilities, the AVTC is available in several configurations and perfectly meets our customers’ needs. AVTC - hybrid chamber Technical specification External dimension (L x W x H) 11.480 m x 9.380 m x 6.000 m Frequency range 26 MHz to 18 GHz (option 40 GHz) Measuring distance 3.0 m Absorber lining Walls and ceiling Full lining with ferrite absorbers; full lining with Frankosorb® hybrid absorbers, a mix of H450, H600 and H1000 Floor Movable absorbers as option Features t Radiated emissions (EMI): Compliance according to CISPR 12 and CISPR 25 (vehicle and components); compliance according to CISPR 11, CISPR 14-1, CISPR 16-1-4, CISPR 22, and CISPR 32 (other EUTs) t Radiated immunity (EMS): Compliance according to DIN/ ISO 11451-2 and DIN/ISO 11452-2 (vehicle and components); compliance according to IEC/EN 61000-4-3 (other EUTs) t Customizable and compact chamber design t Optimized absorber lining with Frankosorb® long-lasting absorbers (Frankonia technology) t Turnkey solution PAGE 20 AVTC - Performance Emission test (EMI) (vehicle and components) Full compliance according to CISPR 12 and CISPR 25 Emission test (EMI) (others) Full compliance according to CISPR 11, CISPR 14-1, CISPR 16-1-4, CISPR 22 and CISPR 32 Quiet zone ø 3.0 m; height 2.0 m Measuring distance 3.0 m Chamber validation According to CISPR 16-1-4 Deviation NSA (30 MHz to 1 GHz) ±4.0 dB (option ±3.5 dB) Deviation SVSWR (1 GHz to 18 GHz) +6.0 dB (option +5.0 dB) Immunity test (EMS) (vehicle and components) Full compliance according to DIN/ISO 11451-2 and DIN/ISO 11452-2 Immunity test (EMS) (others) Full compliance according to IEC/EN 61000-4-3 Uniform area 1.5 m x 1.5 m Measuring distance 3.0 m Chamber validation According to IEC/EN 61000-4-3 Deviation FU (80 MHz to 18 GHz) 0 dB / +6 dB at 75 % of 16 measuring points Fully ANeChOIC ChAmbeR - FAC-3 Frankonia’s fully anechoic chamber solution at 3.0 m measuring distance The FAC-3 is Frankonia’s solution for a fully compliant chamber at 3.0 m measuring distance under free-space conditions. The fully anechoic chamber is designed according to CISPR 16-1-4 as a test site without a ground plane. Without reflections from the floor, a height scan is no longer necessary and measuring time decreases. With its specific requirements for the test site, Frankonia’s FAC-3 is supremely prepared to meet our customers’ demands. Features t Radiated emissions (EMI): Full compliance according to CISPR 16-2-3 t Radiated immunity (EMS): Full compliance according to IEC/EN 61000-4-3 t Customizable and compact chamber design t Optimized absorber lining with Frankosorb® long-lasting absorbers (Frankonia technology) t Turnkey solution FAC-3 Technical specification External dimension (L x W x H) 8.705 m x 4.655 m x 3.750 m Turntable ø 1.5 m with a load of 500 kg Frequency range 30 MHz to 18 GHz (option 40 GHz) Absorber lining Walls and ceiling Full lining with ferrite absorbers; partial lining with Frankosorb® hybrid absorbers H600 Floor Full lining with ferrite absorbers; partial lining with moveable Frankosorb® hybrid absorbers H600 Emission test (EMI) Full compliance according to CISPR 16-2-3 Quiet zone ø 1.5 m; height 1.5 m Measuring distance 3.0 m Chamber validation According to CISPR 16-1-4 Deviation FSNSA (30 MHz to 1 GHz) ±4.0 dB Deviation SVSWR (1 GHz to 18 GHz) +6.0 dB Immunity test (EMS) Full compliance according to IEC/EN 61000-4-3 Uniform area 1.5 m x 1.5 m Measuring distance 3.0 m Chamber validation According to IEC/EN 61000-4-3 Deviation FU (80 MHz to 18 GHz) 0 dB / +6 dB at 75 % of 16 measuring points PAGE 21 FAC-3 - Performance SemI ANeChOIC ChAmbeR - SAC-3 PluS Frankonia’s most versatile fully compliant EMC testing solution at 3.0 m measuring distance The SAC-3 Plus is Frankonia’s most versatile fully compliant EMC testing solution. The semi-anechoic chamber is designed for measuring distances of 3.0 meters on a quiet zone of up to ø 2.0 m for emissions and immunity testing. The innovatively shaped roof, called the dome design, with its optimized absorber layout leads to minimized reflections. The frequency range of the SAC-3 Plus is from 30 MHz to 18 GHz (40 GHz as option) and offers outstanding performance for NSA, SVSWR and FU. Along with our turnkey solution capabilities, the SAC-3 Plus is available in several configurations and perfectly meets our customers’ needs. The SAC-3 Plus has since its introduction been the undisputed leading chamber in its class, and through the innovative concept, the customization and performance, it represents overall an efficient and economic solution that fully satisfies our customers. SAC-3 Plus - hybrid chamber Technical specification Chamber type SAC-3 Plus SAC-3 Plus S SAC-3 Plus L External dimension (L x W x H) 9.680 m x 6.530 m x 6.000 m 8.480 m x 6.530 m x 6.000 m 9.230 m x 6.530 m x 6.000 m Versions Dome or square design Turntable ø 2.0 m with a load of 2.0 tons or 3.0 tons Frequency range 30 MHz to 18 GHz (option 40 GHz) Absorber lining Walls and ceiling Optimized lining with ferrite absorbers; partial lining with Frankosorb® hybrid absorbers H600 and H1000 Floor Moveable Frankosorb® hybrid absorbers H600 for immunity tests; and pyramid absorbers P450 for emission tests PAGE 22 SAC-3 Plus - Performance Emission test (EMI) Full compliance according to CISPR 11, CISPR 14-1, CISPR 16-2-3, CISPR 22 and CISPR 32 Quiet zone ø 2.0 m; height 2.0 m Measuring distance 3.0 m Chamber validation According to CISPR 16-1-4 and ANSI C63.4 Deviation NSA (30 MHz to 1 GHz) ±3.5 dB (option ±3.0 dB) Deviation SVSWR (1 GHz to 18 GHz) +5.5 dB (option +5.0 dB) Immunity test (EMS) Full compliance according to IEC/EN 61000-4-3 Uniform area 1.5 m x 1.5 m Measuring distance 3.0 m Chamber validation According to IEC/EN 61000-4-3 Deviation FU (80 MHz to 18 GHz) 0 dB / +6 dB at 75 % of 16 measuring points ø 1.2 m; height 2.0 m ø 2.0 m; height 2.0 m Features t Radiated emissions (EMI): Full compliance according to CISPR 11, CISPR 14-1, CISPR 16-2-3, CISPR 22 and CISPR 32 t Radiated immunity (EMS): Full compliance according to IEC/EN 61000-4-3 t Adapted steel structure and optimized RF-shielding with dome-shaped roof t Cost-effective and high-performance solution t Advanced absorber lining with Frankosorb® long-lasting absorbers (Frankonia technology) t Compact chamber design t Turnkey solution PAGE 23 Special versions t SAC-5 Plus: A 5.0 m measuring distance is possible with the SAC-5 Plus version. The external dimension is 12.680 m x 7.730 m x 6.000 m (L x W x H) and offers performance identical to the SAC-3 Plus version. t CISPR 12 & CISPR 25: The SAC-3 Plus and SAC-5 Plus offers the possibility to be used for vehicle and components tests according to CISPR 12 and CISPR 25. t Design: The SAC-3 Plus and SAC-5 Plus are available in the innovative dome design, but also in a standard square design with identical performance that can be achieved even in case of building limitations. SemI ANeChOIC ChAmbeR - SAC-10 PluS Frankonia’s Triton Class - a fully compliant EMC testing solution with triple test axes at 10.0 & 3.0 m measuring distance The SAC-10 Plus Triton Class is Frankonia’s fully compliant EMC testing solution. The semi-anechoic chamber is designed for measuring distances of 10.0 and 3.0 meters on a quiet zone of ø 3.0 m. The innovative shape with its optimized absorber layout allows for a simultaneous use of three axes for emission and immunity tests and superior minimized reflections. The SAC-10 Plus Triton Class for EMC testing is a revolution in its class. The benefits of its triple test axes allow our customers to measure all required EMI/EMS procedures without the need to modify the test environment or the test setup. This also includes the test equipment and instruments that can remain connected in the chamber. The antenna and absorber area for each procedure specifically moves to the test scenario either in manual, semi-automatized or fully automatized mode controlled by Frankonia software. Thus, the quality of EMC testing remains at a constantly high level, the testing time decreases, and malfunction and damage is almost impossible. The frequency range of the all-new SAC10 Plus is from 30 MHz to 18 GHz (40 GHz as option) and it offers outstanding performance for NSA, SVSWR and FU. SAC-10 Plus - hybrid chamber Technical specification External dimension (L x W x H) 19.205 m x 12.080 m x 8.325 m (polygonal shape) Turntable ø 3.0 m with a load of 2.0 tons or 3.0 tons Frequency range 30 MHz to 18 GHz (option 40 GHz) Absorber lining Walls and ceiling Partial lining with ferrite absorbers; mix of long and short Frankosorb® pyramid/hybrid absorbers Floor Sliding absorber area for immunity and emission test, individual configured for each test axistests 3 1 2 4 25 2 2 7 PAGE 24 2 6 Explanation: 1) Test axis 1 (NSA 10.0 m & 3.0 m) 2) Test axis 2 (SVSWR & FU) 3) Test axis 3 (FU) 4) Quiet zone ø 3.0 m 5) EUT entrance 6) Control room and Amplifier room 7) Additional space for, e.g., Air conditioning Special versions t CISPR 12 & CISPR 25: The SAC-10 Plus offers the possibility to be used for vehicle and components tests according to CISPR 12 and CISPR 25. Standard configuration and options t Standard: Customized SAC-10 Plus prepared for manual absorber and antenna movement t Option 1: Customized SAC-10 Plus prepared for semi-automatized absorber and antenna movement t Option 2: Customized SAC-10 Plus prepared for fully automatized absorber and antenna movement SAC-10 Plus - Performance per test axis Test axis 1 - emI Emission test (EMI) Full compliance according to CISPR 11, CISPR 14-1, CISPR 16-2-3, CISPR 22, and CISPR 32 Quiet zone ø 3.0 m; height 2.0 m Measuring distance 10.0 m & 3.0 m Chamber validation According to CISPR 16-1-4 and ANSI C63.4 Deviation NSA at 10.0 m (30 MHz to 1 GHz) ±3.5 dB (30 MHz to 80 MHz), ±3.0 dB (80 MHz to 200 MHz) and ±2.0 dB (200 MHz to 1 GHz) Deviation NSA at 3.0 m (30 MHz to 1 GHz) ±2.5 dB (30 MHz to 80 MHz), ±2.0 dB (80 MHz to 200 MHz) and ±1.5 dB (200 MHz to 1 GHz) Test axis 2 - emI Emission test (EMI) Full compliance according to CISPR 11, CISPR 16-2-3, CISPR 22 and CISPR 32 Quiet zone ø 3.0 m; height 2.0 m Measuring distance 3.0 m Chamber validation According to CISPR 16-1-4 Deviation SVSWR (1 GHz to 18 GHz) +5 dB (1 GHz to 18 GHz) Test axis 2 - emS Immunity test (EMS) Full compliance according to IEC/EN 61000-4-3 Uniform area 1.5 m x 1.5 m Measuring distance 3.0 m Chamber validation According to IEC/EN 61000-4-3 Deviation FU (1 GHz to 18 GHz) 0 dB/+6 dB at 100 % of 16 measuring points Immunity test (EMS) Full compliance according to IEC/EN 61000-4-3 Uniform area 1.5 m x 1.5 m Measuring distance 3.0 m Chamber validation According to IEC/EN 61000-4-3 Deviation FU (80 MHz to 1 GHz) 0 dB/+6 dB at 100 % of 16 measuring points Features t Radiated emissions (EMI): Full compliance according to CISPR 11, CISPR 14-1, CISPR 16-2-3, CISPR 22, CISPR 32 t Radiated immunity (EMS): Full compliance according to IEC/EN 61000-4-3 t Compact chamber design with adapted steel structure and optimized RF-shielding in polygonal shape t Advanced absorber lining with Frankosorb® long-lasting absorbers (Frankonia technology) t Efficient and economic test site conditions t Reproducible test procedures at a constant high-performance level t Time saving - no need to modify the test setup t Manual, semi-automatic, or fully automatized absorber and antenna movement t Turnkey solution PAGE 25 Test axis 3 - emS SemI ANeChOIC ChAmbeR - SAC-10 Frankonia’s full compliant and customizable EMC testing solution at 10.0 m measuring distance The SAC-10 is Frankonia’s most versatile fully compliant EMC solution at 10.0 m measuring distance. Due to the high grade of customization that reflects our customers’ demand, the semi-anechoic chamber is adaptable in any dimension and offers several quiet zones, for instance, ø 2.0 m up to ø 5.0 m or even larger. The innovative concept with its impressionable absorber layout achieves exceptional performance for emissions and immunity testing and superior minimized reflections. The fully customizable SAC-10 covers all requirements in today’s and future EMC testing environments, without any difference between EUTs that belong to the road, water or air. Putting specific customers’ demand into practice and the integration of individual applications is without limitation due to our highly specialized and adjustable solution. Furthermore, the chamber is designed for EMC components and complete system testing for all kinds of combustion, hybrid, fuel cell and e-drive system. The frequency range of the SAC10 is from 30 MHz to 18 GHz (40 GHz as option) and offers magnificent performance for NSA, SVSWR and FU. SAC-10 Technical specification Chamber type* SAC-10-2 External dimension (L x W x H) 21.080 m x 13.730 m x 8.550 m SAC-10-3 SAC-10-4 SAC-10-5 21.680 m x 13.730 m x 8.550 m 22.580 m x 15.980 m x 9.000 m 23.480 m x 16.580 m x 9.000 m Absorber configuration Frankosorb® long pyramid absorbers, or as hybrid configuration to reduce the external dimension Turntable ø 2.0 m Turntable Range from 0.3 tons up to 80.0 tons Frequency range 30 MHz to 18 GHz (option 40 GHz) ø 3.0 m ø 4.0 m ø 5.0 m Absorber lining Walls and ceiling Optimized lining with Frankosorb® pyramid absorbers P2200 and P2400, or as a hybrid configuration with Frankosorb® hybrid absorbers H1000 in case of building size limitations Floor Moveable Frankosorb® hybrid absorbers H600 for immunity tests, and pyramid absorbers P450 for emission tests *Chamber type and size adjustable according to customers’ specific requirements PAGE 26 Special versions t Hybrid configuration: In case of building size limitations and the renounce of the advantages of long pyramid absorbers, all SAC-10 chambers can be configured as a hybrid solution. t CISPR 12 & CISPR 25: The SAC-10 offers the possibility to be used for vehicle and components tests according to CISPR 12 and CISPR 25 Features t Radiated emissions (EMI): Full compliance according to CISPR 11, CISPR 14-1, CISPR 16-2-3, CISPR 22, and CISPR 32 t Radiated immunity (EMS): Full compliance according to IEC/EN 61000-4-3 t Highly customizable solution for any kind of EMC testing t Limitless integration of individual applications t Adjustable chamber size, characteristic and configuration due to different EUT requirements t Advanced absorber lining with Frankosorb® long-lasting absorbers (Frankonia technology) t Available with long pyramid absorbers or with hybrid absorbers t Specialized for ‘out-of-the-range’ EMC test environments t Turnkey solution SAC-10 - Performance Emission test (EMI) Full compliance according to CISPR 11, CISPR 14-1, CISPR 16-2-3, CISPR 22, and CISPR 32 Quiet zone ø 2.0 m; height 2.0 m Measuring distance 10.0 m & 3.0 m Chamber validation According to CISPR 16-1-4 and ANSI C63.4 Deviation NSA (30 MHz to 1 GHz) ±3.5 dB Deviation SVSWR (1 GHz to 18 GHz) +6.0 dB Immunity test (EMS) Full compliance according to IEC/EN 61000-4-3 Uniform area 1.5 m x 1.5 m Measuring distance 3.0 m Chamber validation According to IEC/EN 61000-4-3 Deviation FU (80 MHz to 18 GHz) 0 dB / +6 dB at 75 % of 16 measuring points ø 4.0 m; height 2.0 m ø 5.0 m; height 2.0 m PAGE 27 ø 3.0 m; height 2.0 m PAGE 28 ImPReSSIONS PAGE 29 FRANKONIA The unique and trustworthy partner for EMC solutions worldwide. Copyright © by Frankonia GmbH | Anechoic Chambers 03-2015 | English Version 5.0 www.frankoniagroup.com FRANKONIA Frankonia EMC Test-Systems GmbH Daimlerstraße 17, 91301 Forchheim Germany Office: +49 (0) 91 91 / 73 666 - 0 Fax: +49 (0) 91 91 / 73 666 - 20 Mail: sales@frankonia-emv.com Frankonia GmbH Industriestraße 16, 91180 Heideck Germany Office: +49 (0) 9177 / 98 - 500 Fax: +49 (0) 9177 / 98 - 520 Mail: info@frankoniagroup.com