THE APPLICATION OF THE HYDRAULIC ANALOGIES TO

advertisement

THE APPLICATION OF THE HYDRAULIC ANALOGIES

TO PROBLEMS OF WO-DIMENSIONAL CO^PHESSIBLE GAS FLOW

A THESIS

Presented to

the Faculty of the Division of Graduate Studies

Georgia School of Technology

In Partial Fulfillment

of the Requirements for the Degree

Master of Science in Aeronautical Engineering

by

John Elmer Hatch, Jr.

March 1949

1<B&

ii

THE APPLICATION OF THE HYDRAULIC ANALOGIES

TO PROBLEMS OF TWO-DIMECTSIONAL COMPRESSIBLE GAS FLOW

Approved:

r

Date Approved by .Chairman

y^txi^g X

ItYf

T

$

•

iii

ACKNOWLEDGMENTS

I wish to express my sincerest appreciation to Professor

H. W. S. LaVier for his valuable aid and guidance in all phases

of the work required for the completion of this project.

I should

also like to thank HE*, R. S. Leonard, of the Engineering Experiment

Station Machine Shop, and Mr, J. E. Garrett, of the Engineering

Experiment Station Photographic Laboratory, for their full cooperation

in the use of their respective facilities. Constructive criticism and

suggestions of the staff of the Daniel Guggenheim School of Aeronautics

greatly helped in the prosecution of the problems involved in this work.

fcr

T&HLE 07 CONTENTS

PAGE

Approval Sheet

*

ii

Acknowledgements

•

ill

L i f t of Figures

v

Summary • « . • • . • . . • • • • » • • • • • • • • # • • • » . . . . . • . • . • . . • • . * • • . . • • • • • • • •

1

Introduction,

1

•

Theory

Equipment

•••»•«

,

••...*••

••••••.•....•....

Procedure

•••*•••••»

Conclusions

BIBLIOGRAPHY..

APPENDIX 1, Figures

'

13

18

Di scus8ion

He commendations

4-

••••••••».,....*

•

••••• 19

»»•

«

,

#.,..

..

„

•••••23

....23

..

25

2?

fi

LIST OF ILLUSTEATIONS

TITLE

PASS BO.

General VI ew of *Vater Channel

28

General View of Water Channel

29

Top View of V a r i a b l e Speed Drive Mechani sm

30

Schematic Diagram of Water Channel

and L i g h t i n g Equipment,

Shock P o l a r Diagrams For

Diamond A i r f o i l T e s t Speeds

, 3I

,

Shock P o l a r Diagrams For

C i r c u l a r Arc A i r f o i l Test Speeds

Shock P o l a r Diagrams..*

..

32

. 33

3^

Diamond A i r f o i l Model

35

C i r c u l a r Arc A i r f o i l Model

36

Model A i r f o i l Angle of A t t a c k

C a l i b r a t i o n Curve

37

V a r i a t i o n of Ware V e l o c i t y With Wave Length For

A S t a t i c Water Depth of One Q u a r t e r of an

Inch

38

A n a l y s i s of R e f r a c t i o n P a t t e r n s Formed By An

Uhdular Hydraulic Jump, and

C a p i l l a r y Waves

39

Flow About C i r c u l a r Arc A i r f o i l , M =1.56

**Q

Flow About C i r c u l a r Arc A i r f o i l . M z 2.34

41

Flow About C i r c u l a r Arc A i r f o i l , Ms 3.28

1+2

Flow About L e n t i c u l a r A i r f o i l , M =3.71

43

Flow About L e n t i c u l a r A i r f o i l , M= 4 . 2 6 . . . .

^it-

Flow About L e n t i c u l a r A i r f o i l , M = 6 . ? 8

45

Flow About Diamond A i r f o i l , M* 2 f 6 3

46

Flow About Diamond A i r f o i l , M =2.47

^7

J+l ST OF ILLUSTBATIONS

TITLE

PASS NO.

Flow About Diamond A i r f o i l , Ifc3.02

^8

Flow About Diamond A i r f o i l , 8 = 3 . 7 2 . . f .

*+9

Flow About Diamond A i r f o i l , M=4.53

50

Flow About Diamond A i r f o i l , M=5.08.

51

V a r i a t i o n of Shock Wave Angle With F r e e

Stream Mach Number For Diamond A i r f o i l

•

52

V a r i a t i o n of Shock Wave Angle With F r e e

Mach Number For Symetrical C i r c u l a r

Arc A i r f o i l

.

,.

53

Diamond A i r f o i l Local Mach Number D i s t r i b u t i o n

For Various F r e e Stream Mach Numbers.

•.

5^

C i r c u l a r Arc A i r f o i l Local Mach Number D i s t r i b u t i o n

For Various F r e e Stream Mach Numbers

P r e s s u r e C o e f f i c i e n t For riamond

A i r f o i l a t M s K5%.*.*,.,

s

P r e s s u r e C o e f f i c i e n t For C i r c u l a r

Arc A i r f o i l a t M - ^ . 2 6 . . . . . .

s

,

55

56

57

THE APPLICATION OF THE HYDRAULIC ANALOGIES

TO PROBLEMS OF TtfO-DIMJSIONAL COMPRESSIBLE GAS FLOW

SUMMARY

A water channel, with a glass bottom, four feet wide and twentyfeet long, was designed and constructed for the purpose of investigating

the application of the hydraulic analogy to problems of two-dimensional

compressible flow,

Two supersonic airfoil profiles were tested at various speeds.

The speed range covered by analogy was from M * #75 to M »•6,0. Pictures

were taken of the wave formations set up by each airfoil model. Pictures

were also taken of the local water depth distribution about the models.

From a study of the flow photographs, and by applying the hydraulic analogy,

an analysis was made of the local conditions about the models.

INTRODUCTION

There is an analogy between water flow with a free surface, and

two-dimensional compressible gas flow.

The analogy may be used for the

investigation of aerodynamic problems in high speed compressible gas flow.

Vtfhere no supersonic or high speed wind tunnels are available, the application of the hydraulic analogy is particularly useful for the study of compressible gas flow problems.

2

Riabouchinsky

f i r s t presented the mathematical "basis for the

hydraulic analogy, and applied the analogy to the i n v e s t i g a t i o n of

2

the flow in a Laval nozzle,

Binnie and Hooker further investigated

the application of the hydraulic analogy by obtaining surveys along

the center of a channel with a c o n s t r i c t i o n .

Entirely satisfactory

agreement between compressible gas flow theory and the hydraulic anal3

ogy was reached.

Srnst Preiswerk, at the suggestion of Dr. J ,

Ackeret, conclusively proved that the methods of gas dynamics can be

applied to water flow with a free surface.

In 19^0 the National

Advisory Committee for Aeronautics constructed a water channel for

the i n v e s t i g a t i o n of the hydraulic analogy to the flow through nozzles

and about c i r c u l a r cylinders a t subsonic v e l o c i t i e s and extending into

the s u p e r c r i t i c a l velocity range.

Reasonable satisfactory agreement

was found between the water flow and a i r flow about similar bodies,

although i t was concluded from t h i s work that accurate q u a n t i t a t i v e

Riabouchinsky, D., Mecanique des f l u l d e s , Conrptes Rendus. t .

195, No, 22, November 28, 1932, pp. 993-999.

2

Binnie, A.M., and S. G. Hooker, "The Plow Under Gravity of an

Incompressible and Inviscid Fluid Through a Constriction in a Horizont a l Channel", Proceedings of the Royal Society. Vol, 159 (London,

England: 1937), pp". 592-608, "

-^Preiswerk, E r n s t . , "Application of the Methods of Gas Itynamics

to Water Hows With Free Surface,"

P a r t I . "Flows with No Energy Dissipation," NAOA TM. No. 93^,

19^0.

Part I I , "Flows with Momentum D i s c o n t i n u i t i e s . " NACA TM. No.9?5.

19^0.

James Orlin, Norman J . Linder, and Jack G. B i t t e r l y , "Applicat i o n of the Analogy Between Water Flow With a Free Surface and TwoDimensional Compressible Gas Flow." NACA TM. No. 1185, 19^?.

3

Results would require additional i n v e s t i g a t i o n s , "both theoretical and experimental.

North American Aviation Incorporated recognized the posslbil-«

i t i e s of extending experimental compressibility research by means of the

hydraulic analogy, and in 19^+6 constructed a water channel i n which the

water remained stationary and the t e s t models moved through the water. I t

was indicated by North American Aviation Incorporated that with accurate

equipment, q u a n t i t a t i v e as well as q u a l i t a t i v e r e s u l t s could "be expected

from water channel experiments.

The hydraulic analogy offers a convenient and inexpensive way of

i n v e s t i g a t i n g two-dimensional compressible gas flow of phenomena occurring

in a i r a t speeds too high for visual observation.

By means of the water

channel, the two-dimensional flow in a i r at high Mach numbers can be simulated to low speeds, and the r e s u l t s may be easily photographed,

The advantages of using the hydraulic analogy for i n v e s t i g a t i n g

problems of high speed aerodynamics may be summarized as follows:

(1) Cost i s low compared with wind-tunnel or free f l i g h t t e s t s .

(2) Visual observation of flow in the transonic region i s p o s s i ble since the t e s t model can pass through the sonic range with r e l a t i v e

slowness and s t i l l avoid choking phenomena.

(3) Various features of the flow such as shock wave formation,

v o r t i c e s , and turbulence, may be observed and photographed.

(^) High supersonic Mach numbers are simulated at speeds of a

few feet per second.

Bruman, J..E., "Application of the Water Channel Compressible Gas

Analogy." (North American Aviation Incorporated Engineering Report. No.

ttA-^'M-8, 19^7). ~

THEORY

1

The t h e o r y of t h e h y d r a u l i c analogy a s g i v e n "by P r e i s w e r k

w i l l be

reviewed h e r e .

The "basic assumptions made i n the mathematical development of t h e

h y d r a u l i c analogy a r e :

(1) The flow i s i r r o t a t i o n a l .

(2) The v e r t i c a l accelerations a t the free surface are negligible

compared to the acceleration of g r a v i t y .

By t h i s assumption the pressures

a t any point i n the f l u i d depend on only the height of the free surface

above that p o i n t .

(3) The flow i s without viscous l o s s , and i s uniform along any vertical line.

Throughout the following discussion of the development of the hydraul i c analogy the symbol dQ represents the t o t a l head (water depth for V = 0 ) ,

while the symbol d represents any water depth in the flow f i e l d .

discussion of the compressible gas equations the symbols T a o

represent values in the undisturbed gas, and T, P

in the disturbed flow f i e l d .

In the

, and p

and p represent values

Other symbols used are as follows:

L i s t of Symbols

c

Specific heat a t constant pressure

"O

cy

Specific heat a t constant volume

0

Adiabatic gas constant, r a t i o of c to c of gas

P

v

Preiswerk, E r n s t . , "Application of the Methods of Gas Dynamics to

Water Hows *fith Free Surface."

Part I . "Plows With No Energy Dissipation," KACA TM Ho. 93^.

19^0.

5

T

Absolute temperature of gas

^

Mass density of gas

p

Pressure of gas

h

Enthalpy or t o t a l heat content

q

Dynamic pressure of gas

(j*

Surface tension of l i q u i d

P

Pressure coefficient

X

Viscosity of l i q u i d

a

Speed of sound in gas

a*

C r i t i c a l v e l o c i t y . (Velocity a t which M s i ) .

V

Velocity of flow

d

Water depth

M

g

Mach number, stream value unless otherwise indicated

(V for gas; V for water)

a

gd

Acceleration of gravity

P

Compressibility factor

x,y

Rectangular coordinate axes

u,v

Components of velocity in x and y d i r e c t i o n s , respectively

$

Velocity potential i n two-dimensional flow

\

Wave length of surface waves i n f l u i d

U

Velocity of propagation of surface waves i n fluid

R

Reynolds number

p>-p

(L£?)

{M. )

u v Nondimensional velocity components i n x and y d i r e c t i o n s , r e s p e c t i v e l y . (Reference velocity a*; in hydraulic jump a j , the c r i t i c a l

velocity "before the jump, u" u, T v)

a*

a*

Subscripts

No subscript

any value of variable

o

value at stagnation (V= 0)

I

0

l o c a l v a l u e of v a r i a b l e ; v a l u e a t s u r f a c e of model,

a t channel w a l l s , o r I n f i e l d s of flow

s

value i n undisturbed

max

maximum v a l u e of v a r i a b l e

x

p a r t i a l d e r i v a t i v e w i t h r e s p e c t to x

streams

i e (L*$£ ' $ -d£

y

p a r t i a l d e r i v a t i v e with r e s p e c t to y

1

Conditions b e f o r e t h e h y d r a u l i c jump

2

C o n d i t i o n s a f t e r t h e h y d r a u l i c jump

The development of the analogy between t h e flow of water w i t h

a f r e e s u r f a c e and t h e flow of a compressible g a s may be o b t a i n e d by

s e t t i n g up the energy e q u a t i o n s f o r the two f l o w s .

For water* t h e energy e q u a t i o n g i v e s

V2

=

2g(d r t -d)

f

max

&

and

o

I n a g a s t h e energy e q u a t i o n g i v e s

^2

Z

Vmax =

2

&% ( T 0 - T )

an d

/2gcA

3y e q u a t i n g the r a t i o of J

f o r w a t e r to t h e r a t i o of X-

T

max

g a s i t i s seen t h a t

dQ

- d

TQ

f°r

- T

or

O

0

i- - JL

d

o

It is seen, therefore,

*o

that the ratio of the water depth corresponds

to the ratio of the gas temperatures.

7

By a comparison of the equations of continuity for the gas and the

liquid a further condition for the analogy may he derived.

The continuity equation for water i s

3jM)+

&x

£l2&

d y

z 0

For the two dimensional gas flow the equation of continuity i s

$bU4*dkJL

d x

=o

tfy

I t i s seen that the continuity equations of the two flows have the

same form, and from the two equations a further condition for the analogy may he derived

JL* t

a0 "TT

This r e l a t i o n s h i p shows that the r a t i o of the l o c a l density (* to

stagnation d e n s i t y ^ i s analogous to the r a t i o of the local depth d to

the stagnation depth d «

dimensional.

I t i s assumed that the flow i s steady and two

For the liquid flow i t i s assumed that the flow i e steady

and "bounded by a free surface on the top and a f l a t surface on the hot torn,

and that the l i q u i d i s incompressible^

I t has he en shown that the water depth i s analogous both to the

mass density of the gas and to the temperature of the g a s .

These relation-

ships can only e x i s t i f an assumption i s made i n regards to the nature of

the g a s .

The analogy requires that for the compressible gas, T - 2 .

r e l a t i o n s h i p i s shown as follows:

For adiahatic gas flow

/_

£.= (w_Y"

This

8

Since t h e h y d r a u l i c analogy r e q u i r e s t h a t * » jfc and T - d_ i t

X

obvious t h a t d o

d

5

T

o

o

is

d

o

( & )*w and t h e equation i s s a t i s f i e d only when f o

'

From t h e a d i a b a t i c r e l a t i o n

» = <£)!r

Po

?o

i t i s seen t h a t , s i n c e 0 = 2 ,

£ p *o

(i )

The d i f f e r e n t i a l

d

2

o

equation f o r the v e l o c i t y p o t e n t i a l of t h e w a t e r

lZ>-fi)+l,<>-g>^&-<>

The d i f f e r e n t i a l

e q u a t i o n for t h e v e l o c i t y p o t e n t i a l of a two

dimensional compressible gas flow i s

6YKX (i-4?)+d>

a? ' iyr (l-£)-24

<xz/

c

V

The two e q u a t i o n s become i d e n t i c a l when

£d

wI^

=o

gd 2ga0_

a^

2ghQ

That t h e v e l o c i t y J gd i s t h e v e l o c i t y of p r o p a g a t i o n of

surface

waves (small d i s t u r b a n c e s ) i n shallow water may be shown a s f o l l o w s :

Page

2

g i v e s t h e f o l l o w i n g e q u a t i o n f o r t h e v e l o c i t y of w a t e r

waves under t h e a c t i o n of g r a v i t y and s u r f a c e

V.I? g X

X

2][<ntajih

tlzjr

T

fW

tension:

2 7T d- 7

k

AJ

Inspection of the equation shows that as wave length becomes

great in comparison with the water depth ( i.e. d _^.0, tanh 2 Tt d

X

X

27*d)

A

2

Page, Leigh, I n t r o d u c t i o n to T h e o r e t i c a l P h y s i c s . New York:

D. Van No s t r a n d Co. I n c . , 1935, p.250

9

and i f t h e s u r f a c e t e n s i o n i s equal to z e r o , t h e wave v e l o c i t y 1)6001068

Vr/fJ

Since t h e v e l o c i t y of sound, a, i s the v e l o c i t y a t which small

d i s t u r b a n c e s a r e propagated i n ges flow, t h e r a t i o V f o r

t h e shallow

m

water flow i s analogous to the Mach number V i n the gag flow.

a

The local Mach numbers about the model are determined from

(d

d }

v [; °: * 1*

which i s o b t a i n e d by s u b s t i t u t i n g the equation f o r t h e l o c a l v e l o c i t y

i n the e x p r e s s i o n f o r Mach number*

The p r e s s u r e c o e f f i c i e n t f o r t h e w a t e r flow may be determined

as follows:

For a compressible g a s ^

P

*

- 1

s

^o

- 1

Ps"

When t h e analogous r e l a t i o n s h i p s f o r water a r e s u b s t i t u t e d i n t h e

equation for the pressure coefficient the r e s u l t i n g equation i s

P -F

" c

2* - l

is

d 2 o

1

3

O r l i n , J a m e s , , Norman J . L i n d e r and J a c k G. B i t t e r l y , " A p p l i c a t i o n

of t h e Analogy Between Water Flow w i t h a Free Surface and Two-Dimensional

Compressible Gas Flow," HACA TN, No* 1185, 1 W . p . 8

10

k

For a compressible gas the compressibility factor

1

=

c

is

rT^[ ft*V--.,)* -1]

Since the hydraulic analogy requires that

# - 2 the compressibility

factor for the water flow i s

*« =

i+iM

C

I

2

s

I t may "be noticed that no theory has been presented concerning

shock waves or supersonic flow.

In the hydraulic analogy a compressible shock i n the gas i s

analogous to a hydraulic jump in the water flow.

The hydraulic jump

may he defined as an unsteady motion in which the velocity of flow may

strongly decrease for short distances, and the water depth suddenly

increase.

Hydraulic jumps occur in water whose velocity of flow

i s greater than the wave propagation v e l o c i t y .

Preiswerk developed

the r e l a t i o n s h i p s between conditions in front of the shock wave and

behind the shock wave for the hydraulic analogy.

In developing the

theory the assumption i s made that the water motion i s e n t i r e l y unsteady

which i n d i c a t e s that the water jumps suddenly along a l i n e from the lower

water l e v e l to the l e v e l a f t e r the jump.

The assumptions o r i g i n a l l y

made are also carried through the discussion of the shock wave analogy.

For the water flow without a jump the energy equation holds

V2=

where d

the total head ie a constant.

o

place the t o t a l head d

°2

4

2g(d 0 " d)

LoC. Glt»

After a hydraulic jump has taken

i s smaller than d

°1

, since p a r t of the k i n e t i c

energy of the xvater i s converted into heat, and i s treated as l o s t energy,

For the flow a f t e r the jump the energy equation again applies and now "becomes

2

f9

=

2

23(4

- d)

o2

To solve t h i s equation for d

, the new t o t a l head, use i s made of the

°2

shock polar diagram to determine V , the water velocity behind the shock

wave.

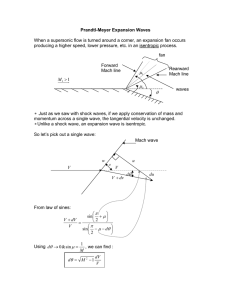

The equation for the shock polar for the hydraulic analogy is

vA/a.-uJfc-u, «/(3,;:^3^~]

By varying the parameter ^r "

and

family of curves will r e s u l t .

solving for v 2

in

terms of

~

a

The curves are similar to the shock

p o l a r s of an i d e a l gas, "but they show one c h a r a c t e r i s t i c difference. For

the maximum velocity "both cases "become c i r c l e s .

However, for water

the c i r c l e passes through the origin while for a perfect gas the c i r c l e

does not pass through the o r i g i n .

The shock p o l a r s for water were con-

structed for the speeds investigated in t h i s t h e s i s find are presented

in Figures 5 anu 6.

In Figure 7 shock polars are drawn for a i r and for water for the

same i n i t i a l flow conditions.

I t may "be seen that for continually de-

creasing shocks the polars approach each other.

The energy l o s s in the flow with hydraulic jumps i s developed

to he

4e =

I-K

~*n

This i s the r e l a t i v e energy converted into h e a t .

However,

for gas the

r i s e i n heat during the shock i s not l o s t energy since the t o t a l heat

12

content remains the game before and after the shock.

energy for water flow are presented by Preiswerk.

Curves of constant

From the carves it

may "be seen that the energy loss is small over a large region. For the

velocities investigated in this thesis the relative loss is less than

one per cent. Because of this small shock loss the analogy between the

two types of flow is still satisfied,

By employing the shock polar diagrams and the equations given

by Preiswerk conditions across a shock wave may be determined*

The various quantities which may be obtained from a shock polar

diagram are illustrated in Figure 7, No further explanation will be

given, since the theory and development of shock polar diagrams is well

covered in appropriate textbooks*

A summary of the analogous relationships is given below.

Two-Dimensional

compressible gas flow

Incompressible liquid flow

(water)

r=2

Temperature Eatio, T,

*o

Water depth r a t i o ,

Density r a t i o ,

Water depth r a t i o ,

£.

d

o

d

d

?o

Pressure r a t i o ,

O

p

r

Square of w a t e r - d e p t h r a d i o / d }

o

V e l o c i t y of sound, a = / p V

fa

Mach number,

Shock wave

V

a

Wave: v e l o c i t y ,

Mach number

Jgd

V

/fr

H y d r a u l i c jump

Liepmann, Hans Wolfgang, and A l l e n E. P u c k e t t , I n t r o d u c t i o n to

Aerodynamics of a Compressible Fluid.(New York: John Wiley and Sons, I n c . ,

1W

p. 53) '

13

EQUIPMENT

In designing the equipment for conducting experiments with the hydraul i c analogy, two methods of approach were a v a i l a b l e .

These methods were:

(1) The model was to remain stationary with the water flowing p a s t

the model,

(2) The water was to remain stationary with the model moving through

the water.

The f i r s t type of channel would necessarily "be the more elaborate,

and therefore, the more expensive.

I t would "be d i f f i c u l t to change Mach

number or to have decelerating flow or accelerating flox*,

The presence of

a "boundary layer on the bottom and sides of the channel would further comp l i c a t e a channel of the f i r s t type.

However, with the model remaining

stationary i t would be easy to measure the water depth ahout the model,

which i s very important i n the hydraulic analogy.

A channel of the second type r e s u l t s i n an easy measurement of

speed and acceleration, and therefore, Mach number.

The big disadvant-

age of t h i s type of channel i s the d i f f i c u l t y of measuring the water depth

about the model, since the model moves r e l a t i v e to the channel.

Taking al] f a c t o r s into consideration, i t was decided to construct

a channel of the second type, Figure 1.

The water channel frame work was made of s t r u c t u r a l steel bolted

together.

The channel i s four

feet wide and twenty feet long.

The

channel bottom i s p l a t e g l a s s one quarter of an inch thick i n two five

foot sections and one ten foot section.

i s located

The ten foot section of g l a s s

a t the " t e s t " end of the channel.

The g l a s s bottom i s sup-

ported by transverse members at t h i r t y inch i n t e r v a l s .

The purpose of

Ik

the glass "bottom i s to provide a smooth surface for the models to s l i d e upon,

and to provide for a method of photographing the flow of water about the

models.

The channel "bottom was maintained to a l e v e l of ,01 inch "by a

screw-jack type device on each of the channel' 8 supporting l e g s .

The ac-

curacy of the channel "bottom l e v e l was determined "by using a surveyor' s

transit.

A drain i s provided at one end of the channel,

The model carriage i s made of steel tubing welded together, and

t r a v e l s the e n t i r e length of the channel on a track which i s located along

each side of the channel, Figure 2„

t i r e d , "ball "bearing wheels.

in a horizontal plane.

The carriage t r a v e l s on four rubber-

Pour additional wheels r e s t r a i n the carriage

Safety stops are provided on the carriage track

to prevent the carriage and model from running off e i t h e r end of the channel.

The carriage i s driven by a r e v e r s i b l e , d i r e c t current motor through

a set of reduction gears and a continuous cable.

19.5 amperes, 2k v o l t s ,

The motor i s rated a t

A d i r e c t current motor i s used to provide a high

s t a r t i n g torque i n order to quickly accelerate the carriage to the desired

speed.

The driving cable i s 3/32 inch diameter conventional a i r c r a f t

s t e e l cable.

The cable goes one end one-half times around the driving

pulley, and i s rigged with about twenty pounds tension.

The speed of the

carriage drive motor i s controlled by a 6.7 amperes, 18 ohm r h e o s t a t .

The

rheostat has a calibrated dial with s e t t i n g s to give carriage speeds from

one to ten feet per second.

By proper operation of the rheostat the car-

riage may be run a t increasing, decreasing, or constant speeds.

After

15

<experimenting with the water channel i t was observed that the d i r e c t current motor did not r e s u l t in constant carriage speeds "below a speed of

one foot per second.

Consequently, a "Speed-Ranger" constant speed

device powered by one-quarter horse power, three phase, a l t e r n a t i n g

current, motor was i n s t a l l e d .

The "Speed-Ranger" device resulted i n

carriage speeds over the range of from .50 feet per second up to one foot

per second.

The "Speed-Ranger" speed control serves as an a l t e r n a t e

drive device since the d i r e c t current motor was found to "be more convenient

for high speed runs, and for accelerating or decelerating runs.

A photo-

graph of the drive mechanises i s shown ir. Figure 3.

An o b s e r v a t i o n p l a t f o r m i s l o c a t e d a t t h e channel t e s t

section.

Mounted on the platform i s a control panel which Includes a l l switches

and controls for operating the water channel.

The control panel and

observation platform are so set up that only one person i s required to

operate the water channel during a t e s t i n g program.

Included on the

platform are mounts for the cameras used to photograph the water flow

about the models.

The arrangement of the equipment for photographing the flow about

the models i s shown schematically in Figure 4.

obtain the flow photographs.

Two cameras are used to

One camera, mounted on the platform floor,

photographs the l o c a l water depth about the models, while the second camera,

mounted on a "boom extending out over the channel, photographs the wave

formation caused "by the models.

As seen in Figure ht the camera used to photograph the flow about

the models i n the horizontal plane p r o j e c t s through a diffusion screen

located approximately four f e e t above the water surface.

A second diffu-

sion screen i s located immediately under the g l a s s i n the area to be

16

photographed.

The l i g h t i n g arrangement consists of a boom spotlight

directed on the model from above and to the rear of the model, and a

large spotlight directed on the diffusion screen above the t e s t section,

Four flood l i g h t s illuminate a cellotex screen located on the floor beneath the channel.

The four flood l i g h t s r e s u l t i n an even l i g h t i n g

effect over the t e s t area,

The spotlights r e s u l t i n the wave formations casting shadows on

the screen d i r e c t l y under the g l a s s , and these shadows are then photographed,

An Eastman Medalist Camera with a s e t t i n g of one four-hundredth

of a second at f: 7,5 lens opening i s used to photograph the wave formations.

The camera shutter was tripped e l e c t r i c a l l y a t the correct time

by a cam device, mounted on the model carriage, a c t i v a t i n g a micro switch

located on the channel track.

The r e s u l t s of using the photographic tech-

nique here described are e n t i r e l y s a t i s f a c t o r y ,

From the development of the theory of the hydraulic analogy i t may

be seen that the water depth d i s t r i b u t i o n about the model i s very important i f a q u a n t i t a t i v e analysis of the flow i s to be made.

To determine

the water depth about the model, a Speed Graphic camera i s used to photograph the water depth d i s t r i b u t i o n i n the v e r t i c a l plane.

The camera i s

mounted on the platform above the water l e v e l to insure no i n t e r f e r r e n c e

from waves between the model and the camera.

by a 500 watt slide p r o j e c t o r .

The model i s illuminated

The projector i s so masked that at the

time the camera i s tripped only the model i s illuminated.

This feature

was found necessary because any extensive side l i g h t i n g i n t e r f e r r e d with

the horizontal flow photographs.

The camera i s tripped by the same switch

and cam arrangement that operates the overhead camera.

The best camera

17

petting was found to be one four-hundredths of a second a t fj 3»? lens

opening*

The a i r f o i l s chosen for t e s t i n g i n the water channel are 5, A, C. A.

a i r f o i l s developed by the National Advisory Comitdttee for Aeronautics, hav1

ing the following designations:

(1) NACA 2S-(50) (03)-(50) (03)

(2) NACA lS-(30)

c i r c u l a r arc a i r f o i l

(03M30) (03) diamond a i r f o i l ,

The designation of the c i r c u l a r arc a i r f o i l i n d i c a t e s that the maximum

thickness of both the upper and lower surface i s located at the f i f t y percent chord point, and that the maximum thickness i s six percent of the

chord length.

The designation of the diamond shaped a i r f o i l shows that

the maximum thickness of the upper and lower surface i s located a t the

t h i r t y percent chord point, and that the t o t a l thickness i s six percent

of the chord.

These p a r t i c u l a r a i r f o i l s were chosen because they are

basic supersonic a i r f o i l s ,

The a i r f o i l models are made of wood.

chord.

Each model has a twelve inch

The models are painted a f l a t white on the bottom and sides while

the top i s painted a f l a t black.

This paint scheme ifas selected to pro-

vide good photographic p r o p e r t i e s for the flow p i c t u r e s .

A single black

l i n e was ruled on each side of the models from the leading edge to the

t r a i l i n g edge.

The l i n e i s used as a reference l i n e in the determination

of the water depth about the models, since the water depth i s scaled from

photographs of the flow in the v e r t i c a l plane.

Figure 8 and Figure 9 show

the model dimensions.

Lindsey, W.F., Bernard N. Daley, smd Milton D, Humphreys, "The

Flow and Force Characteristics of Supersonic A i r f o i l s at High Subsonics Speeds."

U. S. National Advisory Committee for Aeronautics Teclinical Note.No. 1211.

19^7. P . 3 .

18

Since t h e h y d r a u l i c analogy a p p l i e s only to two dimensional flow

,the a i r f o i l models a c t u a l l y s l i d e on t h e g l a s s "bottom of t h e channel to

cause t h e r e q u i r e d flow,

The models a r e a t t a c h e d to t h e c a r r i a g e by

a l i n k a g e a s shown i n F i g u r e 2 .

The a n g l e of a t t a c k of t h e models i s determined by p o s i t i o n i n g

the l e a d i n g edge and t h e t r a i l i n g edge i n r e l a t i o n to t h e channel s i d e s ,

To f a c i l i t a t e the s e t t i n g of each a n g l e of a t t a c k a c a l i b r a t i o n curve

was drawn

g i v i n g t h e d i s t a n c e s of t h e l e a d i n g edge and t r a i l i n g edge

from the channel s i d e s f o r each d e s i r e d a n g l e .

This curve i s p r e s e n t e d

i n H g u r e 10.

^ROCEDUBE

The p r o c e d u r e for model t e s t i n g i n the water channel c o n s i s t e d of

running the two-dimensional a i r f o i l models through t h e water i n t h e chann e l a t predetermined s p e e d s .

The w a t e r depth for a l l t e s t s was one

q u a r t e r of an i n c h w h i l e the a n g l e of a t t a c k of the models i n each case

was zero d e g r e e s .

The time for the c a r r i a g e and model to move a c r o s s

the t e s t s e c t i o n was recorded by an e l e c t r i c timing clock which was

s t a r t e d by a cam d e v i c e on t h e model c a r r i a g e a c t u a t i n g a m i c r o - s w i t c h

l o c a t e d on t h e c a r r i a g e t r a c k .

At the end of the t h r e e f o o t r u n t h e cam

r e l e a s e d t h e m i c r o - s w i t c h and stopped the c l o c k .

The model v e l o c i t y

could then be c a l c u l a t e d .

Simultaneous p i c t u r e s were taken of the wave f o r m a t i o n s set up

by each model and of the l o c a l water d e p t h d i s t r i b u t i o n about the models.

A complete d i s c u s s i o n of p h o t o g r a p h i c t e c h n i q u e i n v o l v e d i s i n c l u d e d i n

t h e p r e v i o u s c h a p t e r on equipment.

19

DISCUSSION

Before t h e h y d r a u l i c analogy may be a p p l i e d to t h e i n v e s t i g a t i o n

of problems of compressible flow, the flow p i c t u r e s must be p r o p e r l y

interpreted.

From an i n s p e c t i o n of t h e flow photographs i n the h o r i z o n t a l

p l a n e a s e r i e s of a l t e r n a t i n g l y dark and l i g h t bands of d e c r e a s i n g i n t e n s i t y may be seen s t a r t i n g a t t h e l e a d i n g e&^e and t r a i l i n g edge of

each model,

A s i m i l a r c o n d i t i o n a l s o e x i s t s a t the s e c t i o n of maxi-

mum t h i c k n e s s of t h e diamond shaped a i r f o i l ,

The problem immediately

a r i s e s a s to which p a r t of the p a t t e r n d i r e c t l y a p p l i e s to t h e h y d r a u l i c

analogy ?

Of major importance i s t h e d e t e r m i n a t i o n of t h a t p a r t of t h e

flow p a t t e r n which r e p r e s e n t s a h y d r a u l i c jump o r shock wave.

Waves on

t h e water s u r f a c e a c t a s l e n s e s i n t h a t they d i v e r t t h e l i g h t r a y s i n

t h e d i r e c t i o n of i n c r e a s i n g w a t e r d e p t h .

Therefore,

the sharp b r i g h t

l i n e s r e p r e s e n t t h a t p a r t of each wave or r i p p l e which h a s t h e maximum

convex c u r v a t u r e .

The d a r k a r e a p r e c e d i n g t h e sharp w h i t e l i n e s r e p -

r e s e n t s t h e remainder of each wave.

I t may be then concluded t h a t a shock

wave i s recorded on t h e photographs a s a white l i n e preceded by a dark

area,

In a d d i t i o n t o , and i n f r o n t of,

g r a p h s show r i p p l e s o r c a o i l l a r y waves.

t h e shock waves t h e flow p h o t o The c a p i l l a r y waves a r e n o t

p a r t of the h y d r a u l i c analogy s i n c e they a r e p u r e l y w a t e r waves and depend p r i m a r i l y on t h e s u r f a c e t e n s i o n of the l i q u i d .

t h e r e l a t i o n of wave p r o p a g a t i o n v e l o c i t y to

depth of one q u a r t e r of an i n c h .

F i g u r e 11

shows

wave l e n g t h f o r a w a t e r

D i s t u r b a n c e s of wave l e n g t h s l e s s than

t h a t corresponding to the minimum w a v e ' v e l o c i t y a r e c a p i l l a r y waves.

The refraction p a t t e r n formed by a hydraulic jump and c a p i l l a r y

waves are shown i n Figure 12.

From these p a t t e r n s a q u a l i t a t i v e study

of the photographs may he made.

I t was found "by North American Aviation Incorporated

t h a t expan-

sion waves in a water channel do not agree with the theory of the hydraul i c analogy, but rather tend to travel a t a constant speed not dependent

on the s t a t i c water depth, or the model speed.

This fact i s "borne out

by an examination of the diamond a i r f o i l flow photographs in the horizont a l plane.

At the point of maximum thickness where an expansion takes

place there i s no d e f i n i t e or consistent p a t t e r n to indicate an expansion

wave.

However,

from the photographs showing the water depth d i s t r i b u -

t i o n about the diamond a i r f o i l a d e f i n i t e l e v e l drop may be seen a t the

change i n section,

Prom the side photographs, then, an expansion wave

may be detected.

A comparison was made between the shock wave angles obtained by

measurement from the flow p i c t u r e s and the shock wave angle as obtained

from the shock p o l a r s for each speed investigated,

A further comparison

was made with the r e s u l t s obtained by using the shock wave charts p r e 2

sented by Lai tone.

The r e s u l t s are given in Figures 25 and 26. I t

may be seen that the three methods of obtaining the shock wave angles

for a given free stream Mach number and semi-wedge angle agree very

closely.

This close agreement i n d i c a t e s that the application of the

Bruman, J . R . , "Application of the Water Channel Compressible Gas

Analogy." North American Aviation Incorporated Engineering Reoort, Ho.

H&-47-87, 1957. '

Lai tone, E.V., "Exact and Approximate Solutions of Two-Dimensional

Oblique Shock Flow." Journal of the Aeronautical Sciences, Vol. 14, Bb.l,

January, 194?, pp. 25-^1.

21

hydraulic analogy i s a useful tool i n the study of

«

shock wave formation.

To insure no d i s t o r t i o n as a r e s u l t of enlarging the flow p i c t u r e s ,

a comparison was made "between contact p r i n t s of each wave and enlargements

of the same wave formation.

No d i s t o r t i o n , as a r e s u l t of enlargement,

was noted.

Curves showing the v a r i a t i o n of l o c a l Mach number about the a i r f o i l

models are presented i n Figure 27 and Figure 28.

The l o c a l Mach number

v a r i a t i o n for each model was calculated from the M* equation^.

I t may be

observed that the local Mach numDer i s a function of the t o t a l head and

the l o c a l water depth.

Since the t o t a l head consists of a velocity

head and a s t a t i c head the shock polar diagrams were employed to find the

water velocity "behind the shock wave, and the s t a t i c head was determined

from the side photographs.

The s t a t i c head was taken as that water depth

where the water l i n e on the model was horizontal.

The local water depth

was obtained "by measurement from the side photographs.

Airfoil theory p r e d i c t s that for a diamond a i r f o i l i n a supersonic

flow a t zero degrees angle of attack the local Mach number remains constant over the forward p a r t of the a i r f o i l up to the point of maximum

thickness, at which time i t increases abruptly to a new value.

From

the curves of l o c a l Mach number d i s t r i b u t i o n for the diamond a i r f o i l

it

may be seen that the l o c a l Mach number i s not constant over the forward

thirty

percent of the a i r f o i l chord, but goes to r e l a t i v e high values

a t the leading edge.

The curve does not change abruptly a t the point of

maximum thickness, as theory p r e d i c t s , but there i s a smooth t r a n s i t i o n

3

Cf Ante,p.10

22

=£rom the lower value to the high value as the expansion takes place.

The l o c a l Mach number then "becomes constant over the remainder of the

airfoil.

The high values of the Mach numbers at the leading edge may "be

explained since in the development of the hydraulic analogy i t was a s sumed that the hydraulic jump took place along a single l i n e , and the

water depth changed abruptly along that l i n e .

Actually, these conditions

did not r e a l i z e since the hydraulic jump required a f i n i t e distance

r e l a t i v e to t i e a i r f o i l i n which to form.

I t therefore appears that

the hydraulic analogy w i l l not give the correct local Mach number d i s t r i b u t i o n immediately following the leading edge for the diamond a i r f o i l .

For the c i r c u l a r arc a i r f o i l an e n t i r e l y different trend of the

l o c a l Mach number curve may be observed.

As for the diamond a i r f o i l ,

the local Mach number goes to a r e l a t i v e high value a t the leading edge.

After the minimum value i s attained the local Mach number increases

over the e n t i r e chord length.

This d i s t r i b u t i o n of local Mach number

i s i n agreement with theory.

An attempt was made to p l o t the l o c a l Mach number d i s t r i b u t i o n

about the models over the range of free stream Mach numbers from .75

to .90.

At these slow speeds the meniscus effect resulted in an e r r a t i c

water depth d i s t r i b u t i o n about the models, and a s a r e s u l t no dependable

data was obtained from the side photographs.

After t h i s condition was

noticed the models were waxed and polished to reduce the surface roughness.

No marked improvement in the water depth d i s t r i b u t i o n was

noted.

I t would seem, then, th&t for slow speed t e s t s deeper water

should be used to reduce the r e l a t i v e magnitude of the meniscus

effect.

23

*COHCLUSIOHS

(1)

The hydraulic analogy o f f e r s a r e l a t i v e l y inexpensive meth-

od of conducting research i n supersonics,

(2)

The water channel i s especially suited for c l a s s room dem-

o n s t r a t i o n of shock wave phenomena.

The r e f l e c t i o n of shock waves

from the channel w a l l s , and the i n t e r s e c t i o n of shock waves may "be

observed as well as the shock waves formed by various shapes.

(3)

With a more a c c u r a t e method of depth measurement more quan-

t i t a t i v e d a t a may be o b t a i n e d ,

(k)

The d e t e r m i n a t i o n of shock wave a n g l e s from t h e flow p h o t o -

graphs for t h e a i r f o i l s t e s t e d agrees very closely with r e s u l t s obtained by a p p l i c a t i o n of t h e o r e t i c a l methods*

(5)

The r e l a t i v e v a l u e of t h e l o c a l Mach number d i s t r i b u t i o n

about the a i r f o i l s t e s t e d a g r e e w i t h t h e o r y .

(b)

A c c u r a t e q u a n t i t a t i v e r e s u l t s w i l l not be o b t a i n e d when

t h e h y d r a u l i c analogy i s a p p l i e d t o t h e study of a i r flow because t h e

w a t e r flow i s analogous to a g a s flow w i t h

.

- 2 , whereas f o r a i r

S Ijfc,

RECOMMESTMIONS

(l)

With t h e p r e s e n t e x c e l l e n t d r i v e mechanism i n s t a l l e d ,

a c c u r a t e model speed i s a s s u r e d .

very

However, t h e d r i v e d e v i c e t r a n s m i t s

a c e r t a i n amount of v i b r a t i o n to the model which c o m p l i c a t e s the flow

photographs by s e t t i n g up e x c e s s i v e secondary r i p p l e s .

To o f f s e t

this

o b j e c t i o n a b l e v i b r a t i o n the model support l i n k a g e should be s t i f f e n e d .

The model i t s e l f

should be made h e a v i e r to h e l p reduce v i b r a t i o n .

(2)

U!he use of fresh water i n the water channel r e s u l t s in

the hydraulic Jump inducing a great number of r i p p l e s ahead of i t self which has no p a r t i n the hydraulic analogy.

By allowing the

water to remain i n the channel over a period of twenty four to forty

eight hours r e s u l t s in clearer wave photographs,

(3)

By further experimentation with the photographic technique

the present large amount of equipment involved could be eliminated

except for the underwater l i g h t s , and the screen r e s t i n g on the floor.

(*4-)

The sides of the model should he wet "before each run

to r e s u l t i n constant meniscus effect,

(5)

For t e s t speeds of l e s s than Mach numher

a water depth

somewhat greater than one quarter of an inch should he used i n the

channel,

25

BIBLIOGRAPHY

i

B i n d e r , R. 0 , ,

F l u i d Mechanics. Hew York: P r e n t i c e - H a l l I n c . , 1 9 ^ 7 . 307 p p .

B i n n i e , A. M., and S.G. Hooker, "The Flow Under G r a v i t y of an Incompressi b l e and I n v i s c i d F l u i d Through a C o n s t r i c t i o n i n a Horizont a l Channel." P r o c e e d i n g s of the Royal S o c i e t y . Vol. 159,

(London, England: 1937), PP. 592-608.

Bruman, J . R., " A p p l i c a t i o n of t h e Water Channel Compressible Gas Analogy."

North American A v i a t i o n I n c o r p o r a t e d Engineering R e p o r t .

No. NA-47-87, W .

E i n s t e i n , H.A, and E.H. B a i r d , " P r o g r e s s Report on the Analogy Between

Surface Waves i n Water and Shock Waves i n a Compressible

G a s . " C a l i f o r n i a I n s t i t u t e of Technology H y d r a u l i c s

L a b o r a t o r y P r o g r e s s Report. No. 5^,19^6.

L a i t o n e , E.V., "Exact and Approximate S o l u t i o n s of Two-dimensional Oblique

Shock Plow." J o u r n a l of t h e Aeroncmtical S c i e n c e s . Vol.

14, N o . l .

Lamb, Horace,

Hydrodynamics. 6 t h E d i t i o n , London: Cambridge U n i v e r s i t y

P r e s s , 1932, 738 p p .

Lindsey, W.P.„ Bernard N. Daley, M i l t o n I), Humphreys, "The Plow and Force

C h a r a c t e r i s t i c s of Supersonic A i r f o i l s a t High Subsonic

Speeds," U. 5. Advisory Committee f o r A e r o n a u t i c s Technical

Note. No. 1211, 19^7, 15 p p .

O r l i n , James , J . L i n d e r and Jack B i t t e r l y , " A p p l i c a t i o n of the Analogy

Between Water Plow With a F r e e Surface and Two-Dimensional

Compressible Gas Flow." U.S. Advisory Committee f o r Aeronaut i c s Technical Note.

No.1185, 19^7, 20 -pv.

Page, Leigh,

I n t r o d u c t i o n t o T h e o r e t i c a l P h y s i c s . New York: D. Van

No s t r a n d Co., I n c . 1935, 250 vv*

P r e i s w e r k , E r n s t . , " A p p l i c a t i o n of the Methods of Gas Dynamics to Water

Plows With F r e e S u r f a c e . "

P a r t I . , "Flows with No Energy D i s s i p a t i o n . "

U.S. N a t i o n a l

Advisory Committee f o r A e r o n a u t i c s Technical Memorandum.

No. 9 3 ^ . 19^0, 69 p p .

P a r t I I . "Flows With Momentum D i s c o n t i n u i t i e s (Hydraulic

Jumps)." U.S. Advisory Committee f o r A e r o n a u t i c s Technical

Memorandum.

No. 935, 19^0, 56 jiV,

Riabouchinsky, D , , Mecaniques des F l u i d e s , Comptes Rendu, t . 195 No.22,

P a r i s , November 28, 1932, p p . 998-999.

Boufee, Hunter, Fluid Mechanics for Hydraullc Engineers. New York and

London: McGraw-Hill Book Company, I n c , , 1933, 420 vv»

Vennard, John K., Elementary Fluid Mechanics. New York: John Wiley

and Sons, I n c . 19^7, 339 pp.

2?

APPENDIX I

FIGURES

03

FIGURE 1

GENERAL VIEW OF WATER CHANNEL

FIGURE 2

GENERAL VIEW OF WATER CHANNEL

30

iE MECHANISM

&OOM SPOT

L/GHT

GLASS

SUN SPOT

L/GHT

^0

*Q

PROJECTOR

SZOOD L/GHTS-.

SCREEN

FIGURE 4

SCHEMATIC DIAGRAM OF WATER CHANNEL AND LIGHTING EQUIPTMENT

BOTTOM

FIGURE 5

SHOCK POLAR DIAGRAMS FOR

DIAMOND AIRFOIL TEST SPEEDS

V<

FIGURE 6

SHOCK POLAR DIAGRAMS FOR

CIRCULAR ARC AIRFOIL TEST SPEEDS

'2 -6

FIGURE 7

SHOCK POLAR DIAGRAM

1

• i j : •' — ... '

i J 1 '^

m.

•

• • : ] . : • .

•

mm

"

:

!

'

:

•

• I

. • .' : i '

: :

:

'

...

••

:;;; I

.

•

'

.

:

<

.

.

"• U '•

:

•

• • • • I

.:'

• : .

0~~

'

• •

. .i

. . :".

i.

i

!;;!:;

!

;:

' j,:':

.....

l

•

•

•

:•':']

. '

• •

• -

.

I

•

•

•

•

:

!:::! ; :. '! :

-

....(.....

• i

.:

'

•

, :

' [ " '

t

1

)'

:

:

m

\':4-

:

• !

!

-i

•

:

.

|

'

.

:;:;

::!i|!!;i

•

. '• : ' 1

ii

•

|

'

.

'

|

•

,

:

•

:

:

•

-

\A-\^

•

:

' :'.j" '

:

p*^

iKf+rr

^Qilri

•"-

•r, *

Ll

•

p

i

:V|

.4

• »

i ji

-

i

|

::'.]..

•

• ']

"

: .

i '

!

•

•

:^~*

• i':

.":'.:

-

.

--i-

'•'•]

'••

"1,

i .

1.0

:

i.

•I''

i - :

n

:

•

•

.]_...

:

' —J

i-l

•

:

|\

•

:

1

1

vu

• •

1

1

•

"

r.\-:.-

•

-..;_

:

•

1

|

;

\

\

1.6

\

•

•

'

• •

] ' '

;; m

•

•

•;:l:;:'

: . i' •

1 •

•..

1.4

:r|'v"

i •

•

<5

;

•

•

:. j .,

1:

"

1

:

:

;

VI

VO

•

•

:".)'

:| :•!

;

::

:

•-I:

L -,k : • :

\.

:

i

\

i

•

' 1

'5:'\

•1

1.2

: : ! : : _ ;

:

^Hsi :

::..;

\& & m l - . i n k ! 9',;l .

- ,T^ 1 i.

.

•

•

: '•':

: •[• :

' :

I

(ft

"A WdJ

'

::.: :: -

'r":\

\ \

'

j "

,

.• r . • •

fTT^P?

I

(

• i

I

:

—-~\"^

'

;

• •]

f " : S '• : - k

:

i

-i.:'

'•;•[

'

•!...:

j . :

•4

: J _

..

T

•

•

]

•

••

:

i.

r ^ f M tuy h " Wn|ve — i i ' ' V !

-

,i-F

.

•

•

:' , i . .

I ' '

j ,

-^r^ir^

:'l '

.6

"

•

i'- •

:

i

'

_j

. •

:'' ! > >

•

.

"

'i

:.. !'

..j. .

'. 1:

•:-

•

:

'

:

,_L-„

:

:

• T

• • ( ' •

Y^<

:

: i' • :.

....,.

...

.:: — -

J. '

1: ::

i

m

r

-L •

•J':

:

•

T—

; "

::::;!

^y~

ili.L: :. !

:

:

riliiif

-

::.-[-

j . ' '

\

'••

;

^ i \y

\\-\f\^/f:-\

•

. ,

• :.i.:-

i >

/

: ! , :. . : . i ' . '

•

•

i

: :

•

:: j . :

'

i

• [

-—- ^->7 :

.

... ! . .

'.] ' ' I "

.j '

•Ii • '-.

... !

• • 1

:

:

:;:-|;; ; ;

;

• I

:: . 1 .

., .

.....

:• l l "

'I-:.'

i

;: :j ;:

.

••

:

;••*!!

.... 1 J

:: ;!;!

:

•

: ;;;

. ;.:;

!

:: *: .. ;

• • C ::

:

:: !';'.

i.

: _ J . . ' : •: f i ' . : - - , 4 ' . _

. I '•

. :;['!

' - + „ —

.,1

:. .1.: " i : :

:'• I : .:;:

.

• .1:

i

—H—"

im K l jym i . •

,,.

1'

.. ..... ....

ii- !:•::

!;i:j)i;!

:

:li •

.

'

"H

:,:

. '..\"\..,

:::i^;

;!. ;i

1.8

:

-DRILL

OEPTH

f^(.3/25)

>,

?

HOLE:

-**<X>z.o*i

1

'

^ Z"

a

--'

:

///- //

i

•«»

-

-<?/

tfAT££

C/J4/v/J<EL

7-£ST/A/<$

•

£/D-3Z{

ONAUTtCS

,A S C M O O L O F

FIGURE 8

DIAMOND AIRFOIL MODEL

TLCHNOLOGV

- De/LL

£(.37S)

Z^.OO

±GGI

I

S£CT*OK

OR.D/MATES

fggg qYMM£T/SiCAL

. 000/STA r/OtJ MA7 JT

A£

/•A

2,4

S*c

o

< 0&£

/JO

• /S4£SO

s.Jr-

c&

7>Z

!

•

*

S.49-0

?.c

2. £

302.

/O-k

#.j

•3Z5

/o-s

*

•

*

&4

<Z-n

•34*

45*

J&C

A//5FO/L

OJ2D/ ss/Airr

fi*i.)

("••.

O

.£.

C/GCOLAZ

//•4

/ zo

•3S&

34&

3*3

•*DZ

•27o

•23C>

/S4

•/SO

O&S

///-//

frt

tjA rc+t

LEAD/MG

C/&COLA&.

EDG£

&AD:uS

/)JSC &AD<U3

=Q

= 4-1. 14-4-'

AVZZ.

Z/.Q.:uLA&

a

A/SC A(&jr<3/ £-

•

'MCA

icoi

FIGURE 9

CIRCULAR ARC AIRFOIL MODEL

.A s<:

.*tte

FIGURE 10

MODEL AIRFOIL ANGLE OF ATTACK CALIFRATION CURVE

:

26

26.1

26.2

26.3

26.4

26.5

26.6

DISTANCE FROM CHANNEL SIDE TO LEADING EDGE AND TRAILING

EDGE OF MODEL AIRFOIL WITH 12 INCH CHORD, INCHES

26.7

-sj

FIGURE 11

VARIATION OF WAVE VELOCITY WITH WAVE LENGTH FOR

A STATIC WATER DEPTH OF ONE QUARTER OF AN INCH

WAVE

8

10

L E N G T H , X , INCHES

14

SCREEN-'

GLASS BOTTOM

(a)

SCREEN

UN'DULAR HYDRAULIC JUMP

GLASS BOTTOM

(b) CAPILLARY WAVES

FIGURE 12

ANALYSIS OF REFRACTION PATTERNS FORMED h\ W

UNDULAR HYDRAULIC JUMP, AND CAPILLARY WAVES

1*0

^rf

•

X

^

§SsS^s

(a)

«•*

i

(b)

FIGURE 13

FLOW ABOUT CIRCULAR ARC AIRFOIL, M=1.56

Ul

(a)

FIGURE 14

FLOW ABOUT CIRCULAR ARC AIRFOIL, M=2.34

k2

(a)

(b)

FIGURE 15

PLOW ABOUT CIRCULAR ARC AIRFOIL,

1=3.28

hi

(a)

(b)

FIGURE 16

FLOW ABOUT LENTICULAR AIRFOIL, M=3.71

kk

(a)

(b)

FIGURE 17

PLOW ABOUT LENTICULAR AIRFOIL, M=4.26

45

(a)

•

• i

MmlLJmmmmmmmmMmmlmM

1

d ^ ^ M H | j | ^

(b)

FIGURE 18

PLOW ABOUT LENTICULAR AIRFOIL, M=6.78

he

(a)

(b)

FIGURE 19

FLOW ABOUT DIAMOND AIRFQIL, M=2.63

47

!

B *>"*"'

•

(a)

(b)

FIGURE 20

PLOW ABOUT DIAMOND AIRFOIL, M=2.47

48

(a)

(b)

FIGURE 21

FLOW ABOUT DIAMOND AIRFOIL, M=3.02

49

(a)

(b)

FIGURE 22

FLOW ABOUT DIAMOND AIRFOIL, M=3.72

50

(a)

(b)

FIGURE 23

PLOW ABOUT DIAMOND AIRFOIL, M=4.53

51

(a)

FIGURE 24

FLOW ABOUT DIAMOND AIRFOIL, M-5,08

FIGURE 2 5

VARIATION OF SHOCK WAVE ANGLE WITH FREE

STREAM MACH NUMBER FOR DIAMOND AIRFOIL

m

w

LxJ

cc

a

a

fcj

w

>

<

••••

K)

3

4

FREE STREAM MACH NUMBER, M

FIGURL 26

VARIATION OF SHOCK WAVE ANGLE WITH FREE STREAM

MACH NUMBER FOR SYMMETRICAL CIRCULAR ARC AIRFOIL

3

4

FREE STREAM MACH NUMBER, M c

5

5*4FIGURE 27

DIAMOND AIRFOIL LOCAL MACM NUMBER DISTRII UTION

FOR VARIOUS FREE STREAM MACH NUMI ERS

20

40

DISTANCE FROM LEADING

60

80

EDGE, PERCENT CHORD

FIGURE 28

55

CIRCULAR ARC AIRFOIL LOCAL MACK NUMI ER DISTRIBUTION

FOR VARIOUS FREE STREAM MACI! NUMBERS

20

40

60

80

DISTANCE FROM LEADING EDGE, PERCENT CHORD

100

56

FIGURE 29

PRESSURE COEFFICIENT FOR

DIAMOND AIRFIIL AT Ms = 4.53

<

H

Z

UJ

I—I

u

UJ

o

u

UJ

c/2

C/3

UJ

cc

a

40

PERCENT

G207

57

FIGURE 30

PRESSURE COEFFICIENT FOR

CIRCULAR ARC AIRFOIL AT M =4.26

<3 |

FW

i—i

CJ

w

O

U

cc

wi

in

cc

cu

PERCENT CHORD