QW. @Si NNI1\LN

advertisement

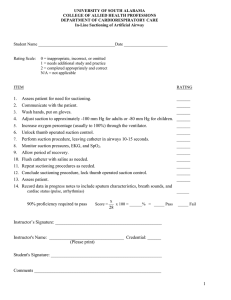

M. A. DROITCOUR. "PAPER` DELIVERY MBGHANISM. APPLICATION FILED FBB.19, 1912. ' ~ Patented NOV. 4, 1913. 1,077,400. _ QW. w w. N \L@NS1Ii N@ „ .w - bb.omhb \M\ Nm) NN M». A. DROITGOUR. PAPER DELIVERY MEGHA NISM. APPLICATION PILED'I‘EB.19, 1912. 1,077,400. ’ Patented N0v.4, 1913. 7 SHEETS-SHEET 2. h@mw,NìmEWïA \Tdi-: M. A. DROITCO'UR.l PAPER DELIVERY MEOHANISM. 1,077,400. APPLICATION PILED 1213.19, 1912. Patented Nov.4,1913. 7 SHEETS-SHEET s. Wag@ M. A. DROITCOUR. PAPER DELIVERY MEGHANISM. 1,077,400. APPLIGATION FILED FEB.19, 1912. Patented Nov. 4, 1913. u\A\. \í \ \ . . @N I M. A. DROITGOUR. PAPER DELIVERY MEGEANISM. 1,077,400. _ APPLICATION FILED I‘EB.19, 1912. 4l'z’atented Nov. 4, 1913. '7 SHEETS-SHEET 5. - M. A. DROITCOUR. PAPER DELIVERY MEGHANISM. APPLICATION FILED PBB.19, 1912. . Patented 'N ov. 4, 1913. 1,077,400. ' .7 SHEETS-SHEET 6. „KNSM h‘.... .ml M. A. DROITGO'UR. PAPER. DELIVERYv MEGHANISM. APPLICATION FILED Hume, 1912. 1,077,400. ì Patented N0v.4,1913. 7 SHEETS-SHEET 7. 77 $5937 ‘Mul in 'no sfrnîrnfs rai-i IIICHAELANDR'EW DROITOO‘U'R., or Oak PARK', ILLINOIS, A'ssIGNon. 'ro MIEHLE PRINTING rniess AND MANUFACTURING COMPANY, or CHICAGO, ILLINOIS, .e CORPURÀTION 0F ILLINOIS. PAPER‘DELIVERY MEGÍFIÀNISM. Bpeciâeation of Letters Patenti 1,077,400. Patented Nov. 4L, 1913. Application ñled February 19, l1912. Serial No. 678,498. To all' whom ¿if may concern : Be it known that I,_MicriAnL A. DROIT ooUIi, a citizen otv the United States, resid ing at Oak Park, in the county of Cook and State of Illinois, have invented certain new shown in Fig. 5; Fig. 7 is an enlarged -trag mentary detail view taken substantially on the _line 7_-7 of Fig. 1; Fig. 8 is a frag mentary view looking toward the right in Fig. 7 and taken substantially on the line 55 and useful lmprovementsin Paper-Delivery 8-8 of Fig. 1; Fig. 9 is a sectional view ' 10 Mechanisms, of which the Jfollowing is a taken on the line 9_9 of Fig. 8; Fig. 10 is a vertical septional view taken through specification. rl‘his invention relates to improvements in one of the suction shoes; Fig. 11 is a sec paper delivery mechanisms and aims topro tional view through the shoe taken on the duce a mechanism of this general character line v11--11 of Fig. 10V; Fig. 12 is a view which shall be particularly adaptable as an looking at the bottom of the structure shown attachment forA printing presses although, in Fig. 11; Fig. 13 ~is av fragmentary plan the invention is not restricted» to this par 15 ticular use. One of the primary objects of this inven tion is the provision of mechanism for vposi 20 the same to a delivery pile or stack' and de positing the sheets on the pile in regular order and in uniform position. With this end in view I have provided pneumatic 65 View taken on the line 13-13 of Fig. 10; Fig. 14 is a side elevation, partially in sec tion, showing one of the initial suction de vices and the adjacent end of a suction shoe; Figi 15 (Sheet 2)A is a sectional view taken tively separating and withdrawing printed on the line 15-«15 of Fig. 10; Fig. 16 is a sheets from a printing cylinder, conveying 60 70 view taken on the line 16-16 of Fig. 15; Fig. 17 is a transverse sectional view taken through the delivery mechanism just back of the brake device; Fig. 18 is an enlarged 75 the sheets from the fraofmentary view taken on the line 18-18 of Fig. 17 g and Fig. 19 is a sectional view 25 printing cylinder an conveyiinrJ the same to taken on the line 19-19 of Fig. 18. the delivery pile and have also provided means for separatin mechanism for controlling the operation of On the drawings, reference character 21 the pneumatic means so _that 4the rear ends designates a printing cylinder mounted upon 80 of the sheets of paper will be released from suitable standards or supports 22 provided 30 35 the carrier and deposited on the pile before with rearwardly projecting brackets or the front ends are deposited, thereby ob arms 23 u on which the delivery mechanism viating any possibility of the forward `end of isy pivotal y mounted, so that its free or de one sheet being- caught under .the rear end livery end may be swung upwardly or down 85 . wardlyv about its receiving end as a center, of a preceding sheet. Many other objects and advantages of the as will `be later described. A. shaft 24, jour present invention will be understood from naled attlie outer ends of the brackets 23, the following description when considered is surroiinded'by a sleeve 25 upon the ends 40 in connection with the accompanying draw of which are fixed the blocks or castings 2G ings illustrating one practical embodiment and27 and to these blocks are secured the receiving ends of the side frame members of the invention. ` 90 YReferring to the drawings~Figure 1 is a 28 and 29. All of the> mechanism herein'- -i after described is carried by these side mem' ing the invention; Fig. 2 is a side elevation bers so that it may be swung upwardly out 95 thereof; Fig. 8 ls a diagrammatic. view illus of position around the axis of the shaft 24, plan view of a delivery mechanism embody if-desired, A delivery table 31 is suspended 45 trating the driving mechanism for the per 50 the operation of the initial> suction device; `by thegdelivery _mechanism from the print be-` _ Fig. 5- is a side elevation showing the suc ing cylinder. Disposed longitudinally beneath the delivery forated bands; Fig. »a is a dia rammatic by vsuitable hangers, view illustrating the manner of c riving the end of the mechanism, toV receive and sup valve operating mechanism which controls‘ port the sheets of paper delivered thereto tion tubes leading to the various suction vde 100 tweenthe side members is a. plurallty of suc vices; Fig. `6 is a plan View of the structure Ition shoes 33, 311 and 85, the receiving ends - 1,077,405 end of the shoes and the pulleys or dnums 37 are splined to move longitudinally on the sleeve 25 between the arms 36 at the other of which are provided with apertured arms 36, between which are mounted the ,pulleys or drums 37 having rims provided with per~ torations 37’ and the delivery ends of which are provided with similar apertured arms 38 between each pair of which is mounted a similar pulley or drum 39 having its rim provided with perforations 441. end of the shoes, these pulleys and the aper tured metallic belts passing around them will be simultaneously and equally shifted with their corresponding suction shoes, sol Each of that under all circumstances these belts or bands 52 and 53 will be maintained in regis~ partition Walls 42, 43 and 44 into four ter with the perfo-rations in their respective chambers or compartments 45, 46, 47 and 48 suction shoes. From an inspection of Figs. of which the one characterized by 45 is com 2 and 5 it will be observed that the pulleys paratively large extending, as will b_e seen,' lor`drums 39 are smaller than the pulleys 37, from areceiving drum 37 to the partition consequently th'e delivery ends of the tapes ' these suction shoes 33, 34 and 35 is divided 10 75 42 disposed substantially midway the lengthy are disposed in a higher plane than the re 15 of the appliance. Each of these shoes is ceiving ends and the paper will be carried made, as will be observed from Fig. 1l, in along with its forward end disposed above its rear end. The suction shoes, of course, are inclined to correspond with the inclina» the form of a shell provided on its under surface with a series of perforations 49. Around the pairs of alined pulleys or drums tion between the lower edges of the pulleys 20 85 37 and 39 are passed endless belts or bands v37 and 39. This inclination of the paper has 5l, 52 and 53, each being preferably made of 'been found desirable for the reason that metal and provided at intervals with aper Ãwhen the paper has been released, rear end tures or slots 54 obliquely disposed to pass first, as will be later described, it will tend 2,5 successively over the apertures 49 in their ias it falls upon the pile to glide or soar 90 respective shoes whereby suction in the shoe toward the cylinder end ofthe delivery table chambers, the apertures of which are cov against the guides disposed thereon, thereby slots in the bands. The center shoe is shown as having two series of apertures and two bands 52 are shown as coöperating there with. The two series of slots and the two 1 ered by these belts- or bands, is made appli ¿assisting the joggers in making a straight cable to the sheets of paper through the edged even pile. v30 The sleeve 25 is given a variable intermit tent rotation causing a variable and inter mittent travel of the perforated steel bands Íor belts by means of mechanism which I bands are employed in this particular loca will now describe: The shaft 6l of the cyl tion to enable the devicev to handle paper inder 21 has fixed thereon a -sprocket wheel which may be slitted in the center inthe 62 around which passes a sprocket chain 63 usual manner but, obviously, a single band vencircling another sprocket wheel 64 on the 35 100 y similar to the bands 5l and 53. may be used shaft 24 rotatably mounted in the side frame in the center of the mechanism if unslitted -members 28 and 29. Upon the opposite end of theshaft 24 is mounted a sprocketwheel ` " In order that the positions of the two out -'65 around which passes a sprocket chain 66 40 paper is to be handled. side suction shoes 33 and 35`may be adjust 45 105 also encircling another sprocket wheel 67 able for proper action on sheets of paper of fixed on a shaft 68 mounted onA the side different widths l have provided each of member 28 and carrying at its inner end a these outside shoes with a pair of open `similar sprocket wheel‘ 69. A sprocket 110 topped internally-threaded lugs 55, one such lug being'shown in Fig. l0. The mecha nism is provided with two comparatively long _screws 56 and 57 rotatably mounted inl ¿chain 7l encircles the sprocket wheel 69 and another wheel 72 mounted on a stub shaft 73 also carried by the side frame member 28. T_he sleeve 25 has fixed to one end thereof 50 „the 55 slde frames 28 and 29 and each having - a sprocket wheel 74, a similar sprocket wheel 115. its halves provided with right and left hand 75 being rotatably mounted on a stub shaft screw-threads disposed in operative engage _76 carried by the side frame member 28 and ment with the lugs 55. In'order to bring va sprocket chain 77 passing around these about a simultaneous and equal rotation of companion wheels 74 and 75 has securely these two screws 56 and 57 .I havev equipped vrfastened thereto three yokes 78, 79 and 81 120 each with a sprocket wheel 58a coöperating each consisting, as is shown in Fig. 3, of a with both of which is- a sprocket chain 58,_ ¿pair of parallel arms spaced apart. These .í one of the screws having an operating han'-"-_ ,yokes are separated one Jfrom another lin~ dle 59. Since the two outside shoes are slid-' :early along the sprocket chain 77 -a distance 60 65 ably supported upon the cross-shaft 6l and substantially equal to that between the re the sleeve 25 it will be apparent that the si lmotest points of the sprocket wheels 69 and multaneous approach or separation of these 72. Coöperating with these yokes I employ shoes may be readily effected by simply three rollers 82, 83' and 84 spaced equidis turning the handle 59. Since the pulleys or tant on the sprocket chain 71, the construc drums 39 are carried by the arms 38 at one :tion being such that as the roller 83 leaves 125 1.30 1,077,400 the yoke 79 the chain 77 will remain sta tionary until the roller 84 travels fro-m the position shown in Fig. 3 to the remotest point of the wheel 69, whereupon it enters the yoke 81 and carries the yoke with it to the remotest point of the wheel 72, thereby . ¿seen that the pipes 94, 95 and 96 are equipped with controlling valves 101,102 and 103, respectively, and the mechanism for intermittently opening and closing these valves is best- shown perhaps in Figs. 7 to 9 70 inclusive. A cross-shaft 104 extends trans intermittently imparting to the chain 77 a versely of the machine above the pipes 94, variable movement. During the period that 95 and 96 and upon this shaft in proximity the chain 77 and, consequently, the perfo to the valves 101, 102 and 103 are secured 10 rated bands 51, 52 and 53 are at rest the downwardly projecting curved arms 105 75 paper will be released at the discharge end shaped at their `free ends to engage with of the mechanism, as hereinafter explained. arms 106 fixed to the stems of said control Referring now to the means for applying ling valves. The shaft 104, which is sup suction to the shoes and the drums mounted portedl in brackets 107 from the frame is 15 at each end thereof and controlling the ac~ oscillated at predetermined intervals to 80 tion of the air it will be observed that the swing the arms 106 from full line to dotted suction pump (not shown) is connected withl line position, shown in Fig. 9 and vice versa, Íeach of the suction devices through a main tube or pipe 85 from which branches lead 20. ing to the various devices are taken. The pipe 85 is connected with the chamber 45 ofthe shoe 34 through a short pipe 86 and is also connected with the chambers 45 of by a link 108 attached at one end to an arm 109 fixed on the shaft 104 and connected at its other end with a lever 111 pivoted on the frame at 112 and adapted to be actuated by a rotary cam 113 which operatively engages a follower 114 mounted on the lever 111. _the movable side shoes 33 and 35 through An expansion spring 115 normally urges the follower into engagement with its operat 25 the flexible pipes or hose 87 and 88, respec tively, these íieXib-le connections being ing cam. A shaft 116 upon which the cam adapted to permit the adjustment of the 113 is fixed extends transversely of the ap outer shoes toward and from the middle " pliance through the valve mechanism 117, \ shoe by the mechanism previously described. 30 A continuous suction is accordingly ap plied to the chambers 45 of each of the shoes. By reference more particularly to Fig. 14 it will be observed that the tape drums or pulleys 37 which are provided with 35 peripheral perforations 37’ and are mount ed to rotate in proximity to the printing cylinder 21 are each disposed in close prox imity to the receiving ends of its respec 118 and 119, to be later described, and car ries at one end a sprocket wheel 121. Re 95 ferring to Figs. 1, 4 and 7, it will be seen that the sprocket Wheel 121 is continuously driven by a sprocket chain 122 encircling a drive 'sprocket wheel 123 mounted on the shaft 24 and a companion sprocket wheel '.100 124 mounted on the side frame member 29, the chain 122 being disposed beneath the wheel 121 and' in engagement therewith and tive shoe chamber 45. A suction member or lbeing adapted to travel at a constant speed> 40 bo-x 89, (Fig. 14) having its hub 91 splined in the direction of the arrow shown in Fig. 105 upon the sleeve 25, is disposed. within the >4. It will be evident thatthe valves 101, perimeter of each drum 37 with its open 102 and 103 will be intermittently opened curved mouth disposed adjacent and within and closed upon each revolution of the cam the revoluble perforated rim of the drum. 113, thereby intermittently turning on and 45 The suction member is held against rotation shutting ofl’ the'suction to the suction boxes 110 with the drum by an arm 92 projecting from 89. Thus it will be seen that’suction is in its hub which is connected by a link 93 with termittently applied to the suction boxes 89 the spaced arms 36 at their junction. Suc~ to separate the printed sheets from the tion is applied to each of the boxes through printing cylinder and that suction is con tinuously applied to the- chambers 45 of the 115 50 suction pipes 94, 95 and 96, the pipe 95 be ing connected with the main suction pipe suction shoes so that the sheets picked up 85 through a branch or connection 97 and by the perforated tapes or bands-traveling the pipes 94 and 96 being connected with past the suction boxes 89 will be carried the suction by connections 98 and 99 com» along by the bands beneath the cham 55 municating with the chambers 45 of the side lbers 45. shoes 33 and 35, respectively.' The tape drums or pulleys 39, mounted at Since it is necessary and desirable that the delivery end of each of the suction shoes suction be applied to the boxes or suction 33, 34 and 35, are likewise equipped with members 89 intermittently only and at the suction boxes 125 similar in construction to 60 time that a sheet is to be delivered from the the boxes 89. The bearings in the support printing cylinder, I have provided mecha ing arms 38 for the pulleys 39 are prefer-` nism for automatically controlling the suc ably elongated to permit of adjustment of tion to the boxes 89, which willnòw be de the pulleys to tighten the- tapes or bands scribed. when required and in order to effect the ad 85 By reference to Figs. 5 and 6 it will be .justment of the pulleys the links 126 con 130 '1,071,400 nected to the arms 127 of the suction boxes brought into successiveregistration with the 125 are each provided, as shown in Figs. 10 respective tubes. The entire apparatus is and 13, with an elongated _slot 127’ through preferably so timed that suction will be ad~ which a guide bolt 1,28 is passed to secure mitted to the chambers 46, 47 and 48 and the link to a guide standard 129. An ad the boxes 125 substantially at or just prior 70 justing bolt 131, projecting through an up to the time that the forward edge of the wardly extending portion of the guide sheet of paper being delivered reaches in its standard, is threaded into the end of the link travel these respective shoes. As the valve so that upon turning the bolt t-he link and member continues to rotate it will be appar- its corresponding pulley 39 will be adjusted longitudinally of its respective shoe to ap~ ply the proper tension to its perforated band. Suction is applied to the .suction 'boxes 125 and the suction chambers 46, 47 15 and 48 of the respective suction shoes 10 through pipes 132, 133, 134 and 135, respec ent that suction will be shut 0E from the 75 chamber 46 first, then from the chamber 47, then from the chamber 48 and, lastly, from the suction box 125, thus permit-ting the rearend of the paper to be first released and t0 drop upon the pile prio-r tothe release of the forward end. l The intermittent and variable travel. of tively, the inner end of each of these tubes being connected with a valve casing 136 the suction tapes and the mechanism for ef~ , housing a valve member 137 mounted on fecting this movement has been previously explained in connection with the diagram 815 the cross-shaft 116. The valve casings and the valve members matic showing in Fig. 3 and it will be re- mounted therein constitute the controlling membered that there is a period, after one valves 117, 118 and 119 previously men tioned, each of these controlling valves con 25 trolling the application of suction to its re of the yokes on the chain 77 has been re leased by one of the rollers on the chain 71 and before the preceding roller has en 90 gaged with a succeeding yoke, when the chain 77 and consequently the suction tapes panion suction shoe. Since it is desirable will remain stationary. ln order to prevent spective delivery pulley 39 and the interme diate chambers 46, 47 and 48 of its com 30 that the rear end of the p'aper loe released accidental movement of the chain 77 at this from the suction means before the'release ol period, which Would, of course, displace the 65 the front end so that the rear end .will first position of the yoke awaiting to receive its fall upon the delivery pile, thus obviating roller mounted on the chain 71, l have pro~ any p'ossibility'of the forward end of the vided a brake mechanism shown on an en succeeding sheet being caught beneath the larged scale in Figs. 18-and 19. Thisbrake 35 40 rear end of its preceding sheet, the control«_ ling valve is so constructed that suction will be shut oft successively from the chambers 46, 47 rand 48 of the suction shoes and last from the suction boxes 125, the forward end mechanism comprises, as-shown, a braking member 142 pivoted at 143 on a bracket 144 above the lower lap of the chain 77, the downward free end of the braking member being adapted to frictionally engage with 'of the sheet being ‘thereby sustained some the chain 77 and thereby hold the chain 105 little time after the rear end has been re against accidental movement during the pe leased. v’l‘o this end the valve members 137 riod when no roller on the chain 71 is en of each of the controlling valves 117, 118 gaged with its respective yoke on the chain and 119 is provided adjacent its periphery 77. The braking member is yieldingly urged -with an elongated arcuate slot 138, (Fig. 16) into engagement with the chain by an err»A 110 the walls of each slot being formed to p-ro vide flanges 139 adapted to Contact with one wall of the casing 136. The rear ends of the suction tubes 94,u 95 and 96 communicate 50 pansion spring 145 encircling an adjustable bolt 146 threaded into a stationary base 147 above the chain. rl‘he -frictional engagement between the braking member and the chain with the casings o-f 'their respective valves can be regulated, as will be obvious, by 115 117, 113 and 119 on one side of the valve manipulation of the bolt 146. rll‘he intermit members 137 while the tubes 132, V133, 134 tent actuation of the perforated tapes is and 135 communicate with the casings on timed, of course, tov correspond with the 55 the opposite side of the valve members. operation of the printing cylinder of the Suction will thus be continually supplied printing press and the sheets- of paper will, to the chamber 141 of each controlling valve therefore, be delivered to practically the as will be evident from an inspection of -same point of the tapes at each operation. Fig. 15. As the shaft 116 rotates, carrying Manifestly there will be a portion of the 120 with it the valve members 137, the slots 133 tapes betweenthe successive delivery por 65 will be first brought into registration' with the tube 133, thereby applying suction to the chamber 46. Similarly suction will be ap» plied to the chamber 47, the chamber 48 and, lastly, to the suction box 125 through the pipes 134, 135 and 132 as the slot 133 is tions with which paper will not be brought Y into operative relation and, obviously, these inoperative portions of the tapes need not be perforated and I accordingly perforate the tapes 51, 52 and 53 throughout portions of their length only, as will be observed » 1,077,400 from Fig. 1, thereby reducing the suction the fact that the rear end is ñrst released, necessary to the successful operation of the device toa minimum; I prefer to employ elongated slots 54 ar-ranged diagonally of the tape so that the in terval between successive applications of suction to the paper from the suction aper tures in the shoe may be brief, and, in some instances, I prefer to have the slots end_and 10 begin respectively on a given cross-line on the sheet will tend to soar .or glide toward and into engagement with the guides at the printing cylinder end of the delivery table 31 so that an even smooth edged pile is pró 70 duced. . While I have shown and described a pre ferred embodiment of my invention‘it will be apparent that various changes in the mechanical construction and `in the size, 75 the tape so that the suction may be continu shape, proportion and arrangement of the ous. This arrangement of the slots is sub various partsmay be resorted to without stantially illustrated in Fig..1. It has been departing from the substance of the inven found also that this construction provides‘a tion or sacrificing any -of the material ad vantages thereof. ' more uniformly strong carrier tape. 80 I claim: . The operation of the mechanism `described 1. In a paper transporting mechanism, is substantially as follows.: As the forward edge of the sheet of paper on the printing the combination of a pneumatic device for cylinder 21 approaches delivery position at> withdrawing a sheet of paper from a print 20 each alternate revolution of the cylinder the lng cylinder, means for supporting the ends 85 travel of the perforated tapes is initiated by of the sheet and transporting said >sheet operative engagement of one of the rollers away _from said cylinder, and controlling means -for causing the 'release of the rear end of said sheet prior to the release of the forward end thereof, substantially as de 90 scribed. 2. In a paper transporting mechanism, the combination ofmeans for pneumatically separating a sheet from a printing cylinder, 80 the perforated tapes separates the printed a traveling tape, means' for pneúmatically 95 on the chain 71 with its companion yoke on the chain 77. Simultaneously suction is ap« 25 plied to the suction boxes 89 in the tapey drums 37 by the automatic opening of the valves 101, 102 and 103. The suction action of the suction boxes 89 through the per forated rims of the drums 37 and through sheet from the printing cylinder, saidv sheet holding the sheet against said tape whereby being carried along by the traveling tapes the sheet is caused to travel with the tape, and held against the tapes after it leaves the and controlling means whereby the Ipneu matic action upon the sheet is discontinued sequentially from one end of the sheet to 100 in the long chambers 45 of. the suction shoes. 85 When _the forward edge' of the sheet of the other, substantially as described. ` suction boxes 89 by the continuous suction 3. In a paper transporting mechanism, paper reaches or approaches the chambers 46 of the shoes, suction is automatically ap the combination of a 'pair òf perforated tape plied 4to said chambers by the controlling drums, a perforated tape surrounding said drums, a suction shoe dis'posed- between said 105 tinues to travel with the tapes suction is ap~ drums and adjacent the lower -travel of said 40 valves 117, 118 and 119 and as the sheet con plied successively to the chambers 47, the tape, means for causing said >tape to travel around ythe_drums, means for inducing suc `tion through said ytape in the drums and in the suction shoe, and means for automati 110 cally controlling the suction inl said dr‘ur'ns and shoe, substantially as described.` 4. In a paper transporting mechanism, the tapes is stopped by disengagement of chambers 48 and finally to the suction boxes 125 disposed within the tape drums 39. 45 When the forward edge .of the paper has been brought approximately to the extreme edge of thesuction boxes 125 the travel of the roller on the chain 71 with its yoke on the combination of a perforated drum, a suction box disposed therein, a suction shoe tapes is prevented by the friction brake comprising a plurality o'fcompartm'ents and 50 the chain 77 and further movement of the 115 member 142. At approximately the time having one end disposed in proximity to that the tapes are stopped the suction is cut said drum, a perforated tape arranged to ofi:l from the chambers 46 thereby releasing travel around said drum and adjacent said 55 the rear edge of the paper and, in succession, shoe, means for applying suction to said V12pc the suction is also cut Vod from the chambers suction box- and said shoe whereby to hold a 47 and the chambers 48 thereby permitting sheet by suction against said traveling tape the rear edge of the paper to drop a con 60 and means for controlling said slîctio‘n, sub siderable distance toward the delivery pile stantially as described. 5. In a paper transporting mechanism, before the forward edge is released by cut 125 ting off the suction to the suction boxes 125. the combinationof a pair of perforated When the suction to these boxes is finally cut oif the sheet is permitted to fall and by reason of the inclined position of the suc 65 tion shoes and, furthermore, by reason of drums, suction boxes arranged in said drums, a suction shoe disposed between said drums with its ends in proximity thereto and comprising. a plurality of compart 130 1,077,400 ments, a .perforated tape arranged to en 11. In a paper transporting mechanism, circle said drums and travel adjacent to said ¿thecombination of a suction shoe-compris shoe, and means for applying suction to the ing a series of suction chambers arranged. suction boxes and the compartments of the end to end, drums mounted at each end of shoe whereby to retain a sheet by suction in said shoe, a suction chamber arranged with contact with the traveling tape, substan in each drum, a suction tube, connections be tially as described. tween said tube and each of said chambers, 6. In a paper transporting mechanism, and means for automatically establishing the combination of a suction shoe divided and suppressing connection between said. into a plurality of compartments, a perfo suction tube and each of said chambers in rated drum at one end of the shoe, a suction succession, substantially as described. 65 70 75 box disposed therein, and means for in 15 25 30 35 40 12. In a paper transporting mechanism, ducing and discontinuing suction in said the combination of an elongated suction shoe compartments and in said-box successively, comprising a series of suction chambers, a substantially as described. drum mounted at one end of said shoe, a \ 7. In a paper transporting mechanism, suction chamber arranged in said drum, a the combination of a suction shoe divided suction pipe connected with each of said into a plurality of compartments, a pair of chambers, and an automatic valve for suc perforated drums disposed at the ends there cessively establishing and suppressing con of, a perforated tape arranged to travel nection through the pipes with said cham 85 around said drums and in proximity to said bers, substantlally as described. shoe, means for inducing suction in one of 13. In a paper transporting mechanism, said drums at predetermined intervals, and the combination of a suction shoe, suction means for successively inducing suction inl drums disposed at each end thereof, a perfo- ‘ a plurality of compartments in said suction rated tape arranged to travel around said shoe and in the other perforated drum at. drums and in proximity to said shoe, means 90 predetermined intervals, substantially as for intermittently applying suction to one described. Y of said drums, means for intermittently ap 8. In a paper transporting mechanism, the combination of a pair of drums, a suc 55 plying suction to the other drum and to said shoe at intervals throughout its length, and tion shoe disposedv between said drums, a means whereby the distance between said perforated tape arranged to travel around drums may be varied to tension said tape, the drums and in proximity to said shoe, substantially as described. means for imparting an intermittent move 1li. A paper transporting device compris ment to said tape, and a device for prevent chain for imparting an intermittent move means for causing said tape to' travel on mentto said paper carrying device, and fric tion means continuously engaging directly with the chain for locking the chain against displacement during the intervals between the intermittent movements thereof, sub the face of said shoe, means for applying suction to said cylinder and said compart ments, and means for withdrawing suction from said compartments in succession, sub . 95 ing a suction cylinder having means asso ing accidental movement of the tape in the ciated therewith ~for limiting the suction interim between said successive movements, area thereof, a suction tape on said cylinder substantially as described. . provided at intervals throughout its length '9. In a paper transporting mechanism, with a plurality of spaced perforations, a the combination of a pair of drums, a paper suction shoe divided into compartments, carrying device arranged to travel around said suction shoe having similarly spaced said drums, driving mechanism including a perforations in each of said compartments, stantially as described. 50 80 stantially as described. 100 105 110 . 15. In a paper transporting mechanism, 10. In a paper transporting mechanism. the combination ofy a suction shoe having a the combination of a suction shoe, a pair of plurality of compartments, a suction drum i115 drums disposed adjacent to the ends thereof, at each end. of said shoe, a perforated tape v a paper carrying device arranged to travel arranged to travel around said drums and around said drums in proximity to and be in proximity to said shoe, and means for neath the shoe, and means for supporting a applying suction to one of said drums and sheet against the under surface of said de to one of said compartments, substantially vice, said shoe and paper carrying device being inclined so that the forward edge of as described. I 16. In a paper transporting mechanism, the sheet being transported is disposed at the combination of a suction shoe divided 60 a higher elevation than the rear edge there into compartments, a suction drum arranged of, whereby upon release of the sheet the to rotate at each end of said shoe, a per rear edge thereof will be deposited upon the foi-ated tape arranged to travel around said pile in advance of the forward edge, sub drums and in proximity to said shoe, means stantially as described. - Í for applying suction to said drums and 125 applying and destroying suc-compartments, and means for successively periodically tion in each of said elements, substantially varying the suction in said compartments, ' as described. substantially as described. In a paper transporting mechanism, 17. In a paper transporting mechanism, the22.combination of a pair of suction car 55 the combination of a hollow suction shoe riers arranged substantially parallel to each divided into compartments, a suction drum other, each of said suction carriers com at the forward and rearward end of said a fore and rear rotatable suction shoe, an endless carrier adapted to travel prising element and an intermediate carrying ele 60 uîpon said drums and across the face of said ment, means for operating said elements, s oe means ~for applying suction to said and means for adjusting said suction car drums and said shoe, whereby a >sheet of riers- laterally ' to accommodate various paper is held and transported upon said widths of paper to be carried thereby, sub carrier, and means for releasing said paper as described. from said carrier by ñrst destroying the stantially 23. In a mechanism of the character de suction in said shoe and then destroying the scribed, the combination of a pair of suc 15 20 25 65 suction in said rear suction cylinder, sub tion carriers arranged substantially paral 70 stantially as described. with each other, and means for simul 18. In a paper transporting mechanism, lel taneously adjusting the front and rear ends the combination of a hollowl suction shoe of said carriers to accommodate having a series of compartments, openings various widths of laterally sheets to be carried there into said compartmentsthrough the face by, each of said carriers comprising a >pair 75 portion of said shoe, a suction drum ar of rotary suction elements and an endless ranged at the rear end of said shoe, an end belt traveling on said rotary elements, to less carrier having perforations therein ar gether with means for applying suction to ranged to travel on said drum and substan said Vrotary elements, substantially as de tially upon the face portion of said shoe, means for applying suction to said drum and said compartments, whereby a sheet of 30 scribed. 80 Y 24. In a paper transporting mechanism, the with suction elements hav paper may be maintained and carried by ing combination plurality of suction apertures therein said carrier, and means-for releasing said of a atape carrier provided with a `plurality sheet by destroying the suction successively of elongated slots disposed diagonally of in said compartments and drum, substan the tape and arranged with respect to each 85 tially as described. other so that the rear end of one slot and 19. In a paper transporting mechanism, the forward end of the succeeding slot in the 35 the combination of rotary suction means Jfor tape are substantially in registration with successively withdrawing sheets of paper one of said suction apertures at the same 90 from an impression cylinder, means for substantially as described. , transporting said sheets successively, and time, 25. In a paper, transporting mechanism, rotary suction means for successively caus the combination ofa suction shoe, suction 40 ing said sheets to be released from said drums disposed at each end thereof, a per transporting ~means, ysubstantially as de Íorated tape arranged to travel around said 95 and in proximity to said shoe, means 20. In a paper transporting device, the drums for intermittently applying suction to one combination of a pair of suction elements, of said drums, means for intermittently ap a belt carrier between said elements, and 45 plying suction to the other drum and to means for automatically and periodically said shoe at intervals throughout its length, 100 applying and destroying suction in said suc and means for varying .the tension on said tion elements alternately, substantially as scribed. described. 50 . ’ . “ 21. In a paper transporting mechanism, the combination of a pair of rotary suc tion elements, a carrier between said ele ments, and means for. alternately and tape„substantially as described. MICHAEL ANDREW DROITCOUR. Witnesses: C. I. MANSEN, | CEAS. HICKMAN. ^