A Novel EUV Phase Shift Mask Structure

C. Constancias1, M. Richard1, A.M. Nugrowati2, J-Y. Robic1

1. CEA - MINATEC -17 rue des Martyrs -38054 Grenoble, France

2. Optics Research Group, Technische Universiteit Delft, Lorentzweg 1, 2628CJ Delft, the Netherlands

christophe.constancias@cea.fr

EUV lithography is expected now to be inserted at 22 nm node. Phase shift mask (PSM) is a potential technical solution to

achieve such resolution without increasing the NA of the exposure tool. This poster describe an innovative structure which

complies with attenuated PSM requirements in terms of reflectivity and phase shift. Refined imaging simulation by taking

into account conical 2-D illumination has been used to study the effects of each imaging component, and to compare PSM

design to the standard binary mask (BIM) for printing 2-D lines. From the simulation result, we found that our PSM design

allows for 22 nm node at a low numerical aperture of 0.25, a larger process window, and a longer focus range when

compared to the aerial image of a BIM structure.

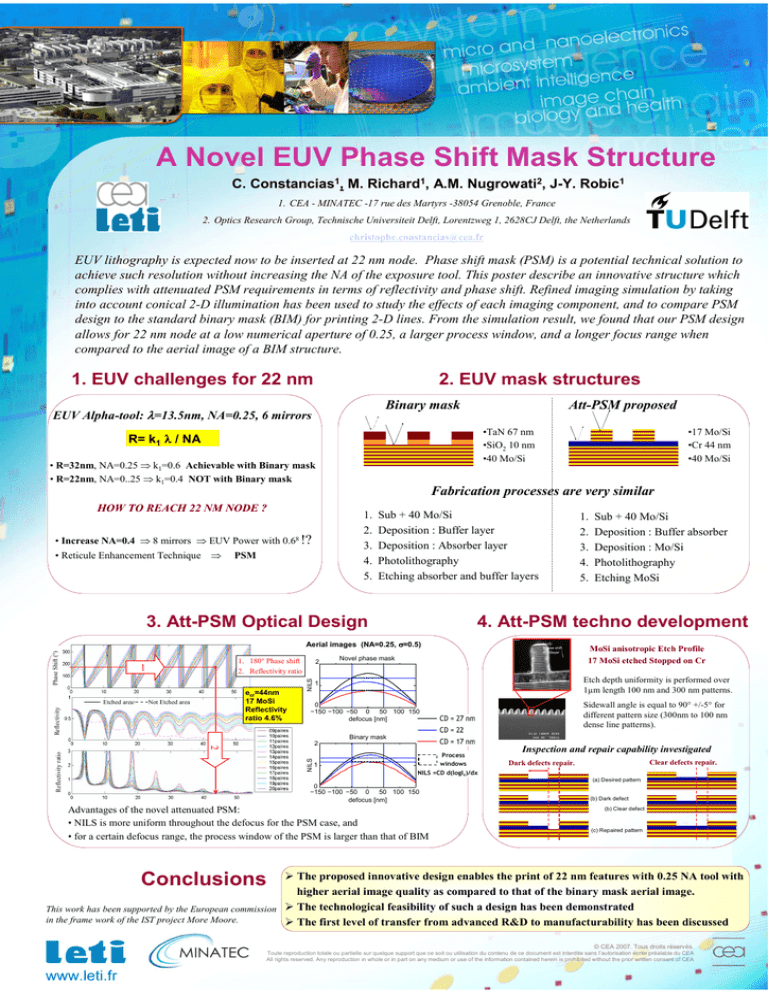

2. EUV mask structures

1. EUV challenges for 22 nm

Binary mask

EUV Alpha-tool: λ=13.5nm, NA=0.25, 6 mirrors

Att-PSM proposed

•TaN 67 nm

•SiO2 10 nm

•40 Mo/Si

R= k1 λ / NA

• R=32nm, NA=0.25 ⇒ k1=0.6 Achievable with Binary mask

• R=22nm, NA=0..25 ⇒ k1=0.4 NOT with Binary mask

•17 Mo/Si

•Cr 44 nm

•40 Mo/Si

Fabrication processes are very similar

HOW TO REACH 22 NM NODE ?

1.

2.

3.

4.

5.

• Increase NA=0.4 ⇒ 8 mirrors ⇒ EUV Power with 0.68 !?

• Reticule Enhancement Technique ⇒

PSM

Sub + 40 Mo/Si

Deposition : Buffer layer

Deposition : Absorber layer

Photolithography

Etching absorber and buffer layers

1.

2.

3.

4.

5.

Sub + 40 Mo/Si

Deposition : Buffer absorber

Deposition : Mo/Si

Photolithography

Etching MoSi

200

7

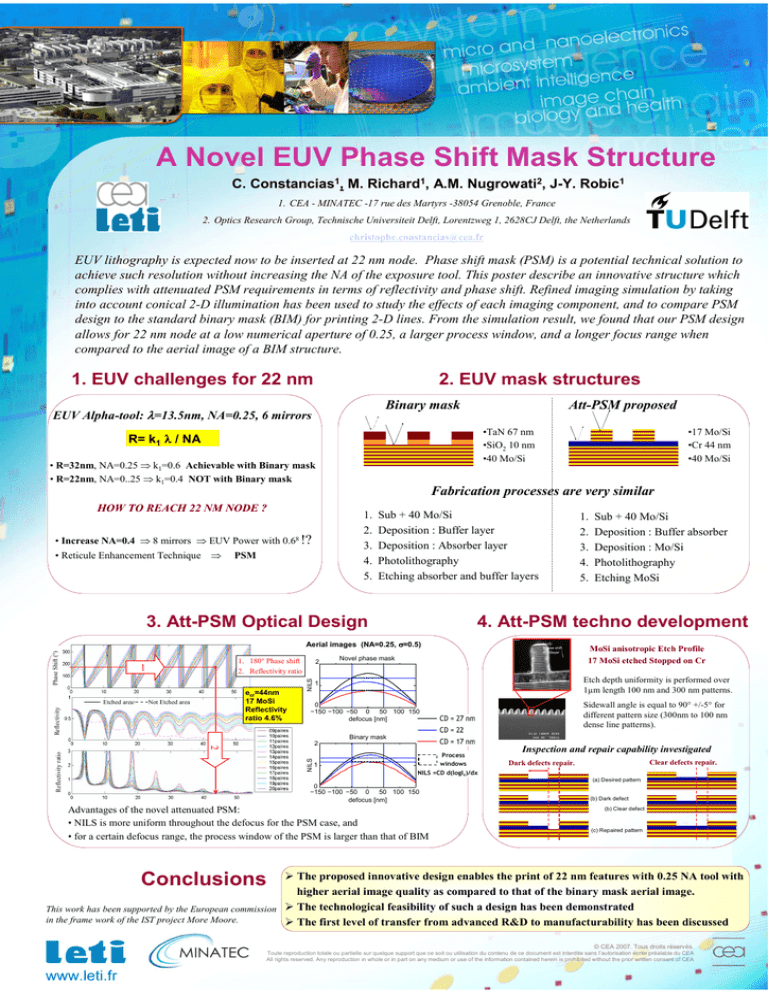

3. Att-PSM Optical Design

4. Att-PSM techno development

1. 180° Phase shift

2. Reflectivity ratio

1

Not Etched area

Reflectivity

Etched area

ecr=44nm

17 MoSi

Reflectivity

ratio 4.6%

2

MoSi

Phase shift

multilayer

Novel phase mask

MoSi Blank multilayer

1

Binary mask

CD = 22 nm

CD = 15 nm

2

2

NILS

Process

windows

1

Etch depth uniformity is performed over

1µm length 100 nm and 300 nm patterns.

Sidewall angle is equal to 90° +/-5° for

different pattern size (300nm to 100 nm

dense line patterns).

0

−150 −100 −50 0 50 100 150

defocus [nm]

CD = 27 nm

σ = 0.5

NA = 0.25

Reflectivity ratio

MoSi anisotropic Etch Profile

17 MoSi etched Stopped on Cr

Chromium layer

NILS

Phase Shift (°)

Aerial images (NA=0.25, σ=0.5)

Inspection and repair capability investigated

Clear defects repair.

Dark defects repair.

NILS =CD d(logIx)/dx

(a) Desired pattern

0

−150 −100 −50 0 50 100 150

defocus [nm]

Advantages of the novel attenuated PSM:

• NILS is more uniform throughout the defocus for the PSM case, and

• for a certain defocus range, the process window of the PSM is larger than that of BIM

(b) Dark defect

(b) Clear defect

(c) Repaired pattern

Conclusions

The proposed innovative design enables the print of 22 nm features with 0.25 NA tool with

higher aerial image quality as compared to that of the binary mask aerial image.

The technological feasibility of such a design has been demonstrated

This work has been supported by the European commission

in the frame work of the IST project More Moore.

The first level of transfer from advanced R&D to manufacturability has been discussed

© CEA 2007. Tous droits réservés.

Toute reproduction totale ou partielle sur quelque support que ce soit ou utilisation du contenu de ce document est interdite sans l’autorisation écrite préalable du CEA

All rights reserved. Any reproduction in whole or in part on any medium or use of the information contained herein is prohibited without the prior written consent of CEA

www.leti.fr