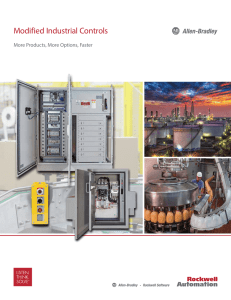

Scalable technologies provide an economical, customizable

advertisement

a t io n , ical m o Ro con r users e ss, e n c ro e a ion fo bilit y. d or P i f v r ge pro solut availa ana s e M i t n log izable e high o gme e n S k, tech custom achiev trz y e e i l P b rt to la By A Sca el c kw >> In everyday life, availability is a relatively simple matter — can you join us for dinner tomorrow? However, on the plant floor, availability is a far more serious matter. If a system is available, it’s operating successfully. If it’s not, critical uptime and productivity are being lost — and sometimes personnel and equipment put in harm’s way. More directly, in process automation — especially in heavy industries — achieving availability generally means doing your engineering best to make sure nothing gets lost, stops working or is damaged. Thanks to ever-evolving technology, expanded product offerings and design best practices, process industry stakeholders now have more ways to achieve high availability for process control systems. The catch is that no one-sizefits-all proposition exists. Manufacturers need to examine each application against their overall business objectives to determine the solution that best meets their performance requirements and protects their assets. Reliability and Maintainability Availability can be defined as the probability that a system is operating successfully when needed. Availability is most often expressed as a percentage. It’s calculated by the expression A= MTBF/ MTBF + MTTR. Today many suppliers can supply control systems with availability ranging from 99.9 to 99.9999 percent. The term high availability encompasses all aspects related to productivity, especially reliability and maintainability. Reliability is the likelihood that a device will perform its intended function during the mission time. An engineer can enlist numerous methods to achieve reliability. For example, reliability can be designed into the 16 THE JOURNAL | OCTOBER 2010 l om Au t system using techniques such as Component Derating and Design through Six Sigma. However, even the most reliable system might not be the most available. To be available, an automation system also must be easy to troubleshoot, modify and repair during mission time, which may exceed a decade or more. In other words, it needs to be maintainable. Personnel should be qualified and trained, and they should be able to remove and add components to the system without interrupting the mission. Consequently, replacements should not require rewiring or reprogramming. Some features that help improve maintainability include system-level diagnostics, such as controller, network, I/O, server and field-device diagnostics. To assist with troubleshooting, users can leverage network-monitoring tools, products with onboard LED indicators, graphical programming languages and human-machine interface (HMI) with built-in alarm displays. Features that help improve maintainability on the control side include online editing, executing partial downloads, adding I/O online, and removing and inserting modules under power. Furthermore, the ability to add tags to the HMI online helps with the availability of the HMI and information layers. More Scalable Solutions Tailored to Meet Specific Needs New multidiscipline plant process-control systems are more scalable and more economical for end users and machine builders (OEMs) that provide skid-mounted process equipment. Equipment suppliers can purchase scalable, more economical controls to meet their specific requireWWW.ROCKWELLAUTOMATION.COM/THEJOURNAL The term high availability encompasses to productivity, especially reliability and ments, and be able to offer control technology that easily integrates into the plant control and information systems. In general, some form of redundancy is used if a control system shutdown or loss of visibility would cause a major loss in data, product or revenue damage equipment; or create a potential hazard. Redundancy means the duplication or triplication of equipment needed to operate without disruption, if and when the primary equipment fails. Redundant HMI, servers, networks and controllers that include media are common ways to achieve high availability. While most users traditionally have achieved high availability through redundancy, this increases the number of components, thus increasing the number of potential component failures. Therefore, redundancy — if not applied properly — can decrease system availability. To avoid weighing down a system with redundancy overload, process manufacturers should determine the cost of potential failures and make high availability investments accordingly. For example, would the loss of control, view, product or data be most devastating? What about damage to equipment? Is downtime the biggest concern? Once priorities are defined, users can invest resources in redundancy in critical areas to achieve high availability and best protect assets. Because most processes are enclosed in pipes and tanks and spread out over large areas, process manufacturers rely on vision systems and instrumentation to monitor the processes and systems at work. In an oil and gas refining process, for example, instrumentation is the only way to see what’s going on within the pipes and tanks. Therefore, to achieve high availability, redundant networks, redundant instruments, redundant HMI and alarm management are critical. These process operations also require redundant processors, networks and some I/O. Full system redundancy is necessary for critical operations that can’t be stopped without damaging equipment or creating a dangerous hazard. For example, an offshore, unmanned oil platform could lose millions of dollars per hour if production is halted or tens of millions of dollars if equipment is destroyed. In pharmaceutical production, a reactor may contain hundreds of thousands of dollars worth of product, so integrity of the product must be maintained. In addition, FDA and other regulations require constant tracking and recording of the ingredients and process so redundant controllers, networks and servers may be critical. For a food and beverage process operations, FDA regulations require tracking and tracing, so high availability is required for data and information. To keep track of data, redundant networks and servers are required. However, since much of the operations are batch and continuous control less critical, only certain equipment may require redundancy of the control system. >> Rockwell Automation Partners Support Process Safety For fault-tolerant solutions that help extend the continuity of your control systems, consider the Rockwell Automation-compatible products from these participating Rockwell Automation EncompassTM Product Partners. Marathon Technologies www.rockwellautomation.com/go/p-marathon Fault tolerant software for Microsoft Windows applications Moore Industries-International Inc. www.rockwellautomation.com/go/p-moore Fault tolerant Foundation Fieldbus connectivity system NEC Corp. of America www.rockwellautomation.com/go/p-nec Fault tolerant servers for Microsoft Windows applications Phoenix Digital Corp. www.rockwellautomation.com/go/p-phoenixdigital Fault tolerant, redundant fiber optic communication Stratus Technologies www.rockwellautomation.com/go/p-stratus Fault tolerant server for Microsoft Windows or Red Hat Linux operating systems Ultra Electronics www.rockwellautomation.com/go/p-ultra_electronics Fault tolerant, redundant fiber optic communication 18 THE JOURNAL | OCTOBER 2010 WWW.ROCKWELLAUTOMATION.COM/THEJOURNAL >> New Solutions Make High Availability Easier, Simpler all aspects related maintainability. Meanwhile, 100% availability may be required for water wastewater treatment operations because of regulations, and because people depend on water for survival. In addition to redundancy, process manufacturers can use design techniques — including for the controller, HMI and information system — to help achieve high availability, where redundancy is less critical. In this case, the designer must be willing to accept the fact that anything can fail, and design the facility around this notion. This often has been referred to as modular distributed design, and involves the following areas: • Distributed control architectures. • Distributed control design with independent line, zones, etc. • Distributed HMI. • Distributed databases. For example, in continuous and batch processing operations, following the S88 model helps achieve availability by allowing recipes and procedures to be ported to various equipment, lines and plants. Human interface into a process or operation is crucial and, in many cases, a requirement that often is achieved using hardwired indicator lights and manual controls. Designing in diversity is another typical method. This might mean using diverse HMI devices in conjunction with local indicator lights. Client server configurations with multiple clients linked with redundant servers provide yet another method. Technology Driving High Availability Emerging technologies are coming together to form comprehensive solutions for process manufacturers interested in achieving high availability — whether they meet that goal through design, redundancy or other means. For example, redundant communication interfaces are becoming available for a variety of network protocols, increasing connectivity down to the field device, and helping with predictive maintenance and other factors related to asset management. Distributed and more available communications can be accomplished with redundant ControlNet or with a Device Level Ring EtherNet/IP configuration. Options also exist for fault tolerance in field device networks, thanks to solutions, like intelligent junction boxes, that allow continued field indication or commands with up to two faults in the field. Rockwell Automation continues to expand its Allen-Bradley ® PlantPAxTM Process Automation System to help manufacturers meet high availability demands more easily and cost-effectively. The expansion includes: • Allen-Bradley L7x programmable automation controllers and 19.50 firmware: The L7x controllers offer significant improvements in performance and provide faster cross-loading for redundancy systems. • 1715 redundant I/O: 1715 fault-tolerant I/O provides SIL 2-rated redundant input and output modules including analog outputs configured by Rockwell Software® RSLogixTM 5000 software and supporting redundant Ethernet adapters all with no additional programming required. • FactoryTalk® Supervisory Edition View 6.0: FactoryTalk View SE 6.0 supports alarm and event server redundancy for auto-synchronization of device-based and tag-based alarms between active and standby servers and a single alarm history configuration. • EtherNet/IP I/O: DLR, Star and other EtherNet/IP topologies provide scalable resiliency to meet all network availability, cost and performance requirements. Rockwell Automation offers a complete end-to-end high availability solution that helps protect production and product quality, critical equipment and plant assets, plant personnel, the environment and surrounding community. For more information, visit www.rockwellautomation.com/go/prps. ing, the need is growing for networks to capture more data, perform additional diagnostics, access all instrumentation and other process device information remotely and leverage the data across the manufacturing enterprise to ensure high availability. With the Device Level Ring topology, the EtherNet/ IP network can be set up without the need for additional switches and the wiring is daisy-chained from node to node. This helps to reduce time and costs compared to the wiring in a star topology. This means tomorrow’s process plants can tap into well-established, robust automation networks — making it easier to connect field instrumentation with the rest of the enterprise. Maximizing Availability System interruptions and losses can threaten the productivity and performance for process manufacturers. With this in mind, process engineers can leverage emerging technologies to increase system availability and, in so doing, mitigate potential hazards and risks that could harm people, machinery or profits. The Role of EtherNet/IP Rockwell Automation Process Solutions As business drivers and regulations become more demand- www.rockwellautomation.com/go/tj10pr WWW.ROCKWELLAUTOMATION.COM/THEJOURNAL OCTOBER 2010 | THE JOURNAL 19