Twice the potential from twice the shearing

advertisement

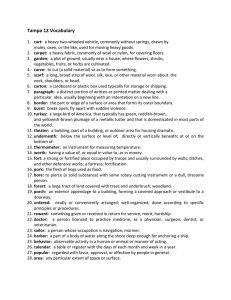

Twice the potential from twice the shearing Once or twice: During 2010, Dr Fred Wilkinson compared shearing three groups of ewes once or twice a year. The twiceyearly shorn sheep, including these 5/8 Merino 3/8 Finn ewes, produced more wool of a higher value than their annually shorn counterparts. As wool producers continue to build their flocks on better seasons and wool prices, there is growing interest in the potential benefits of shearing every six months. Pamela Lawson looks at the results from a Western Australian trial comparing different breeds being shorn traditionally — or twice a year T At a glance... ▸▸Trials in WA showed sheep shorn twice a year produce more wool at a higher percentage value than annually shorn sheep, resulting in more profit ▸▸Twice-yearly shearing also produces stronger wool of a combined longer length than annual shearing ▸▸Fibre diameter was finer in sheep shorn in autumn than spring, and spring shearing produced the whitest wool ▸▸Shorter wool is quicker to shear and makes skirting, classing and shed work easier 72 Farming Ahead July 2012 No. 246 oo much fibre length convinced former Department of Agriculture and Food Western Australia researcher Dr Fred Wilkinson to try shearing his Merino-Finn cross ewe flock twice a year. Under his traditional shearing program his fleece wool was consistently more than 100mm, much more than the market wanted. So in 2005 he made the change and was so encouraged by the positive production results from the change in November 2009 he did a breed comparison trial to compare shearings in flocks of pure Merinos, 3/8 Finn – 5/8 Merinos and 3/4 Finn – 1/4 Merinos. According to Fred these trials showed twice-a-year shearing produced more wool (especially fleece wool) and fewer pieces. “The wool was also stronger, longer (as a combined length) and whiter than wool from annual shearing, which is very encouraging for producers looking to change shearing from once to twice a year,” he said. Trial details Each trial flock was 50-head of 2008-born ewes which had run together since January 2009. After the November 2009 shearing, the ewes were paired according to greasy fleece weight and then allocated to either once-a-year shearing in November or twice-a-year shearing in May and November. This made six groups: Merinos one shearing (1X), Merinos two shearings (2X), 3/8 Finn one shearing (1X), 3/8 Finn two shearings (2X), 3/4 Finn one shearing (1X) and 3/4 Finn two shearing (2X). “At shearing in May and November 2010, composite wool samples and midside samples were taken for testing,” Fred said. “The mid-side samples were also assessed for colour as per the Australian Wool Innovation visual sheep scores guide, where score 1 is bright white and score 5 is bright yellow.” At the November shearing, the time taken to shear sheep with six and 12 www.kondiningroup.com.au Photo: Fred Wilkinson | Wool Sheep management Sheep management wool | The increase in locks in the twice-yearly shorn flocks was due to the fleece not hanging together and the parted wool falling when being taken to, or placed on, the table.” months wool was also recorded, by measuring in seconds the time from the shearer lifting the handpiece to putting it down. Telling results The one-year trial showed an increase in the annual weight of wool shorn from all three twice-yearly shorn flocks compared to the once-yearly shorn flocks. The Merinos shorn in May and November produced 0.41kg or 9 per cent more wool than their annually-shorn counterparts, while the increases were less in the crossbred flocks at 0.24kg for 3/8 Finn flock and 0.16kg for the 3/4 Finn flock shorn twice yearly (see Table 1). “A more important finding was the larger increase in the percentage of valuable fleece wool of 18 per cent, 11 per cent and 5 per cent respectively with twice yearly shearing and the corresponding decrease in the less valuable pieces,” Fred said. “The increase in locks in the twiceyearly shorn flocks was due to the fleece not hanging together and the parted wool falling when being taken to, or placed on, the table.” Quality, length and strength The autumn (May) shearing resulted in finer wool than when the same sheep were shorn in November, and when compared to the sheep only shorn in November (see Table 2). The annual wool length was increased by shearing twice yearly, with the combined length of the two shearings being 16 per cent, 18 per cent and 20 per cent longer for the Merinos, 3/8 Finns and 3/4 Finns respectively, compared to the length from once-yearly shearing. “The greatest difference between shearings was in wool strength, with the twice-yearly shearing resulting in wool nearly the double the strength of onceyearly shorn wool,” he said. “Wool from traditionally-shorn Western Australian flocks often becomes tender in autumn, with breaks in fibre occurring from March to May, decreasing its value. “The twice yearly shearing also produced much whiter wool (see Table 3) in November, improving the value of these fleeces.” Time trials Table 4 shows the shorter-wool sheep were not surprisingly quicker to shear than the www.kondiningroup.com.au Table 1 The average weight of fleece wool, pieces, bellies and locks and total wool shorn from 1X and 2X Merino, ⅜ Finn and ¾ Finn flocks Flock Merino ⅜ Merino ¾ Finn 1X 2X 1X 2X 1X 2X Fleece (kg) 3.75 4.41 3.39 3.76 2.66 2.80 Pieces (kg) 0.39 0.09 0.31 0.14 0.14 0.10 Bellies (kg) 0.26 0.25 0.28 0.27 0.09 0.12 Locks (kg) 0.11 0.17 0.05 0.10 0.05 0.08 Total (kg) 4.51 4.92 4.03 4.27 2.94 3.10 Table 2 The micron, length, strength and vegetable matter from Merino, ⅜ Finn and ¾ Finn flocks shorn 1X or 2X per year Flock Merino 1X Nov Micron (µm) ⅜ Finn 2X 1X May 18 17 Nov 19 22 ¾ Finn 2X 1X May 21 2X Nov 23 22 May 21 23 Length (mm) 97 58 55 105 61 63 100 60 60 Strength (Nktex) 32 58 50 23 58 49 17 58 39 Veg. Matter (%) 0.8 0.4 0.8 1.2 0.5 0.9 1.3 0.9 0.6 Table 3 The percentage of sheep with wool in colourscores of 1 to 3 for flocks shorn 1X or 2X per year Wool colour score 1 2 3 1X (%) 0 56 44 2X May (%) 20 80 0 2X November (%) 35 65 0 Table 4 The average time in seconds to shear sheep with 12 months and 6 months wool in November together with maximum and minimum times in the 3 flocks Flock Merino ⅜ Finn ¾ Finn Wool growth period (months) 12 6 12 6 12 6 Average time (s) 180 154 154 140 100 96 Maximum time (s) 233 203 210 236 125 121 Minimum time (s) 139 103 104 91 63 64 annually-shorn sheep, and the Merinos were slower to shear than Finn-cross animals which have clean legs and faces. “The twice-yearly shearing also saves time by being easier to skirt, as they generally just need dags and stains removed,” Fred added. “Classing this wool is also easier as tender and coloured fleeces are rare, so almost all the fleeces can be baled in the top fleece line.” Overall results Fred is confident the differences in these trials could be used to predict the effect of changing a Merino flock from annual to twice-yearly shearing. “There would be about 10 per cent more wool, with an extra 20 per cent fleece wool,” he said. “The length would increase by about 20 per cent, so 100mm produced annually would change to 60mm produced twice a year. “However, producers should consult with their wool broker as to when any penalties for short or long wool kick in, to ensure the wool cut every six month will not be unduly penalised. “From our trial results, the strength of wool cut every six months could be nearly double annually shorn wool, and the micron at the autumn shearing would be two less than the spring shearing and one less than the annual shearing.” Acknowledgements Harry Williams, the Wilkinson family and John Stanton. Contact ▶ Dr Fred Wilkinson (08) 9453 3554 Sunpick@Highway1.com.au No. 246 July 2012 Farming Ahead 73 Photo: Rural Press | Wool sheep management case studies Case study Production proof: Mark, Dianne, Geoff and Andrew Peters with a race of 2010-drop ewes that were entered in the 2012 Peppin Shaw Riverina Ewe Flock Competition. The ewes were three weeks off shears, weighing 77 kilograms on average and won the best short wool entry. Farm inform ation Biannual shearing pays dividends Property owners Mark, Dianne, Geoff and Andrew Peters Location Hillston, NSW Property size 30,000ha Annual rainfall 320mm Enterpris es Beef cattle, cereal cropping , stud and commerc ial Poll Merinos Geoff and Dianne Peters and their twin sons Andrew and Mark run a mixed farming business near Hillston in south-western NSW Geoff and Dianne Peters and their twin sons Andrew and Mark run a mixed farming business near Hillston in south-western NSW. Their properties total about 30,000ha in a region which can expect an average annual rainfall of 320mm. In addition to beef cattle and cereal cropping, the Peters run 8000 Poll Merino sheep and lambs and 5000 ewes, which form the base flock for the Ballatherie Poll Merino stud. Time for change The Peters had traditionally crutched their 21.5 micron flock in early February each year, before shearing from mid-July right through to mid-August. But after receiving wool price discounts for long staple length, and after talking to their shearing contractor about the problems associated with handling full wool sheep, in 2011 the Peters decided to try shearing twice a year, in mid-January and mid-July. “We had read in the media about wool producers seeing many benefits from sixmonthly shearing in climates similar to ours,” Geoff said. 74 Farming Ahead July 2012 No. 246 “Another incentive for us to change was that our management didn’t need to change remarkably, as we were now just shearing in January instead of crutching in February.” Many benefits In addition to avoiding the price discounts for long staple length and the easier handling of shorter-wool sheep at shearing, the Peters have seen many benefits from switching to six-monthly shearing. “We have seen an increase in annual wool production of two kilograms per head from shearing twice a year, but the seasons have been exceptional so this may decrease in the future,” Geoff said. ”Two shearings has not only improved cash flow, but also allowed us to spread our marketing risks,” he said. “We sell through a broker, who manages the sale of our wool according to market trends, selling different lines when the market is optimal. “We have also seen increased growth rates in the sheep, particularly the weaners, which in turn has resulted in better lambing and weaning percentages and better prices for cull animals. “Animal health has also improved as the lighter fleece at lambing has minimised ewe and lamb losses at this time and allowed us better lice and fly control during high risk times of year.” Making the switch According to Geoff, changing to six-monthly shearing for them was simply a matter of shearing a second time instead of crutching in winter. “We looked at eight-monthly shearing but it was impossible to fit it into our whole property management schedule, considering lambing in April, surplus sheep sales in September and our cropping program,” Geoff said. “We therefore changed all our sheep over to six-monthly shearing and haven’t looked back, experiencing no major problems so far.” Contact ▶ Geoff Peters 0428 678 136 ballatherie@bordernet.com.au www.kondiningroup.com.au sheep management case studies Wool | Photo: Peta Kellock Case study Caption: to come//// Farm inform ation Property owners ///// Location ///// Many benefits: By shearing every six Property size are avoiding the months, the Kellocks //// discounts for long wool they were 150c/kg previously Annualreceiving, rainfall while increasing overall /////wool and lamb production and improving cash flow. Case study Title//// Farm inform ation Property owners Kellock family Location Keith and Farrell Flat, SA Property size 1300ha and 1800ha Annual rainfall 450mm Enterpris es ///// A South Australian experience Kicker///// Enterpris es Stud and commerc ial Poll Merinos, irrigated lucerne, cereal cropping The Kellock family runs a Poll Merino stud, featuring a 1100-head flock of stud ewes on their 1300ha property at Keith in the upper south-east of South Australia /////run This flock is in addition to 800 commercial Poll Merino ewes (plus 1000 replacements) also run at Keith, and another 1700 commercial Poll Merino ewes (plus 800 replacements) run at their 1800ha Farrell Flat property in the state's Mid North. Each property receives an average rainfall of 450mm and is also used for irrigated lucerne seed and winter cereal cropping. Avoiding discounts The Kellocks breed a type of Merino which has long-stapled, free growing, white wool with a micron of 20.5. For many years they had traditionally shorn at the Keith property in September and crutched in April, while at the Farrell Flat property they shore in April and crutched in October. According to Stephen Kellock, the 12 months of wool growth was getting to 120mm on their breeding ewes and incurring a discount of 150c/kg. “We tried eight-month shearing at Farrell Flat for two years but got caught trying to shear before the lambs had been weaned," Stephen said. "The logistics of eight-monthly shearing is very difficult,” he said. www.kondiningroup.com.au “So in 2010, after speaking to other producers who had been shearing every six months, we bit the bullet and changed all our age groups to six-monthly shearing. “We now shear at Keith in September and March each year, and at Farrell Flat in October and April, with a pre-shearing stain crutch at each property.” A good fit Stephen says six-monthly shearing is easier to fit in with a breeding program than an eight- or 10-month shearing program, because crutching is simply replaced by shearing. “Breeding ewes are also easier to keep in forward condition, so they rear more lambs,” he said. “Once you get your head around the concept, the management falls into place. “The only problem we are incurring is the length of the wool. We aim to grow staple length of 70mm every six months as we need to have above 60mm to avoid any discounts.” Production changes “We are cutting about an extra 0.25kg per head per shearing,” Stephen said. “Tensile strength has gone from about 32nkt to 50–60nkt. But our micron has also increased by about 0.5 microns due to the short wool length.” Marketing options The Kellocks currently sell their wool at auction, due to the good wool prices at the moment. “From a budget point of view having two wool clips in a year from each property has made cashflow more even, taking into account needing to pay for four shearings,” Stephen said. “Through our broker we are monitoring any potential discounts on length, which have not been incurred so far. "In the future we will be investigating the option of selling direct to mills with the support of our broker.” Contact ▶ Stephen Kellock In addition to higher lambing and weaning 0427 438 138 percentages, the Kellocks have seen other Contact ▶ emuflat.kelvale@bigpond.com Name production improvements from six-monthly 0000 000 000 www.kelvalepollmerinos.com.au shearing. name.name@company.com.au www.company.com.au No. 246 July 2012 Farming Ahead 75