draft specifications and standards for electrical

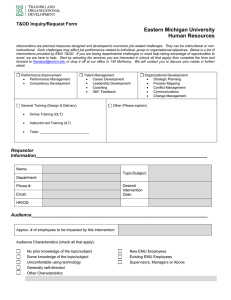

advertisement