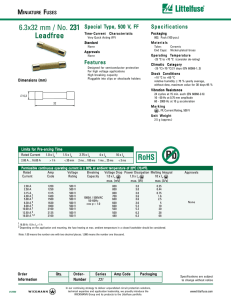

LITTELFUSE (V200CH8) VARISTOR SURF MNT 5X8MM PKG 13

advertisement

Distributed by: www.Jameco.com ✦ 1-800-831-4242 The content and copyrights of the attached material are the property of its owner. Jameco Part Number 1763587 Varistor Products Surface Mount Varistors > CH Series RoHS CH Varistor Series Description CH series transient surge suppressors are small, metal-oxide varistors (MOVs) manufactured in leadless chip form. They are intended for use in a variety of applications from low voltage DC to off-line board-level protection. These devices, which have significantly lower profiles than traditional radial-lead varistors, permit designers to reduce the size and weight and increase the reliability of their equipment designs. CH series varistors are available in a voltage range from 14V to 275V VM(AC)RMS , and energy ratings up to 23J. See the Littelfuse Multilayer Suppressor Series also. Agency Approvals Recognized under the components program of Underwriters Laboratories. Features t -FBE'SFF AGENCY AGENCY FILE NUMBER t -FBEMFTT4VSGBDF Mount Chip in 5 x 8mm Size UL E75961/E135010 t 4VQQMJFEJO5BQFBOE Reel or Bulk Pack t /P%FSBUJOHVQUP 125ºC Ambient t 7PMUBHF3BUJOHT VM(AC)RMS 14V to 275V Absolute Maximum Ratings t'PSSBUJOHTPGJOEJWJEVBMNFNCFSTPGBTFSJFTTFF%FWJDF3BUJOHTBOE4QFDJmDBUJPOTDIBSU Continuous Steady State Applied Voltage: AC Voltage Range (VM(AC)RMS) DC Voltage Range (VM(DC)) CH Series Units 14 to 275 18 to 369 V V UP A UP -55 to + 125 UP J C O C OC Transient: Peak Pulse Current (ITM) 'PST$VSSFOU4FF'JHVSF Single Pulse Energy Range 'PST$VSSFOU8BWF8TM) Operating Ambient Temperature Range (TA) Storage Temperature Range (TSTG) Temperature Coefficient (αV) of Clamping Voltage (VC) at Specified Test Current O CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied. ©2008 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com/series/CH.html for current information. 169 Revision: April 29, 2008 CH Varistor Series Varistor Products Surface Mount Varistors > CH Series Device Ratings and Specifications Maximum Ratings (125ºC) Continuous Part Number Specifications (25ºC) Varistor Voltage at 1 mA Dc Max Clamping Volt VC at Test Current (8/20μs) Test Current Transient Typical Capacitance VRMS VDC VM(AC) VM(DC) Energy (10/1000μs) WTM Peak Current (8/20μs) ITM (V) (V) (J) MIN V/%$ MAX VC IP f=1MHz (A) (V) (V) (V) (V) (A) (pF) V22CH8 14 /PUF /PUF 18.7 47 5 V27CH8 17 22 31.1 57 5 V33CH8 26 29.5 36.5 68 5 V39CH8 25 31 79 5 V47CH8 38 1.2 92 5 V56CH8 35 45 1.4 5 V68CH8 56 1.5 127 7$) 75 † 7$) 95 127 † 7$) 115 153 295 † 7$) 175 † 7$) † 7$) 395 † 7$) 595 † 7$) † 7$) 275 369 /05&4 1PXFSEJTTJQBUJPOPGUSBOTJFOUTOPUUPFYDFFE8 &OFSHZSBUJOHGPSJNQVMTFEVSBUJPOPGNTNJOJNVNUPPOFIBMGPGQFBLDVSSFOUWBMVF 3. Also rated to withstand 24V for 5 minutes. p77$)7BSJTUPSTBSFSFDPHOJ[FEVOEFS6-mMF&BTBSFDPHOJ[FEDPNQPOFOU Current, Energy and Power Derating Curve Continuous power dissipation capability is not an applicable design requirement for a suppressor, unless transients occur in rapid succession. Under this condition, the average power dissipation required is simply the energy (watt-seconds) per pulse times the number of pulses per second. The power so developed must be within the specifications shown on the Device Ratings and 4QFDJmDBUJPOTUBCMFGPSUIFTQFDJmDEFWJDF'VSUIFSNPSF the operating values need to be derated at high tempera UVSFTBTTIPXOJO'JHVSF#FDBVTFWBSJTUPSTDBOPOMZ dissipate a relatively small amount of average power they are, therefore, not suitable for repetitive applications that involve substantial amounts of average power dissipation. CH Varistor Series PERCENT OF RATED VALUE 100 90 80 70 60 50 40 30 20 10 0 -55 50 60 70 80 90 100 110 120 130 140 150 AMBIENT TEMPERATURE ( oC) 170 Revision: April 29, 2008 ©2008 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com/series/CH.html for current information. Varistor Products Surface Mount Varistors > CH Series PERCENT OF PEAK VALUE Peak Pulse Current Test Waveform 100 17JSUVBM0SJHJOPG8BWF 55JNFGSPNUPPG1FBL T17JSUVBM'SPOU5JNFYU T2 = Virtual Time to Half Value (Impulse Duration) 90 50 Example 'PSBOçT$VSSFOU8BWFGPSN 8 s = T17JSUVBM'SPOU5JNF T52 = Virtual Time to Half Value 10 O1 T TIME T1 T2 Clamping Voltage for V22CH8 – V68CH8 4,000 MAXIMUM CLAMPING VOLTAGE MODEL SIZE 5 x 8mm 22 TO 56VN(DC) RATING TA = -55oC TO 125 oC 200 100 90 80 70 60 50 40 V68CH8 V56CH8 V47CH8 V39CH8 V33CH8 V27CH8 V22CH8 30 20 10 10 -3 10 -2 10 -1 10 0 MAXIMUM CLAMPING VOLTAGE MODEL SIZE 5 x 8mm 100 TO 430VN(DC) RATING TA = -55oC TO 125 oC 3,000 MAXIMUM PEAK VOLTS (V) MAXIMUM PEAK VOLTS (V) 500 400 300 Clamping Voltage for V120CH8 – V430CH8 10 1 10 2 2,000 1,000 900 800 700 600 500 400 V240CH8 V220CH8 V200CH8 300 200 V180CH8 V150CH8 V120CH8 100 10 -3 10 3 V430CH8 V390CH8 V360CH8 10 -2 10 -1 PEAK AMPERES (A) 10 0 10 1 10 2 PEAK AMPERES (A) 10 3 10 4 Pulse Rating Curves Surge Current Rating Curves For V120CH8 - V430CH8 Surge Current Rating Curves for V22CH8 - V56CH8 1 200 2 100 10 50 10 2 20 2,000 MODEL SIZE 5 x 8mm V22CH8 - V56CH8 10 5 2 1 500 10 4 10 5 10 6 10 3 MODEL SIZE 5 x 8mm V120CH8 - V430CH8 1,000 SURGE CURRENT (A) SURGE CURRENT (A) 500 INDEFINITE 1 10 100 50 20 10 10 6 5 INDEFINITE 0.5 0.2 20 10 2 10 3 10 4 10 5 2 200 2 100 1,000 IMPULSE DURATION (μs) 1 10,000 20 100 1,000 10,000 IMPULSE DURATION (μs) NOTE: If pulse ratings are exceeded, a shift of VN(DC) (at specified current) of more than ±10% could result. This type of shift, which normally results in a decrease of VN(DC), may result in the device not meeting the original published specifications, but it does not prevent the device from continuing to function, and to provide ample protection. ©2008 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com/series/CH.html for current information. 171 Revision: April 29, 2008 CH Varistor Series Varistor Products Surface Mount Varistors > CH Series Lead (Pb) Soldering Recommendations The principal techniques used for the soldering of components in surface mount technology are IR Re-flow & 8BWFTPMEFSJOH5ZQJDBMQSPmMFTBSFTIPXOPOUIFSJHIU Reflow Solder Profile 250 The recommended solder for the CH suppressor is B4O1C"H 4O1C PS4O1C Littelfuse also recommends an RMA solder flux. MAXIMUM TEMPERATURE 230°C TEMPERATURE °C 200 8BWFTPMEFSJOHJTUIFNPTUTUSFOVPVTPGUIFQSPDFTTFT To avoid the possibility of generating stresses due to thermal shock, a preheat stage in the soldering process is recommended, and the peak temperature of the solder process should be rigidly controlled. 40-80 SECONDS ABOVE 183°C 150 RAMP RATE <2°C/s 100 PREHEAT DWELL 50 0 8IFOVTJOHBSFnPXQSPDFTTDBSFTIPVMECFUBLFOUP ensure that the CH chip is not subjected to a thermal gradient steeper than 4 degrees per second; the ideal gradient being 2 degrees per second. During the soldering QSPDFTTQSFIFBUJOHUPXJUIJOEFHSFFTPGUIFTPMEFSÓT peak temperature is essential to minimize thermal shock. PREHEAT ZONE 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 TIME (MINUTES) Wave Solder Profile 300 Once the soldering process has been completed, it is still necessary to ensure that any further thermal shocks are avoided. One possible cause of thermal shock is hot printed circuit boards being removed from the solder process and subjected to cleaning solvents at room temperature. The boards must be allowed to cool gradually UPMFTTUIBO$CFGPSFDMFBOJOH MAXIMUM WAVE 260°C TEMPERATURE °C 250 200 150 SECOND PREHEAT 100 FIRST PREHEAT 50 0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 TIME (MINUTES) 3.5 4.0 4.5 Lead-free (Pb-free) Soldering Recommendations 5IFQSFGFSSFETPMEFSJT4O"H$V XJUIBO RMA flux, but there is a wide selection of pastes & fluxes available with which the nickel barrier parts should be compatible. Lead-free Re-flow Solder Profile 300 MAXIMUM TEMPERATURE 250˚C, TIME WITHIN 5˚C OF PEAK 20 SECONDS MAXIMUM 250 TEMPERATURE °C The reflow profile must be constrained by the maximums JOUIF-FBEGSFF3FnPX1SPmMF'PS1CGSFF8BWFTPMEFSJOH UIF8BWF4PMEFS1SPmMFTUJMMBQQMJFT /PUFUIF1CGSFFQBTUFnVYQSPmMFXFSFVTFEGPS evaluation purposes by Littelfuse, based upon industry standards & practices. There are multiple choices of all three available, it is advised that the customer explores the optimum combination for their process as processes vary considerably from site to site. RAMP RATE <3˚C/s 200 60 - 150 SEC > 217˚C 150 100 PREHEAT ZONE 50 0 0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 TIME (MINUTES) CH Varistor Series 172 Revision: April 29, 2008 ©2008 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com/series/CH.html for current information. Varistor Products Surface Mount Varistors > CH Series Part Numbering System V 220 CH 8 X LITTELFUSE VARISTOR TECHNOLOGY PACKAGING OPTIONS No Letter: Standard 13 Inch Reel T: 7 Inch Reel S: Bulk Pack NOMINAL VARISTOR VOLTAGE SERIES DESIGNATOR RELATIVE SIZE INDICATOR Dimensions 1"%-":065%&.&/4*0/4 C NOTE 1 Symbol B Inches Min Max B C $)*1-":065%*.&/4*0/4 Min A D A Millimeters Max - - E L 8 /05&"WPJENFUBMSVOTJOUIJTBSFB4PMEFSJOHSFDPNNFOEBUJPOT.BUFSJBM4O1C "HPSFRVJWBMFOU5FNQFSBUVSFo$.BYT.BY'MVY3." E L D W ©2008 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com/series/CH.html for current information. 173 Revision: April 29, 2008 CH Varistor Series Varistor Products Surface Mount Varistors > CH Series Tape and Reel Specifications Symbol P0 E W P P2 F K0 D SECTION THRU CAVITY B0 A0 D1 PLAN VIEW OF STRIP CROSS SECTION (REF. PLANE FOR A 0 & B0) H0 B0 R1 R2 K0 R3 A0 B Cavity Length $BWJUZ8JEUI K Cavity Depth .JO H 3FG1MBOFGPS"BOE# R1, R2, R3 T T T R4 CAVITY DETAILS Tape Cavity Radii .BY Carrier Tape Thickness .BY T1 Cover Tape Thickness .BY E Sprocket Hole from Edge P Sprocket Hole Pitch D Sprocket Hole Diameter P2 Hole Centre to Component Centre R4 Min. Bending Radius .JO MINIMUM BENDING RADIUS REELED RADIUS DETAILS Size (mm) A T1 K Parameter 1.5 D1 Ejection Hole Diameter 1.5 Min. K Overall Thickness .JO P Pitch Of Component ' Sprocket Hole to Ejection Hole 8 $BSSJFS5BQF8JEUI /PUFT t$POGPSNTUP&*"3FWJTJPO" t$BOCFTVQQMJFEUP*&$QVCMJDBUJPO Standard Packaging Special Packaging CH Series varistors are always shipped in tape and reel.The TUBOEBSEJOSFFMVUJMJ[FEDPOUBJOTQJFDFT Option 1JODISFFMTDPOUBJOJOHQJFDFTBSFBWBJMBCMF To order 7in reels add a T suffix to the part number; e.g., V47CH8T. Option 2'PSTNBMMRVBOUJUJFTMFTTUIBOQJFDFT UIF units are shipped bulk pack. To order, add a S suffix to the part number; e.g., V47CH8S. /PUFBMTPUIBUUIF$)4FSJFTSFDFJWFTOPCSBOEJOHPOUIF chip itself. CH Varistor Series 174 Revision: April 29, 2008 ©2008 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com/series/CH.html for current information.