siemens.com/generator-breaker

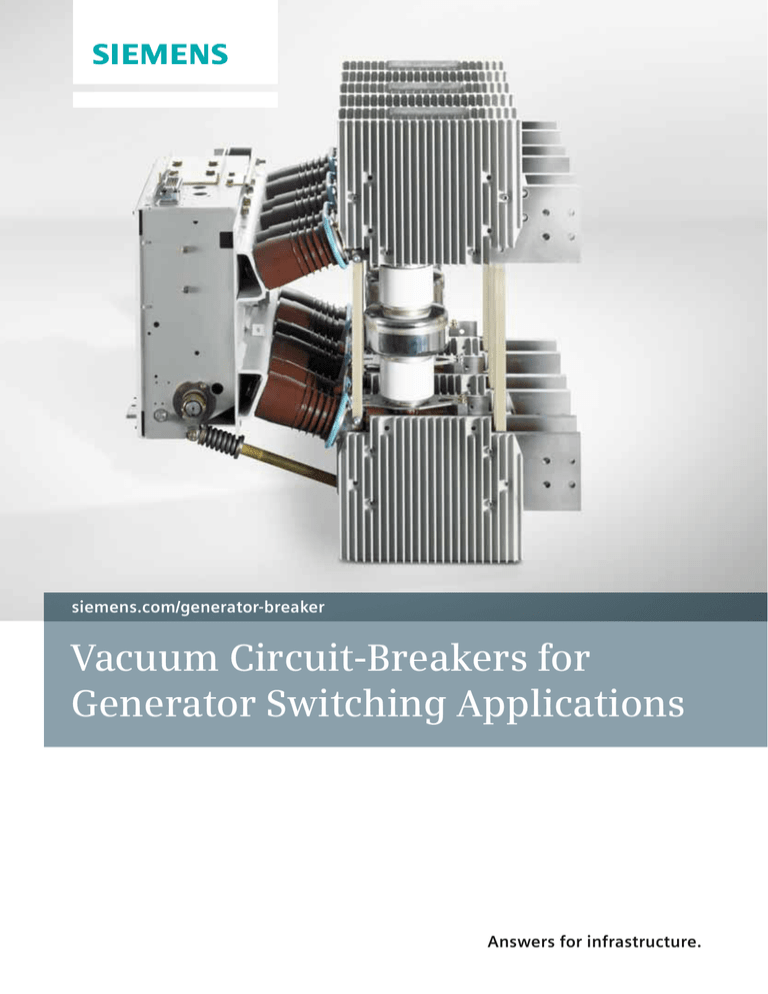

Vacuum Circuit-Breakers for

Generator Switching Applications

Answers for infrastructure.

Convincing all along the line

Switchgear and switching devices from Siemens

Whether it be vacuum interrupters,

vacuum circuit-breakers, or complete

switchgear assemblies: Siemens

offers the suitable solution for

every requirement.

Grow with your requirements

No question: The worldwide energy

demand will continue to increase rapidly,

placing higher performance requirements

on energy suppliers and industrial

facilities.

■

■

■

■

To provide them with the decisive advantage, Siemens has been constantly developing and improving high-current and

generator circuit-breakers, which are able

to withstand increasingly higher currents.

The top priorities are reliability and maintenance-free design throughout the entire

service life. With comprehensive simulations, preliminary studies, state-of-the-art

development technologies, and modern

manufacturing processes, Siemens sustainably maintains its leading position

in the field of vacuum circuit-breakers.

With Siemens products, the performance,

reliability and economic efficiency of the

entire switchgear assembly grows, and

life-cycle costs are reduced.

Over 40 years of experience

in vacuum switching technology

In particular, Siemens has perfected its

vacuum circuit-breakers for generator

switching applications, where they are

subjected to high thermal and mechanical

stress:

■ Special contact material for minimum

contact wear

■ Specifically developed contact system

2

Optimized design for efficient cooling

Post insulator construction for highest

mechanical stability

Safe breaking operations by controlling

long arcing times even in case of

missing zero crossings

Transient recovery voltages with high

rates-of-rise, typical for generators, are

controlled without additional capacitor

circuits

Application of the proven vacuum switching technology is thus possible with ever

increasing ratings, which formerly had

to be implemented with SF6 switching

technology.

Vacuum switching technology

established on the market

The exceptional economic and technological aspects of the vacuum quenching

principle have made the vacuum circuitbreaker the device that is mostly used

worldwide for voltage ratings from

1 kV to 52 kV.

In the last years, the application of

the vacuum switching technology has

expanded to very high current ratings,

and it is largely accepted even in the

field of generator switching duties.

Siemens offers a wide range of vacuum

circuit-breakers for generator switching.

Features of the

Siemens vacuum switching technology

Constant dielectric

■ The hermetically closed vacuum interrupters are

insensitive to environmental influences

■ Switching processes in the vacuum do not produce

any decomposition products as this is the case with

SF6 circuit-breakers

Constant contact resistance

■ As there is no oxidation in the vacuum,

the contact surfaces remain metallically pure

■ The very small contact resistance prevails

throughout the entire service life

■ Separate main and arcing contacts, such as

required for SF6 circuit-breakers, are not necessary

Suitable for all switching duties

■ Small chopping currents

■ Free of restrikes

■ Breaking of highest normal and short-circuit currents

Economic advantages

■ Vacuum interrupters are maintenance-free

■ Modern vacuum circuit-breakers are maintenance-free

up to 10,000 operating cycles

Advantages of arc extinction

in the vacuum

Vacuum circuit-breakers have a minimum arc power, as there is only contact

material, but no ionisable medium available. The arc already extinguishes at a

minimum contact distance (2–3 mm).

Near current zero, the arc power is not

sufficient to maintain the plasma. The

current is interrupted. With this contact

distance, the dielectric recovery of the

contact gap is enough to assume the

transient recovery voltage.

High reliability of vacuum circuit-breakers

■ Low number of moving parts inside the arcing chamber

■ Extremely high mean-time-to-failure (MTTF) values

of the vacuum interrupters

Minimum use of plastic material

in vacuum circuit-breakers

■ Air is the main insulator

■ Avoidance of creepage paths and partial discharges

Safety first

■ In the extremely unlikely case of loss of vacuum,

only an arc develops, as the current is interrupted

inside a ceramic-metal housing

3

Proven quality from Siemens

Type-tested according to all relevant standards

Type tests as specified in IEC 62271-100 are performed as a rule for

all Siemens circuit-breakers. Generator circuit-breakers are additionally

tested in accordance with IEEE C37.013. This North American

ANSI Standard is the only worldwide standard to take into account

the increased requirements to which the devices are subjected when

switching generators. As a result, ANSI has also become the leading

standard for generator circuit-breakers in IEC-oriented professional

circles.

Standard IEEE C37.013 includes in particular:

■ For generator-side faults: High DC components

and the resulting missing zero crossings

■ For system-side faults: Higher TRV rates-of-rise

■ Higher test voltage levels

Vacuum circuit-breakers for generator switching applications up to 17.5 kV

“Classic” design

“Phase-segregated” design

In

17.5 kV

12,000 A

360 MVA

8,000 A

240 MVA

3AH371

3AH373

6,300 A

180 MVA

3AH375

4,000 A

120 MVA

3AH381

3,150 A

100 MVA

3AK763

40 kA

4

50 kA

63 kA

72 kA

80 kA

90 kA

Ik

3AH37 and 3AH38

Reliable switching capacity up to 90 kA resp.

a rated normal current of 12,000 A

Today, in numerous power supply companies worldwide, the high-current

and generator circuit-breaker 3AH38 is standard for breaking normal currents

up to 4,000 A. It is the first vacuum circuit-breaker with 63 kA and 72 kA to

be type-tested according to the criteria of generator circuit-breaker standard

IEEE C37.013.

Its counterpart for higher generator ratings is 3AH37, the first vacuum circuitbreaker worldwide which can carry a normal current of 6,300 A on a sustained

basis up to 24 kV without forced cooling. Moreover, at a voltage level of 24 kV

it controls short-circuit currents up to 72 kA – with forced cooling, the 3AH37

can be operated with normal currents up to 8,000 A.

Being optimized for interconnected operation, the circuit-breakers can be

used in switchgear with enclosed phases, and flexibly in retrofit business.

Hereby, highest normal currents up to 12,000 A with a short-circuit breaking

capacity of 80 kA, and up to 6,300 A at 90 kA are reached.

Vacuum circuit-breakers for generator switching applications up to 24 kV

“Classic” design

“Phase-segregated” design

In

24 kV

12,000 A

500 MVA

8,000 A

330 MVA

3AH371

3AH374

6,300 A

260 MVA

3AH376

4,000 A

160 MVA

3,150 A

130 MVA

with forced cooling

50 kA

63 kA

72 kA

80 kA

90 kA

Ik

5

3AK763

The compact vacuum circuit-breaker for generator switching applications

Compact design – high performance

Due to its pole shells with a pole-centre

distance of only 210 mm, the 3AK7

combines high mechanical resistance

with a very compact design, and is thus

perfectly suitable for use in compact

switchgear.

As the construction is almost identical

with 3AK7 IEC 50 kA, it offers a profitable opportunity for switchgear manufacturers to cover also smaller generator

switching applications besides the

IEC high-current market. The 3AK763

is designed for 10,000 mechanical operating cycles and type-tested according

to IEEE C37.013.

The 3AK is used, for example,

in the Siemens switchgear type

NXAirP for generator switching.

Rated short-circuit breaking current ISC (3s)

DC component of the rated short-circuit breaking current

[kA]

40

[%]

75

Asymmetrical breaking current

[kA]

58

Rated short-circuit making current

[kA]

110

Generator short-circuit breaking current ISC gen

[kA]

20

[%]

117

DC component of the short-circuit breaking current

Asymmetrical breaking current

Rated currents

[kA]

39

[A]

1,250; 2,000; 2,500; 3,150; 4,000 (with forced cooling)

Rated voltage 17.5 kV (IEC 62271); 15 kV (IEEE C37.013a)

50/60 Hz; Up = 95 kV; Ud = 38 kV

3AK763

Rated operating sequence

– at short-circuit breaking current

CO – 30 min – CO, up to 30 short-circuit breaking operations

Further operating sequences possible:

O – 3 min – CO – 3 min – CO, …

– at normal current

O – 3 min – CO – 3 min – CO, up to 10,000 operating cycles

Up = Rated lightning impulse withstand voltage

6

Ud = Rated short-duration power-frequency withstand voltage

3AH37 and 3AH38

Vacuum circuit-breakers for generator switching applications

Modular design – maximum flexibility

Due to the modular design of the circuitbreaker, the best materials can be used

each for the current path, electric flux

and cooling. Thus, the 3AH37 combines

low resistance of the main circuit with

high mechanical stability and ideal cooling performance.

Moreover, the modular construction

enables even horizontal installation of

the circuit-breaker, if required. To do

this, cooling elements can be installed

that are especially provided for this

mounting position. Thus, the 3AH37

can be operated continuously in every

position without additional fans, reliably

excluding any overheating.

3AH37 and 3AH38 are installed,

for example, in the Siemens

switchgear type HB1.

Rated short-circuit breaking current ISC (3s)

[kA]

50

63

72

[%]

75

65

65

Asymmetrical breaking current

[kA]

73

86

98

Rated short-circuit making current

[kA]

137

173

197

Generator short-circuit breaking current ISC gen

[kA]

DC component of the rated short-circuit breaking current

DC component of the short-circuit breaking current

Asymmetrical breaking current

Rated currents

31.5

36

[%]

110

130

130

110

[kA]

46

52

66

67

[A]

25

3,150; 4,000; 5,000; 6,300; 8,000 (with forced cooling)

Rated voltage 17.5 kV (IEC 62271); 15.5 kV (IEEE C37.013a)

50/60 Hz; Up = 110 kV; Ud = 50 kV

3AH3817 3AH3712 3AH3818 3AH3713 3AH3819 3AH3714

(≤ 4000 A) (> 4000 A) (≤ 4000 A) (> 4000 A) (≤ 4000 A) (> 4000 A)

Rated voltage 24 kV (IEC 62271; IEEE C37.013a)

50/60 Hz; Up = 125 kV; Ud = 60 kV

3AH3722 3AH3722

(≤ 4000 A) (> 4000 A)

3AH3723

3AH3724

Rated operating sequence

– at short-circuit breaking current

CO – 30 min – CO, up to 30 short-circuit breaking operations

Further operating sequences possible:

O – 3 min – CO – 3 min – CO, …

– at normal current

O – 3 min – CO – 3 min – CO, up to 10,000 operating cycles

Up = Rated lightning impulse withstand voltage

7

Ud = Rated short-duration power-frequency withstand voltage

3AH37

The three-circuit-breaker solution for “phase-segregated” design

For generator switching applications

with designs where the phases are

segregated, the requirements for pole

synchronism have been implemented

according to IEC 62271-100, and tested

with short-circuit currents up to 80 kA

and normal currents up to 12,000 A.

The three-circuit-breaker solution is also used as a single-phase enclosed design

in the Siemens switchgear type HB3.

Rated short-circuit breaking current ISC (3s)

[kA]

50

63

72

[%]

75

65

65

65

[kA]

73

86

98

109

Rated short-circuit making current

[kA]

137

173

197

219

Generator short-circuit breaking current ISC gen

[kA]

25

31.5

36

40

[%]

110

130

110

110

[kA]

46

66

67

74

DC component of the rated short-circuit breaking current

Asymmetrical breaking current

DC component of the short-circuit breaking current

Asymmetrical breaking current

Rated currents

[A]

80

4,000; 5,000; 6,300; 8,000; 10,000; 12,000

Rated voltage 17.5 kV (IEC 62271); 15.5 kV (IEEE C37.013a)

50/60 Hz; Up = 110 kV; Ud = 50 kV

3AH3732

3AH3733

3AH3734

3AH3735

Rated voltage 24 kV (IEC 62271; IEEE C37.013a)

50/60 Hz; Up = 125 kV; Ud = 60 kV

3AH3742

3AH3743

3AH3744

3AH3745

Rated operating sequence

– at short-circuit breaking current

– at normal current

Up = Rated lightning impulse withstand voltage

CO – 30 min – CO, up to 30 short-circuit breaking operations

Further operating sequences possible:

O – 3 min – CO – 3 min – CO, …

O – 3 min – CO – 3 min – CO, up to 10,000 operating cycles

Ud = Rated short-duration power-frequency withstand voltage

8

In order to control generator switching applications up to 90 kA, this circuit-breaker was

developed based on the well-known 3AH37

operating mechanism, and an advanced

vacuum interrupter was installed.

Example for a retrofit installation: Replacement of compressed-air

generator circuit-breakers (6 kV – 86.5 kA – 3,500 A)

Rated short-circuit breaking current ISC (3s)

[kA]

DC component of the rated short-circuit breaking current

90

[%]

45

[kA]

107

Rated short-circuit making current

[kA]

247

Generator short-circuit breaking current ISC gen

[kA]

45

[%]

110

Asymmetrical breaking current

DC component of the short-circuit breaking current

Asymmetrical breaking current

Rated currents

[kA]

83

[A]

4,000; 5,000; 6,300

Rated voltage 17.5 kV (IEC 62271); 15.5 kV (IEEE C37.013a)

50/60 Hz; Up = 110 kV; Ud = 50 kV

3AH3756

Rated voltage 24 kV (IEC 62271; IEEE C37.013a)

50/60 Hz; Up = 125 kV; Ud = 60 kV

3AH3766

Rated operating sequence

– at short-circuit breaking current

– at normal current

Up = Rated lightning impulse withstand voltage

CO – 30 min – CO, up to 30 short-circuit breaking operations

Further operating sequences possible:

O – 3 min – CO – 3 min – CO, …

O – 3 min – CO – 3 min – CO, up to 10,000 operating cycles

Ud = Rated short-duration power-frequency withstand voltage

9

More than a good technology

The Siemens performance portfolio – from customer advice to reliable switchgear

Correct selection of the

generator circuit-breaker

Selection criteria are:

■ Rated voltage

■ Rated current

■ System-side short circuit

■ Generator-side short circuit

Design for normal operation

In the vicinity of generators, special

conditions arise. Thus, every application

is specifically adapted to the customer’s

requirements.

Sectional view of a vacuum

interrupter

Basis for the solutions is the application

guide in IEEE C37.013.

The DC component of the generatorside short-circuit current is higher,

which must also be taken into account

for assessment of the breaking capacity.

Overvoltage protection measures

From the view of the vacuum switching

principle, no overvoltage protection

measures are necessary for switching

generators, unless the short-circuit

current of the generator is smaller

than 600 A. However, surge arresters

are usually equipped for this switching

application in order to protect the

expensive generators from all other

overvoltages.

Design for the case of fault

In general, the symmetrical system-side

short-circuit current (case of fault a)

is higher than the generator-side shortcircuit current (case of fault b), and

therefore determines the required

breaking capacity of the generator

circuit-breaker.

In the case of fault, two different fault current components overlap.

The short-circuit current component to be interrupted is supplied by

a) High-voltage system or

b) Generator or

c) High-voltage system and generator

System

transformer

b)

C)

Fault location a: System-side short-circuit

with permanent AC component

Auxiliary

transformer

a)

G

Fault location b: Generator-side short-circuit

with missing zero crossing

10

You know your application.

And we know the behaviour

and features of our switching

devices.

Together we work out the

perfect solution for your

application.

For this purpose, we kindly ask you

to submit the following data:

■ Data sheets of:

– Generator

– Transformer

– Auxiliary transformer & motors,

if applicable

■ Single-line diagram

■ Information on equipment operation,

e.g. interconnected circuits

Based on the information concerning

your application, our experts select a

circuit-breaker which reliably controls

all service conditions, including tripping

in case of fault.

Among other things, the result of the

calculations contains a graphical representation of the current characteristics,

as shown below:

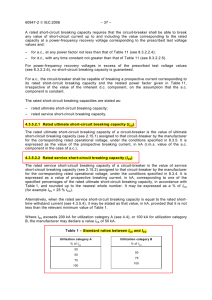

Basic representation of the analysis for the case of fault

Three-phase short-circuit current

Phase T – first-pole-to-clear

isc(t)

(kA)

R

S

T

100

Isc=24.2 kA

80

Isc=20.4 kA

1st zero crossing

60

40

20

Isc=20.2 kA

DC 59%

0

–20

tarc total=11 ms

–40

tarc min=4.4 ms

–60

Contact separation

tcp=49 ms

–80

Time (s)

–100

0.000

0.020

0.040

0.060

0.080

0.100

11

More than 1,300 systems are installed

in generator switching applications

worldwide

Siemens AG

Infrastructure & Cities Sector

Low and Medium Voltage Division

P.O. Box 3240

91050 Erlangen, Germany

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 8437

Fax:

+49 180 524 2471

(Charges depending on provider)

E-mail: support.IC@siemens.com

© Siemens AG 2013

Printed in Germany

TH 260-120542 WS 04131.0

Order No. IC1000-G310-A100-X-7600

All rights reserved.

Trademarks mentioned in this

document are the property

of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document

contains general descriptions of

the technical options available,

which do not always have to be

present in individual cases. The

required features should therefore

be specified in each individual case

at the time of closing the contract.