Measurement of the absolute reflectance of PTFE immersed in liquid

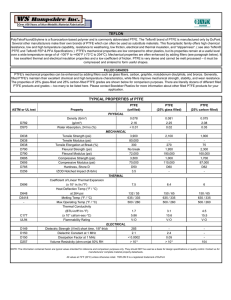

advertisement

Measurement of the absolute reflectance of PTFE immersed in liquid xenon F. Neves, A. Lindote, A. Morozov, V. Solovov, C. Silva and I. Lopes IDM2016, 18-22 July Outline ● Context & method; ● Experimental setup; ● Experimental results; ● Reflectivity models & MC simulations: ● – Fitting the exp. results using a diffuse-only reflectivity model; – Fitting the exp. results using a diffuse+specular reflectivity model; Summary & Conclusions. IDM 2016, 18-23 July 2 Context Several Liquid Xenon (LXe) detectors used in direct DM searches (ZEPLIN-II, LUX, XENON, PANDA-X) and other rare event searches (EXO, MEG) used PTFE reflectors to improve the light collection from xenon scintillation (178 nm); PTFE reflectance has been measured to be 50-70% for xenon scintillation light in vacuum and at room temperature and it is known to be much higher when immersed in LXe; Nevertheless, extrapolations for the reflectance of the PTFE immersed in LXe are systematically and significantly lower than the values � (>95%) obtained by fitting the measured light collection to detailed MC simulations of light propagation; Temperature (≈-100 ºC), light absorption in the liquid by impurities and Rayleigh scattering put severe constrains on using traditional methods (e.g. goniometers) to measure directly the reflectance of PTFE immersed in LXe; Even in a dedicated setup, detailed MC simulations of light propagation in the liquid are necessary to take into consideration the effect of Rayleigh scattering and light absorption, with the former depending strongly on the experimental conditions. Measure candidate samples to choose the best PTFE for LZ; IDM 2016, 18-23 July 3 Context Several Liquid Xenon (LXe) detectors used in direct DM searches (ZEPLIN-II, LUX, XENON, PANDA-X) and other rare event searches (EXO, MEG) used PTFE reflectors to improve the light collection from xenon scintillation (178 nm); PTFE reflectance has been measured to be 50-70% for xenon scintillation light in vacuum and at room temperature and it is known to be much higher when immersed in LXe; Nevertheless, extrapolations for the reflectance of the PTFE immersed in LXe are systematically and significantly lower than the values � (>95%) obtained by fitting the measured light collection to detailed MC simulations of light propagation; Temperature (≈-100 ºC), light absorption in the liquid by impurities and Rayleigh scattering put severe constrains on using traditional methods (e.g. goniometers) to measure directly the reflectance of PTFE immersed in LXe; Even in a dedicated setup, detailed MC simulations of light propagation in the liquid are necessary to take into consideration the effect of Rayleigh scattering and light absorption, with the former depending strongly on the experimental conditions. Measure candidate samples to choose the best PTFE for LZ; IDM 2016, 18-23 July 4 Context Several Liquid Xenon (LXe) detectors used in direct DM searches (ZEPLIN-II, LUX, XENON, PANDA-X) and other rare event searches (EXO, MEG) used PTFE reflectors to improve the light collection from xenon scintillation (178 nm); PTFE reflectance has been measured to be 50-70% for xenon scintillation light in vacuum and at room temperature and it is known to be much higher when immersed in LXe; Nevertheless, extrapolations for the reflectance of the PTFE immersed in LXe are systematically and significantly lower than the values � (>95%) obtained by fitting the measured light collection to detailed MC simulations of light propagation; Temperature (≈-100 ºC), light absorption in the liquid by impurities and Rayleigh scattering put severe constrains on using traditional methods (e.g. goniometers) to measure directly the reflectance of PTFE immersed in LXe; Even in a dedicated setup, detailed MC simulations of light propagation in the liquid are necessary to take into consideration the effect of Rayleigh scattering and light absorption, with the former depending strongly on the experimental conditions. Measure candidate samples to choose the best PTFE for LZ; IDM 2016, 18-23 July 5 Experimental setup The method: Measure the light collection efficiency as a function of h (Changes the LXe volume and PTFE area) and compare with a detailed MC model of the setup. The setup: Allows an easy and fast replacement of the PTFE samples; sub-mm precision in determining the thickness (h) of the LXe layer between the 241Am source and the PMT; IDM 2016, 18-23 July 6 Experimental setup Level sensor Moving PTFE wall 7.6 mm 241 Am source Fixed PTFE walls PMT (R1668) Optical Surface (fixed walls) Moving PTFE wall PMT HV divider IDM 2016, 18-23 July 7 Experimental results Measured 3 PTFE samples ● 807NX, NXT85 (APT); ● 8764 (Technetics) – LUX; Cool down to ≈-100 ºC and let the setup stabilize for ~12 hours prior to condensing Xe; Multiple runs per sample (cool down / warm up cycle) and multiple sweeps per run to test reproducibility; Xenon purity monitored (elivetime): > 40 us (sens. max). Absolute light collection (�) indicates that the LUX PTFE has the highest reflectance followed by the NXT85 and 807NX. IDM 2016, 18-23 July 8 Optical Simulation Moving PTFE wall MC simulation using the ANTS2 package (http://coimbra.lip.pt/ants/ants2.html) Simulated only the inner chamber; 241 Am source Photons (not detected) Fixed PTFE walls Photon (detected) PMT window Optical processes/boundaries considered: PMT quartz window: n=1.59 (Gupta, 1998); SS (source): n=1.07, k=0.6 (Karlsson, 1982); Rayleigh scatt. (LXe): 29 cm (Seidel, 2002); Absorption (LXe): � LXe=[0.1; 5] m; PTFE reflectivity models: Diffuse-only (D): APTFE=[0.6;1]; Diffuse+Specular (DS): APTFE=[0.6;1], nPTFE=[1.3;2.0]; nLXe=1.69 (Solovov, 2003) 3D/4D � template grid on the free optical parameters ( � LXe,APTFE[,nPTFE])+h with linear interpolation for each of the PTFE models (D/DS). (shown: 1 event with 20 photons) IDM 2016, 18-23 July 9 Optical simulation: 241 Am source The reflectance of the SS (241Am source) is unknown, but this is the 1st surface seen by ~50% of the light. Tested three values of the reflectance (Karlsson, 1982 [SS1, SS2], Solovov 2003 [SS3]) for different SS: Significantly different values of the absolute light collection (⧍�~30%)! A=0.95 nPTFE=1.7 � =1900 mm But the same relative light collection (scale factor). IDM 2016, 18-23 July 10 Analysis (fitting) procedure Cannot fit the absolute light collection (�) due to the uncertainties on the Stainless Steel (SS) reflectance and also on the PMT QE. Instead we fit the relative light collection by scaling the simulated light collection (�𝓜 ): scale factor exp. light collection exp. stat. errors sim. stat. errors sim. light collection re-positioning of the source 𝓜: Model specification: Diffuse-only (D); Diffuse+Specular (DS); �: Model-specific parameters: ( � LXe,APTFE)D or ( � LXe,APTFE,nPTFE)DS; I𝓜: Simulated light collection from 100k photons per α particle, for a total of 300 αs distributed uniformly over the 241Am source surface; � src: Measured to be <0.1 �m when re-positioning the source (room temperature); IDM 2016, 18-23 July 11 PTFE reflectivity: diffuse model The Albedo (A) sets the probability of the light being reflected (not absorbed) from the PTFE; The reflected light follows a Lambert law: dI/dΩ=Acos(�); No surface description (e.g. roughness); In spite of its simplicity, this is the model assumed by most experiments using reflector PTFE panels (e.g. LUX); IDM 2016, 18-23 July 12 PTFE reflectivity: diffuse model Can only set a lower limit for the reflectance (R) due to A and � being degenerate Fails to describe the excess of light for h<40 mm PTFE (Fitting h>40 mm where the Lambert component dominates and for λ ≤ 5 m) IDM 2016, 18-23 July R (reflectivity) Best fit 95% CL 807NX 0.972 >0.97 NXT85 0.986 >0.984 LUX 0.987 >0.985 13 PTFE reflectivity: diffuse+specular model Probability of specular reflection: Rspec(nPTFE/nLXe;�) (Snell’s equations for unpolarized light); Probability of diffuse reflection: Rdif=A[1-Rspec(nPTFE/nLXe;�)]; No surface description (e.g. roughness); The reflectance now depends on the incident light distribution. IDM 2016, 18-23 July 14 PTFE reflectivity: diffuse+specular model The reflectance is calculated for a white sky illumination (Bi-Hemispherical Reflectance); Can only set a lower limit on the BHR due to the degeneracy between A and �; Good agreement with LUX data (PRD, in preparation) IDM 2016, 18-23 July PTFE BHR Best Fit 95% CL 807NX 0.961 >0.955 NXT85 0.975 >0.973 LUX 0.978 >0.975 15 Summary & conclusions We designed & built an experimental setup for measuring the absolute reflectance of PTFE immersed in LXe; We fitted the experimental results from three different samples of PTFE against a detailed MC simulation using two different optical models for PTFE reflectivity: diffuse-only and diffuse+specular reflection; The implemented method is sensitive to small differences, � (0.1%), in the absolute reflectivity of the PTFE samples; Our results confirms that the reflectance of the PTFE immersed in LXe is very high � (>97%) and also strongly support the existence of a specular reflection component, which is usually not considered in the simulation of LXe DM detectors: The correct description of this specular component may be very important (depending on the geometry) for the correct reconstruction of events near the PTFE walls (e.g. LZ, LUX, XENON); … the ability to choose the PTFE with the highest reflectivity for the xenon scintillation light plays a very important role in obtaining a low energy threshold in these detectors! IDM 2016, 18-23 July 16 Summary & conclusions We designed & built an experimental setup for measuring the absolute reflectance of PTFE immersed in LXe; We fitted the experimental results from three different samples of PTFE against a detailed MC simulation using two different optical models for PTFE reflectivity: diffuse-only and diffuse+specular reflection; The implemented method is sensitive to small differences, � (0.1%), in the absolute reflectivity of the PTFE samples; Our results confirms that the reflectance of the PTFE immersed in LXe is very high � (>97%) and also strongly support the existence of a specular reflection component, which is usually not considered in the simulation of LXe DM detectors: The correct description of this specular component may be very important (depending on the geometry) for the correct reconstruction of events near the PTFE walls (e.g. LZ, LUX, XENON); … the ability to choose the PTFE with the highest reflectivity for the xenon scintillation light plays a very important role in obtaining a low energy threshold in these detectors! IDM 2016, 18-23 July 17 Extra plots IDM 2016, 18-23 July 18 LUX PTFE: 95% CL band � (mm) DS Model Best Fit A IDM 2016, 18-23 July 19 LUX PTFE: 95% CL band � (mm) DS Model Best Fit nPTFE IDM 2016, 18-23 July 20 LUX Results IDM 2016, 18-23 July 21